Welcome to Club SAITO !

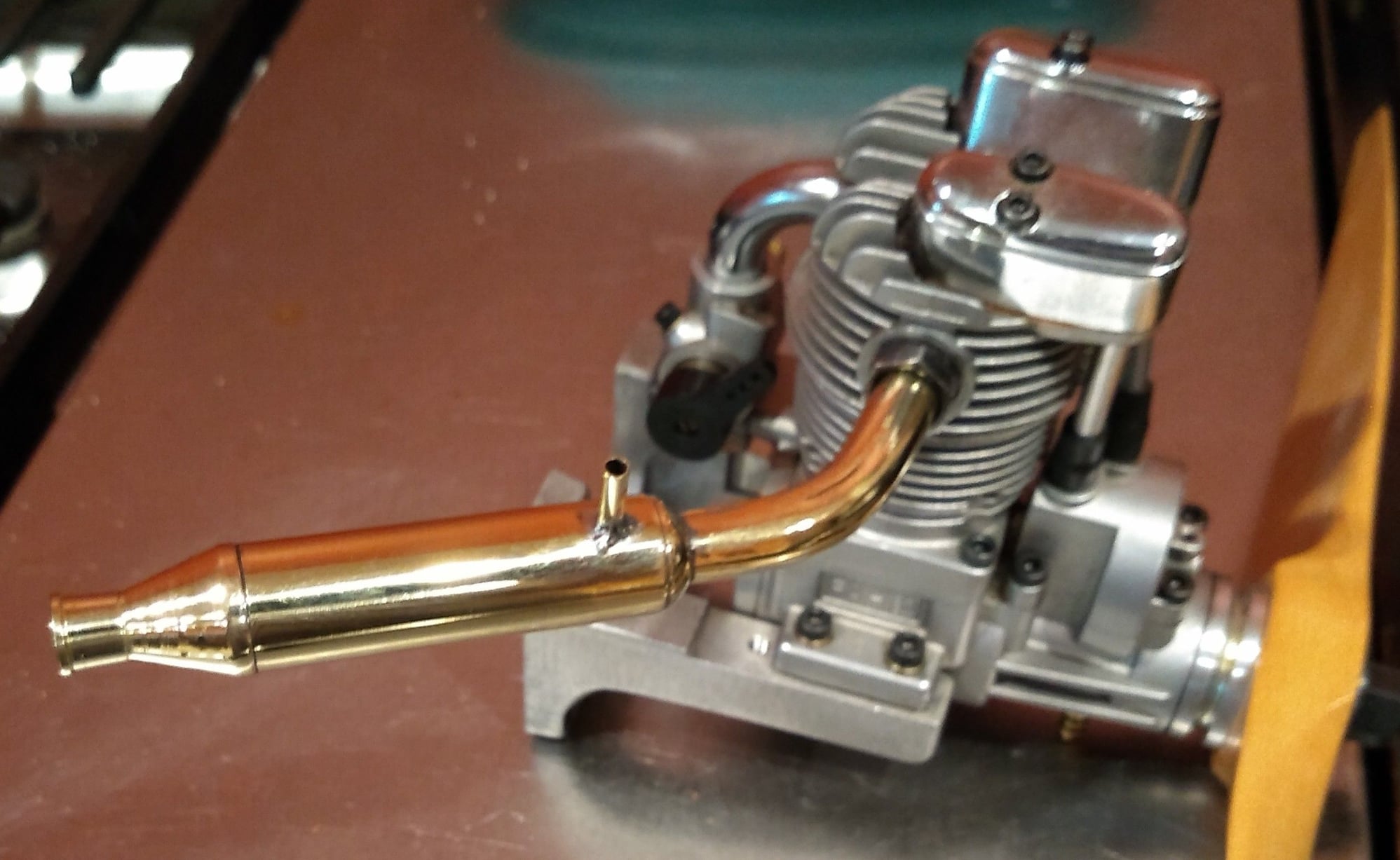

I took the valve covers off for inspection and I'm really glad I did! The exhaust side rocker arm pin fell right out. It must have come loose. The threads are done, both in the pin and the cylinder head. So I ordered new rocker arm pins from Horizon. I will screw it in best I can. I thought I may try JB Weld since I can't get a cylinder head. Plus it's lots cheaper! Do you guys think JB Weld will hold a rocker arm pin in place?

Hyjinx,

Your Blue Angel Buddies were about six miles down the road at Selfridge ANG performing at an air show yesterday. Did several flyovers of Utica.

This pic was taken by my son, Keith when they were here a couple of years ago,

Last edited by Jesse Open; 08-08-2021 at 07:08 AM.

Sheech. We went to the Heinrich Meijer Gardens in GR yesterday and gooned at plants. LolNo Saitos there. Even in the Japanese Garden section.

Stock photo, Fifi

Last edited by Jesse Open; 08-08-2021 at 05:33 AM.

I took the valve covers off for inspection and I'm really glad I did! The exhaust side rocker arm pin fell right out. It must have come loose. The threads are done, both in the pin and the cylinder head. So I ordered new rocker arm pins from Horizon. I will screw it in best I can. I thought I may try JB Weld since I can't get a cylinder head. Plus it's lots cheaper! Do you guys think JB Weld will hold a rocker arm pin in place?

An overnight soak in laquer thinner will release/dissolve the JB Weld in the event the pin needs to be removed later.

Back around 1998, B-29 "Fifi" was at Selfidge. The crowd was huge so I decided to fly RC instead. The Fraser Club field is about 3 miles west of Selfridge, during the day, Fifi flew directly over our field at about 600 feet with a P-51 escort at her side. Quite a sight, with sounds to match.

Stock photo, Fifi

Stock photo, Fifi

Two summers ago I was IN the glass ball with my hands on the bomb sight as it started the turn. About six hundred feet. You could see turkeys in my backyard.

What a RIDE!

I muttered " bombs away" under my breath. Could have screamed it and no one would have heard me over the droning wasps.

They were considerably louder than my Saito radials.

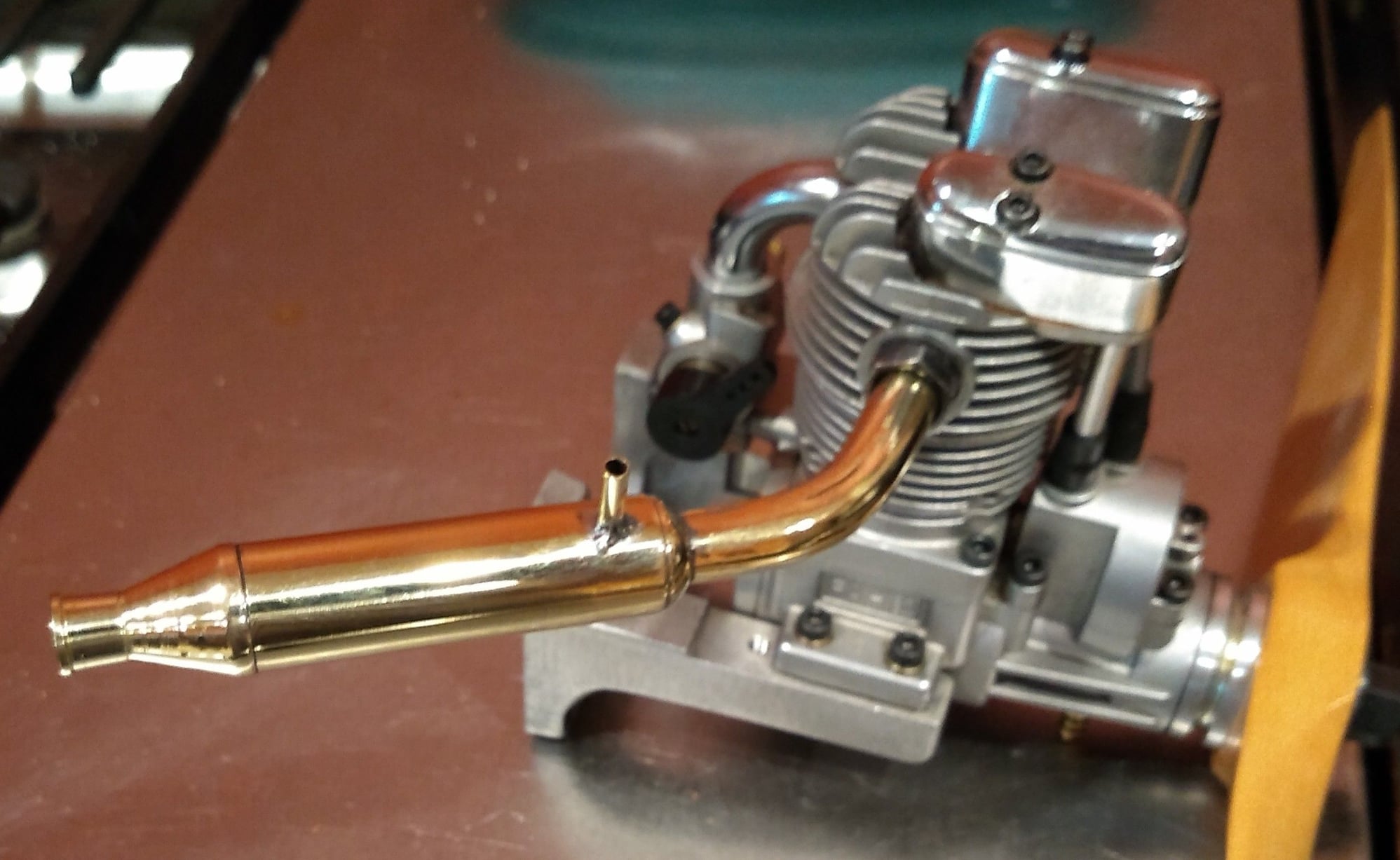

After polishing. Would look stellar on a GK as is. Was going to paint it high temp silver but alas!, a 5/8" long crack on the top of the header tube at the bend. Rat farts!

Last edited by Glowgeek; 08-08-2021 at 07:52 AM.

YYeah buddy. We get treated to The Yankee Lady over the house regularly.. She makes a lazy rudder turn over our house as it swings back to Ypsi on the $450 joy rides.

Two summers ago I was IN the glass ball with my hands on the bomb sight as it started the turn. About six hundred feet. You could see turkeys in my backyard.

What a RIDE!

I muttered " bombs away" under my breath. Could have screamed it and no one would have heard me over the droning wasps.

They were considerably louder than my Saito radials.

Two summers ago I was IN the glass ball with my hands on the bomb sight as it started the turn. About six hundred feet. You could see turkeys in my backyard.

What a RIDE!

I muttered " bombs away" under my breath. Could have screamed it and no one would have heard me over the droning wasps.

They were considerably louder than my Saito radials.

Came in as a badly weathered, stripped cabin section and boxes upon boxes of parts. We totally refinished it and made new woring looms to restore function. Had a blast on that project!

Last edited by Jesse Open; 08-08-2021 at 09:40 AM.

Yes, if the threaded hole in the rocker perch is not too wallowed out and you get the parts very clean before applying the epoxy. I use brake cleaner. I would epoxy the pin into both sides of the rocker perch to help limit movement.

An overnight soak in laquer thinner will release/dissolve the JB Weld in the event the pin needs to be removed later.

An overnight soak in laquer thinner will release/dissolve the JB Weld in the event the pin needs to be removed later.

May sound crazy to some here but this is just a goofy observation of this. The valve cover must prevent the pin from sliding out of its reciept. While if it does come to back out of its threads it can slide over to the interior wall of the cover but not remove itself. Probably peen the slotted end when it rides on the wall but can't come out.

May have no effect on tuning or running the motor. May seize with time, but again, my observation has been a lot of lubricant makes it's way up the pushrod tubes and keeps that area pretty cool and slippery.

I expect even with the tighter thread fit and factory torque regimen many folks have found this condition when checking and adjusting valves.

They do loosen up though, I have lost pins running motors without the covers replaced. Probably shouldn't admit that here among purists. 😳

Pretzel logic with Sunday morning comin down.

May have no effect on tuning or running the motor. May seize with time, but again, my observation has been a lot of lubricant makes it's way up the pushrod tubes and keeps that area pretty cool and slippery.

I expect even with the tighter thread fit and factory torque regimen many folks have found this condition when checking and adjusting valves.

They do loosen up though, I have lost pins running motors without the covers replaced. Probably shouldn't admit that here among purists. 😳

Pretzel logic with Sunday morning comin down.

My Feedback: (1)

The threaded hole in the rocker perch has just a slight amount of thread left. I planned on (carefully) epoxying the pin to both sides of the rocker perch. I was going to attack the holes in the perches with a pipe cleaner and mineral spirits. I like the idea of brake cleaner! I DID think about what if I need to remove a valve later. Thank you for the tip about overnight soak in lacquer thinner to dissolve JB Weld.

maybe Garry and or Dave will comment about this glue if it will work for you.

Garry, I sure wish I knew about that 91. LOL

Jim

Last edited by the Wasp; 08-08-2021 at 05:57 PM.

As an example, I bought a used Saito 62 that had a bad front bearing bore. The bearing had no press fit in the crankcase at all. I lightly sanded the bearing outer race and the bearing bore, cleaned everything up with brake cleaner and epoxied the bearing in with JB Weld. 6 yrs and countless hours of run time later it still runs great.

Last edited by Glowgeek; 08-08-2021 at 02:31 PM.

I am actually following a build on Facebook by David Zotzman for the 182 and Sig 1/4 cub combo. He has installed the motor and cut the cowl to fit around it. The last time I checked he had not finished the plane for the maiden but hopefully it will be before I maiden mine and can learn from his experience.

These pictures are Dave's from his Facebook post.

These pictures are Dave's from his Facebook post.

Well, this was amusing, was searching for something else and found my plane here LOL.

Just started getting it in paint finally. It's only been 2 years and 7 months in the making. Then again, the Mustang in the background has been three years LOL.

I realize that this can end up being a Chev/Ford or Pepsi/Coke debate, regardless, this is the route I have chosen for more than one reason, I've looked into it and haven't found anyone cause damage by it. I would think if it were high risk, Saito would have said so in their manual.

Last edited by HAL9KPCM; 08-08-2021 at 03:40 PM.

Ok, sent you a PM anyway. Just my thoughts as I have never run a 182T in either position. I tested an OS boxer inverted, vent near the top of the rear cover. I was told that the engine would fill with oil. I didn't believe them due to the high levels of pulsing pos/neg case pressure, more positive as you say, and I envision it as an oily mist. The boxer collected exactly 3cc more oil in the case after 15 and 30 minutes of run time vs in the upright position. Harmless. I suspect the inverted odd fire 182T will collect more oil, how much I can't say.

For me its Chevy cars, Ford trucks, Pepsi straight, Coke with Rum.

For me its Chevy cars, Ford trucks, Pepsi straight, Coke with Rum.

Last edited by Glowgeek; 08-08-2021 at 04:21 PM.

The following users liked this post:

HAL9KPCM (08-08-2021)

Could be the camera angle but the rocker arm does appear to be canted (not centered on the valve stem). If so it would indicate very badly worn threads and/or the clearance hole. Epoxy (JB Weld) is great at holding things in place but lacks in compressive strength. Subjected to a constant vibration and pressure it will deform if applied too thick, as in filling large voids. As long as the pin fits the clearance hole and threading fairly tight it will likely work and last. If not it may be time for a thread repair kit, custom brass bushing and a machinist....or a new cylinder.

As an example, I bought a used Saito 62 that had a bad front bearing bore. The bearing had no press fit in the crankcase at all. I lightly sanded the bearing outer race and the bearing bore, cleaned everything up with brake cleaner and epoxied the bearing in with JB Weld. 6 yrs and countless hours of run time later it still runs great.

As an example, I bought a used Saito 62 that had a bad front bearing bore. The bearing had no press fit in the crankcase at all. I lightly sanded the bearing outer race and the bearing bore, cleaned everything up with brake cleaner and epoxied the bearing in with JB Weld. 6 yrs and countless hours of run time later it still runs great.

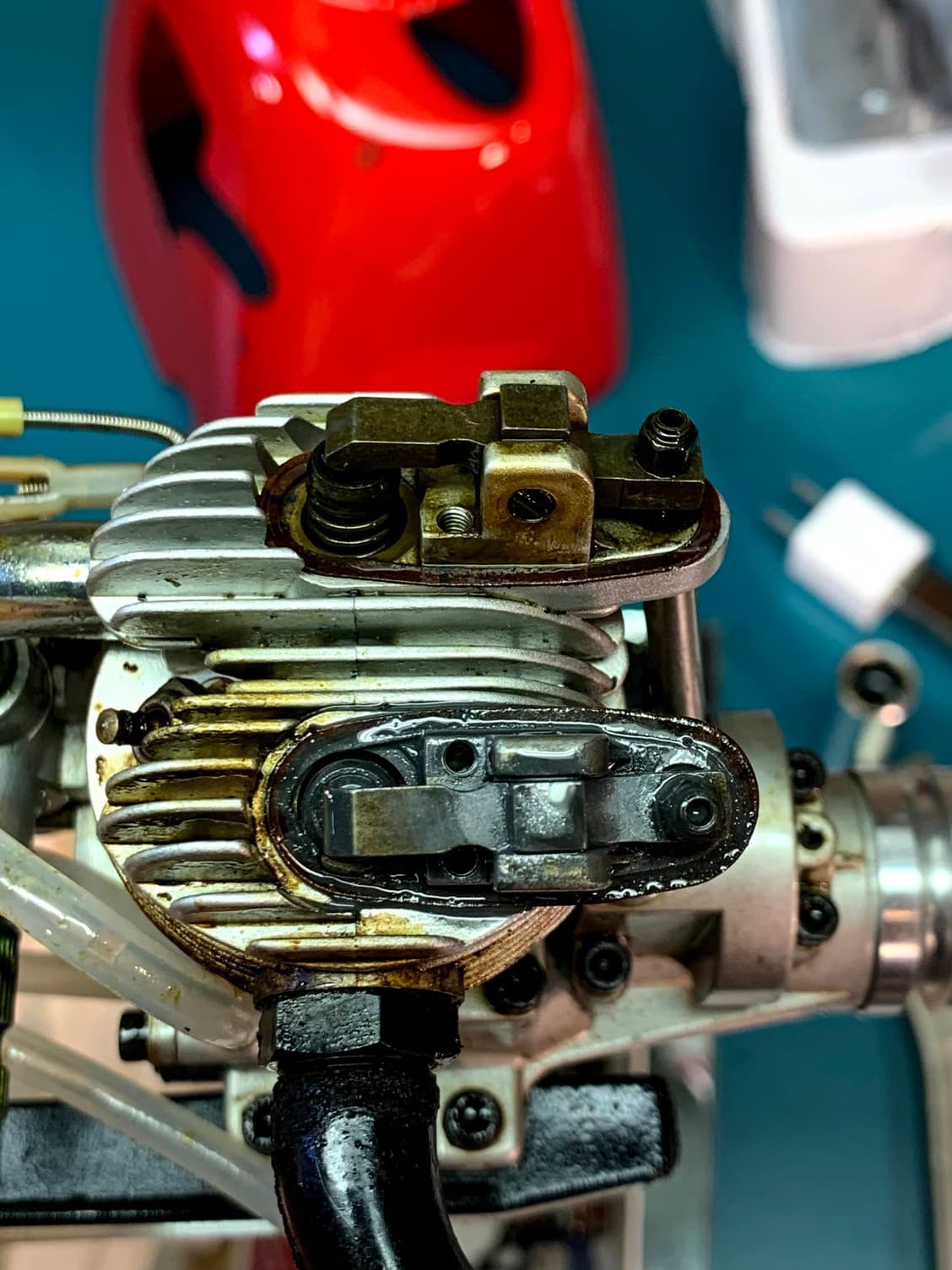

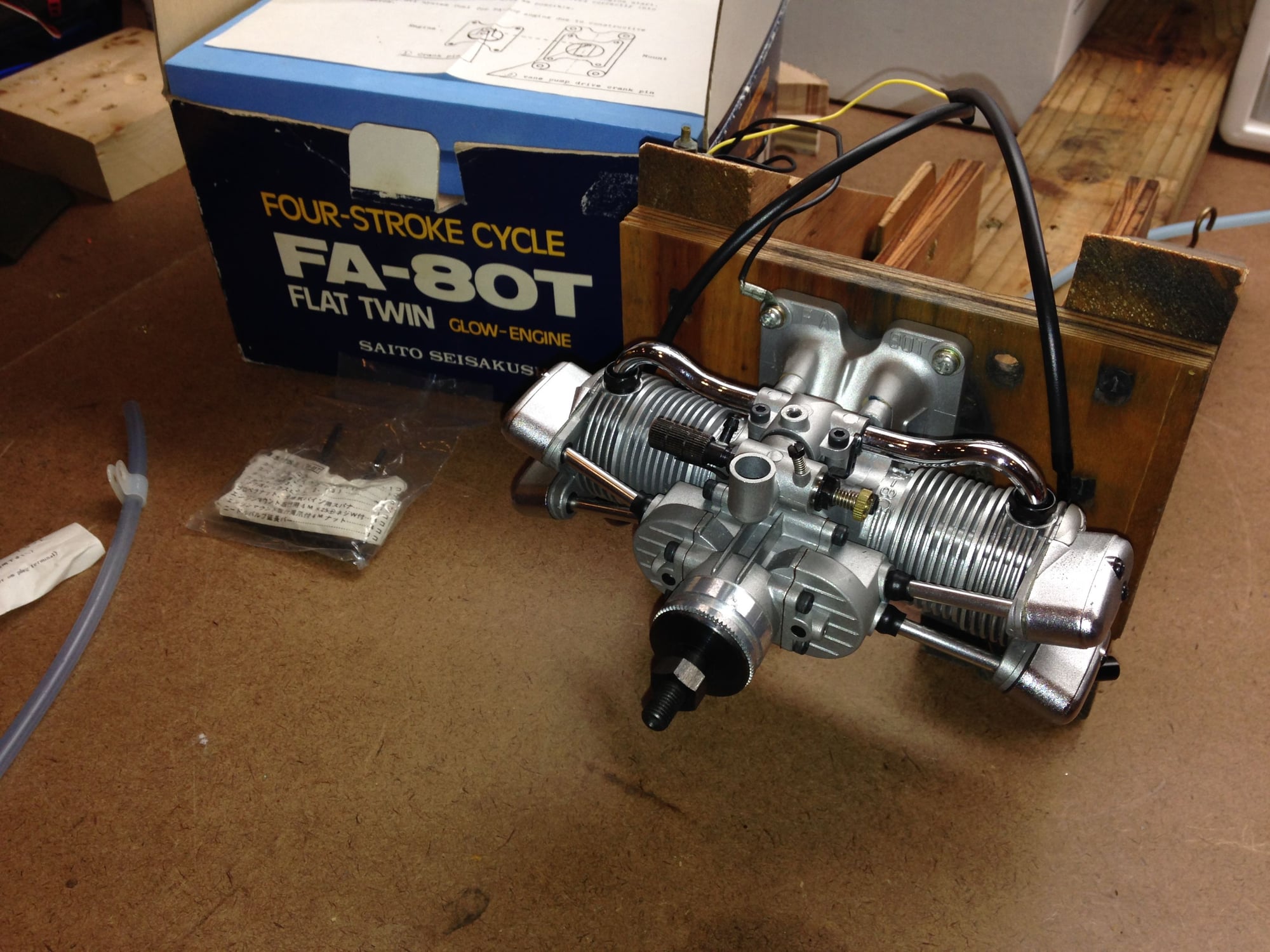

Vinnie6,

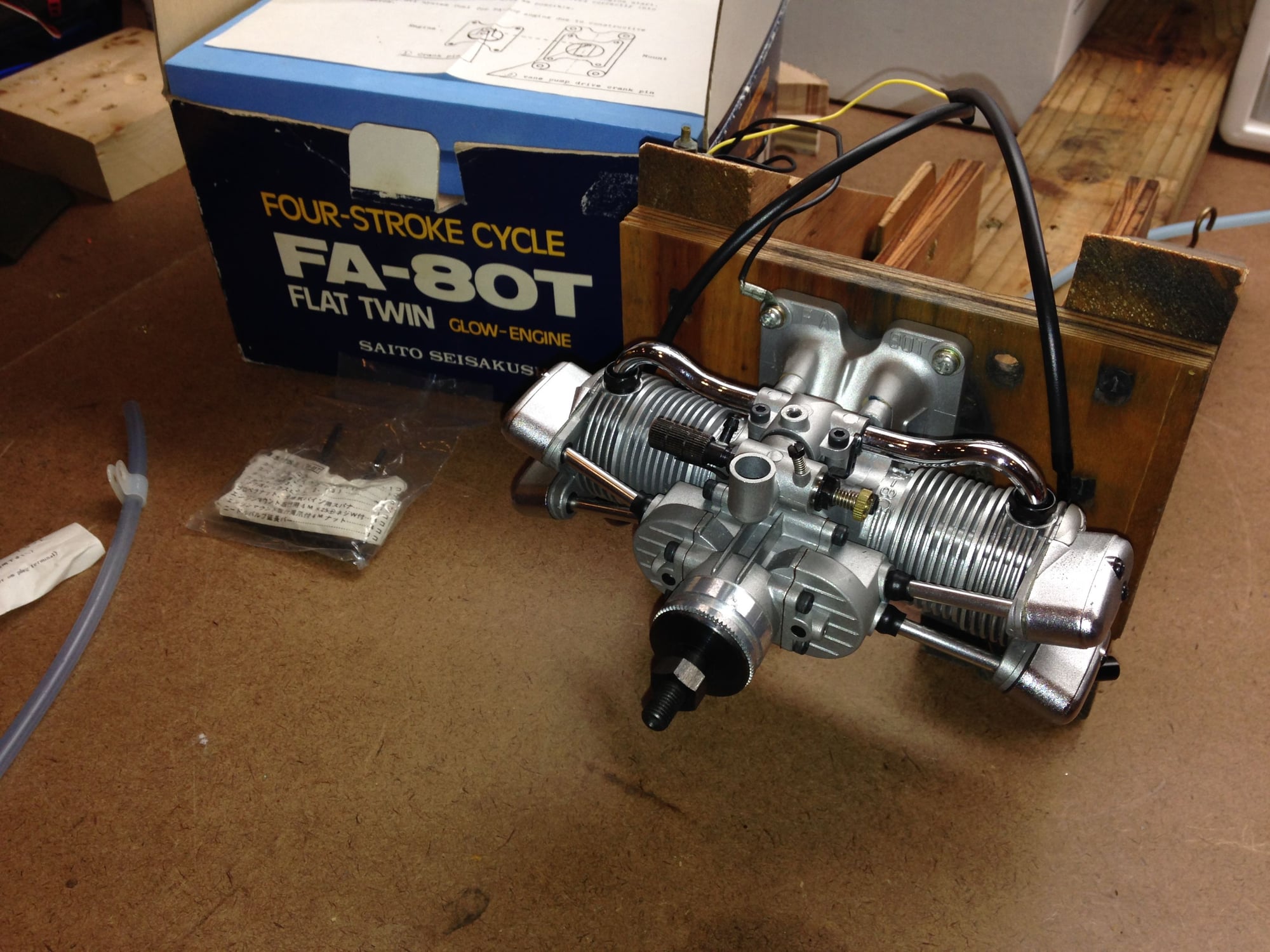

I have used a Helicoil to repair a rocker issue on one of my FA-80T twins. The product I purchased was an E-Z Coil M3-0.5 SKU Number SK40210 11543411. It comes with almost everything you need to repair a threaded hole. I have also used it to repair a jug bolt hole in the case of one of my FA-90 engines where the aluminum threads had stripped when I was tightening the jug down. It is a somewhat easy fix to a big problem.

es.

I have used a Helicoil to repair a rocker issue on one of my FA-80T twins. The product I purchased was an E-Z Coil M3-0.5 SKU Number SK40210 11543411. It comes with almost everything you need to repair a threaded hole. I have also used it to repair a jug bolt hole in the case of one of my FA-90 engines where the aluminum threads had stripped when I was tightening the jug down. It is a somewhat easy fix to a big problem.

es.

Glowgeek, Thank you for your very insightful comments. That picture was taken after the rocker pin had fallen out. The rocker arm is unsupported in that picture. For comparison sake I took the "good" pin from the intake side and put it in the exhaust side with the rocker arm and it was just as tight of a fit as the intake side. So even though the threads for the rocker arm pin on the exhaust side are compromised, it appears the holes are not elongated. Plus I measured both rocker arm pins. The "good" pin is .1370 inches diameter and the bad pin is .1365. Is that where all my metal came from?

Last edited by Glowgeek; 08-09-2021 at 04:01 AM.

The following users liked this post:

Vinnie6 (08-09-2021)

Vinnie6,

I have used a Helicoil to repair a rocker issue on one of my FA-80T twins. The product I purchased was an E-Z Coil M3-0.5 SKU Number SK40210 11543411. It comes with almost everything you need to repair a threaded hole. I have also used it to repair a jug bolt hole in the case of one of my FA-90 engines where the aluminum threads had stripped when I was tightening the jug down. It is a somewhat easy fix to a big problem.

es.

I have used a Helicoil to repair a rocker issue on one of my FA-80T twins. The product I purchased was an E-Z Coil M3-0.5 SKU Number SK40210 11543411. It comes with almost everything you need to repair a threaded hole. I have also used it to repair a jug bolt hole in the case of one of my FA-90 engines where the aluminum threads had stripped when I was tightening the jug down. It is a somewhat easy fix to a big problem.

es.

Hi,

Showing the fix for a broken FA-80T Rocker Arm.

Below are photos of the FA-80T where the rocker arm broke. The issue with these early 1980s Saito engines is the rocker has a weak spot where the rocker arm connects with the PIN by a set screw.

Saito changed this design and I assume it was due to a similar issue that I had where the rocker just broke at the pivot joint.

The rocker and PIN are secured with a set screw and the PIN floats freely within the rocker assembly. I have two of these FA-80Ts and both have had this issue. The first time it happened I scoured the world for an exact replacement and through a company in the UK who went all the way to Satio Japan to get the last rocker Saito Japan could find. It took months. When my second engine broke a rocker I decided to try something different and sized up the rocker and PIN from one of my FA-91 engines. The rocker is the same size and the PIN is also the same. The only issue was the FA-80T just had open holes without threads. I use a HeliCoil to add threads to the rocker retainer and the rocker and pin from the FA-91 fit perfectly. Issue solved.

Early 1980s FA-80T

Saito FA-80T broken rocker with set screw compared with a rocker from an FA-91.

Comparing the broken FA-80T rocker, set screw and pin with an FA-91 rocker and threaded pin.

Before photo of the FA-80T rocker assembly before the install of the helicoil so I could use the FA-91 rocker in the FA-80T.

After showing the helicoil installed. I left the tang in the helicoil on purpose.

Another photo showing the install of the FA-91 rocker and threaded pin in the FA-80T rocker assembly.

Showing the fix for a broken FA-80T Rocker Arm.

Below are photos of the FA-80T where the rocker arm broke. The issue with these early 1980s Saito engines is the rocker has a weak spot where the rocker arm connects with the PIN by a set screw.

Saito changed this design and I assume it was due to a similar issue that I had where the rocker just broke at the pivot joint.

The rocker and PIN are secured with a set screw and the PIN floats freely within the rocker assembly. I have two of these FA-80Ts and both have had this issue. The first time it happened I scoured the world for an exact replacement and through a company in the UK who went all the way to Satio Japan to get the last rocker Saito Japan could find. It took months. When my second engine broke a rocker I decided to try something different and sized up the rocker and PIN from one of my FA-91 engines. The rocker is the same size and the PIN is also the same. The only issue was the FA-80T just had open holes without threads. I use a HeliCoil to add threads to the rocker retainer and the rocker and pin from the FA-91 fit perfectly. Issue solved.

Early 1980s FA-80T

Saito FA-80T broken rocker with set screw compared with a rocker from an FA-91.

Comparing the broken FA-80T rocker, set screw and pin with an FA-91 rocker and threaded pin.

Before photo of the FA-80T rocker assembly before the install of the helicoil so I could use the FA-91 rocker in the FA-80T.

After showing the helicoil installed. I left the tang in the helicoil on purpose.

Another photo showing the install of the FA-91 rocker and threaded pin in the FA-80T rocker assembly.