OS FS .70 Crankshaft bearing fit

#1

Hi all,

A little question... Should the outer races of the crankshaft bearings on an 4 stroke OS engine have tight fits? I noticed that my engine had axial play in the crankshaft, approx 0,5mm. Thought that was to much for this engine so I decided to replace its bearings. Noticed during tear-down that the outer race of the front bearing was sliding in and out of the crankcase together with the play, which did not sounded right to me. Engine put apart and new bearings in. This engine had a bent crankshaft that was replaced many years ago after a severe crash, so I though that running the engine a tank with a bent crankshaft might had deformed the bearing fit for the front bearing. I added some permanent loctite to the outer race when installed the new front bearing for fixing this one in place. Rest went back in by the book and no play after assembly. Did two flights and engine ran nicely and smooth, but I noticed that the crankshaft felt warmer than it used to be after landing. So, have I actually done something wrong here by adding the loctite to fix the bearing? Should the outer bearing be able to float a bit axially to compensate for the movement in the materials due to heat build up? The play I noticed before replacement was actually internally in the old worn rear bearing? This is probably not a big deal, but details like this just takes my sleep.....

A little question... Should the outer races of the crankshaft bearings on an 4 stroke OS engine have tight fits? I noticed that my engine had axial play in the crankshaft, approx 0,5mm. Thought that was to much for this engine so I decided to replace its bearings. Noticed during tear-down that the outer race of the front bearing was sliding in and out of the crankcase together with the play, which did not sounded right to me. Engine put apart and new bearings in. This engine had a bent crankshaft that was replaced many years ago after a severe crash, so I though that running the engine a tank with a bent crankshaft might had deformed the bearing fit for the front bearing. I added some permanent loctite to the outer race when installed the new front bearing for fixing this one in place. Rest went back in by the book and no play after assembly. Did two flights and engine ran nicely and smooth, but I noticed that the crankshaft felt warmer than it used to be after landing. So, have I actually done something wrong here by adding the loctite to fix the bearing? Should the outer bearing be able to float a bit axially to compensate for the movement in the materials due to heat build up? The play I noticed before replacement was actually internally in the old worn rear bearing? This is probably not a big deal, but details like this just takes my sleep.....

Last edited by MrRover75; 09-23-2021 at 03:53 AM.

#2

The rear, larger bearing bears the primary thrust load , it isthe tighter of the two on the outside race.

The front bearing outer moves more freely in the bore to allow for expansion.

The front bearing outer moves more freely in the bore to allow for expansion.

#3

I guess I can not get the front bearing out without damage it now

I guess I can not get the front bearing out without damage it now

#4

Hi!

None of the bearings on any glow engine or gas engine should move on its outher surfaces!! All ball bearings should be fastened (and removed) by heating the alu crank case, and after they have been seated (cooled down) the bearings should not move! On all glow engines its the front bearing that takes the axial load (to which the crank shaft is fastened as you tighten the prop nut).

The rear bearing takes the trust load.

None of the bearings on any glow engine or gas engine should move on its outher surfaces!! All ball bearings should be fastened (and removed) by heating the alu crank case, and after they have been seated (cooled down) the bearings should not move! On all glow engines its the front bearing that takes the axial load (to which the crank shaft is fastened as you tighten the prop nut).

The rear bearing takes the trust load.

Last edited by jaka54; 10-01-2021 at 06:46 AM.

#5

Sorry Jaka but yes, the outer race may and does indeed float axially within it's bore by design.

The axial load is the thrust load.

The axial load is the thrust load.

Last edited by Jesse Open; 10-01-2021 at 01:59 PM.

#7

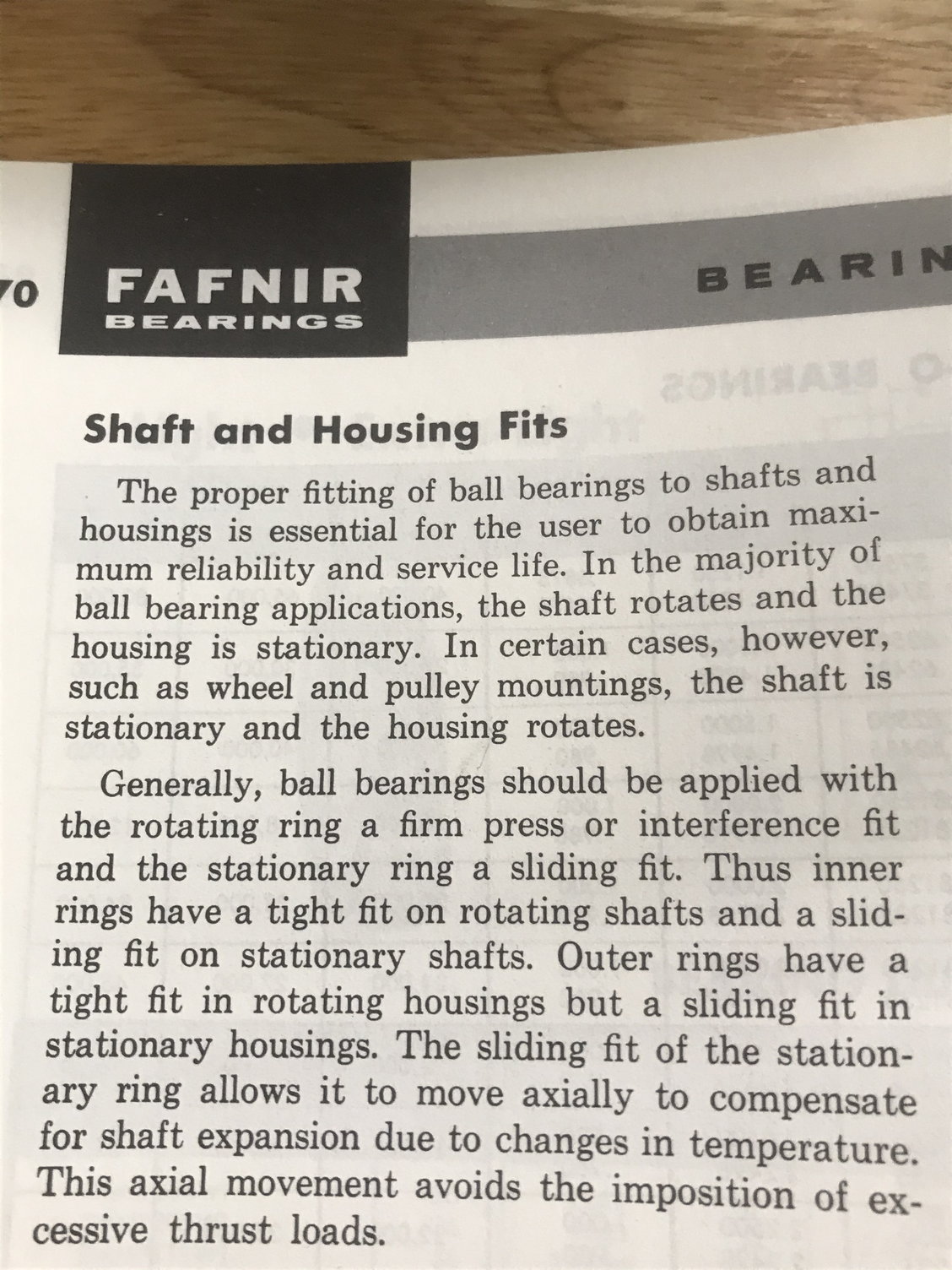

"As a rule, the bearing race that rotates relative to the load should have an interference fit; the other one may have a loose fit. The higher the load, the higher the interference. The clearances or interference fits adequate for each use can be found in the material published by the bearing manufacturers. The typical situation, in the case of rotating machines, is to have the inner race mounted with an interference fit on the shaft and the outer race installed with a loose fit."

(Typical design notes as found in ball bearing manufacturer info)

The larger, rear bearing handles most of the thrust and radial loadings; as a result, greater interference. The smaller front is lightly loaded, a very light interference that allows slight movement as the case heats and expands.

(Typical design notes as found in ball bearing manufacturer info)

The larger, rear bearing handles most of the thrust and radial loadings; as a result, greater interference. The smaller front is lightly loaded, a very light interference that allows slight movement as the case heats and expands.

#8

"As a rule, the bearing race that rotates relative to the load should have an interference fit; the other one may have a loose fit. The higher the load, the higher the interference. The clearances or interference fits adequate for each use can be found in the material published by the bearing manufacturers. The typical situation, in the case of rotating machines, is to have the inner race mounted with an interference fit on the shaft and the outer race installed with a loose fit."

(Typical design notes as found in ball bearing manufacturer info)

The larger, rear bearing handles most of the thrust and radial loadings; as a result, greater interference. The smaller front is lightly loaded, a very light interference that allows slight movement as the case heats and expands.

(Typical design notes as found in ball bearing manufacturer info)

The larger, rear bearing handles most of the thrust and radial loadings; as a result, greater interference. The smaller front is lightly loaded, a very light interference that allows slight movement as the case heats and expands.

#9

A common misperception is that the front bearing floats to accommodate the thermal expansion differences between the aluminum case and steel crankshaft. This is totally untrue! The outer races of both front and rear bearings stay put in their bores as the engine heats and cools.

In a properly assembled engine there is a small clearance between the rear bearing and the crankshaft counterweight which accommodates thermal expansion. The case expands more than the crank and as it does the rear bearing moves rearward taking up some of that clearance. Remember, the front and rear bearings are a press fit into the case but are a slip fit on the crank at operating temp; in the case of the rear bearing this is why, to allow for movement rearward. I've measured several engines, cold and hot to verify the clearance exists, and narrows, as the engine temp increases so it is not theory, it's how it works.

I have been running a Saito and an OS with epoxied in bearings due to problems with loose bearing/case fit for years, no problem. Lock them in, won't hurt a thing. I use epoxy because in the event I need to change bearings a good overnight soak in lacquer thinner is all it takes break the bond.

Lonnie

In a properly assembled engine there is a small clearance between the rear bearing and the crankshaft counterweight which accommodates thermal expansion. The case expands more than the crank and as it does the rear bearing moves rearward taking up some of that clearance. Remember, the front and rear bearings are a press fit into the case but are a slip fit on the crank at operating temp; in the case of the rear bearing this is why, to allow for movement rearward. I've measured several engines, cold and hot to verify the clearance exists, and narrows, as the engine temp increases so it is not theory, it's how it works.

I have been running a Saito and an OS with epoxied in bearings due to problems with loose bearing/case fit for years, no problem. Lock them in, won't hurt a thing. I use epoxy because in the event I need to change bearings a good overnight soak in lacquer thinner is all it takes break the bond.

Lonnie

Last edited by Glowgeek; 10-05-2021 at 04:33 AM.

#10

A common misperception is that the front bearing floats to accommodate the thermal expansion differences between the aluminum case and steel crankshaft. This is totally untrue! The outer races of both front and rear bearings stay put in their bores as the engine heats and cools.

In a properly assembled engine there is a small clearance between the rear bearing and the crankshaft counterweight which accommodates thermal expansion. The case expands more than the crank and as it does the rear bearing moves rearward taking up some of that clearance. Remember, the front and rear bearings are a press fit into the case but are a slip fit on the crank; in the case of the rear bearing this is why. I've measured several engines to verify that clearance so it is not theory, it's how it works.

I have been running a Saito and an OS with epoxied in bearings due to problems with loose bearing/case fit for years, no problem. Lock them in, won't hurt a thing. I use epoxy because in the event I need to change bearings a good overnight soak in lacquer thinner is all it takes break the bond.

Lonnie

In a properly assembled engine there is a small clearance between the rear bearing and the crankshaft counterweight which accommodates thermal expansion. The case expands more than the crank and as it does the rear bearing moves rearward taking up some of that clearance. Remember, the front and rear bearings are a press fit into the case but are a slip fit on the crank; in the case of the rear bearing this is why. I've measured several engines to verify that clearance so it is not theory, it's how it works.

I have been running a Saito and an OS with epoxied in bearings due to problems with loose bearing/case fit for years, no problem. Lock them in, won't hurt a thing. I use epoxy because in the event I need to change bearings a good overnight soak in lacquer thinner is all it takes break the bond.

Lonnie

By design and intent the outer race of the lightly loaded front bearing does indeed float.

That some folks get away with defeating that design element with epoxy or Loctite changes nothing. It is exactly what the bearing makers specify for the application.

In a "properly assembled" engine;

The rear bearing race should always bear on the bottom of the bore. The front face of the crank, directly against the bearing inner race. The primary thrust load is taken properly on the larger, rear bearing by design. The relationship of the crankpin, rod and piston more constant.

That is by design, as learned in "Anti friction bearings 101"

Any gap between the the front of crank shoulder and the larger rear bearing would improperly transfer thrust loads to the smaller, front bearing. Not a good condition.

No misconception here. The engine makers got it right by listening to the bearing makers.

Last edited by Jesse Open; 10-05-2021 at 04:27 AM.

#11

Of course the bearings must be fully seating in their bores during assembly. No argument there.

The small .006-.009" clearance between the rear bearing and crank shoulder is minimal, not enough to cause any problems on cold start and The clearance closes down to less than ,004" on a heated engine. I've measured the clearances and done the math, as you know from a previous debate on the subject and the numbers don't lie. The front bearing does not move to accomodate thermal expansion, at least not measurably.

As before, we can agree to disagree; you in theory and me in practice. I'm fine with that.

The small .006-.009" clearance between the rear bearing and crank shoulder is minimal, not enough to cause any problems on cold start and The clearance closes down to less than ,004" on a heated engine. I've measured the clearances and done the math, as you know from a previous debate on the subject and the numbers don't lie. The front bearing does not move to accomodate thermal expansion, at least not measurably.

As before, we can agree to disagree; you in theory and me in practice. I'm fine with that.

#12

To the OP

If the crankshaft/nose of the case is getting hotter than normal after disassembly/reassembly it's likely due to castor or corrosion buildup at the rear bearing area of the crank. That buildup can resist the needed movement of the crank through the rear bearing inner race as the engine heats up and can cause excessive rearward pulling pressures on the front bearing. When all cleaned up the rear bearing should slip fit onto the crank, a very light interference fit is ok too. Magically your hot front bearing problem will disappear.

In addition: Make sure both front and rear bearings are fully seated in clean bores.

If the crankshaft/nose of the case is getting hotter than normal after disassembly/reassembly it's likely due to castor or corrosion buildup at the rear bearing area of the crank. That buildup can resist the needed movement of the crank through the rear bearing inner race as the engine heats up and can cause excessive rearward pulling pressures on the front bearing. When all cleaned up the rear bearing should slip fit onto the crank, a very light interference fit is ok too. Magically your hot front bearing problem will disappear.

In addition: Make sure both front and rear bearings are fully seated in clean bores.

Last edited by Glowgeek; 10-05-2021 at 11:58 AM.

#13

Hi all,

Thanks for the feedback. Conflicting advice as always, but that might be good and create a good debate If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

I have recently done another OS FS70 (engine #2) , exact same engine I had laying around. This engine had a tighter fit on the front bearing towards the casing, and the crank slipped right in. I think everything is as it should on this one.

So, next reasonable step would be to pull the crankshaft out of engine #1 and to a cleanup. and inspection, then bench test it and observe for temperature build ups around the front bearing.

Thanks for the feedback. Conflicting advice as always, but that might be good and create a good debate

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there. I have recently done another OS FS70 (engine #2) , exact same engine I had laying around. This engine had a tighter fit on the front bearing towards the casing, and the crank slipped right in. I think everything is as it should on this one.

So, next reasonable step would be to pull the crankshaft out of engine #1 and to a cleanup. and inspection, then bench test it and observe for temperature build ups around the front bearing.

#14

The front bearing, regardless of the brand of model engine, should have an interference fit between the outer race and the front housing. Of the few hundred engines I’ve owned, 2 & 4-cycle, have ever had loose bearing fits against the case. If the outer race is capable of spinning when fully installed, there is a big risk of that outer race spinning and further wallowing out the crankcase. Anyone remember seeing the video of the OS 4-stroke engine flying a plane with so much crank play you could see the prop wobbling as it flew? I wish I could find the video; I’d post a link.

Note I am not talking about the fit between the inner race and the crankshaft. That should be a slip fit.

Note I am not talking about the fit between the inner race and the crankshaft. That should be a slip fit.

Last edited by 1QwkSport2.5r; 10-06-2021 at 02:01 AM.

#15

Hi all,

Thanks for the feedback. Conflicting advice as always, but that might be good and create a good debate If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

I have recently done another OS FS70 (engine #2) , exact same engine I had laying around. This engine had a tighter fit on the front bearing towards the casing, and the crank slipped right in. I think everything is as it should on this one.

So, next reasonable step would be to pull the crankshaft out of engine #1 and to a cleanup. and inspection, then bench test it and observe for temperature build ups around the front bearing.

Thanks for the feedback. Conflicting advice as always, but that might be good and create a good debate

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.I have recently done another OS FS70 (engine #2) , exact same engine I had laying around. This engine had a tighter fit on the front bearing towards the casing, and the crank slipped right in. I think everything is as it should on this one.

So, next reasonable step would be to pull the crankshaft out of engine #1 and to a cleanup. and inspection, then bench test it and observe for temperature build ups around the front bearing.

I have run into rear bearing/crankshaft fits that were too tight, namely on an OS fs70, an OS fs91 and on a YS91AC/FZ. In those cases the front bearing got hot. In the case of the YS the front bearing got so hot that it spun the front bearing in the housing. Lessons learned on how important the rear bearing/crankshaft fit is. The rear bearing must be able to slide on the crank when at operating temp.

How much interference fit between the rear bearing and crank is acceptable at room temp is not something I can answer by theory. All I know is that generally, under load, the inner ring of a bearing heats to a higher temp than its accompanying shaft and therefore the interference fit between the two will decrease; making it easier for the bearing to slide on the shaft.

With clean parts test fit the rear bearing on the crank at room temp to make sure the bearing will either slip fit or lightly interference fit the crank before assembly. The bearing should slide on to within an 1/8" or so of the crank counter weight (shoulder) without much pressure. Fully seat the front and rear bearings in a hot crankcase, allow to cool to room temp and then slide the crank in as far as possible using your thumbs. Mount the prop hub, prop, washer, nut and tighten the prop. The prop should turn freely without resistance. If it feels stiff or notchy there's too much interference between the inner race of the rear bearing and crankshaft or your bearings are not fully seated in clean bores.

FYI, in the engine examples I noted I had to chuck up the crankshafts in a lathe and sand/polish them down for less interference fit.

Last edited by Glowgeek; 10-06-2021 at 09:04 AM.

The following users liked this post:

MrRover75 (10-06-2021)

#16

Senior Member

This is a Suevia 150, the rear bearing is a roller bearing, so the front bearing is held in by a large snap ring.

Last edited by 1200SportsterRider; 10-09-2021 at 11:24 AM.

#17

Hi all,

Thanks for the feedback. Conflicting advice as always, but that might be good and create a good debate If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

I have recently done another OS FS70 (engine #2) , exact same engine I had laying around. This engine had a tighter fit on the front bearing towards the casing, and the crank slipped right in. I think everything is as it should on this one.

So, next reasonable step would be to pull the crankshaft out of engine #1 and to a cleanup. and inspection, then bench test it and observe for temperature build ups around the front bearing.

Thanks for the feedback. Conflicting advice as always, but that might be good and create a good debate

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.

If I remembered correctly, I had to tap the crankshaft back in place. There was probably more than a light interference fit there.I have recently done another OS FS70 (engine #2) , exact same engine I had laying around. This engine had a tighter fit on the front bearing towards the casing, and the crank slipped right in. I think everything is as it should on this one.

So, next reasonable step would be to pull the crankshaft out of engine #1 and to a cleanup. and inspection, then bench test it and observe for temperature build ups around the front bearing.

LOL

Not only conflicting advice, silly too!

In nearly sixty years of RC flying, not once have I had to resort to JB Welding an outer race nor had to destroy a proper crank to inner race fit. For a living I have rebuilt, repaired, designed machine tools for over fiflty years, installed bearings costing several thousand dollars. From micro small to over 20 inch diameter, including spindles on high speed, precision grinders. Always followed the manufacturers direction, both the equipment maker and the bearing maker, preserved the design fit.

Never needed to second guess, or epoxy a race!

Our toy engines are a very basic application.

Stationary housing, rotating shaft. The Fafnir directions are typical and in perfect agreement with what I was taught as an apprentice.

Nor is it different from what I usually see the engine folks doing.

Not only "theory" but backed up by decades of experience. Proven by practice.

Last edited by Jesse Open; 10-10-2021 at 06:45 AM.

#18

Gary - my comment on using green locktite on the outer race is ONLY if the outer race spins when seated within the crankcases front housing. Parts are getting scarce for some engines, so going out to find a new crankcase to repair an old engine may not be as feasible for some. A little green locktite on the outer race of a LOOSE fitting (again, spins within its seated position in the crankcase) bearing may prolong the life of an otherwise limited lifespan engine. Maybe I’m overthinking it, but I wouldn’t run an engine with a loose bearing fit for risk of completely destroying the crankcase/front housing.

YMMV.

YMMV.

#19

Well Jesse Open, all those years of experience is very impressive. So why does the simple concept escape you that the slip fit rear bearing will move on the crank before a press fit front bearing will move in it's bore? There IS clearance for the rear bearing to move rearward on the crank during thermal expansion of the engine case.

Test my "practice", heat an engine up and measure how far the front bearing moved forward in it's bore. You'll find it moved zero, because it doesn't have to.

Test my "practice", heat an engine up and measure how far the front bearing moved forward in it's bore. You'll find it moved zero, because it doesn't have to.

Last edited by Glowgeek; 10-10-2021 at 11:51 AM.

#20

Well Jesse Open, all those years of experience is very impressive. So why does the simple concept escape you that the slip fit rear bearing will move on the crank before a press fit front bearing will move in it's bore? There IS clearance for the rear bearing to move rearward on the crank during thermal expansion of the engine case.

Lonnie,

Does not escape me in the least. Unlike you, I also realize that in most cases the prevailing thrust load is forward,as I noted, the crank, properly installed, should not have that clearance. As the Fafniir and other manufacturers specify that inner race should have the prescibed interference fit to the shaft.

Now, with those specs met, the forward bearing inner race on Saito for example is locked in axial location against the crank shoulder on the rear, thrust surface and the drive collet forward.

The front bearing outer race by design and specification is fitted (see the Fafnir sheet) to allow axial movement Also note this whole plan is to minimize excessive thrust loadings.

The larger rear bearing, is sized to better handle the combined radial and axial loads.

Your "test" is absolutely ridiculous. Push the crank forward, the front bearing in the warm casting will easily slip forward. Exactly where it belongs, by design. Also exactly where the propeller thrust loads should take it

Why does solid engineering behind the manufacturer design and time proven practice escape you?

Have yet to see a factory Saito with bearings JB welded in place. As trained, I use heat when removing or installing bearings in aluminum housings, precisely to preserve the design fit.

No "misconception" here.

Last edited by Jesse Open; 10-10-2021 at 12:25 PM.

#21

Gary - my comment on using green locktite on the outer race is ONLY if the outer race spins when seated within the crankcases front housing. Parts are getting scarce for some engines, so going out to find a new crankcase to repair an old engine may not be as feasible for some. A little green locktite on the outer race of a LOOSE fitting (again, spins within its seated position in the crankcase) bearing may prolong the life of an otherwise limited lifespan engine. Maybe I’m overthinking it, but I wouldn’t run an engine with a loose bearing fit for risk of completely destroying the crankcase/front housing.

YMMV.

YMMV.

One of the most laughable "fixes" is the screwballs who ***** punch bearing bores!

#22

Not a "bad" word! forwards or backwards. kcirp hcnup.

***** punch

nounSave WordTo save this word, you'll need to log in.

Log In

Definition of ***** punch

(Entry 1 of 2): a pointed steel punch used to mark a reference point on metal or to puncture sheet metal for the insertion of rivets or bolts

Last edited by Jesse Open; 10-12-2021 at 03:52 PM.

#23

Hi,

I have now taken the #1 .70 surpass apart. I had to tap the Crankshaft out of the crankcase, so it had definitely a tight fit towards the rear bearing. I put the crankshaft in a drill and gently polished the rear bearing surface with some scotch brite. The crankshaft did now slip into the bearings with my thumb the same way as it did on the #2 .70 surpass and another OS 46FX I recently replaced bearings on. I am of the impression that the fit should be like this, regardless that it is not according to standard industrial practice mentioned above. After putting the propeller on, there is a nearly not noticeable axial play in the crankshaft, probably its the internal play in the front bearing I am feeling. Turns around smoothly and freely now. There was a very slight resistance after the first assembly, probably due to the axial load between the two bearings as the crankshaft sat in both bearing bores.

Next step is to remove the valves, clean them up and give them a gently lap with some metal polish before everything goes back together. Crossing fingers that all will be good now.

I have now taken the #1 .70 surpass apart. I had to tap the Crankshaft out of the crankcase, so it had definitely a tight fit towards the rear bearing. I put the crankshaft in a drill and gently polished the rear bearing surface with some scotch brite. The crankshaft did now slip into the bearings with my thumb the same way as it did on the #2 .70 surpass and another OS 46FX I recently replaced bearings on. I am of the impression that the fit should be like this, regardless that it is not according to standard industrial practice mentioned above. After putting the propeller on, there is a nearly not noticeable axial play in the crankshaft, probably its the internal play in the front bearing I am feeling. Turns around smoothly and freely now. There was a very slight resistance after the first assembly, probably due to the axial load between the two bearings as the crankshaft sat in both bearing bores.

Next step is to remove the valves, clean them up and give them a gently lap with some metal polish before everything goes back together. Crossing fingers that all will be good now.

#24

Hi,

I have now taken the #1 .70 surpass apart. I had to tap the Crankshaft out of the crankcase, so it had definitely a tight fit towards the rear bearing. I put the crankshaft in a drill and gently polished the rear bearing surface with some scotch brite. The crankshaft did now slip into the bearings with my thumb the same way as it did on the #2 .70 surpass and another OS 46FX I recently replaced bearings on. I am of the impression that the fit should be like this, regardless that it is not according to standard industrial practice mentioned above. After putting the propeller on, there is a nearly not noticeable axial play in the crankshaft, probably its the internal play in the front bearing I am feeling. Turns around smoothly and freely now. There was a very slight resistance after the first assembly, probably due to the axial load between the two bearings as the crankshaft sat in both bearing bores.

Next step is to remove the valves, clean them up and give them a gently lap with some metal polish before everything goes back together. Crossing fingers that all will be good now.

I have now taken the #1 .70 surpass apart. I had to tap the Crankshaft out of the crankcase, so it had definitely a tight fit towards the rear bearing. I put the crankshaft in a drill and gently polished the rear bearing surface with some scotch brite. The crankshaft did now slip into the bearings with my thumb the same way as it did on the #2 .70 surpass and another OS 46FX I recently replaced bearings on. I am of the impression that the fit should be like this, regardless that it is not according to standard industrial practice mentioned above. After putting the propeller on, there is a nearly not noticeable axial play in the crankshaft, probably its the internal play in the front bearing I am feeling. Turns around smoothly and freely now. There was a very slight resistance after the first assembly, probably due to the axial load between the two bearings as the crankshaft sat in both bearing bores.

Next step is to remove the valves, clean them up and give them a gently lap with some metal polish before everything goes back together. Crossing fingers that all will be good now.

A snug fit on the inner race of the rear bearing is not nearly as important as is the design intended float of the outer race of the front bearing. The prevailing thrust loads will accomodate a slight mis-fitting at the more heavily loaded rear bearing. A

relaxed fit on the shaft at the rear will increase the internal running clearance of the bearing.

#25

Hi all,

A little question... Should the outer races of the crankshaft bearings on an 4 stroke OS engine have tight fits? I noticed that my engine had axial play in the crankshaft, approx 0,5mm. Thought that was to much for this engine so I decided to replace its bearings. Noticed during tear-down that the outer race of the front bearing was sliding in and out of the crankcase together with the play, which did not sounded right to me. Engine put apart and new bearings in. This engine had a bent crankshaft that was replaced many years ago after a severe crash, so I though that running the engine a tank with a bent crankshaft might had deformed the bearing fit for the front bearing. I added some permanent loctite to the outer race when installed the new front bearing for fixing this one in place. Rest went back in by the book and no play after assembly. Did two flights and engine ran nicely and smooth, but I noticed that the crankshaft felt warmer than it used to be after landing. So, have I actually done something wrong here by adding the loctite to fix the bearing? Should the outer bearing be able to float a bit axially to compensate for the movement in the materials due to heat build up? The play I noticed before replacement was actually internally in the old worn rear bearing? This is probably not a big deal, but details like this just takes my sleep.....

A little question... Should the outer races of the crankshaft bearings on an 4 stroke OS engine have tight fits? I noticed that my engine had axial play in the crankshaft, approx 0,5mm. Thought that was to much for this engine so I decided to replace its bearings. Noticed during tear-down that the outer race of the front bearing was sliding in and out of the crankcase together with the play, which did not sounded right to me. Engine put apart and new bearings in. This engine had a bent crankshaft that was replaced many years ago after a severe crash, so I though that running the engine a tank with a bent crankshaft might had deformed the bearing fit for the front bearing. I added some permanent loctite to the outer race when installed the new front bearing for fixing this one in place. Rest went back in by the book and no play after assembly. Did two flights and engine ran nicely and smooth, but I noticed that the crankshaft felt warmer than it used to be after landing. So, have I actually done something wrong here by adding the loctite to fix the bearing? Should the outer bearing be able to float a bit axially to compensate for the movement in the materials due to heat build up? The play I noticed before replacement was actually internally in the old worn rear bearing? This is probably not a big deal, but details like this just takes my sleep.....

Typically, standard (C2, usually not even marked as such) bearings have a slighly looser fit on the outer race, and a tighter fit on the inner race. These bearings will usually come out with the shaft.

C3 bearings usually fit a bit tighter in their seat (outer race) and a bit looser on the inner race, and will stay put while the shaft is pulled out.

Not a rule set in stone, and I have seen wallowed out bearing seats, but most engines that I fix for people, if the bearing comes out with the shaft, it is because it is not a C3 bearing, and fitting one usually solves the whole issue.

Brgds, Bert