Corsair with DLA 128 4 Cylinder Build

#1

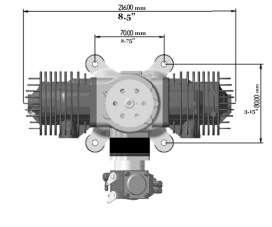

This is a build of the Ziroli 93” wing span FG-1D Corsair using their fiberglass fuselage and built up wing and tail. The engine will be the new DLA 128 cc quad cylinder gas engine. It has four 32 cc cylinders with a CNC machined crankcase, 4 FAG German ball bearings and two Walbro carburetors. It comes with two ignition modules and two exhaust stacks. As you probably guessed from my last build (Hellcat Build with 250cc Radial) I love cool engines. The beauty part is that with the optional slanted plug configuration it fits nicely in the stock cowl. With 2 degrees of right thrust and with the plug caps installed there is ¼ inch of clearance to the cowl on both sides. The actual width of the engine as I measure it plug cap to plug cap is 9 7/8” wide.

I purchased the engine from Lee at Golden Skies R/C Aircraft, Inc.

The fuselage, canopy, cowl, plans, Robart retracts and wheels were purchased from Mike at Nick Ziroli Plans.

I purchased the engine from Lee at Golden Skies R/C Aircraft, Inc.

The fuselage, canopy, cowl, plans, Robart retracts and wheels were purchased from Mike at Nick Ziroli Plans.

#4

The Cowl has a cool nose art that I had to do some work to be able to create a graphic image that would be useable for my model. Here is what I started with.

Then I stretched in in photo shop so that the fasteners were round and the front and rear panel lines were vertical to get a flat perspective.

Then after cleaning up the text I have this which I can use to create a vinyl image, decal or dry transfer image.

Then I stretched in in photo shop so that the fasteners were round and the front and rear panel lines were vertical to get a flat perspective.

Then after cleaning up the text I have this which I can use to create a vinyl image, decal or dry transfer image.

#5

I started with the stab and elevators. On the plans the elevator arrangement is for a U shaped music wire to join both elevator halves and then use an external horn and clevis to control it. The hinge used is a simple V shaped leading edge on the elevator using flat hinges.

#6

I wanted to have the control linkage internal and also have each elevator half controlled by a separate servo for safety in case one should fail in flight. I also wanted to use a more scale like hinge where the leading edge of the elevator was round and fit in a pocket in the stab. I make a sketch on tracing paper over the plans for the elevator hinge.

#9

I cut slots in the elevator and stab with my dremel for the hinges. I used a length of 3/16” music wire bent at a right to use with an internal horn. It is sandwiched between two sheets of 1/8” light ply with supporting 3/16” balsa frame work around it. It is on the center line of the nylon tube.

Last edited by flyn2high; 08-04-2014 at 08:37 AM.

#12

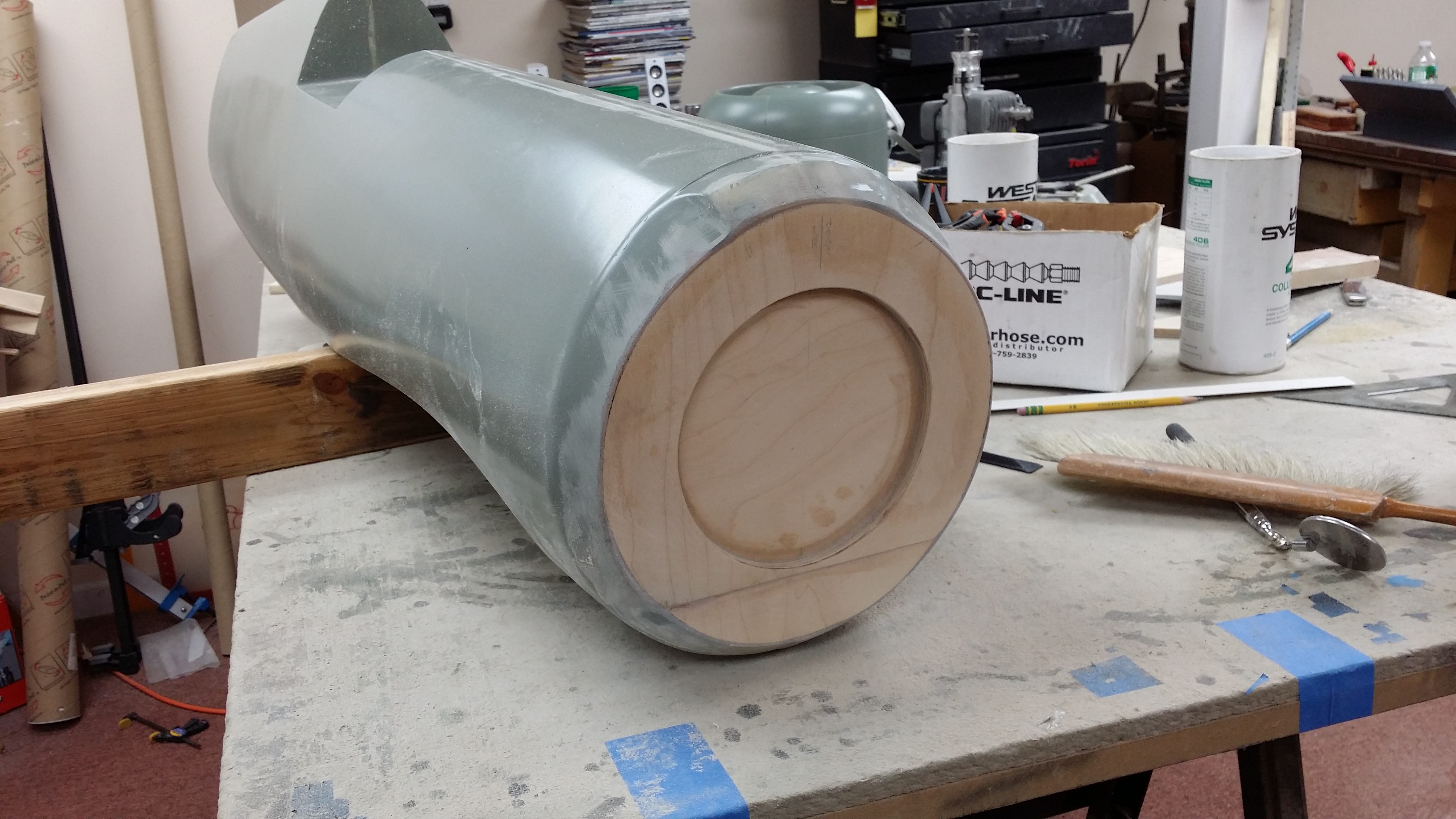

The Ziroli fiberglass fuselage is of high quality and comes with a separate tail section that will be attached later. It is actually easier to work with for now in two halves. I can set the forward section vertical and it will stand up unsupported. As you can see I already cut out for the stab. I will be attaching the stab and fin later and access the control linkage through the retractable tail wheel doors that have not been cut out yet. My first task is to accurately measure where I need to cut the front to accommodate the longer engine.

#13

Since the cowl will kind of float without mounting to s surface, I made a sketch showing the cowl position in relation to the fuselage. Since the engine is approximately 9.00” deep the engine mounting surface needs to be 0.85” from the rear datum line. However, my firewall will be two layers of 3/8” aircraft ply and the outer later will be cut out for the engine. This moves the cut line out 3/8” to 1.22”

Last edited by flyn2high; 08-04-2014 at 07:46 AM.

#14

I positioned my fuselage leading edge down on my work bench and set it up so that it leaned 2 degrees to the left looking at the top. Using a marking pen in a block of wood set to the correct height I marked the cut line. I cut the nose off using my dremel and a fiberglass cutting wheel.

#16

My plan was to install it from the inside and epoxy it in place. Naturally I discovered that it would not fit through the wing opening. I had to cut a section off and piece it together while it was glued in place. This really did not sacrifice any strength as most of it is one piece and it will get fiberglass cloth and resin on both sides later. To glue the firewall in place I used west system epoxy with low density fairing filler (#407) for added strenght and some colloidal silica (#407) to thicken it. The last photo shows the 2 degrees of right thrust that I will be using.

Last edited by flyn2high; 08-04-2014 at 07:56 AM.

#17

With the right thrust the engine mount position should be offset so that the prop shaft comes out at the center of the cowl. I was more concerned with the spark plug cap clearance. I set it up so that the clearance to the closest plug on one side to the other side was equal. It is approximately ¼” clearance. I needed to offset the engine approximately 1/8” which you can see in the next photo. I used #10-32 blind t-nuts mounted from the rear with a little gorilla glue so they don’t push out too easily.

#19

Lou,

Everything looks great so far. I only question your Marines Dream choice. Every ESM Corsair, big or small has the same paint scheme, "Marines Dream" and there are a crap load of them everywhere. I would suggest, seeing how you have fantastic Ziroli Corsair, a clean slate to do what ever you want, pick a paint scheme that no one else has. There are a lot of cool paint schemes from the Pacific, WWII era. I purchased the ESM 50cc Corsair installed the 7-77 radial and it is close to being finished. The first thing I did, I gave it a new paint job and nose art, nothing is more disturbing to me than showing up to a Warbird event and seeing a whole squadron of the same plane.

Just my .02

Dirk

Everything looks great so far. I only question your Marines Dream choice. Every ESM Corsair, big or small has the same paint scheme, "Marines Dream" and there are a crap load of them everywhere. I would suggest, seeing how you have fantastic Ziroli Corsair, a clean slate to do what ever you want, pick a paint scheme that no one else has. There are a lot of cool paint schemes from the Pacific, WWII era. I purchased the ESM 50cc Corsair installed the 7-77 radial and it is close to being finished. The first thing I did, I gave it a new paint job and nose art, nothing is more disturbing to me than showing up to a Warbird event and seeing a whole squadron of the same plane.

Just my .02

Dirk

#21

Hi Gunny: I am having a ball doing this but I keep getting interrupted by beautiful flying days.

Hi Dirk: Nice job on your Corsair. I hear what you are saying and I can relate to your post. At least 6 of our club members have the big Top Flight Tarheel Hal including me. At this year’s War Birds over Delaware there were maybe 5 or 6 more. Then at Top Gun last year Andreas Gietz from CARF brings a ¼ scale Tarheel Hal complete with a Moki 250. I was thinking the same as you.

That being said I never saw a giant scale Marines Dream at any of the meets I go to. Our club is IMAA legal size only so having a few foamies with the same color scheme is not a deal breaker for me. The truth of the matter is that I really like the scheme. This will probably take me about a year to complete and I want to choose a scheme that can keep my interest up. One other benefit is that the full size is not too far away if I want to pay a visit.

Hi Dirk: Nice job on your Corsair. I hear what you are saying and I can relate to your post. At least 6 of our club members have the big Top Flight Tarheel Hal including me. At this year’s War Birds over Delaware there were maybe 5 or 6 more. Then at Top Gun last year Andreas Gietz from CARF brings a ¼ scale Tarheel Hal complete with a Moki 250. I was thinking the same as you.

That being said I never saw a giant scale Marines Dream at any of the meets I go to. Our club is IMAA legal size only so having a few foamies with the same color scheme is not a deal breaker for me. The truth of the matter is that I really like the scheme. This will probably take me about a year to complete and I want to choose a scheme that can keep my interest up. One other benefit is that the full size is not too far away if I want to pay a visit.

#22

My Feedback: (16)

Join Date: Apr 2002

Location: Macedon,

NY

Posts: 301

Likes: 0

Received 0 Likes

on

0 Posts

Lou, great job so far. I like you had to make a choise for my Kit and ARF Corsair. I chose Sky Boss. I did the earlier version and now have the present day on the ARF.

hope to fly it near the end of this month. John Taylor Corsair brotherhood #96, Spitfire Brotherhood #110, Mustang Brotherhood #55

hope to fly it near the end of this month. John Taylor Corsair brotherhood #96, Spitfire Brotherhood #110, Mustang Brotherhood #55

#23

Senior Member

Join Date: Jan 2003

Location: Spring Hill,

FL

Posts: 4,734

Likes: 0

Received 0 Likes

on

0 Posts

#25

Senior Member

Join Date: Jan 2003

Location: Spring Hill,

FL

Posts: 4,734

Likes: 0

Received 0 Likes

on

0 Posts

I've never found it that difficult to paint the tri-color. I've never built an RC model having it though - all my experience is plastic display models. I just start a little bit away from where I want to end up to get my arm motion (the curve) right and use low pressure while working my way to the final line.

Of course everything is simpler when they've already molded in all the surface detail for me.

http://www.airfieldmodels.com/galler...images/002.jpg

http://www.airfieldmodels.com/galler...sair/index.htm

Of course everything is simpler when they've already molded in all the surface detail for me.

http://www.airfieldmodels.com/galler...images/002.jpg

http://www.airfieldmodels.com/galler...sair/index.htm