Welcome to Club SAITO !

The following users liked this post:

SigMan (08-04-2022)

My Feedback: (3)

Hello again Saito Savers Society. Saito .72 here. I installed new bearings and plug (OS F) and I adjusted the valve lash. It was at .006" and I brought it down to a tight .004 or actual .003". Unfortunately this did not solve the problem. The symptoms are exactly the same before and after the overhaul. So I am asking for suggestions.

Engine has been running awesome for years (OSF plug and 30% nitro heli fuel, APC prop, a Saito "crack pipe" on it with a pressure line to the tank, machined metal backplate with carb mount). It has always ticked over at a slow and reliable idle with that great putt, putt sound from the pipe and ripping top end. Now what is happening (and this started suddenly) is after pulling the glow plug wire it will drop rpm's and start to kick, like it is back firing or trying to throw the prop, it will die rather quickly and usually with some nasty vibrations. If I increase the idle speed it still labors and kicks but if I can get it into the air quickly it runs well at part throttle and WOT is great, decent smoke trail, and it will idle much longer, but still starts kicking and popping at low rpm. I did not fly it long like that!

Note: I believe that I may have a leak in my fuel system as there was raw fuel around the engine (this is a profile fun fly type plane with rubber band mounted tank) and the tank is pretty old. I will replace that tank but I do not believe that is the problem with the engine, I just think the tank is leaking around the bung. Could affect the tank pressure.

Thanks in advance!

Engine has been running awesome for years (OSF plug and 30% nitro heli fuel, APC prop, a Saito "crack pipe" on it with a pressure line to the tank, machined metal backplate with carb mount). It has always ticked over at a slow and reliable idle with that great putt, putt sound from the pipe and ripping top end. Now what is happening (and this started suddenly) is after pulling the glow plug wire it will drop rpm's and start to kick, like it is back firing or trying to throw the prop, it will die rather quickly and usually with some nasty vibrations. If I increase the idle speed it still labors and kicks but if I can get it into the air quickly it runs well at part throttle and WOT is great, decent smoke trail, and it will idle much longer, but still starts kicking and popping at low rpm. I did not fly it long like that!

Note: I believe that I may have a leak in my fuel system as there was raw fuel around the engine (this is a profile fun fly type plane with rubber band mounted tank) and the tank is pretty old. I will replace that tank but I do not believe that is the problem with the engine, I just think the tank is leaking around the bung. Could affect the tank pressure.

Thanks in advance!

Last edited by husafreak; 08-03-2022 at 04:36 PM.

One possible is cam timing off by one tooth. Easy to do once, could even happen twice in a row. Results much as your description.

If you want a fresh perspective, send it here. I will return it in running order along with a report on the problem

If you want a fresh perspective, send it here. I will return it in running order along with a report on the problem

The following users liked this post:

husafreak (08-03-2022)

My Feedback: (3)

Thanks Jesse. I doubt it is the timing as it is running the same before and after its overhaul. I used the rubber band method to hold the crank pin at TDC and also the paintbrush handle in the valve hole to hold the cam. Have you ever heard of one of these skipping a tooth while running? Seems impossible. But if I can't fix it with a couple more tries I will PM you. I had a Honda 250 which had valve stretch issues so I was also wondering if that ever happens to these, or any damage to the valve seat, maybe a broken spring, sheesh.

The following users liked this post:

husafreak (08-03-2022)

The following users liked this post:

husafreak (08-03-2022)

The following users liked this post:

SigMan (08-04-2022)

My Feedback: (1)

hey guys check out this one. I am wondering if a Saito 130 would fit in it's cowl correctly ??

SEAGULL MODELS CASSUTT 3M RACER 65in SEA164 R – RED – LEGEND HOBBY

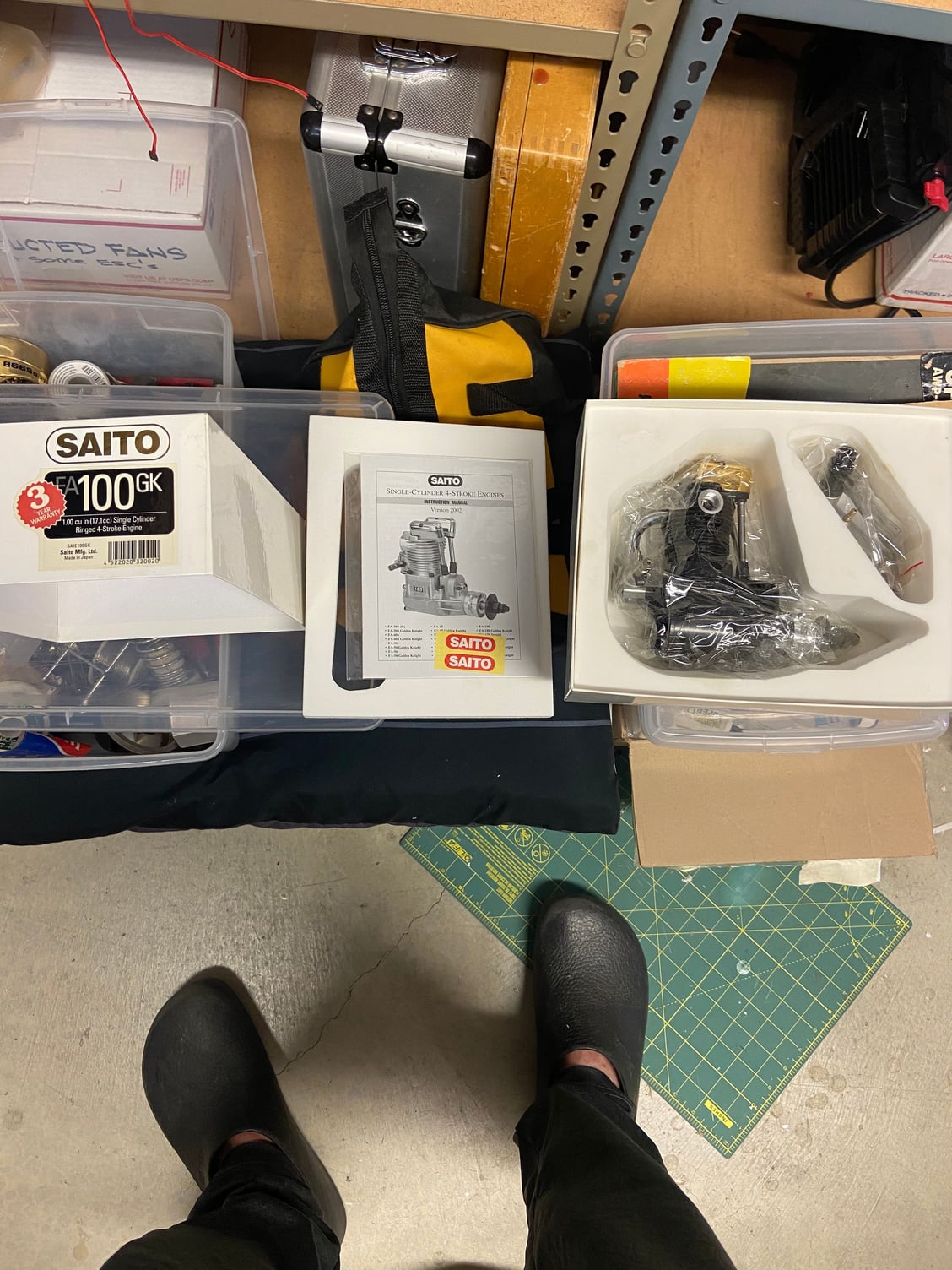

a nice Saito 100GK setting there!

Jim

SEAGULL MODELS CASSUTT 3M RACER 65in SEA164 R – RED – LEGEND HOBBY

a nice Saito 100GK setting there!

Jim

The following users liked this post:

husafreak (08-03-2022)

Thanks Jesse. I doubt it is the timing as it is running the same before and after its overhaul. I used the rubber band method to hold the crank pin at TDC and also the paintbrush handle in the valve hole to hold the cam. Have you ever heard of one of these skipping a tooth while running? Seems impossible. But if I can't fix it with a couple more tries I will PM you. I had a Honda 250 which had valve stretch issues so I was also wondering if that ever happens to these, or any damage to the valve seat, maybe a broken spring, sheesh.

Feel free to PM anytime

The following users liked this post:

husafreak (08-04-2022)

[QUOTE=Jesse Open;12738187]

Got the flared remains of the Timesert out by using a square easy out. Tapped it in lightly and turned clockwise threading the broken piece into the cylinder. I'm stoked now!  Just ordered the Timesert kit but the price still hurts a bit.

Just ordered the Timesert kit but the price still hurts a bit.

I've never stripped glow plug threads and seriously doubt I ever will. I'll have 4 Timeserts left in the kit so if any of you want to borrow the kit or send a cylinder to me for repair I would be happy to do it.

Thanks for the info on the exhaust. I have the knowledge and OA torch to silver braze but my access to machining equipment has disolved. I have the nuts from the original exhaust but I'm a little apprehensive about bending thin wall brass tubing. Lots of folks have tried and failed using sand, frozen soap and water or cerrobend. From what I understand it takes a mandrel type bender to get smooth 90° small radius bends. I need to create four 90° bends having approx a 3/4" bend radius. Talk me into attempting it please.

Just ordered the Timesert kit but the price still hurts a bit.

Just ordered the Timesert kit but the price still hurts a bit.

I've never stripped glow plug threads and seriously doubt I ever will. I'll have 4 Timeserts left in the kit so if any of you want to borrow the kit or send a cylinder to me for repair I would be happy to do it.

Thanks for the info on the exhaust. I have the knowledge and OA torch to silver braze but my access to machining equipment has disolved. I have the nuts from the original exhaust but I'm a little apprehensive about bending thin wall brass tubing. Lots of folks have tried and failed using sand, frozen soap and water or cerrobend. From what I understand it takes a mandrel type bender to get smooth 90° small radius bends. I need to create four 90° bends having approx a 3/4" bend radius. Talk me into attempting it please.

Last edited by Glowgeek; 08-04-2022 at 01:30 PM.

Lonnie please have a go at bending your own exhaust up, very rewarding and makes tight cowl fitting installations easier.

husafreak, I'd replace the fuel tank and ALL fuel lines first.

husafreak, I'd replace the fuel tank and ALL fuel lines first.

Lonnie,

You can do it! Well fitted hardwood forms are very helpful and I know you know wood.

Here is some info on Woods Metal ( Cerrobend)

CS Alloys - Cerro Alloys Tube Bending Filler

What size are the exhaust port threads you need?

BTW, I see gasket sets for your engine on ebay.

You can do it! Well fitted hardwood forms are very helpful and I know you know wood.

Here is some info on Woods Metal ( Cerrobend)

CS Alloys - Cerro Alloys Tube Bending Filler

What size are the exhaust port threads you need?

BTW, I see gasket sets for your engine on ebay.

Lonnie,

You can do it! Well fitted hardwood forms are very helpful and I know you know wood.

Here is some info on Woods Metal ( Cerrobend)

CS Alloys - Cerro Alloys Tube Bending Filler

What size are the exhaust port threads you need?

BTW, I see gasket sets for your engine on ebay.

You can do it! Well fitted hardwood forms are very helpful and I know you know wood.

Here is some info on Woods Metal ( Cerrobend)

CS Alloys - Cerro Alloys Tube Bending Filler

What size are the exhaust port threads you need?

BTW, I see gasket sets for your engine on ebay.

Hardwood forms, ok. I've been looking at cheap hand held benders for 1/4", 5/16", 3/8" on blamazon. Will those work if I anneal the brass and fill with Cerrabend?

Last edited by Glowgeek; 08-06-2022 at 05:02 AM.

Senior Member

https://www.rcuniverse.com/forum/market/11701095

This FG 11 looks black, is that a camera trick or am I having an optical dillusion? Thanks

This FG 11 looks black, is that a camera trick or am I having an optical dillusion? Thanks

My Feedback: (1)

the collor does look strange. so I thought it was a camera thing too. but if it is the camera why is the exhaust port silver?

Jim

Jim

Last edited by the Wasp; 08-07-2022 at 06:02 PM.

My Feedback: (3)

Soo, Saito Savers Society, I am hoping I have fixed my .72. I'll know tomorrow. I was having some serious problems with rough running and backfiring and dying at idle. Without going back over everything I took my heli out today (with the same jug of 30% nitro fuel) and right away I remembered having issues recently with that YS .96 two stroke engine as well, so I grabbed an unopened gallon of the same fuel on my way out the door. I made my first flight with the new fuel, easy start, smooth idle, nice flight but maybe a bit lean, burned the plug out actually. I remembered having leaned it the last time out. Richening it up a couple clicks back to where it was (2 clicks is a big deal on a YS BTW) had it running perfectly. Next flight I used the old fuel and it idled rough and quit the instant I pulled the glow plug wire. Drained the tank and went back to the new fuel. Nice running again. I decide I had somehow got bad fuel and dumped the 6-8 ounces left in the jug. I couldn't get home fast enough to see if my Saito .72 was also affected by this fuel. Strangely enough it ran rough on the new fuel! Unbelievable! I took the carb apart and tried to check the o-rings. They look OK but the pipe is a bit loose in the head. Nice and tight at the carb. Then I pulled the rocker covers off and while the springs looked fine one of the valve pushrods was not in place in the indent on the rocker arm. Could an engine run like that? I turned the prop slowly by hand and it felt strange. After reseating the pushrod it felt normal. Normal compression cycle. The next runs I concentrated on adjusting the idle needle. I found that closing it approximately 1&1/4 turns the idle came up a bit and smoothed out. Now with the APC 13x6 it is idling reliably at about 2800 and WOT at 10500. It sounds much better at idle and revs smoothly without hesitation or kicking. I sure hope I fixed it. I installed a new fuel system too, fingers crossed.

I would like to know a few things while I am at it if anyone can advise. Who is selling Saito parts? I may as well replace those o-rings either end of the fuel delivery pipe. For the gaskets, is it at all important to replace them at the cam covers and camshaft housing? I didn't think so but now I wonder. Also this engine has a very long prop shaft. I had been running it with the stock washer and nut, and then a heavy hub on top for CG and the starter cone, which looks dumb. The threaded heavy hub alone is not deep enough without the washer and nut. Does anyone know of a part to use besides a big old spinner (which I think looks dumb on a profile)? I could try to drill out and tap the heavy hub...

I would like to know a few things while I am at it if anyone can advise. Who is selling Saito parts? I may as well replace those o-rings either end of the fuel delivery pipe. For the gaskets, is it at all important to replace them at the cam covers and camshaft housing? I didn't think so but now I wonder. Also this engine has a very long prop shaft. I had been running it with the stock washer and nut, and then a heavy hub on top for CG and the starter cone, which looks dumb. The threaded heavy hub alone is not deep enough without the washer and nut. Does anyone know of a part to use besides a big old spinner (which I think looks dumb on a profile)? I could try to drill out and tap the heavy hub...

Last edited by husafreak; 08-07-2022 at 06:30 PM.