Welcome to Club SAITO !

Senior Member

Thanks Gary, Lonnie and phone chatted last pm and he also made that suggestion, I'll try to contact Dan and possibly work something out, Dan and I have traded a part or two over the years and he repaired an older CHI for me. I'll PM him first.

Senior Member

Senior Member

Lonnie, this per our phone conversation last pm. interesting stuff.

er compression rations also promote better breathing and allow more benefit from a larger carburetor. Note the highlighted section below.

Quote:

Originally Posted by SrTelemaster View Post

Over the last few days I had the opportunity to test performance of 4 different versions of FA-180 engines, all burning 15% Cool Power fuel lit off with CDI. The initial advance setting for the spark was 35* BTDC. A Dynathrust 18X8 propeller was used for all tests.

The base version was an otherwise stock FA-180 with CH-Ignitions CDI.

A few days ago I did a baseline pull of 7800 RPM. This was off about 200 RPM from the best previous performance of this engine. Cold damp weather was obviously putting a damper on performance. I also did a control pull with my 12.7:1 high compression version FA-180 with the 12mm Big Bore carburetor, ported intake manifold & Bowman ring set up with .002" end gap. That engine pulled 8400 RPM with the same propeller.

Since those test runs, in the stock engine, I installed a Bowman ring on an FG-57T piston with the end gap set up at .002" just like the high compression engine.The FG-57T piston has a .016" taller compression height to maintain the same 3.4cc combustion chamber as an FA-180 in the FG-57T engine that utilizes the bore of the FA-180 on the FA-150 based stroke of gas twin.

The taller FG-57T piston in an otherwise unmodified FA-180 results in a compression increase to 10.7:1 from the stock CR of 9.6:1.

Here are the results:

Stock FA-180 CDI---7800 RPM

FA-180/FG57T piston 10.7:1 CR---8050 RPM

FA-180/FG57T piston with 12mm carburetor/manifold--- no performance gain

FA-180/.035" case deck reduction 12.7:1 CR---8200 RPM

FA-180/.035" case deck reduction 12.7:1 CR with 12mm carburetor/manifold---8400 RPM

The fact that the 12.7:1 CR engine pulled the same RPM as it did on the day that the baseline test with the stock FA-180 CDI validates the comparison of the data from the 2 different test sessions.

Conclusions:

The CR boost to 10:7:1 using the FG-57T piston with the Bowman ring was good for a 250 RPM power gain.

Although the 12mm carburetor/manifold is good for 200 RPM withe the 12.7:1 CR engine, the breathing ability of the modest 10.7:1 CR was not improved enough to benefit from the improved induction.

Increasing CR from 10.7:1 to 12.7:1 resulted in another 150 RPM gain.

The 12.7:1 CR improved breathing to a point where the 12mm carburetor/manifold induction improvement resulted in another 200 RPM.

The FG-57 piston is an easy "plug & play" modification that is a simple bolt on modification that does not require any clearance checks.

I will tear down the engine with the FG-57T piston to have the case deck reduced by .020". This will have the same result as reducing the deck by .035" with the stock FA-180 piston. The CR will be increased to 12.7:1 but valve notches will have to be checked & most likely clearanced. I will also port the manifold & employ a 12mm carburetor.

Last edited by 1200SportsterRider; 12-17-2021 at 04:53 AM. Reason: Add content

Lonnie, this per our phone conversation last pm. interesting stuff.

er compression rations also promote better breathing and allow more benefit from a larger carburetor. Note the highlighted section below.

Although the 12mm carburetor/manifold is good for 200 RPM withe the 12.7:1 CR engine, the breathing ability of the modest 10.7:1 CR was not improved enough to benefit from the improved induction.

er compression rations also promote better breathing and allow more benefit from a larger carburetor. Note the highlighted section below.

Although the 12mm carburetor/manifold is good for 200 RPM withe the 12.7:1 CR engine, the breathing ability of the modest 10.7:1 CR was not improved enough to benefit from the improved induction.

Last edited by Glowgeek; 12-17-2021 at 06:22 PM.

Jim,

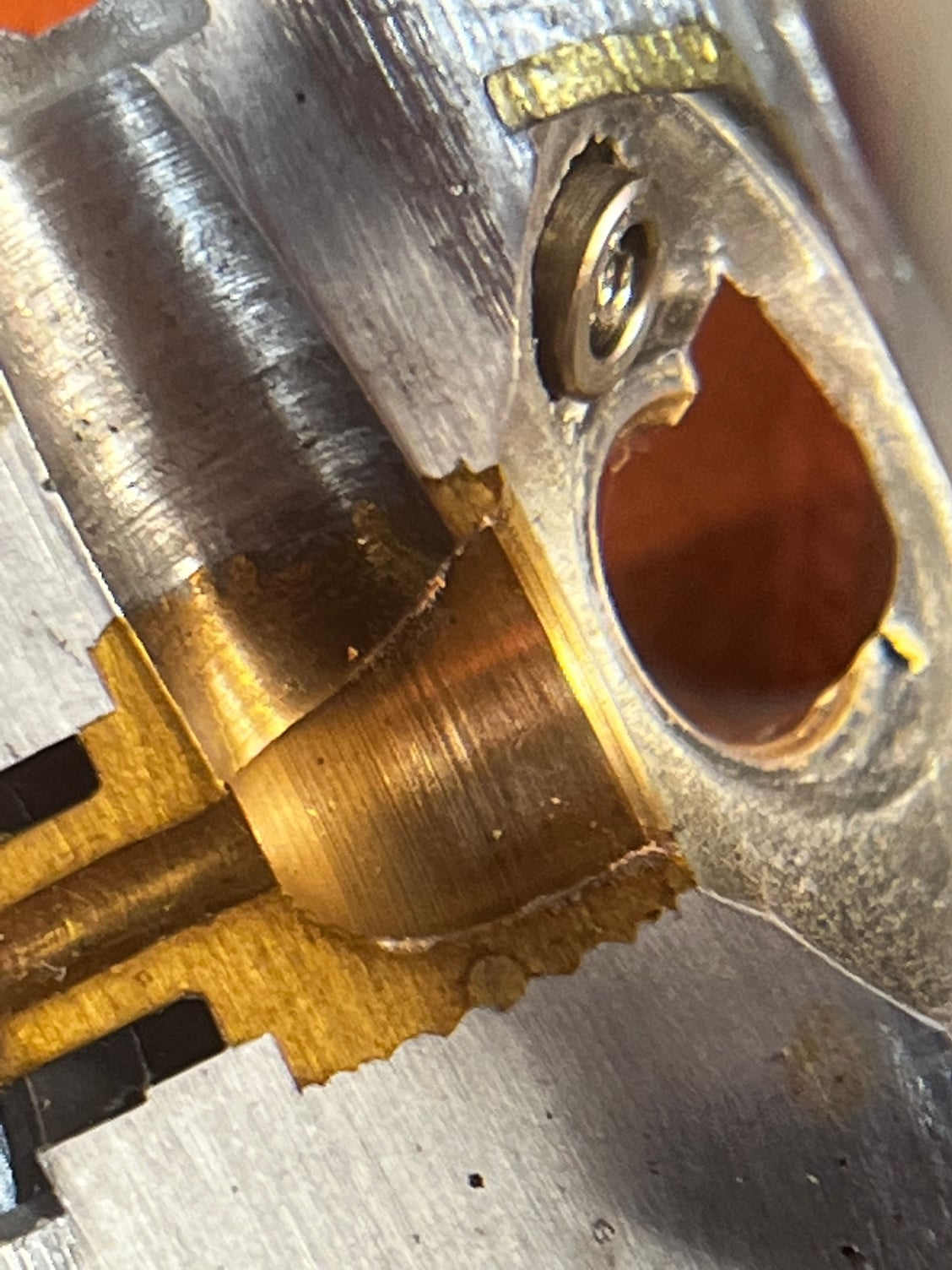

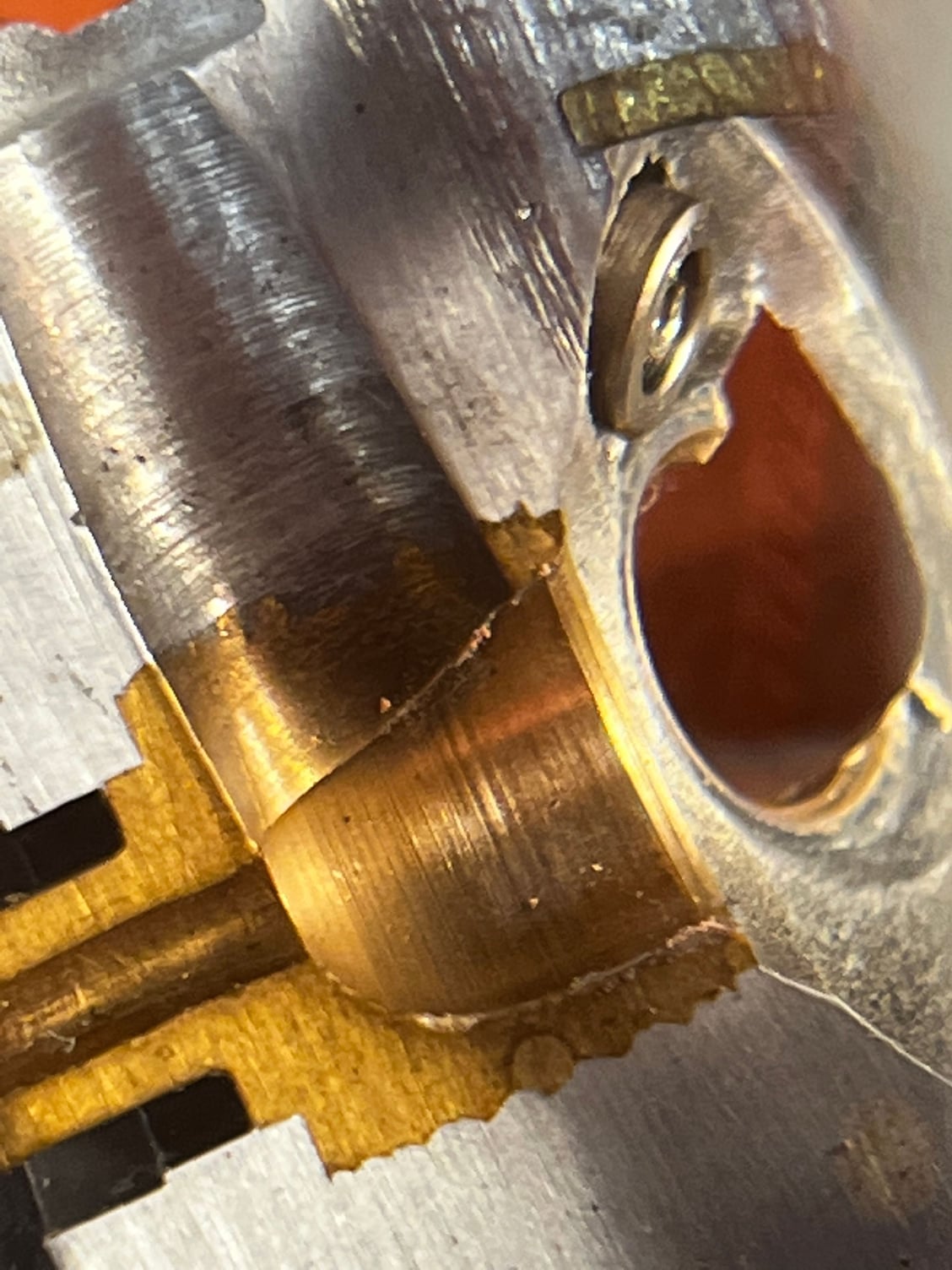

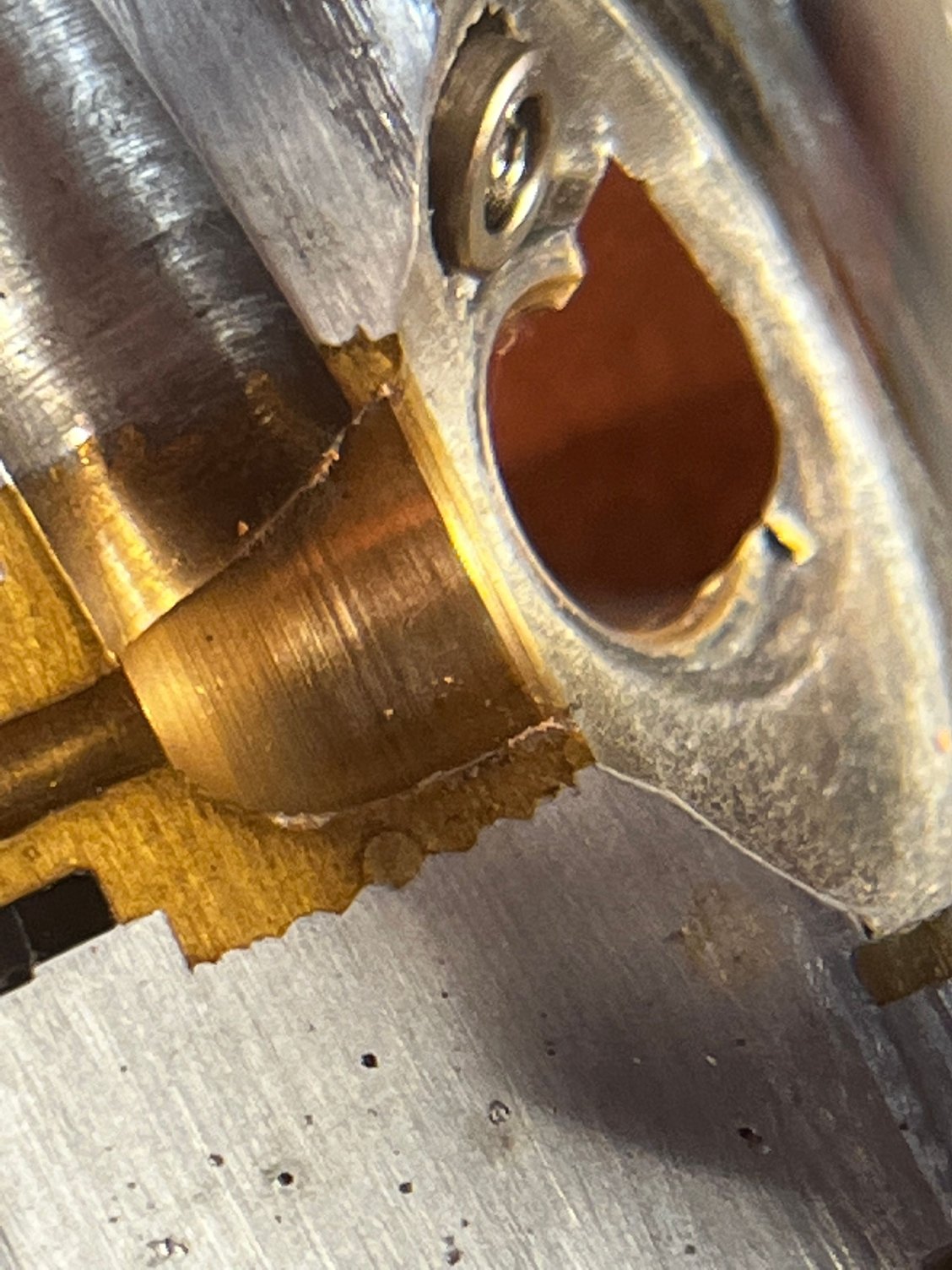

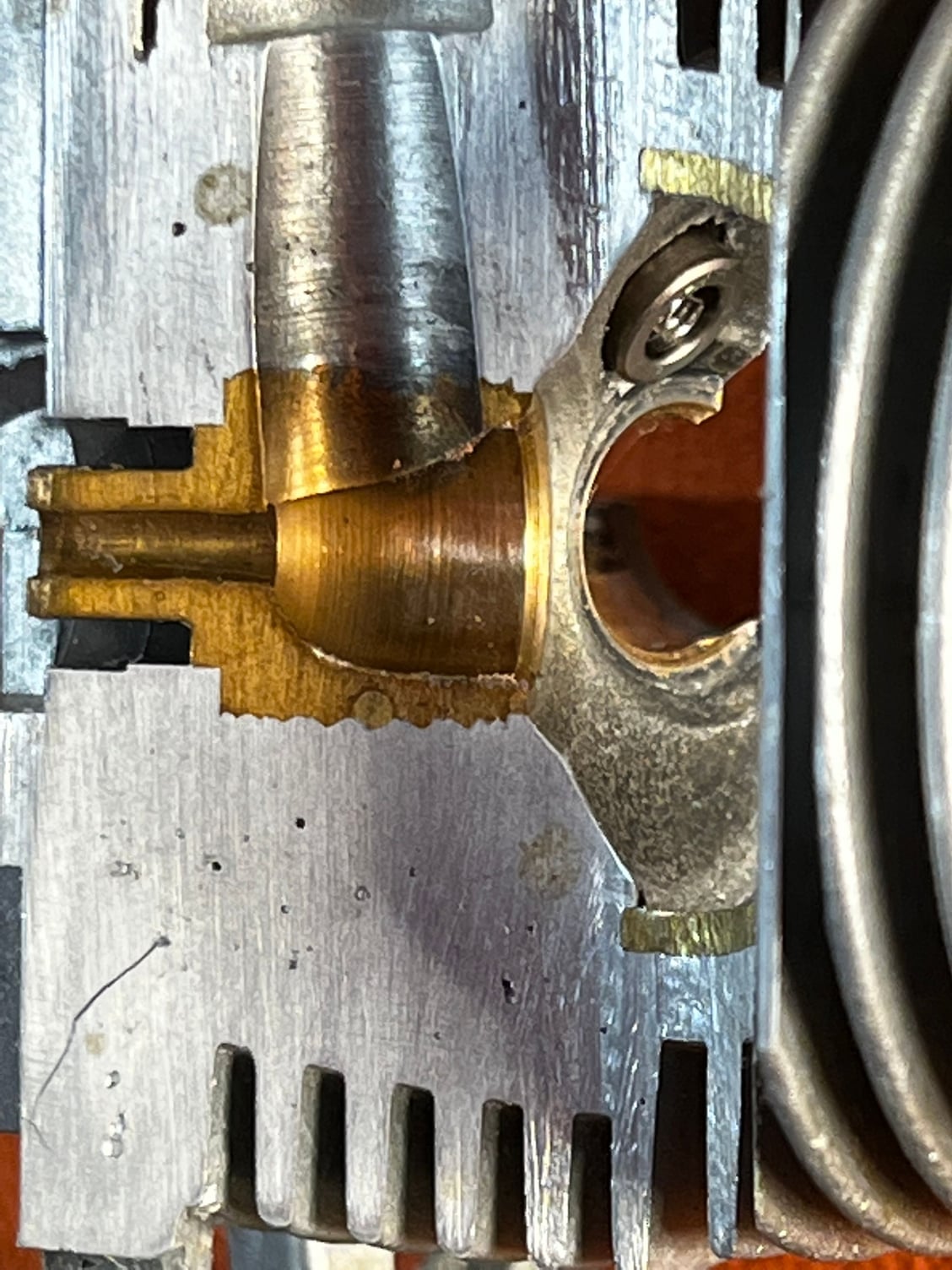

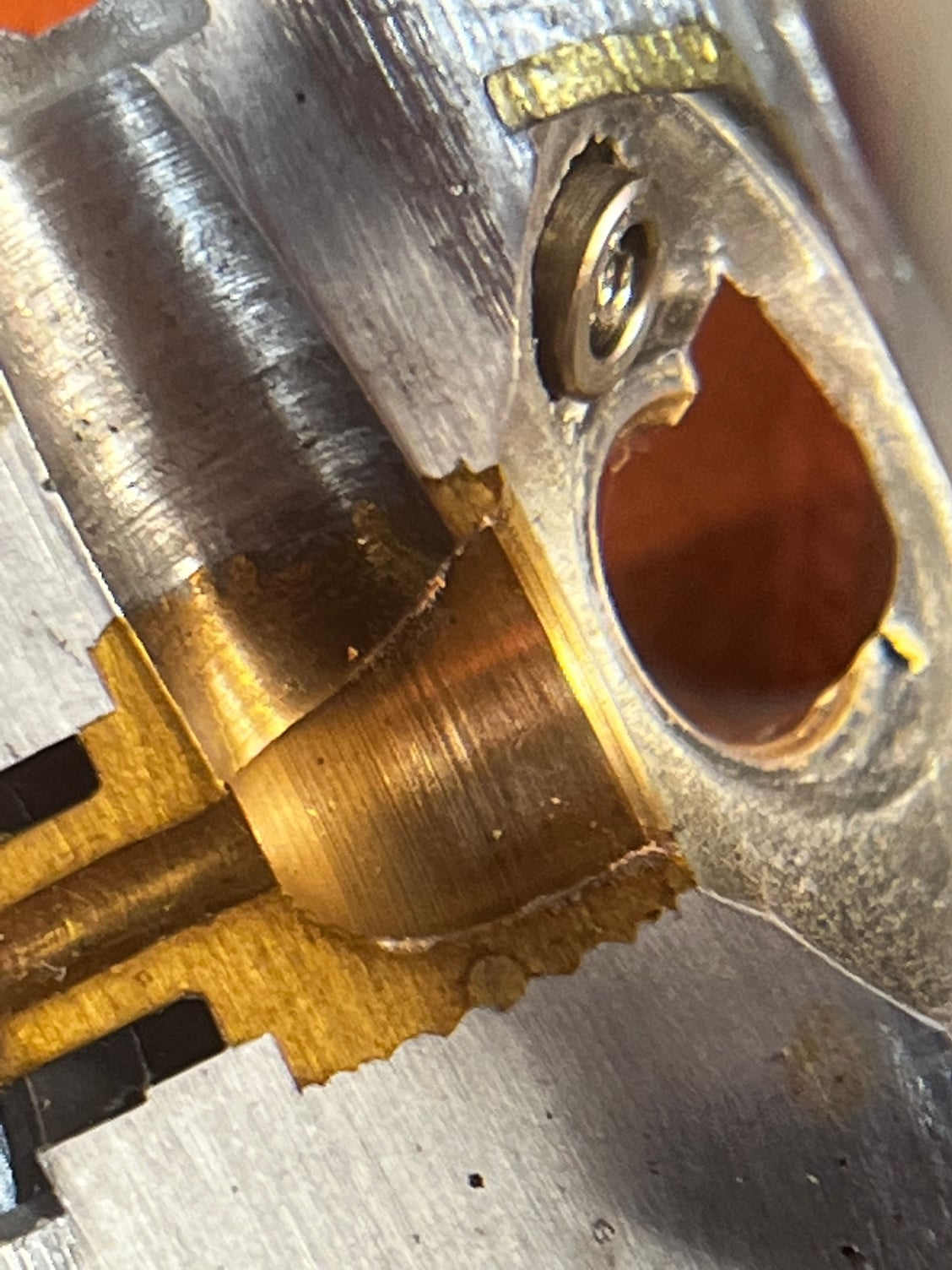

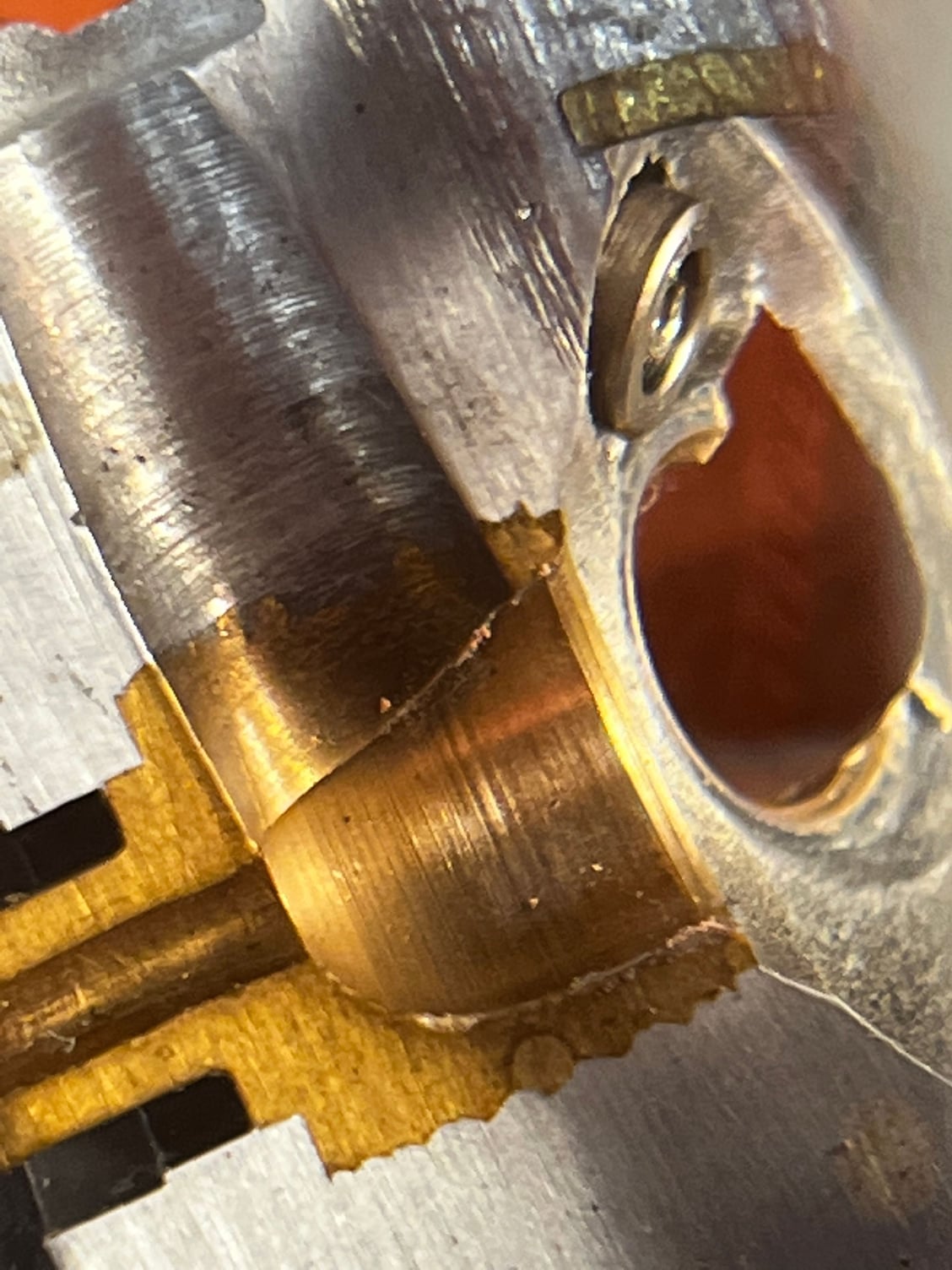

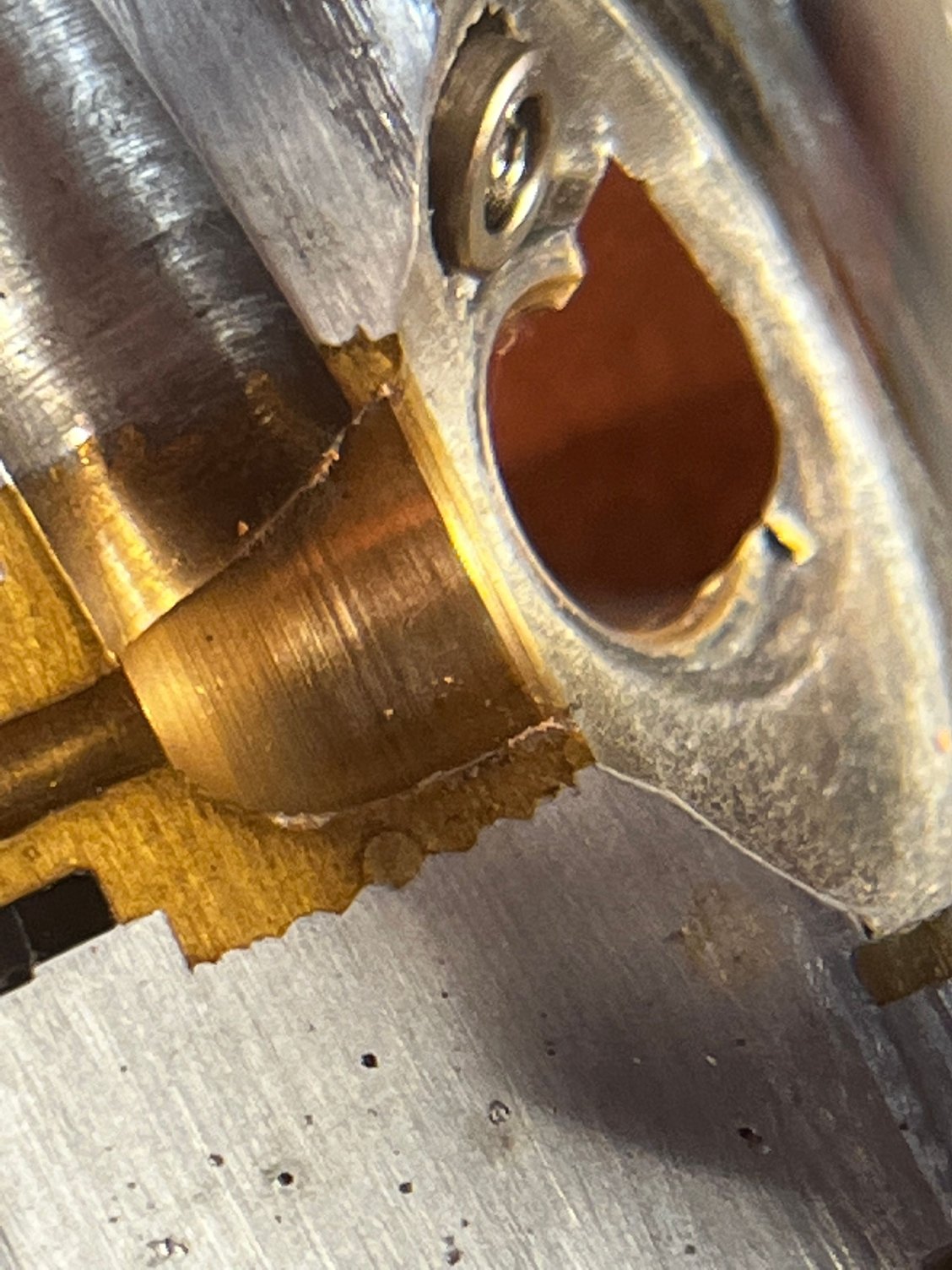

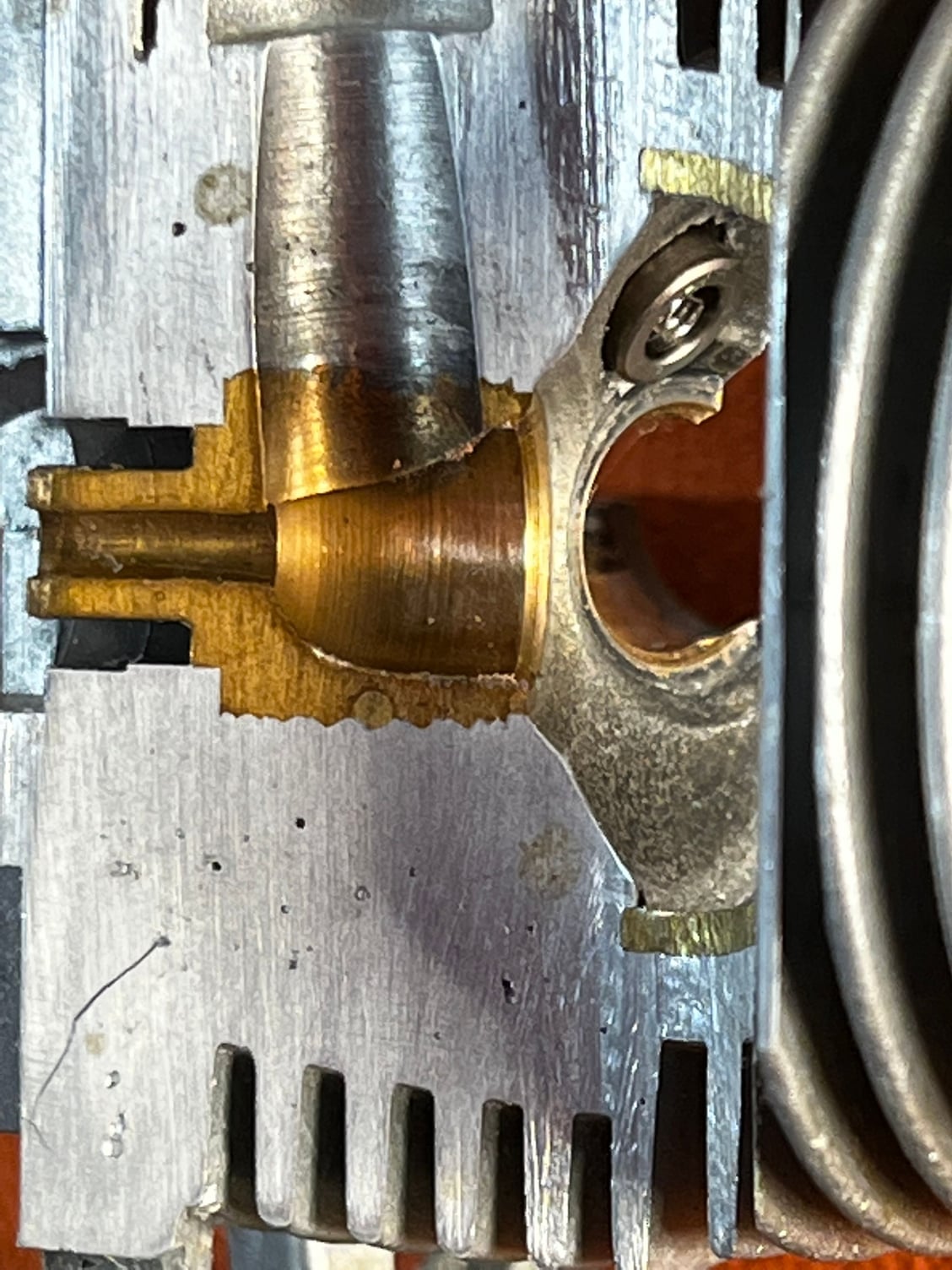

A few years ago our friend Pedro sent me a busted up cylinder to do a cutaway of the valve pocket area.

This is a 65 with cast in, bronze seats. Hard to see in photos but looking closely, in person you can see the tooling paths. It looks to have been finishec with a form cutter that made the throat, top and seat in one or two cuts. I am pretty much finished with the thing so I will drop it in a box and tell the lol mailman to take it to you. Maybe help further your salvage efforts LOL.

enyhoo keep ur eyes open, it should be in ur paws by Christmas .

A few years ago our friend Pedro sent me a busted up cylinder to do a cutaway of the valve pocket area.

This is a 65 with cast in, bronze seats. Hard to see in photos but looking closely, in person you can see the tooling paths. It looks to have been finishec with a form cutter that made the throat, top and seat in one or two cuts. I am pretty much finished with the thing so I will drop it in a box and tell the lol mailman to take it to you. Maybe help further your salvage efforts LOL.

enyhoo keep ur eyes open, it should be in ur paws by Christmas .

My Feedback: (1)

Jim,

A few years ago our friend Pedro sent me a busted up cylinder to do a cutaway of the valve pocket area.

This is a 65 with cast in, bronze seats. Hard to see in photos but looking closely, in person you can see the tooling paths. It looks to have been finishec with a form cutter that made the throat, top and seat in one or two cuts. I am pretty much finished with the thing so I will drop it in a box and tell the lol mailman to take it to you. Maybe help further your salvage efforts LOL.

enyhoo keep ur eyes open, it should be in ur paws by Christmas .

A few years ago our friend Pedro sent me a busted up cylinder to do a cutaway of the valve pocket area.

This is a 65 with cast in, bronze seats. Hard to see in photos but looking closely, in person you can see the tooling paths. It looks to have been finishec with a form cutter that made the throat, top and seat in one or two cuts. I am pretty much finished with the thing so I will drop it in a box and tell the lol mailman to take it to you. Maybe help further your salvage efforts LOL.

enyhoo keep ur eyes open, it should be in ur paws by Christmas .

Jim

Last edited by the Wasp; 12-17-2021 at 07:08 PM.

My Feedback: (1)

Lonnie, you say your Hot 82 had been finicky in mid range at times. here is something new for you to try with it. try changing the length of it's Intake Manifold. longer produces more torque, and shorter produces more RPM. I say try lengthen it first.

Jim

Jim

Should I toss your favorite muffler into the box that is going your way this week? Should be swell on your newborn 150!

Classic old salt shaker muffy.

You are all set then. I will toss a pair of new lock nuts in the box.

Also, a special pipe that I hope you will keep and use. A "Merry Christmas" keepsake.

My Feedback: (6)

I made a discovery this pass week. I like to use Remote Glow Plug Adapters on aircraft with the engine located in a cowling or the glow plug is hard to reach. It saves propeller bites. I discovered Hanger 9 (Horizon) had some still available on Amazon.

My Feedback: (1)

any one notice something in those FA65 pics above. the Valve Guides are not presses in, I can't remember the term they use to call that, but they are casted in. then machined

Jim

Jim

Last edited by the Wasp; 12-20-2021 at 05:46 PM.

Senior Member

Jim, that would be interesting to know more about.

El Capitain is sending to me a a 300 T-L to freshen up. I am learning some 270 and 300 facts while trying to help this gent: Backplate on Saito 300 twin

El Capitain is sending to me a a 300 T-L to freshen up. I am learning some 270 and 300 facts while trying to help this gent: Backplate on Saito 300 twin

Jim,

My bad, that is actually a 50 or 56 cylinder.

The valve pocket is bronze, not brass and yes, it is cast in place. Look carefully and you can see the brass edge of the cylinder in one shot too.

The valve pocket is probably pre machined or at least partially machined befgore casting in place.

Dave, The 300T is a blast to work on, one of my favorites. You may find the factory instructions on cam timing are a bit ambiguous. Remember it is an even fire with dual and the timing is different from the odd-fire Saito twins

My Feedback: (1)