OS Gemini Twin Rear Walbro Gas Conversion

#101

My worn out cam bearings comment was not about all O.S. engines. It was about, only about the O.S. Gemini 120 and 160.

Regardless the fuel.

Real world operation outcomes frequently fail to follow idealized theories.

Regardless the fuel.

Real world operation outcomes frequently fail to follow idealized theories.

Last edited by Jesse Open; 07-14-2022 at 05:33 AM.

#102

FWIW: I have never needed to change OS or ASP cam bearings due to wear. Corrosion, yes, but wear never. They are pretty much up to the task.

Can't speak for the OS Boxer, but in the ASP version, the cam has larger bearings than in the singles, especially the rear one, close to the gear. The front one is the same size as on the singles. The valve spring forces are not that large, about 10~15 N at full valve opening, and there's only one valve at max opening at a time. Logic dictates that the inertial forces of a valve is always smaller than the springforce (otherwise the valve would float), therefore the maximum force exerted on the cam bearings by the valve (inertia combined with springforce upon opening) is less than 30N. Well within range for these bearings. These forces also build up relatively gradually.

Crankbearings are quite a bit larger of course, but also get a lot heavier punches: A .60 engine generates conrod forces in excess of 1500N, and these forces are pretty much "shockloads" due to the basically explosive nature of the igniting fuel/air charge.

Can't speak for the OS Boxer, but in the ASP version, the cam has larger bearings than in the singles, especially the rear one, close to the gear. The front one is the same size as on the singles. The valve spring forces are not that large, about 10~15 N at full valve opening, and there's only one valve at max opening at a time. Logic dictates that the inertial forces of a valve is always smaller than the springforce (otherwise the valve would float), therefore the maximum force exerted on the cam bearings by the valve (inertia combined with springforce upon opening) is less than 30N. Well within range for these bearings. These forces also build up relatively gradually.

Crankbearings are quite a bit larger of course, but also get a lot heavier punches: A .60 engine generates conrod forces in excess of 1500N, and these forces are pretty much "shockloads" due to the basically explosive nature of the igniting fuel/air charge.

#103

Quote: "Twenty five year old Saito 50. It had been laid up in storage. Always run on 14% nitro, 12% synthetic and 2% castor. Taken from storage, fueled up and flown. The running became erratic last week so I pulled the tank for replacement. While I was at it, I pulled the engine, removed the rear cover for the first look inside since 1997"

This is an interesting story. Without after run oil that engine would NOT have looked so good! This brings to mind a related story I have:

A fellow club member was given a dusty old cub-type airplane with an original Gemini 120 in it by the son of an old modeler who had passed away. It appears the old guy flew it never considering after run oil then it sat after the final flight for who knows - decades? The engine was seized SOLID so the club member just gave it to me (he knows I have a machine shop).

This engine was real challenge to disassemble. I took apart everything I could then had to soak and ultrasound clean etc. You should've seen the bearings once I got them out! Fortunately, all the running surfaces were acceptable but I did have to manufacture one new cylinder liner and piston ring (I was NOT going to spend any money on this thing - other than bearings, that is). I put it back in the plane (I just remembered that it was a Balsa USA Citabria Parasol) and flew it as the "club plane" for a season. It ran like a watch - albeit without much power (not because of my piston/liner. That's just the nature of the original)

That whole process was almost a fun as this engine conversion!

This is an interesting story. Without after run oil that engine would NOT have looked so good! This brings to mind a related story I have:

A fellow club member was given a dusty old cub-type airplane with an original Gemini 120 in it by the son of an old modeler who had passed away. It appears the old guy flew it never considering after run oil then it sat after the final flight for who knows - decades? The engine was seized SOLID so the club member just gave it to me (he knows I have a machine shop).

This engine was real challenge to disassemble. I took apart everything I could then had to soak and ultrasound clean etc. You should've seen the bearings once I got them out! Fortunately, all the running surfaces were acceptable but I did have to manufacture one new cylinder liner and piston ring (I was NOT going to spend any money on this thing - other than bearings, that is). I put it back in the plane (I just remembered that it was a Balsa USA Citabria Parasol) and flew it as the "club plane" for a season. It ran like a watch - albeit without much power (not because of my piston/liner. That's just the nature of the original)

That whole process was almost a fun as this engine conversion!

Last edited by mitchilito; 07-16-2022 at 01:41 AM.

#104

Thanks, and same here... Although my job is operating and maintaining engines (and toilets, lightbulbs, water faucets, dishwashers and tumbledryers, airconditioners, hydraulics in general and all other kinds of mechanical crap.) I can really get lost in the marvelling deeper thoughts behind why an engine fails or survives, why it is designed a certain way and why not different, what pressures, temperatures, forces and velocities are at play, and how they vary with changing parameters and/or conditions. Wildly fascinating.

The following users liked this post:

TheEdge (07-17-2022)

#105

Well, I have some things to discuss as I continue to operate the heck out of this engine. First and foremost, it's running GREAT. I spend at least half my flight time at very reduced power settings with the Rascal at full flaps and minimum airspeed. Just floating around LOW and SLOW doing touch and go's, posing for pictures etc. Then full throttle for some spirited aerobatics - which this aircraft does surprisingly well. Everyone who sees it says the same thing: "That thing sounds great!"

After today's flights I was wiping the oil off of it etc and flipped the prop over a couple times (mainly to judge compression) and the valve train sounded kind of funny. When I got it home I pulled the valve covers to check valve lash and to see if anything funny popped up - which it did. The right cylinder exhaust valve was very sluggish to actuate. It had loaded up with carbon and was very sticky. This is the second time this has happened and this is why I put 2 ounces of Sea Foam (decarbonizer) in the gas - although I may have forgotten it this last gallon. As soon as I put a drop of it on the valve stem - BOOM - unstuck! The stuff is amazing. I immediately added an ounce to my remaining half gallon of fuel.

Another interesting thing: I noticed oil collecting on the left spark plug cap/insulator and found the insulator was loose in the plug body and actually leaking. I put another set of plugs in and tossed the old ones. What do you folks out there in engine land use for a spark plug gap? The ones I took out were at .020 and running fantastic.

And last but not least, there was no sign of vapor lock - even with the high heat and humidity we had out there today. The mods solved that!

After today's flights I was wiping the oil off of it etc and flipped the prop over a couple times (mainly to judge compression) and the valve train sounded kind of funny. When I got it home I pulled the valve covers to check valve lash and to see if anything funny popped up - which it did. The right cylinder exhaust valve was very sluggish to actuate. It had loaded up with carbon and was very sticky. This is the second time this has happened and this is why I put 2 ounces of Sea Foam (decarbonizer) in the gas - although I may have forgotten it this last gallon. As soon as I put a drop of it on the valve stem - BOOM - unstuck! The stuff is amazing. I immediately added an ounce to my remaining half gallon of fuel.

Another interesting thing: I noticed oil collecting on the left spark plug cap/insulator and found the insulator was loose in the plug body and actually leaking. I put another set of plugs in and tossed the old ones. What do you folks out there in engine land use for a spark plug gap? The ones I took out were at .020 and running fantastic.

And last but not least, there was no sign of vapor lock - even with the high heat and humidity we had out there today. The mods solved that!

Last edited by mitchilito; 07-17-2022 at 10:47 AM.

#106

After today's flights I was wiping the oil off of it etc and flipped the prop over a couple times (mainly to judge compression) and the valve train sounded kind of funny. When I got it home I pulled the valve covers to check valve lash and to see if anything funny popped up - which it did. The right cylinder exhaust valve was very sluggish to actuate. It had loaded up with carbon and was very sticky. This is the second time this has happened and this is why I put 2 ounces of Sea Foam (decarbonizer) in the gas - although I may have forgotten it this last gallon. As soon as I put a drop of it on the valve stem - BOOM - unstuck! The stuff is amazing. I immediately added an ounce to my remaining half gallon of fuel.

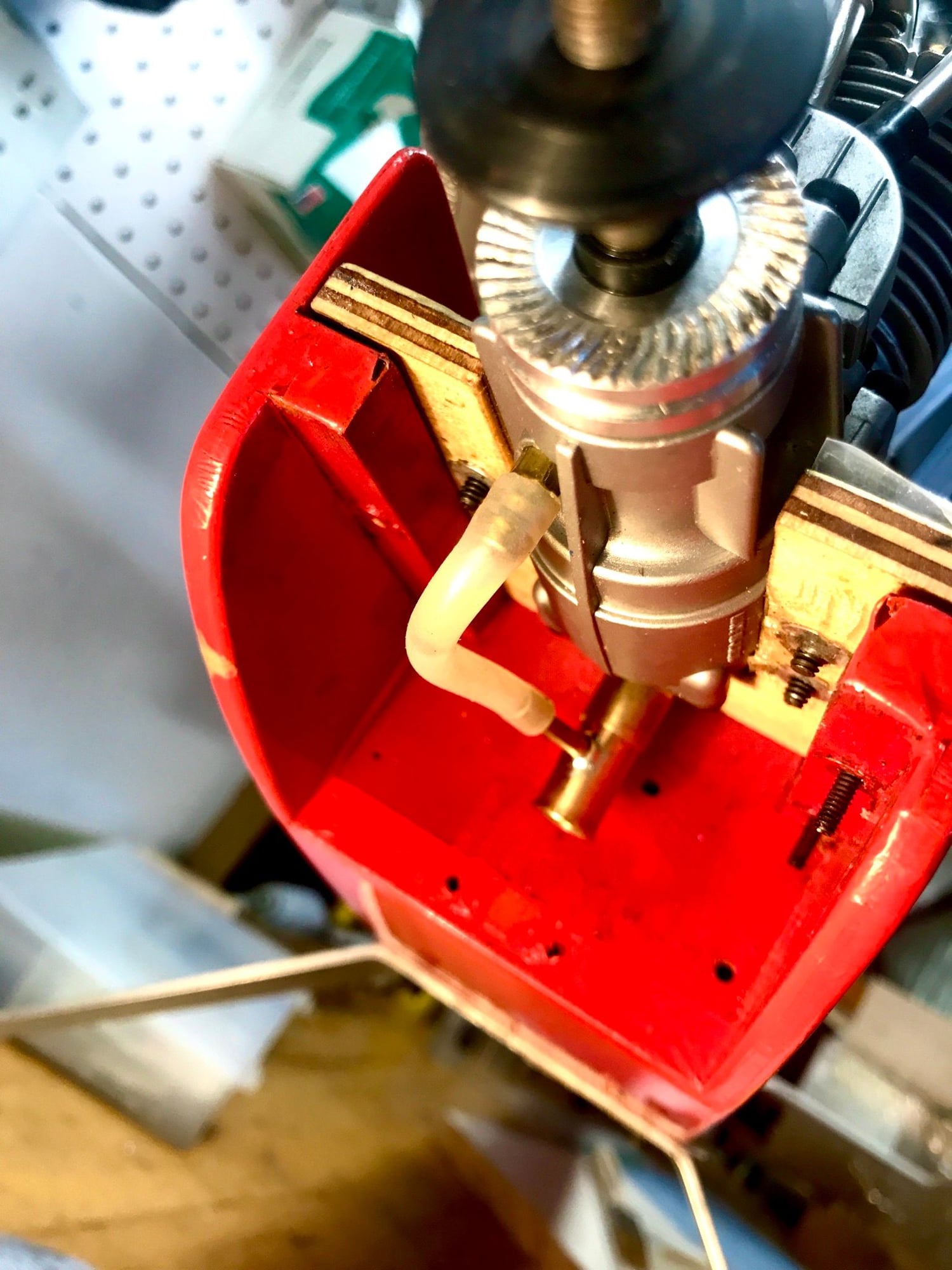

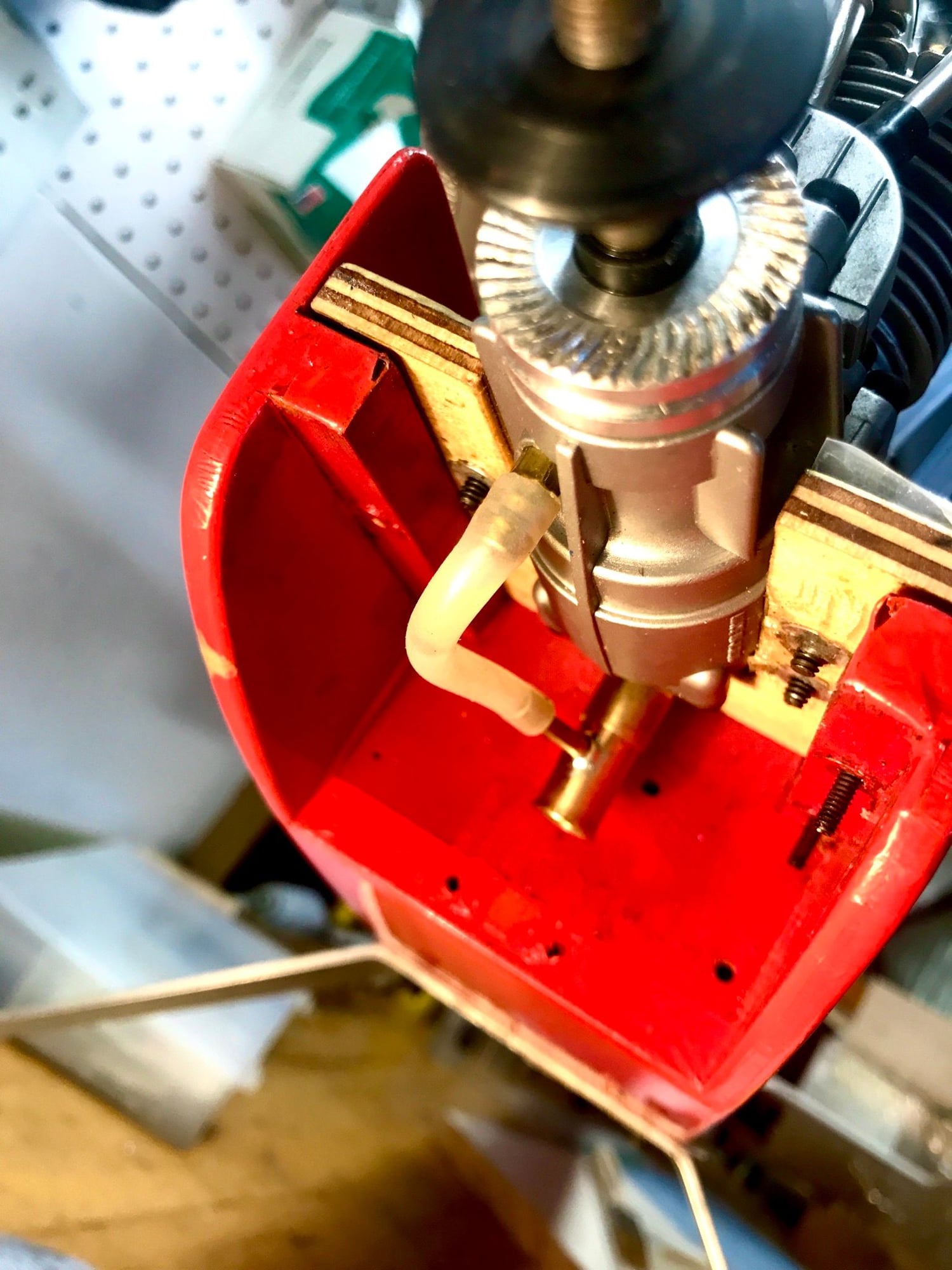

It looks a bit weird, but I can really recommend it. The plumbing can be done a lot neater than I did it, but for function it does not matter so I never bothered to make neater tubing.. I haven't really adjusted a valve in the last 2 years or so. I check every 5 running hours, but thinking about reducing that to 20 hour intervals, because I only risk wearing out the threads of the retaining bolts. It is advisable to make gaskets for the rockercovers, because they do not seal metal to metal, they are not designed or made to...

Of course, this is a personal choice, you're free to do or not do this.

Another interesting thing: I noticed oil collecting on the left spark plug cap/insulator and found the insulator was loose in the plug body and actually leaking. I put another set of plugs in and tossed the old ones. What do you folks out there in engine land use for a spark plug gap? The ones I took out were at .020 and running fantastic.

Spark gap should be 0,5 mm (0.02") but is not all that critical. Some say, 0,6~0,7 mm (0,025" approx) causes a higher spark voltage and thus better running if midrange is a touch rich. I have indeed seen that work as advertised, but not always. I stick to 0,5 mm.

Last edited by 1967brutus; 07-17-2022 at 01:22 PM.

#107

That valve oiling is an interesting idea, Brutus. When I took off my left valve cover yesterday I was surprised by a little gush of oil out of the cover. When I took off the right one (the one with the stuck valve) No gush of oil. Also, I notice when running that a LOT more oil collects on the aircraft from the left cylinder, very little out of the right side. I'm thinking the right cylinder is running leaner than the left but I'm not too keen on changing anything. It's running so darned good!

I'm hoping extra Sea Foam will prevent the sticky valve. I think there was enough oil to prevent premature wear in there, just not enough decarbonizer migrating in.

I'm hoping extra Sea Foam will prevent the sticky valve. I think there was enough oil to prevent premature wear in there, just not enough decarbonizer migrating in.

Last edited by mitchilito; 07-18-2022 at 02:30 AM.

#108

That valve oiling is an interesting idea, Brutus. When I took off my left valve cover yesterday I was surprised by a little gush of oil out of the cover. When I took off the right one (the one with the stuck valve) No gush of oil. Also, I notice when running that a LOT more oil collects on the aircraft from the left cylinder, very little out of the right side. I'm thinking the right cylinder is running leaner than the left but I'm not too keen on changing anything. It's running so darned good!

I'm hoping extra Sea Foam will prevent the sticky valve. I think there was enough oil to prevent premature wear in there, just not enough decarbonizer migrating in.

I'm hoping extra Sea Foam will prevent the sticky valve. I think there was enough oil to prevent premature wear in there, just not enough decarbonizer migrating in.

As for the mixture distribution, the slightest assymetry in the induction tract tends to cause uneven distribution, but that is mainly the oil and not so much the fuel (fuel evaporates and separates from the oil pretty rapidly after leaving the carb). In my case the lateral movement of the throttle barrel (the ASP has, contrary to the OS, a carb that works that way) is causing a change in distribution that varied with throttle opening, so the cylinders are never receiving the same quantity of oil, yet they do run more or less equally "rich" when it comes to fuel distribution.

I have never worked with seafoam or the likes, and never have had the need for it. The valve oiling and the fairly fat fuel/oil ratio so far have kept all problems with carbonizing at bay. Initially I did regularly pull a head to check, but I stopped doing that as the levels of deposit seemed to stabilize.

I can really recommend at least lubricating a bit fatter than 20:1 (which from memory, I think you are using?). Because it most definitely will NOT hurt your engine or its performance, and is in the grand scheme of things a cheap way of keeping things AOK. No idea what seafoam costs by the way, but now you're pouring in 6,4 oz of oil and 1~2 oz of seafoam, but probably just pouring in 2 oz extra oil (the difference between 20:1 and 15:1) might do the trick just as well, and 2 liquids is easier than 3

The following users liked this post:

mitchilito (07-19-2022)

#109

Quote: "I can really recommend at least lubricating a bit fatter than 20:1 (which from memory, I think you are using?)"

I have actually increased the oil to around18:1 (prior to recirculating) so I'm somewhere in the vicinity of at least 15:1.

The thing that baffles me about this is just how much difference there is in the amount of residual oil (both in the covers and out the exhaust) there is between the two cylinders. Next time out I will take my laser thermometer and see if there is a huge difference between cylinder temps. I'm guessing the right one is going to be a lot hotter (running leaner). Unfortunately, with a single carburetor there's not much I can do now.

It is running so darned good that I refuse to change a thing so I'll just take whatever extra wear may be happening. . . . .

I have actually increased the oil to around18:1 (prior to recirculating) so I'm somewhere in the vicinity of at least 15:1.

The thing that baffles me about this is just how much difference there is in the amount of residual oil (both in the covers and out the exhaust) there is between the two cylinders. Next time out I will take my laser thermometer and see if there is a huge difference between cylinder temps. I'm guessing the right one is going to be a lot hotter (running leaner). Unfortunately, with a single carburetor there's not much I can do now.

It is running so darned good that I refuse to change a thing so I'll just take whatever extra wear may be happening. . . . .

#110

Quote: "I can really recommend at least lubricating a bit fatter than 20:1 (which from memory, I think you are using?)"

I have actually increased the oil to around18:1 (prior to recirculating) so I'm somewhere in the vicinity of at least 15:1.

The thing that baffles me about this is just how much difference there is in the amount of residual oil (both in the covers and out the exhaust) there is between the two cylinders. Next time out I will take my laser thermometer and see if there is a huge difference between cylinder temps. I'm guessing the right one is going to be a lot hotter (running leaner). Unfortunately, with a single carburetor there's not much I can do now.

It is running so darned good that I refuse to change a thing so I'll just take whatever extra wear may be happening. . . . .

I have actually increased the oil to around18:1 (prior to recirculating) so I'm somewhere in the vicinity of at least 15:1.

The thing that baffles me about this is just how much difference there is in the amount of residual oil (both in the covers and out the exhaust) there is between the two cylinders. Next time out I will take my laser thermometer and see if there is a huge difference between cylinder temps. I'm guessing the right one is going to be a lot hotter (running leaner). Unfortunately, with a single carburetor there's not much I can do now.

It is running so darned good that I refuse to change a thing so I'll just take whatever extra wear may be happening. . . . .

I'll see if I can dig up a pic. Sometimes solutions can be really simple and minimalistic.

#111

I had another "anomaly" while out flying today. I had changed the spark plugs (cuz one was leaking/oily, remember?) and when I fired it up out at the field today that oily right cylinder refused to run! I could hear it trying to catch and when I messed with he plug cap that cylinder started running. I had most of a great flight when it cut out again and would never fire back up.

Now, this made me realize I had this same problem WITH THOSE PLUGS when I was doing all my experimenting/running in the beginning. It's related to the cap itself because I know the plugs work well. Then while looking at cap replacement kits online I see "spring sets" for sale. These, like the bigger CM6 style caps, go inside the cap to help make the ground. I do not have any in my caps! Apparently, the Rimfire plugs (which worked fine with these caps - but leaked) would make the ground where the RCExcell plugs will not.

I ordered a set. We'll see if that fixes it. I have a STRONG feeling it will.

NEWS FLASH!!!!!!

Just got in from running the Gemini in the shop and I can't believe what the problem was!@*&^)

So I made my own "ground spring" to see if that would fix it. DIDN'T. I happened to take the cap off while it was running (which you shouldn't really do) and holy cow the sparks were flying inside that little cap! So I took the plug out of the cylinder that would NOT run and put it in the cap: big beautiful obvious spark - and yet that cylinder would not run on it!

Long strory short: there was only one thing left that I could try - reduce the gap. It was set to .020 as we had discussed above so I reduced it to .016 and put it back in. That cylinder would now fire about half the time. When I set it to .013 she took of running like a raped ape!! What a beautiful sound. . . .

Internal combustion engines are so interesting aren't they? Sometimes there's just no telling what is going to do what in that combustion process.. . . .

Now, this made me realize I had this same problem WITH THOSE PLUGS when I was doing all my experimenting/running in the beginning. It's related to the cap itself because I know the plugs work well. Then while looking at cap replacement kits online I see "spring sets" for sale. These, like the bigger CM6 style caps, go inside the cap to help make the ground. I do not have any in my caps! Apparently, the Rimfire plugs (which worked fine with these caps - but leaked) would make the ground where the RCExcell plugs will not.

I ordered a set. We'll see if that fixes it. I have a STRONG feeling it will.

NEWS FLASH!!!!!!

Just got in from running the Gemini in the shop and I can't believe what the problem was!@*&^)

So I made my own "ground spring" to see if that would fix it. DIDN'T. I happened to take the cap off while it was running (which you shouldn't really do) and holy cow the sparks were flying inside that little cap! So I took the plug out of the cylinder that would NOT run and put it in the cap: big beautiful obvious spark - and yet that cylinder would not run on it!

Long strory short: there was only one thing left that I could try - reduce the gap. It was set to .020 as we had discussed above so I reduced it to .016 and put it back in. That cylinder would now fire about half the time. When I set it to .013 she took of running like a raped ape!! What a beautiful sound. . . .

Internal combustion engines are so interesting aren't they? Sometimes there's just no telling what is going to do what in that combustion process.. . . .

Last edited by mitchilito; 07-23-2022 at 07:49 AM.

#112

Which ignition do youy have? RcExl or CH?

I have one CH and the rest RcExl, and it is my definite impression the RcExl have a slightly stronger spark.

All my plugs are gapped at 0,5 mm (0,02") when installed but will continue to work without issues even when eroded up to 1 mm (0,04") gap.

I have one CH and the rest RcExl, and it is my definite impression the RcExl have a slightly stronger spark.

All my plugs are gapped at 0,5 mm (0,02") when installed but will continue to work without issues even when eroded up to 1 mm (0,04") gap.

#113

This one is a C&H. I looked for a RC Excel unit yesterday but I couldn't find one with 90 degree caps like my C&H has although when I pulled the cap off this C&H unit while it was running yesterday I was amazed at how strong the spark looked. I'm gonna take it out flying again today and we'll see if it continues to work.

This whole gap thing sure seems strange/unlikely to me. If It acts up again, I may have to buy a RC Excel unit and change the caps to 90's. Funny how the Rimfire plugs showed no signs of this and these RC Excel plugs did it every time (always only one - and I'm guessing it was the right cylinder, but at the time I didn't troubleshoot)

This whole gap thing sure seems strange/unlikely to me. If It acts up again, I may have to buy a RC Excel unit and change the caps to 90's. Funny how the Rimfire plugs showed no signs of this and these RC Excel plugs did it every time (always only one - and I'm guessing it was the right cylinder, but at the time I didn't troubleshoot)

#114

This one is a C&H. I looked for a RC Excel unit yesterday but I couldn't find one with 90 degree caps like my C&H has although when I pulled the cap off this C&H unit while it was running yesterday I was amazed at how strong the spark looked. I'm gonna take it out flying again today and we'll see if it continues to work.

This whole gap thing sure seems strange/unlikely to me. If It acts up again, I may have to buy a RC Excel unit and change the caps to 90's. Funny how the Rimfire plugs showed no signs of this and these RC Excel plugs did it every time (always only one - and I'm guessing it was the right cylinder, but at the time I didn't troubleshoot)

This whole gap thing sure seems strange/unlikely to me. If It acts up again, I may have to buy a RC Excel unit and change the caps to 90's. Funny how the Rimfire plugs showed no signs of this and these RC Excel plugs did it every time (always only one - and I'm guessing it was the right cylinder, but at the time I didn't troubleshoot)

#115

According to Adrian at CH Ignitions, his CH boards and components are identical to RCexl production components, right from RCexl.

The main difference being the RCexl are potted. Adrian will supply you with 90 degree connectors on either CH or RCexl.

The main difference being the RCexl are potted. Adrian will supply you with 90 degree connectors on either CH or RCexl.

Last edited by Jesse Open; 07-24-2022 at 06:29 AM.

#116

Join Date: Jan 2004

Location: lake in the Hills,

IL

Posts: 977

Likes: 0

Received 14 Likes

on

14 Posts

I really love what Adrian (who bought C&H) has brought to this hobby. His work on gas ignitions, glow ignitions and glow to gas conversions has been a great resource for me.

He has a real downloadable knowledge base to benefit from. Great products and support as well. Some of his products are in my Saito 180 glow to gas conversion.

I bet Bill Cunningham is reading this thread out in the heavens.

He has a real downloadable knowledge base to benefit from. Great products and support as well. Some of his products are in my Saito 180 glow to gas conversion.

I bet Bill Cunningham is reading this thread out in the heavens.

#117

I really love what Adrian (who bought C&H) has brought to this hobby. His work on gas ignitions, glow ignitions and glow to gas conversions has been a great resource for me.

He has a real downloadable knowledge base to benefit from. Great products and support as well. Some of his products are in my Saito 180 glow to gas conversion.

I bet Bill Cunningham is reading this thread out in the heavens.

He has a real downloadable knowledge base to benefit from. Great products and support as well. Some of his products are in my Saito 180 glow to gas conversion.

I bet Bill Cunningham is reading this thread out in the heavens.

#118

Did the whole "spark plug gap" problem seem fishy to you folks out there? It did to me.

Well, it happened again at the flying field yesterday. I could coax it into running so I got a couple flights but that ignition box has got to go. I'm no electronics expert but I suspect there's some kind of continuity breakdown in one of the components in the box (maybe the coil is failing?). I pulled the plug cap apart on that cylinder and it looks absolutely fine. Anyway, I ordered a new RC excel unit from eBay.

And here's an interesting thing I realized: I never had "vapor lock" at all: it was this ignition problem all along. It took me until yesterday to realize this was the exact problem from the beginning.

Believe it or not, I'm enjoying all of this immensely. It breaks up the monotony of my Bücker project!

JW Büker Jungmeister build

Well, it happened again at the flying field yesterday. I could coax it into running so I got a couple flights but that ignition box has got to go. I'm no electronics expert but I suspect there's some kind of continuity breakdown in one of the components in the box (maybe the coil is failing?). I pulled the plug cap apart on that cylinder and it looks absolutely fine. Anyway, I ordered a new RC excel unit from eBay.

And here's an interesting thing I realized: I never had "vapor lock" at all: it was this ignition problem all along. It took me until yesterday to realize this was the exact problem from the beginning.

Believe it or not, I'm enjoying all of this immensely. It breaks up the monotony of my Bücker project!

JW Büker Jungmeister build

The following users liked this post:

1967brutus (07-25-2022)

#119

Trust me, I 100% believe you. Because I have been and still am in similar shoes as you... And same like you, I have drawn conclusions that in hindsight were proven wrong.

Trust me, I 100% believe you. Because I have been and still am in similar shoes as you... And same like you, I have drawn conclusions that in hindsight were proven wrong.  It is called "learning", and I have done that by the bucketload in the past 8 or 9 years of first messing with ignitions and methanol, then converting to gas, then the mixture thing, etc etc etc.

It is called "learning", and I have done that by the bucketload in the past 8 or 9 years of first messing with ignitions and methanol, then converting to gas, then the mixture thing, etc etc etc.Been a wild ride and I would not have missed it for the world... Extremely satisfying.

#120

You are absolutely correct about Adrian at C&H. Every time I call he picks the phone right up and answers all my questions. He happens to be on vacation (or some such) right now so he's not filling orders. Otherwise I would've bought the RC excel unit that I just ordered from him.

He is on vacation and will be back soon.

Tinkering with engines is great fun. Began working on engines here since the early 1960s. Back then it was model engines, leading to go-karts and from there to motorcycles and cars.

Very early on, began converting kart engines to methanol, really enjoyed that learning curve. In the late 1970s took up converting RC glow over to spark ignition, initially to run gasoline but later using methanol fuel.

At first those conversions used home-brew breaker point/coil ignitions later on, the Bill Carpenter boxes were pressed into service with excellent results. Along the way, I built a few of my own CDI boxes and transistor switched magnetic based systems.

Along the way my Brother in law and I opened up a full service automotive machine shop.

Today flying both glow and spark ignition, both using methanol fuel.

One failure mode with the CDI box is the secondary, high tension coil winding. The insulation can break down easily if the firing voltage is raised above the normal designed operating range. Running the system without a plug for example can cause a huge increase in voltage. Bad connections or broke Sustained running with wide gapped plugs can also lead to insulation breakdown.

The breakdown may show up as a complete loss of spark, or a drop in the strength of the spark.

Waste spark systems develop higher voltages already because the two plug gaps are in series while firing.

Weather is great out here today at the field, hope you can get some flying in as well!

Last edited by Jesse Open; 07-25-2022 at 10:25 AM.

#121

You have quite a background for this particular thread of mine, Jesse! It might be a good thing for you that you live so far away (I live in coastal NC) or else I might become a nuisance at your place, ha ha ha ha ha!!

Also: I had an interesting development with this project but I'm not going to post until I run it all to ground. . . .

Also: I had an interesting development with this project but I'm not going to post until I run it all to ground. . . .

Last edited by mitchilito; 07-26-2022 at 07:13 AM.

#122

Will standby for an update

If you ever head towards (coastal) Michigan please stop by! We do have some shared interests indeed. Bring a plane or fly mine

Could be a lot of fun. We had a fellow RCG member from California on visit for a few months. Got some good flying time in at a couple of the many local fields.

I have a few acres on the French Broad River, near Knoxville TN. Due for a stay down there pretty soon. Maybe just move there to stay if and when the economy and the current national mess gets "corrected".

If you ever head towards (coastal) Michigan please stop by! We do have some shared interests indeed. Bring a plane or fly mine

Could be a lot of fun. We had a fellow RCG member from California on visit for a few months. Got some good flying time in at a couple of the many local fields.

I have a few acres on the French Broad River, near Knoxville TN. Due for a stay down there pretty soon. Maybe just move there to stay if and when the economy and the current national mess gets "corrected".

Last edited by Jesse Open; 07-26-2022 at 08:32 AM.

#123

So, this problem turned out not to be an ignition problem after all. Remember how I said that the right cylinder was throwing off a LOT more waste oil that the right? Well, that has been fouling that spark plug. Apparently the Rimfire plugs would tolerate it better than these RC excel plugs (they aways ran better on that cylinder). So I'm going to do some experimenting with disconnecting the crankcase rebreather to see if that will fix it. There is a LOT of oil being re-breathed so I suspect it will. I have no intention of doing away with the waste oil recirculation system so I will have to figure out how to get the induction system to better distribute that oil.

I don't find it surprising that I'm have these teething problems with this little gem - I did make some huge changes to the operating parameters with this conversion. In the mean time it's keeping me out of trouble, HA!

I don't find it surprising that I'm have these teething problems with this little gem - I did make some huge changes to the operating parameters with this conversion. In the mean time it's keeping me out of trouble, HA!

#124

Hang on... you were re-introducing the crankcase expelled oil back into the intake?

I can see the reasoning behind opting for that idea, but in both my experience as well as my opinion, it is a bit "asking for trouble". My .91 single fourstroke had such a recirculation from factory, that I disconnected because it caused an irregular running behaviour that I could not "adjust away". Hence the repurposing of that oil discharge for valve lubrication.

I can see the reasoning behind opting for that idea, but in both my experience as well as my opinion, it is a bit "asking for trouble". My .91 single fourstroke had such a recirculation from factory, that I disconnected because it caused an irregular running behaviour that I could not "adjust away". Hence the repurposing of that oil discharge for valve lubrication.

#125

The problem with the OS system is how and where the case vent is introduced. They dump it in the intake between carb and valve where it functions much like a variable air bleed. As such it can upset mixtures intermittently. I have been introducing the vent ahead of the carb, via a side connection at the velocity stack. Zero problems here with glow fired methanol.

A fellow over at RCG has been doing likewise with sparked gassers and has never mentioned issues with spark plugs, nor any running problems. Aside from a small issue with the stack

Check out the video:

https://streamable.com/sv5kqw

A fellow over at RCG has been doing likewise with sparked gassers and has never mentioned issues with spark plugs, nor any running problems. Aside from a small issue with the stack

Check out the video:

https://streamable.com/sv5kqw

Last edited by Jesse Open; 07-30-2022 at 05:47 AM.