Welcome to Club SAITO !

Oh, I should add; I use manual fuel pumps and crank them slow, electrics fill the tank too quickly and create too much fuel line pressure.

Last edited by Glowgeek; 01-29-2022 at 05:33 PM.

My Feedback: (27)

Gary

Yes, I bought a FA80 at the swap meet for almost nothing with a smashed intake manifold. If I can't find the part, I will just use it for parts for the 80 that I'm flying in my 4-star 60.

Yes, I bought a FA80 at the swap meet for almost nothing with a smashed intake manifold. If I can't find the part, I will just use it for parts for the 80 that I'm flying in my 4-star 60.

My Feedback: (12)

Sure, they'll flood with a 3 line tank. I used quick connect refueling valves early on but got frustrated with them sticking. Most of my Saitos are cowled inverted installs with 3 line tanks, no problem with refueling if the throttle is completely closed. Adjust the throttle cut to completely close the carb (servo at the point of binding), turn off the RX with throttle cut engaged and then refuel. It does work, my engines never flood.

Oh, I should add; I use manual fuel pumps and crank them slow, electrics fill the tank too quickly and create too much fuel line pressure.

Oh, I should add; I use manual fuel pumps and crank them slow, electrics fill the tank too quickly and create too much fuel line pressure.

I think a Cline regulator may do the same thing but Iím not sure.

Senior Member

Neither the Cline nor the Iron Bay regulator will allow fuel to flow until there is a demand. They eliminate the need for the 300 rpm rich from peak setting. The engine always thinks the fuel supply is only .75" away. The little 30 with the air bleed carb works perfectly with the either brand.

John at Iron Bay was not certain that the regulator would flow enough fuel for the 2.20, I tied it on a 2.20 and on a Super Tigre 4500. It worked perfectly.

John at Iron Bay was not certain that the regulator would flow enough fuel for the 2.20, I tied it on a 2.20 and on a Super Tigre 4500. It worked perfectly.

Last edited by Jesse Open; 01-31-2022 at 10:14 AM.

My Feedback: (1)

Neither the Cline nor the Iron Bay regulator will allow fuel to flow until there is a demand. They eliminate the need for the 300 rpm rich from peak setting. The engine always thinks the fuel supply is only .75" away. The little 30 with the air bleed carb works perfectly with the either brand.

John at Iron Bay was not certain that the regulator would flow enough fuel for the 2.20, I tied it on a 2.20 and on a Super Tigre 4500. It worked perfectly.

John at Iron Bay was not certain that the regulator would flow enough fuel for the 2.20, I tied it on a 2.20 and on a Super Tigre 4500. It worked perfectly.

Jim

Last edited by the Wasp; 01-31-2022 at 01:22 PM.

My Feedback: (8)

I just acquired a NIB FA-450R3 that had been sitting in the engine display case for years. BEAUTIFUL engine.

Although I am mostly into turbines now, I still fly everything from control line to R/C.

I couldn't pass up the deal but I really don't have it earmarked for any project.

Any suggestions?

Thanks,

Bob

Although I am mostly into turbines now, I still fly everything from control line to R/C.

I couldn't pass up the deal but I really don't have it earmarked for any project.

Any suggestions?

Thanks,

Bob

Last edited by rjbob; 01-31-2022 at 09:50 PM.

I just acquired a NIB FA-450R3 that had been sitting in the engine display case for years. BEAUTIFUL engine.

Although I am mostly into turbines now, I still fly everything from control line to R/C.

I couldn't pass up the deal but I really don't have it earmarked for any project.

Any suggestions?

Thanks,

Bob

Although I am mostly into turbines now, I still fly everything from control line to R/C.

I couldn't pass up the deal but I really don't have it earmarked for any project.

Any suggestions?

Thanks,

Bob

Hoping Aaron sees this and drops in. He is our resident, rotary geek!

Last edited by Jesse Open; 02-01-2022 at 08:20 AM.

The following users liked this post:

rjbob (02-01-2022)

My Feedback: (1)

LOL I hate balancing props !

I balanced my Xoar 17x8 that came on the 4-star 120, this prop looks to be brand new.

well it balanced out great with little tape (both hub and blades). then I remove the tape on the blade and added CA 3 different times. it balanced out great. I'm happy. well was happy LOL.

next day, check the balance and it was great. I removed the tape on the hub and added Velcro, balance was off, added glue, balance was off, added more glue, the hub balance was almost prefect. so I checked the blade balance and the blade balance was way off, what ?

so for 2 hours I added tape hear and there and it didn't balance and then it hit me. I remembered what Lonnie told me about that old but brand new out of the bag wood M-Airscrew. so I measured. the Zoar's hub hole is off center. BTW, the hole has a step in it because the prop hub is wider than the shank on the crank and the shank has an OD larger than the treads. so the prop hole was stepped and both the step and hole are off centered. the step is off centered by .030"..

so then LOL I had a thought. I have round stock here, the same size of the hub's hole, sO,, I inserted the shaft in the hole and you can see the hole is not straight. I hate balancing props.

oh but wait, don't run off. heehee the story is not over!

so I had another thought. I should try something, I took an APC for my OS 50. this prop was new, never even mounted. I balanced it very well last week. sO. I put it on the balancer and it's balance was off. what I found here goes along with my Xoar story above^. I knew what the problem is, so I check and I was correct. I balanced the APC again by adding tape, then I turned the Cones against the prop and checked the balance and the balance was off. so yes the cones on my balancer are not balanced and that is enough to off set a balanced prop. so, in other words> if the cones are not balance you can not properly balance a prop correctly!.

it just go's to show, if it's not 5/16 of one thing it's 3/8 of something else.

now what to do with this $20 Zoar ? just balance it the best I can. mount it and do not think about it again LOL

Jim

I balanced my Xoar 17x8 that came on the 4-star 120, this prop looks to be brand new.

well it balanced out great with little tape (both hub and blades). then I remove the tape on the blade and added CA 3 different times. it balanced out great. I'm happy. well was happy LOL.

next day, check the balance and it was great. I removed the tape on the hub and added Velcro, balance was off, added glue, balance was off, added more glue, the hub balance was almost prefect. so I checked the blade balance and the blade balance was way off, what ?

so for 2 hours I added tape hear and there and it didn't balance and then it hit me. I remembered what Lonnie told me about that old but brand new out of the bag wood M-Airscrew. so I measured. the Zoar's hub hole is off center. BTW, the hole has a step in it because the prop hub is wider than the shank on the crank and the shank has an OD larger than the treads. so the prop hole was stepped and both the step and hole are off centered. the step is off centered by .030"..

so then LOL I had a thought. I have round stock here, the same size of the hub's hole, sO,, I inserted the shaft in the hole and you can see the hole is not straight. I hate balancing props.

oh but wait, don't run off. heehee the story is not over!

so I had another thought. I should try something, I took an APC for my OS 50. this prop was new, never even mounted. I balanced it very well last week. sO. I put it on the balancer and it's balance was off. what I found here goes along with my Xoar story above^. I knew what the problem is, so I check and I was correct. I balanced the APC again by adding tape, then I turned the Cones against the prop and checked the balance and the balance was off. so yes the cones on my balancer are not balanced and that is enough to off set a balanced prop. so, in other words> if the cones are not balance you can not properly balance a prop correctly!.

it just go's to show, if it's not 5/16 of one thing it's 3/8 of something else.

now what to do with this $20 Zoar ? just balance it the best I can. mount it and do not think about it again LOL

Jim

Last edited by the Wasp; 02-01-2022 at 12:13 PM.

My Feedback: (1)

I just acquired a NIB FA-450R3 that had been sitting in the engine display case for years. BEAUTIFUL engine.

Although I am mostly into turbines now, I still fly everything from control line to R/C.

I couldn't pass up the deal but I really don't have it earmarked for any project.

Any suggestions?

Thanks,

Bob

Although I am mostly into turbines now, I still fly everything from control line to R/C.

I couldn't pass up the deal but I really don't have it earmarked for any project.

Any suggestions?

Thanks,

Bob

how about an AT-6

Jim

The following users liked this post:

rjbob (02-01-2022)

Senior Member

I have yet to find a unbalanced Xoar..

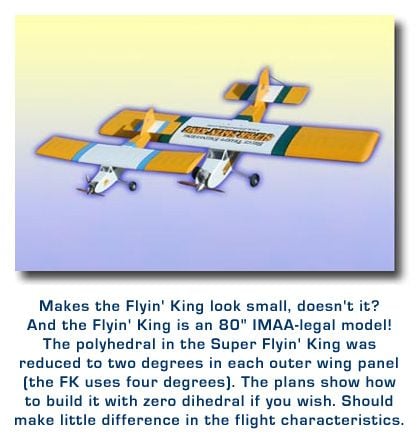

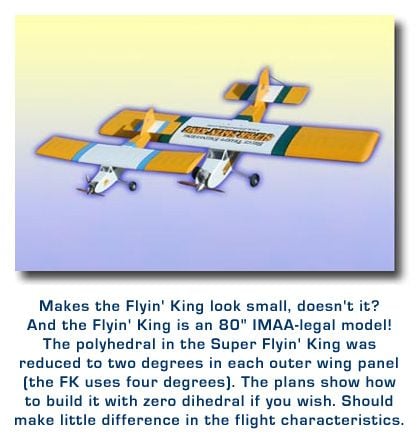

That big 450 would be perfect for the Super Flyin KIng: BTE - Super Flyin' King

That big 450 would be perfect for the Super Flyin KIng: BTE - Super Flyin' King

Last edited by 1200SportsterRider; 02-01-2022 at 02:18 PM. Reason: Add content

My Feedback: (1)

a balancing update.

don't ask me how or why, because I don't care and LOL I don't want to know. I have seen some odd things go on in this hobby. but in this case it must be a Chinese thing.

so, if you guys remember the first balancer I bought had a damaged cone, and after Horizon sent me a 2nd balancer I just threw out that damaged cone. so I had that 1 good cone left. well I swapped it for one on this 2nd balancer that I've been using.

I mounted the APC prop on the balancer and it was balanced prefect at all angles..

I mounted the 2nd APC prop on the balancer and it was balanced prefect at all angles.

I even turned each cone against each prop and everything is Slick. I'm going crazy.

and with knowing the hole was not straight on the Xoar I mounted it on the balancer and of course it was not balanced.

so now I said I don't care, I'm going to do it, if it works and still fits OK, and if it doesn't work so be it I don't care.. sO.. I did it. I re-reamend the Xoar. remember I said the Xoar was supper tight on the crank's shank, well the reamer was tight in the prop hole and it took out some wood and I also removed that step that I said was in the front of the hole. when done I found it still fit tight enough on the crank's shank to use.

well I mounted the newly reamend Xoar on the balancer, and, Baa-Zing-Gaa. it shows the hub on the Xoar is perfectly balance but the blade that I had put CA on was heavy. so I sanded the CA off that blade and put it back on the balancer, it was just about balanced but that one blade was still a tiny too heavy. so I put 1 drop of CA on the lighter blade, let it dry. put it on the balancer, it was a tiny bit heavy so I sanded off some glue and balanced again and it was balanced 100% perfect. the hub did not need any weight added to it. it was perfectly balanced at all angles.

I figured that 1 cone has an air bubble in it or the hole in it was not machined straight. but I'm not asking the Spirits of Flying any questions. I'm taking what I got and being thankful and happy.

Jim

don't ask me how or why, because I don't care and LOL I don't want to know. I have seen some odd things go on in this hobby. but in this case it must be a Chinese thing.

so, if you guys remember the first balancer I bought had a damaged cone, and after Horizon sent me a 2nd balancer I just threw out that damaged cone. so I had that 1 good cone left. well I swapped it for one on this 2nd balancer that I've been using.

I mounted the APC prop on the balancer and it was balanced prefect at all angles..

I mounted the 2nd APC prop on the balancer and it was balanced prefect at all angles.

I even turned each cone against each prop and everything is Slick. I'm going crazy.

and with knowing the hole was not straight on the Xoar I mounted it on the balancer and of course it was not balanced.

so now I said I don't care, I'm going to do it, if it works and still fits OK, and if it doesn't work so be it I don't care.. sO.. I did it. I re-reamend the Xoar. remember I said the Xoar was supper tight on the crank's shank, well the reamer was tight in the prop hole and it took out some wood and I also removed that step that I said was in the front of the hole. when done I found it still fit tight enough on the crank's shank to use.

well I mounted the newly reamend Xoar on the balancer, and, Baa-Zing-Gaa. it shows the hub on the Xoar is perfectly balance but the blade that I had put CA on was heavy. so I sanded the CA off that blade and put it back on the balancer, it was just about balanced but that one blade was still a tiny too heavy. so I put 1 drop of CA on the lighter blade, let it dry. put it on the balancer, it was a tiny bit heavy so I sanded off some glue and balanced again and it was balanced 100% perfect. the hub did not need any weight added to it. it was perfectly balanced at all angles.

I figured that 1 cone has an air bubble in it or the hole in it was not machined straight. but I'm not asking the Spirits of Flying any questions. I'm taking what I got and being thankful and happy.

Jim

Last edited by the Wasp; 02-01-2022 at 07:20 PM.

Jim, remember what I said about wind while balancing? ANY wind? That includes your central heat and air, someone walking by or even your breath. One of those may be the issue.

If you're worried about the balancer being defective just put the shaft, with cones installed, on your balancer with no prop. The shaft should not turn on its own from any position it's placed at. If it does then the shaft is bent or the cones are out of balance.

Good luck

If you're worried about the balancer being defective just put the shaft, with cones installed, on your balancer with no prop. The shaft should not turn on its own from any position it's placed at. If it does then the shaft is bent or the cones are out of balance.

Good luck

I just acquired a NIB FA-450R3 that had been sitting in the engine display case for years. BEAUTIFUL engine.

Although I am mostly into turbines now, I still fly everything from control line to R/C.

I couldn't pass up the deal but I really don't have it earmarked for any project.

Any suggestions?

Thanks,

Bob

Although I am mostly into turbines now, I still fly everything from control line to R/C.

I couldn't pass up the deal but I really don't have it earmarked for any project.

Any suggestions?

Thanks,

Bob

The following users liked this post:

rjbob (02-02-2022)

My Feedback: (1)

"hopefully explained"; yes,that can go around LOL. my son and I was just talking about that some 2 weeks ago LOL . it seems that his Production Manager at work needs some of that at times.

Jim

Senior Member

Quick, I hope that the velocity stack arrived, it will take some serious thumb pressure to get it on far enough to get the bolts through both sets of holes.. The O-ring will compress enough.

The following users liked this post:

acdii (02-03-2022)