DLE 20ra goes from Idle to full rpm in 1/4 throw of throttle arm.

#1

Junior Member

Thread Starter

Join Date: Oct 2020

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

I am new to gas engines and just put a DLE 20ra on my Citabria Pro. I've been able to get it running after about two weeks of fiddling with it, but now it will idle OK but when I increase throttle a tiny bit it jumps immediatly to full rpms. The throttle arm on the carb is moving less that 1/4 of it's full travel. I have only run about two tanks so far but I am afraid of over reving the engine if I am not careful.

#2

My Feedback: (2)

1st, there's no need to be concerned about over revving if you have the right size prop on it. A Citabria Pro should work pretty good on a 17x6. That's the easy part of your question.

The other piece, where the throttle stick is acting like an on/off switch, is about your throttle linkage. Going into this it helps to know that a butterfly type carb, on ANYTHING, is pretty much done making power at about 60% open. Beyond 60% there's very little left. The 60% figure is not exact, but it's close enough here. Why that is, or whether or not it is, are both topics for a different conversation.

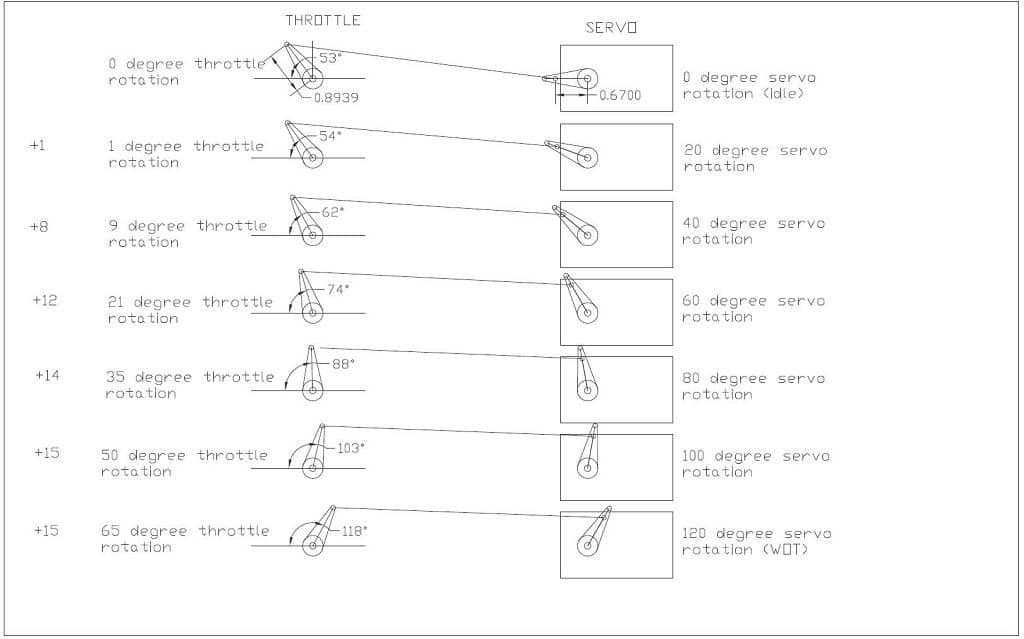

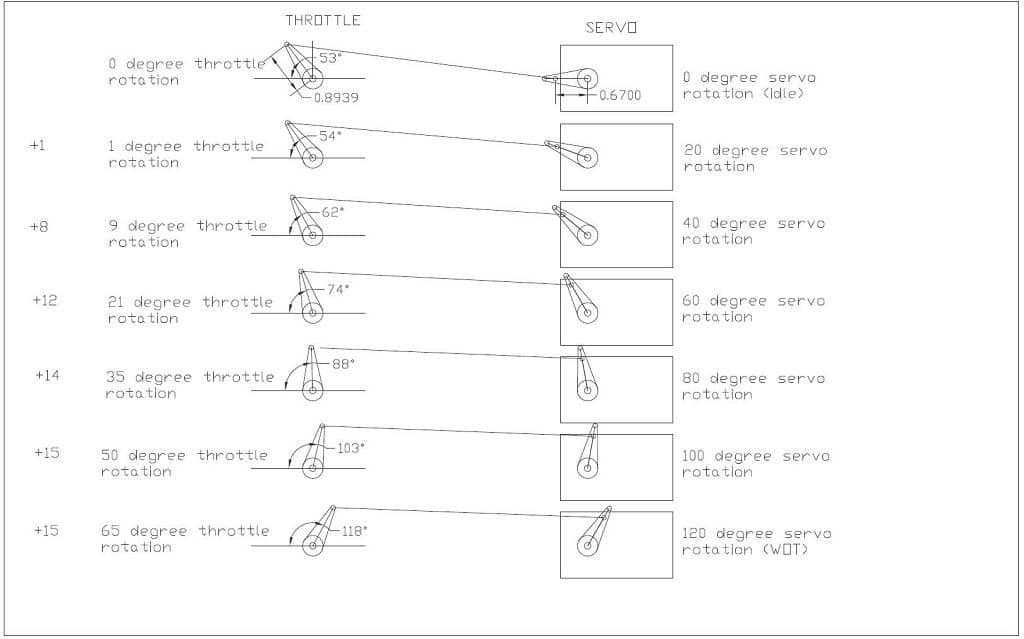

So we want to focus on that first 60% of the carb's travel, and spread it out to minimize that on/off syndrome. It's possible to handle it 2 ways. The first is with a throttle curve on your radio. That works well, but leaves you with fairly low servo resolution. Like you mentioned, maybe 1/4 of it's travel, unless you start playing with servo arm length - and that gets us into the second method of correcting the on/off syndrome. Setting it up to do what we need to do mechanically. For an idea of what's involved there, see the diagram below. The drawing has been around forever and posted countless times, but if you've never seen it before it might take a little pondering to figure out the idea it's trying to illustrate. Once you get what's happening you likely won't need to reference the drawing any more. Noteworthy as well, is the fact that if set up exactly as illustrated, you may have some trouble with adjustments at very low throttle settings. Starting at about the 20 degree rotation point works out much better.

For a throttle curve done with your radio, a 5 point curve, might look like 10%, 25%, 50%, 75%, and 100%. The first 3 points will be the most critical, and you can mess with those to get them just right. If done properly, you should get fairly linear response from your throttle stick. On/off tendency gone....

Last, for many of us that have been around a while, it's been found that if we start off with a mechanical setup, it can then be trimmed using the throttle curve for absolute perfection.

Welcome to gas! -Al

The other piece, where the throttle stick is acting like an on/off switch, is about your throttle linkage. Going into this it helps to know that a butterfly type carb, on ANYTHING, is pretty much done making power at about 60% open. Beyond 60% there's very little left. The 60% figure is not exact, but it's close enough here. Why that is, or whether or not it is, are both topics for a different conversation.

So we want to focus on that first 60% of the carb's travel, and spread it out to minimize that on/off syndrome. It's possible to handle it 2 ways. The first is with a throttle curve on your radio. That works well, but leaves you with fairly low servo resolution. Like you mentioned, maybe 1/4 of it's travel, unless you start playing with servo arm length - and that gets us into the second method of correcting the on/off syndrome. Setting it up to do what we need to do mechanically. For an idea of what's involved there, see the diagram below. The drawing has been around forever and posted countless times, but if you've never seen it before it might take a little pondering to figure out the idea it's trying to illustrate. Once you get what's happening you likely won't need to reference the drawing any more. Noteworthy as well, is the fact that if set up exactly as illustrated, you may have some trouble with adjustments at very low throttle settings. Starting at about the 20 degree rotation point works out much better.

For a throttle curve done with your radio, a 5 point curve, might look like 10%, 25%, 50%, 75%, and 100%. The first 3 points will be the most critical, and you can mess with those to get them just right. If done properly, you should get fairly linear response from your throttle stick. On/off tendency gone....

Last, for many of us that have been around a while, it's been found that if we start off with a mechanical setup, it can then be trimmed using the throttle curve for absolute perfection.

Welcome to gas! -Al

#3

Junior Member

Thread Starter

Join Date: Oct 2020

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Ahicks, that's a great explanation of the problem and how to fix it. I think I will try both approaches and put linkage on an inner hole of the servo arm and also set up the throttle curve as you suggested. Then I think I can get it tuned to where it will run reliably. I am using a 16x8 wood prop and a Hanger9 tack. to check RPM. I found that with that tack you have to be in the sun light (or sun light spectrum) for it to work. Tried it in my garage and was getting all kinds of strange reading. Moved the whole thing into the sun light at it work a lot better. I guess some time it pays to read the instructions.

I put the work on the motor aside for a while and am finishing the covering on the fuselage and some detail work. Hopefully I will be able to maiden flight in a couple of weeks if it ever warms up around here.

I put the work on the motor aside for a while and am finishing the covering on the fuselage and some detail work. Hopefully I will be able to maiden flight in a couple of weeks if it ever warms up around here.

#4

My Feedback: (29)

There are a couple more things that will help along with the posted chart. First, lengthen your throttle arm on the carb and as you already plan use a shorter servo arm. The idea here is to maintain 100% or even higher travel volume in your TX in order to get maximum resolution. The next thing is to have your carb opening only to about 80% to 85% at full stick. As Al has already stated there is no more power to be had after about 75% opening. The side benifit of this is a very flat torque curve that really helps with your take off run.