Welcome to Club SAITO !

Moderator

My Feedback: (58)

Moderator

My Feedback: (58)

Btw, I found this in the late Bill Robison's notes:

"A couple you mention though - the white ring is Teflon, it is used to seal the choke plate when one is fitted, it goes in the groove on the outside of the carb, the choke slider holds it in place, There are two places for the tiny ones, inside the needle valve as an air seal, and on the front end of the axle the cam turns on."

I just cut one of the bigger washers, and it is homogeneously white inside. Looks like it is teflon.

"A couple you mention though - the white ring is Teflon, it is used to seal the choke plate when one is fitted, it goes in the groove on the outside of the carb, the choke slider holds it in place, There are two places for the tiny ones, inside the needle valve as an air seal, and on the front end of the axle the cam turns on."

I just cut one of the bigger washers, and it is homogeneously white inside. Looks like it is teflon.

Btw, I found this in the late Bill Robison's notes:

"A couple you mention though - the white ring is Teflon, it is used to seal the choke plate when one is fitted, it goes in the groove on the outside of the carb, the choke slider holds it in place, There are two places for the tiny ones, inside the needle valve as an air seal, and on the front end of the axle the cam turns on."

I just cut one of the bigger washers, and it is homogeneously white inside. Looks like it is teflon.

"A couple you mention though - the white ring is Teflon, it is used to seal the choke plate when one is fitted, it goes in the groove on the outside of the carb, the choke slider holds it in place, There are two places for the tiny ones, inside the needle valve as an air seal, and on the front end of the axle the cam turns on."

I just cut one of the bigger washers, and it is homogeneously white inside. Looks like it is teflon.

Interesting that Saito elected to put chokes on a lot of their glow engines but not on others. It was never needed as placing ones finger over the exhaust outlet and rolling the engine over pressurizes the tank thereby forcing plenty of fuel to the carb. Unfortunately Saito elected to forego the implantation of a choke on their gassers where it IS needed due to the absence of muffler pressure.

Senior Member

Yep, two of those locations are what I was referring to. The smaller washers you have are too small to be cam thrust washers as they would need to be 4mm ID. The larger washers don't appear to be thick enough to be choke plate washers. That's why I feel neither are for Saito.

Interesting that Saito elected to put chokes on a lot of their glow engines but not on others. It was never needed as placing ones finger over the exhaust outlet and rolling the engine over pressurizes the tank thereby forcing plenty of fuel to the carb. Unfortunately Saito elected to forego the implantation of a choke on their gassers where it IS needed due to the absence of muffler pressure.

Interesting that Saito elected to put chokes on a lot of their glow engines but not on others. It was never needed as placing ones finger over the exhaust outlet and rolling the engine over pressurizes the tank thereby forcing plenty of fuel to the carb. Unfortunately Saito elected to forego the implantation of a choke on their gassers where it IS needed due to the absence of muffler pressure.

My Feedback: (27)

Yesterday I went to a swap meet north of Dallas. I had to drive right through Dallas to get there. I now remember why I donít like big cities and live out in the country. The early morning traffic was crazy. This was the first swap meet Iíve been to in two years because of the covid crisis. I was able to pick up several Saito bargains. Some of these engines will be winter rebuild projects.

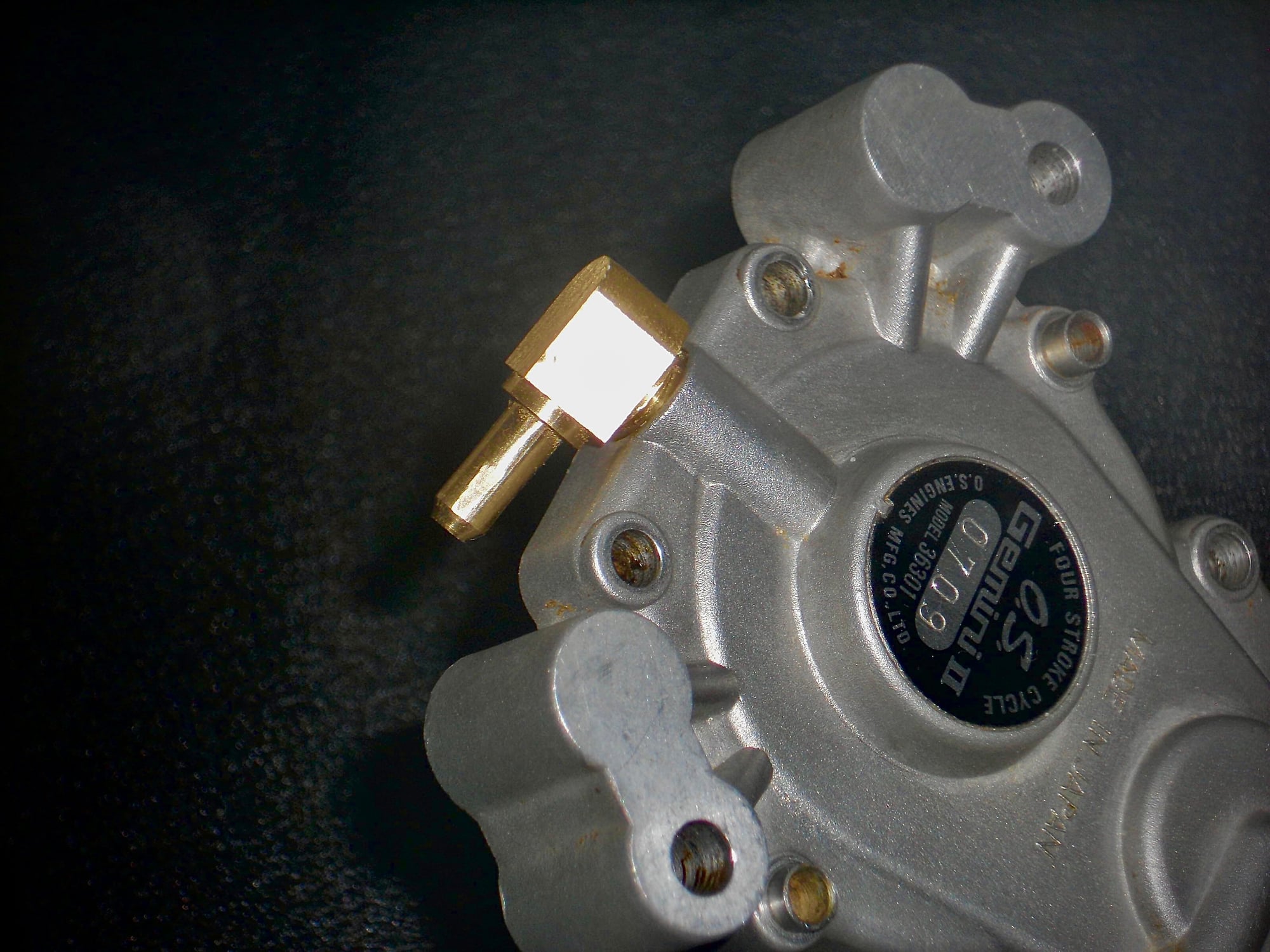

For the rebuilds projects I picked up two Saito 80 engines and one Saito 65 that I think is the high compression version. The 65 has the bump on the piston and has an old version of the carb with an air bleed. One of the Saito 80 engines needs an exhaust system that I will be keeping an eye out for.

I also got a nice early version open rocker Saito 30. This engine is in really nice shape. I will probably never fly it but for the price it will be a nice addition to my collection.

Of the non-Saito things, I was able to pick up: I bought 2 gallons of nitro at a good price. Since I mix my own fuel that is one of the things that I really have to look for to keep the price of fuel in hand. I also picked up a new Sig LT-40 kit to build. I have the little LT-25 with an old pre-Surpass FS40 so I hope this plane will fly as nice. I also picked up a couple of non Saito engines. I think I am pretty well set for winter projects.

For the rebuilds projects I picked up two Saito 80 engines and one Saito 65 that I think is the high compression version. The 65 has the bump on the piston and has an old version of the carb with an air bleed. One of the Saito 80 engines needs an exhaust system that I will be keeping an eye out for.

I also got a nice early version open rocker Saito 30. This engine is in really nice shape. I will probably never fly it but for the price it will be a nice addition to my collection.

Of the non-Saito things, I was able to pick up: I bought 2 gallons of nitro at a good price. Since I mix my own fuel that is one of the things that I really have to look for to keep the price of fuel in hand. I also picked up a new Sig LT-40 kit to build. I have the little LT-25 with an old pre-Surpass FS40 so I hope this plane will fly as nice. I also picked up a couple of non Saito engines. I think I am pretty well set for winter projects.

Congrats on your swap meet finds Pedro! You're going to love that HC 65 using your 3% nitro mix. That FA30 looks to be in excellent shape. Should clean up to like-new condition.

Post a pic or two of the HC 65 please.

nitro, Nitro, NITRO!

Post a pic or two of the HC 65 please.

nitro, Nitro, NITRO!

Last edited by Glowgeek; 09-26-2021 at 06:01 AM.

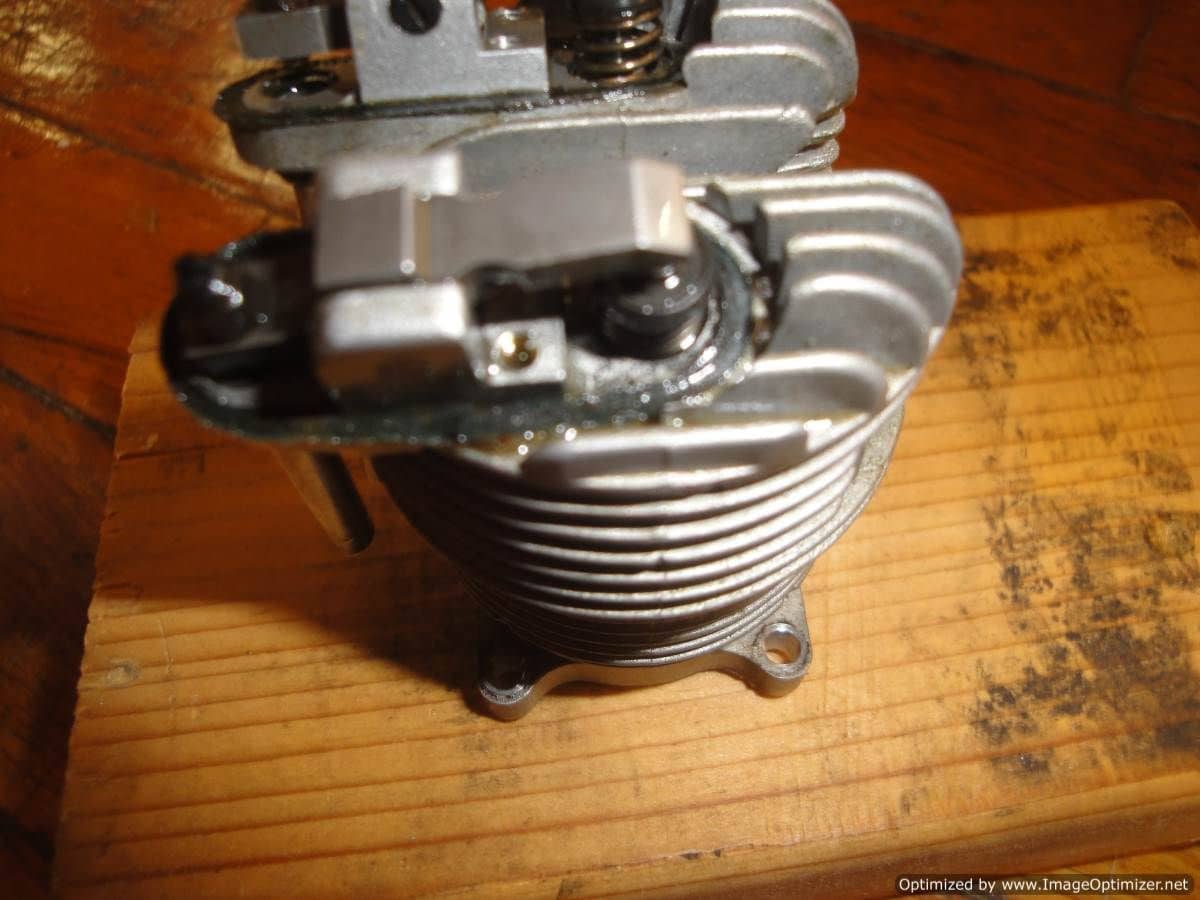

Thanks Pedro. Yep, it has the curvie cylinder mounting flange like all HC 65's that I've seen. Looks to be a very low time engine but what's up the piston top? Looks like something got in there and bounced around a bit before it was ejected out the exhaust. Do the valves seal properly?

My Feedback: (27)

Lonnie

When I saw that it bothered me. The inside of the cylinder looks great. The valves seal good. Those marks are only around the top of the piston near the outside diameter. If something were bouncing around in there I would think it would be all over the top of the piston. If you look at the picture in this review Saito FA-65 (2) (sceptreflight.com) it does not have those marks. I seem to remember reading about someone else asking about the same thing. What are your thoughts on this?????

When I saw that it bothered me. The inside of the cylinder looks great. The valves seal good. Those marks are only around the top of the piston near the outside diameter. If something were bouncing around in there I would think it would be all over the top of the piston. If you look at the picture in this review Saito FA-65 (2) (sceptreflight.com) it does not have those marks. I seem to remember reading about someone else asking about the same thing. What are your thoughts on this?????

Lonnie

When I saw that it bothered me. The inside of the cylinder looks great. The valves seal good. Those marks are only around the top of the piston near the outside diameter. If something were bouncing around in there I would think it would be all over the top of the piston. If you look at the picture in this review Saito FA-65 (2) (sceptreflight.com) it does not have those marks. I seem to remember reading about someone else asking about the same thing. What are your thoughts on this?????

When I saw that it bothered me. The inside of the cylinder looks great. The valves seal good. Those marks are only around the top of the piston near the outside diameter. If something were bouncing around in there I would think it would be all over the top of the piston. If you look at the picture in this review Saito FA-65 (2) (sceptreflight.com) it does not have those marks. I seem to remember reading about someone else asking about the same thing. What are your thoughts on this?????

I've seen that saw toothed appearance on a lathed part back was I was managing test fixture production for Dell. The company that produced the parts said it looked like the part slipped in their lathe chuck. The marks weren't exactly like those on your piston but it did have a similar sawtoothed appearance.

Last edited by Glowgeek; 09-26-2021 at 12:31 PM.

My Feedback: (1)

Yesterday I went to a swap meet north of Dallas. I had to drive right through Dallas to get there. I now remember why I donít like big cities and live out in the country. The early morning traffic was crazy. This was the first swap meet Iíve been to in two years because of the covid crisis. I was able to pick up several Saito bargains. Some of these engines will be winter rebuild projects.

For the rebuilds projects I picked up two Saito 80 engines and one Saito 65 that I think is the high compression version. The 65 has the bump on the piston and has an old version of the carb with an air bleed. One of the Saito 80 engines needs an exhaust system that I will be keeping an eye out for.

I also got a nice early version open rocker Saito 30. This engine is in really nice shape. I will probably never fly it but for the price it will be a nice addition to my collection.

Of the non-Saito things, I was able to pick up: I bought 2 gallons of nitro at a good price. Since I mix my own fuel that is one of the things that I really have to look for to keep the price of fuel in hand. I also picked up a new Sig LT-40 kit to build. I have the little LT-25 with an old pre-Surpass FS40 so I hope this plane will fly as nice. I also picked up a couple of non Saito engines. I think I am pretty well set for winter projects.

For the rebuilds projects I picked up two Saito 80 engines and one Saito 65 that I think is the high compression version. The 65 has the bump on the piston and has an old version of the carb with an air bleed. One of the Saito 80 engines needs an exhaust system that I will be keeping an eye out for.

I also got a nice early version open rocker Saito 30. This engine is in really nice shape. I will probably never fly it but for the price it will be a nice addition to my collection.

Of the non-Saito things, I was able to pick up: I bought 2 gallons of nitro at a good price. Since I mix my own fuel that is one of the things that I really have to look for to keep the price of fuel in hand. I also picked up a new Sig LT-40 kit to build. I have the little LT-25 with an old pre-Surpass FS40 so I hope this plane will fly as nice. I also picked up a couple of non Saito engines. I think I am pretty well set for winter projects.

Jim

My Feedback: (1)

Lonnie, this guy had more problems than I had.

in the end I put both cones on the shaft back to back and held the cones in one hand between my fingers and turned the shaft, I could feel/found the cones are not drilled/machined accurately straight. this is something DuBro should fix

Jim

in the end I put both cones on the shaft back to back and held the cones in one hand between my fingers and turned the shaft, I could feel/found the cones are not drilled/machined accurately straight. this is something DuBro should fix

Jim

Last edited by the Wasp; 09-26-2021 at 07:55 PM.

Senior Member

My Feedback: (27)

Dave,

I will keep that in mind. I want to see if there is a collet to fit the piston at the shop I work at part time. If I do send you the piston, can I send you an Enya 53 also?

I will keep that in mind. I want to see if there is a collet to fit the piston at the shop I work at part time. If I do send you the piston, can I send you an Enya 53 also?

And that would lower the compression ratio

(Depending on how thick the band is)

(Depending on how thick the band is)Your unhandy guy could have more easily ground off or filed down the piston hump. A shim under the cylinder made from aluminum pie plate would do as well and easily removed later.

Be very careful about holding pistons in three or four jaw, hard jaw chucks.

All too easy to distort the skirts.

Better to use an exact, on-size colllet or custom bored, on-sized aluminum jaws, lightly clamped to avoid the hard, pressure points. At very least , a six jaw chuck would be less risky than a three.

Last edited by Jesse Open; 09-27-2021 at 03:23 AM.

Lonnie, this guy had more problems than I had.

in the end I put both cones on the shaft back to back and held the cones in one hand between my fingers and turned the shaft, I could feel/found the cones are not drilled/machined accurately straight. this is something DuBro should fix

Jim

https://youtu.be/iJqe1dCD8tg

in the end I put both cones on the shaft back to back and held the cones in one hand between my fingers and turned the shaft, I could feel/found the cones are not drilled/machined accurately straight. this is something DuBro should fix

Jim

https://youtu.be/iJqe1dCD8tg

Irregularities on the prop, before and after reaming will affect balance as well eg off axis reaming, mold flash or burrs on the center hole at the hub faces.

One last thing that's often overlooked is air movement. An open door or window, a fan blowing in the background or the AC kicking on and off can really mess with balancing. Even someone walking by you can throw things off momentarily.

Last edited by Glowgeek; 09-27-2021 at 11:05 AM.

My Feedback: (27)

I took my disassembled high compression 65 to my part time job in the CNC lathe shop this morning. The owner spent an hour looking over all the parts. This guy loves stuff like this. Looking at the top of the piston under magnification we could not see any file or machine marks. Could this piston have come from Saito this way? We found a collet that will fit the piston. As soon as one of the CNC Mazak lathes is free it is going for a trim. The collet pressure will be turned way down. I am tempted to just use some emery cloth on the ragged part of the piston. If we do use a cutting tool I will let the shop owner, do it. Any suggestions????

I took my disassembled high compression 65 to my part time job in the CNC lathe shop this morning. The owner spent an hour looking over all the parts. This guy loves stuff like this. Looking at the top of the piston under magnification we could not see any file or machine marks. Could this piston have come from Saito this way? We found a collet that will fit the piston. As soon as one of the CNC Mazak lathes is free it is going for a trim. The collet pressure will be turned way down. I am tempted to just use some emery cloth on the ragged part of the piston. If we do use a cutting tool I will let the shop owner, do it. Any suggestions????

Next a question. What spray product are you guys using to identify a pesky intake leak in your Saitos? I am having fits with my 325 R5 this season. Normal troubleshooting procedures and obvious stuff are not going anywhere fast. Used to use carb clean years ago. Brake kleen now but not sure if that is good with methanol. Anybody ever just try a blow gun of compressed air to cause a lean rpm increase response?

To get exactly 1 gl of 80/20 add 24.8 oz oil to 103.2 oz methanol.

Or, to use up the entire 124.8 oz of methanol you purchased add 30 oz of oil. You will then have 154.8 oz of 80/20.

Last edited by Glowgeek; 09-29-2021 at 03:22 PM.

My Feedback: (27)

When I mix fuel I do it in metric. Four liters will fit in a gallon jug. Doing it in metric you do not have to deal with fractions of an ounce. Not that the math dealing with ounces is that hard to work with, it just seems more easy to deal will milliliters as whole numbers.

Last edited by modeltronics; 09-29-2021 at 03:06 PM.