OS Gemini Twin Rear Walbro Gas Conversion

#76

One has to make choices...

The following users liked this post:

Steve (07-02-2022)

#79

I got my first lathe in High School. Widow down the street had a 1930 vintage South Bend sitting in her garage and wanted it gone. My grandfather and I hauled it home in my Radio Flyer wagon. Together we got it set up and running. Have owned about ten lathes since then, always had at least one lathe around, often two. Would never be without one for sure!

Got my first full size, real Bridgeport about 35 years ago at a local auction. Fairly late model, hard chromed "J" head version. It was all apart but all the parts were there. Good thing in two ways, being all apart it made it easier to move, and it scared off most bidders. Opening bid was $100 and that one was the only one. I went home with a load of parts.

Plenty of experience working on Bridgeports so it was up and running after just a few evening's work. Another machine that, once you have one, you never let it go!

Now in the market for a Roland CNC micro-mill as well as a Deckel pantograph.

Oxy-acetylene torch sets are another resource.

Got my first full size, real Bridgeport about 35 years ago at a local auction. Fairly late model, hard chromed "J" head version. It was all apart but all the parts were there. Good thing in two ways, being all apart it made it easier to move, and it scared off most bidders. Opening bid was $100 and that one was the only one. I went home with a load of parts.

Plenty of experience working on Bridgeports so it was up and running after just a few evening's work. Another machine that, once you have one, you never let it go!

Now in the market for a Roland CNC micro-mill as well as a Deckel pantograph.

Oxy-acetylene torch sets are another resource.

#81

That should bring some improvement, but I hate to sound like nitpicking: a 45 degree angle on that dam would have the best results: perpendicular creates turbulence which in part nullifies the low pressure zone behind the dam. A 45 degree angle would deflect the air downwards, strongly deepening the low pressure zone at the air exit.

Again, not nitpicking, just trying to help.

Again, not nitpicking, just trying to help.

#82

Got my first full size, real Bridgeport about 35 years ago at a local auction. Fairly late model, hard chromed "J" head version. It was all apart but all the parts were there. Good thing in two ways, being all apart it made it easier to move, and it scared off most bidders. Opening bid was $100 and that one was the only one. I went home with a load of parts.

Plenty of experience working on Bridgeports so it was up and running after just a few evening's work. Another machine that, once you have one, you never let it go!

Now in the market for a Roland CNC micro-mill as well as a Deckel pantograph.

Oxy-acetylene torch sets are another resource.

Plenty of experience working on Bridgeports so it was up and running after just a few evening's work. Another machine that, once you have one, you never let it go!

Now in the market for a Roland CNC micro-mill as well as a Deckel pantograph.

Oxy-acetylene torch sets are another resource.

). I spent years upgrading my Chinese equipment. Now they're pretty darned decent.

). I spent years upgrading my Chinese equipment. Now they're pretty darned decent.

The following users liked this post:

Steve (07-03-2022)

#83

Join Date: Jan 2004

Location: lake in the Hills,

IL

Posts: 977

Likes: 0

Received 14 Likes

on

14 Posts

Nice air dam, should see an improvement.

I really like the photo though. It reminds me of all the photos my father took. My mother always complained because he would take an Easter photo of the family all dressed up. Managing to get the house and car prominently into the frame.

Great photo!

I really like the photo though. It reminds me of all the photos my father took. My mother always complained because he would take an Easter photo of the family all dressed up. Managing to get the house and car prominently into the frame.

Great photo!

#84

Nice air dam, should see an improvement.

I really like the photo though. It reminds me of all the photos my father took. My mother always complained because he would take an Easter photo of the family all dressed up. Managing to get the house and car prominently into the frame.

Great photo!

I really like the photo though. It reminds me of all the photos my father took. My mother always complained because he would take an Easter photo of the family all dressed up. Managing to get the house and car prominently into the frame.

Great photo!

#86

#87

I put three VIGOROUS flights on the Gemini today and it seems to run better every time out. I didnít experience the vapor lock either. Maybe my cowl spoiler is working. . . .

Iíve been in this hobby going on 60 years now and I can honestly say this is my favorite airplane of all time.

Iíve been in this hobby going on 60 years now and I can honestly say this is my favorite airplane of all time.

#89

I'm guessing many of you out there that have followed this thread have already seen this video but in case you haven't I'm posting it here.

This is the first Rascal I had (that I later lost in crash) with this Gemini running on glow (I think 10% nitro). This (maiden) flight demonstrates why I strongly felt the need to work on the weak points of this engine, the primary one of which was dying in flight quite often. If you look close you see I had an on-board glow driver - for all the good it did. Those batteries were heavy and would not last long at all. I had a Chinese Turnegy prop on it that worked really well for the engine set up this way: you can hear it really singing and I can see it had noticeably more zip than my current gas conversion. But this is not a surprise when you consider there was nitromethane involved. The converted engine still has plenty of power especially when you consider the list of failings I fixed in the conversion. I also notice in this vid that running on nitro the Gemini doesn't have the raspy/crackly exhaust note that gasoline gives it. One last thing that occurs to me: the fact that the engine is producing slightly less power should mean that it is less stressed and should actually have a longer service life.

I still have the tow hitch release assembly in a drawer somewhere but I lost my glider tow buddies so I haven't installed it (yet):

This is the first Rascal I had (that I later lost in crash) with this Gemini running on glow (I think 10% nitro). This (maiden) flight demonstrates why I strongly felt the need to work on the weak points of this engine, the primary one of which was dying in flight quite often. If you look close you see I had an on-board glow driver - for all the good it did. Those batteries were heavy and would not last long at all. I had a Chinese Turnegy prop on it that worked really well for the engine set up this way: you can hear it really singing and I can see it had noticeably more zip than my current gas conversion. But this is not a surprise when you consider there was nitromethane involved. The converted engine still has plenty of power especially when you consider the list of failings I fixed in the conversion. I also notice in this vid that running on nitro the Gemini doesn't have the raspy/crackly exhaust note that gasoline gives it. One last thing that occurs to me: the fact that the engine is producing slightly less power should mean that it is less stressed and should actually have a longer service life.

I still have the tow hitch release assembly in a drawer somewhere but I lost my glider tow buddies so I haven't installed it (yet):

Last edited by mitchilito; 07-12-2022 at 02:35 AM.

#90

Amazing

Maybe slightly longer. I have yet to wear out a Saito or an O.S. anyhow.

Maybe slightly longer. I have yet to wear out a Saito or an O.S. anyhow.

Of course.

When setting the same RPM on a given prop it is the same power.

Maybe slightly longer. I have yet to wear out a Saito or an O.S. anyhow.

Maybe slightly longer. I have yet to wear out a Saito or an O.S. anyhow.Of course.

When setting the same RPM on a given prop it is the same power.

Last edited by Jesse Open; 07-11-2022 at 05:28 AM.

#91

It also runs hotter, so thermal load on the piston crown is a bit higher, but strange enough (well, it is not strange, it is in fact very logical but it feels a bit counterintuitive), with proper carb adjustments the exhaust gas temperatures are significantly lower so at least the threads in the exhaust ports are less at risk of giving in...

On the other side of the medal, there is better lubrication even with way less oil due to the lubricating properties of gas and the anyway better properties of gas-compatible oils, as well as the total absence of any form of corrosion.

But the way I see it, having run the cheaper variant on gasoline for close to 5 years now, is that as long as you prevent bearing faillure by replacing them in time, all that might be needed is new piston rings in 20 years time or so, and it will otherwise basically last indefinitely.

Word of warning, don't wear out the sparkplugs, if the center electrode falls out you'll have piston and liner damage.

You might see some issues with O-rings hardening up and deteriorating a bit, but that should not be an issue. At least, I cannot determine ANY wear or tear on mine, and as said, mine is a cheap copy, not a real OS.

Last edited by 1967brutus; 07-11-2022 at 11:57 AM. Reason: expanding a bit more

#93

Quote: "But the way I see it, having run the cheaper variant on gasoline for close to 5 years now, is that as long as you prevent bearing faillure by replacing them in time, all that might be needed is new piston rings in 20 years time or so, and it will otherwise basically last indefinitely."

Brutus, you mention bearing life. It would not occur to me that the bearings would fail in this engine - at least not for years and years. Back in the day we used glow fuel, bearings had a horrible life due to corrosion but in this application there is none and generally they are lightly loaded and well lubricated.

I was constantly worried about my turbine engine bearings but it never even occurred to me in this little jewel.

Brutus, you mention bearing life. It would not occur to me that the bearings would fail in this engine - at least not for years and years. Back in the day we used glow fuel, bearings had a horrible life due to corrosion but in this application there is none and generally they are lightly loaded and well lubricated.

I was constantly worried about my turbine engine bearings but it never even occurred to me in this little jewel.

#94

After those fifty hours, the centre electrode has worn away to below the rim of the body so proper gapping becomes impossible.

The faillure point lies a fair bit further in the future than that...

Don't worry about that, sorry I put that into your head. Basically all I am saying is: check the plugs yearly and replace when the centre post is flush with the threaded part and you will have nothing to worry about.

Reason I am stating it is because I have seen ONE occasion of a guy that never even considered checking his sparkplug and it failed after 5 years ruining a pretty nice engine (.50 helicopter, running spark and methanol).

Last edited by 1967brutus; 07-12-2022 at 10:10 AM.

#95

Quote: "But the way I see it, having run the cheaper variant on gasoline for close to 5 years now, is that as long as you prevent bearing faillure by replacing them in time, all that might be needed is new piston rings in 20 years time or so, and it will otherwise basically last indefinitely."

Brutus, you mention bearing life. It would not occur to me that the bearings would fail in this engine - at least not for years and years. Back in the day we used glow fuel, bearings had a horrible life due to corrosion but in this application there is none and generally they are lightly loaded and well lubricated.

I was constantly worried about my turbine engine bearings but it never even occurred to me in this little jewel.

Brutus, you mention bearing life. It would not occur to me that the bearings would fail in this engine - at least not for years and years. Back in the day we used glow fuel, bearings had a horrible life due to corrosion but in this application there is none and generally they are lightly loaded and well lubricated.

I was constantly worried about my turbine engine bearings but it never even occurred to me in this little jewel.

This Boxer has a LOT of bearings and a pretty good balance. I would expect them to last at the very least about a 1000 hours and it is doubtful if the engine would last that long. Average users get maybe 25 hours per year in, frequent users maybe 50 (I managed about 60 hours in 4 years on this specific engine, and I fly a lot but it is one of about 10 engines I regularly use). So that is something like 20~40 years realistically.

Singles, I would definitely consider changing bearings every ten years when running gas. 5 if it is glowfuel.

Last edited by 1967brutus; 07-12-2022 at 10:13 AM.

#96

The corrosion is greatly accelerated when nitromethane is in the fuel mix. I run zero nitromethane with CDI ignition, just a blend of synthetic oil, castor oil and methanol. Corrosion has never been an issue in those engines.

The most common bearing failures I have seen in the O.S. Gemini engines by far has been the camshaft bearings. Not corrosion, just flat worn. A heavy clue is the valve lash clearances become erratic. The Gemini engines were extremely popular here for many years.

The most common bearing failures I have seen in the O.S. Gemini engines by far has been the camshaft bearings. Not corrosion, just flat worn. A heavy clue is the valve lash clearances become erratic. The Gemini engines were extremely popular here for many years.

Last edited by Jesse Open; 07-13-2022 at 05:08 PM.

#99

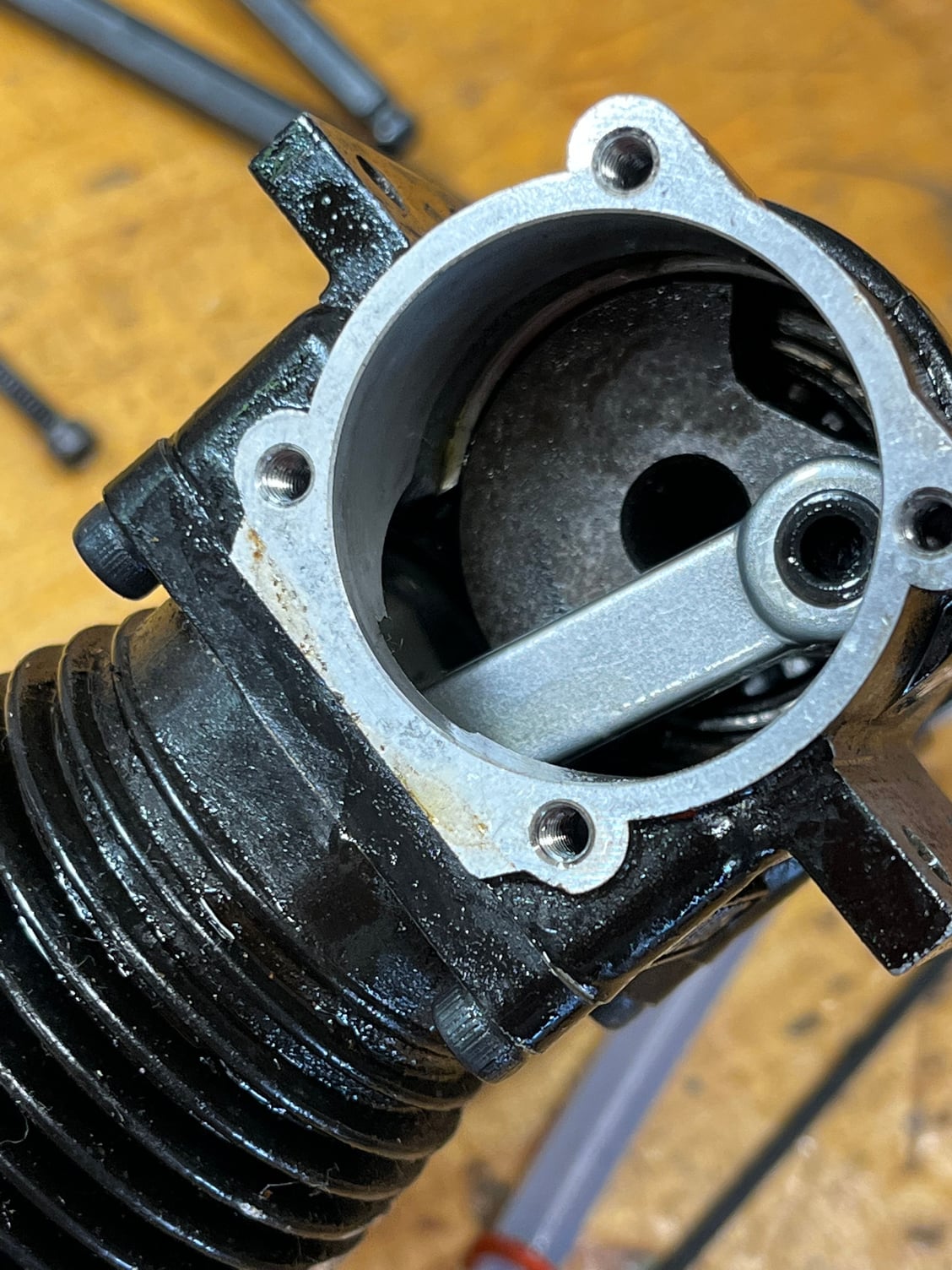

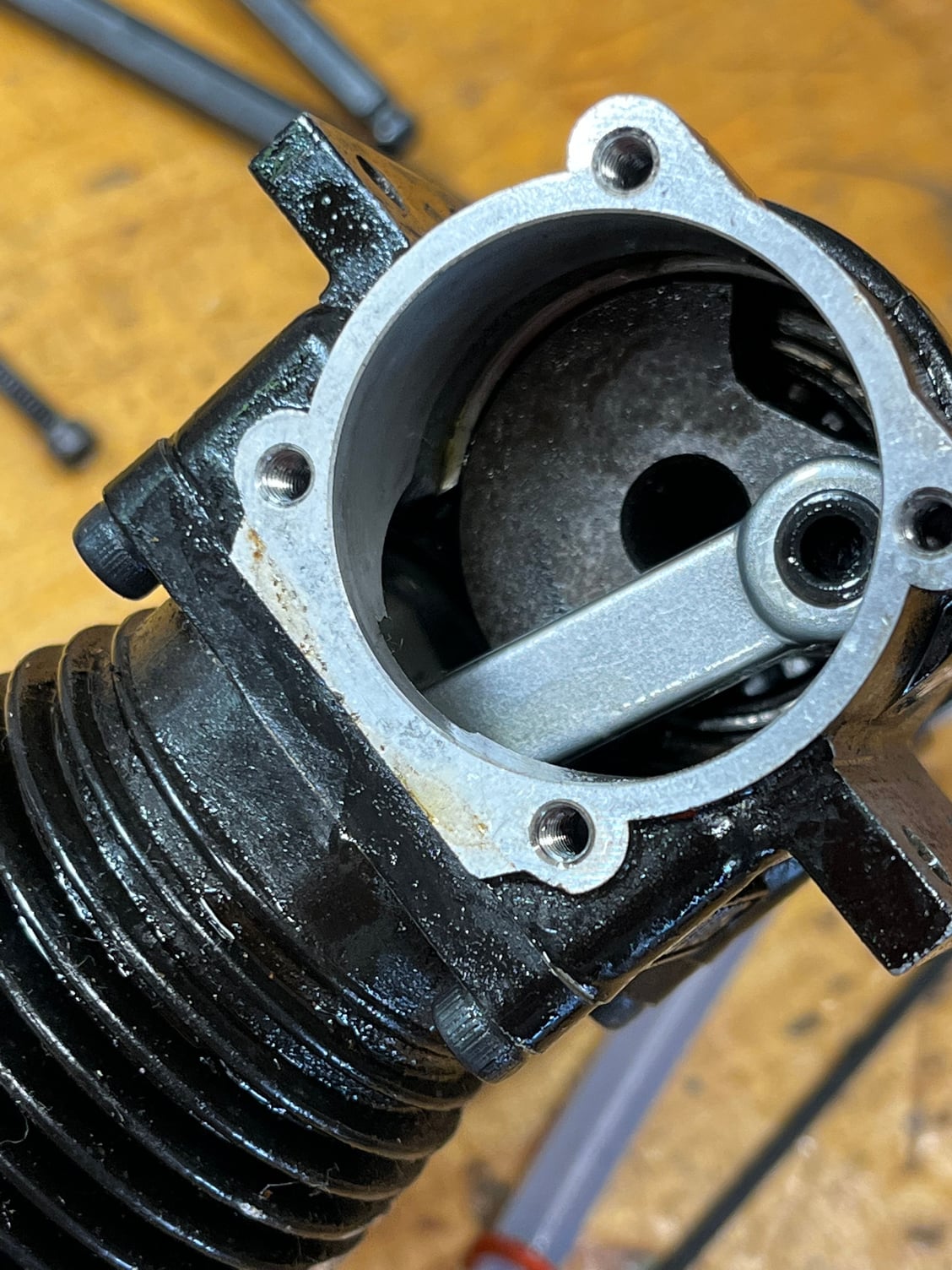

Twenty five year old Saito 50. It had been laid up in storage. Always run on 14% nitro, 12% synthetic and 2% castor. Taken from storage, fueled up and flown. The running became erratic last week so I pulled the tank for replacement. While I was at it, I pulled the engine, removed the rear cover for the first look inside since 1997.

https://streamable.com/lqm48l

Ryan STA, engine is not a 56 as I had remembered. Actually a GK 50.

And it didn't leak a drop!

After run oiling pays off.

ARO pays off.

The nickel plated klunk Attacked by a combination of methanol, nitromethane and hugely the gunk from muffler pressure.

https://streamable.com/lqm48l

Ryan STA, engine is not a 56 as I had remembered. Actually a GK 50.

And it didn't leak a drop!

After run oiling pays off.

ARO pays off.

The nickel plated klunk Attacked by a combination of methanol, nitromethane and hugely the gunk from muffler pressure.

Last edited by Jesse Open; 07-14-2022 at 05:22 AM.

#100

Can't speak for the OS Boxer, but in the ASP version, the cam has larger bearings than in the singles, especially the rear one, close to the gear. The front one is the same size as on the singles. The valve spring forces are not that large, about 10~15 N at full valve opening, and there's only one valve at max opening at a time. Logic dictates that the inertial forces of a valve is always smaller than the springforce (otherwise the valve would float), therefore the maximum force exerted on the cam bearings by the valve (inertia combined with springforce upon opening) is less than 30N. Well within range for these bearings. These forces also build up relatively gradually.

Crankbearings are quite a bit larger of course, but also get a lot heavier punches: A .60 engine generates conrod forces in excess of 1500N, and these forces are pretty much "shockloads" due to the basically explosive nature of the igniting fuel/air charge.

Last edited by 1967brutus; 07-14-2022 at 07:02 AM. Reason: crooked sentences and better grammar.