Jetcat P180RX OFF

#1

Member

Thread Starter

Hello I have a jetcat P180RX

It is the 3rd time that it unexpectedly shuts down at different RPMs.

One was in flight throttle 70% and another at takeoff not full throttle 80% or 90% approx.-

The error in the GSU is LOW RPM.-

1) No air bubbles

2) Tank, filter hoses were checked. They are not obstructed

3) Tested with two different JET A1 fuels @5% jetcat oil

My question, apart from any advice you can give me is:

According to the manual:

LOW RPM error is because detected engine LOW RPM (below idle, 33000 on my turbine)

I understand that you go through some of these things

1) Turbine in idle, air bubbles then lower rpm (less than 33000) -> causing shutdown

2) Turbine at throttle 80%, RPM sensor failure (records less than 33000) -> causing shutdown

I fine with those points or could there be another cause?

regards

Jonathan

It is the 3rd time that it unexpectedly shuts down at different RPMs.

One was in flight throttle 70% and another at takeoff not full throttle 80% or 90% approx.-

The error in the GSU is LOW RPM.-

1) No air bubbles

2) Tank, filter hoses were checked. They are not obstructed

3) Tested with two different JET A1 fuels @5% jetcat oil

My question, apart from any advice you can give me is:

According to the manual:

LOW RPM error is because detected engine LOW RPM (below idle, 33000 on my turbine)

I understand that you go through some of these things

1) Turbine in idle, air bubbles then lower rpm (less than 33000) -> causing shutdown

2) Turbine at throttle 80%, RPM sensor failure (records less than 33000) -> causing shutdown

I fine with those points or could there be another cause?

regards

Jonathan

#3

Member

Thread Starter

#5

What Bubble trap? The pump figures are high and white smoke proves it’s fuel system and not an electronic shut down, the fact that you see no bubble in the line now does not mean there was not a bubble, it’s just gone through the turbine!

Have you checked the filter is clean and cap type?

Picture of the install?

Dave

Have you checked the filter is clean and cap type?

Picture of the install?

Dave

#7

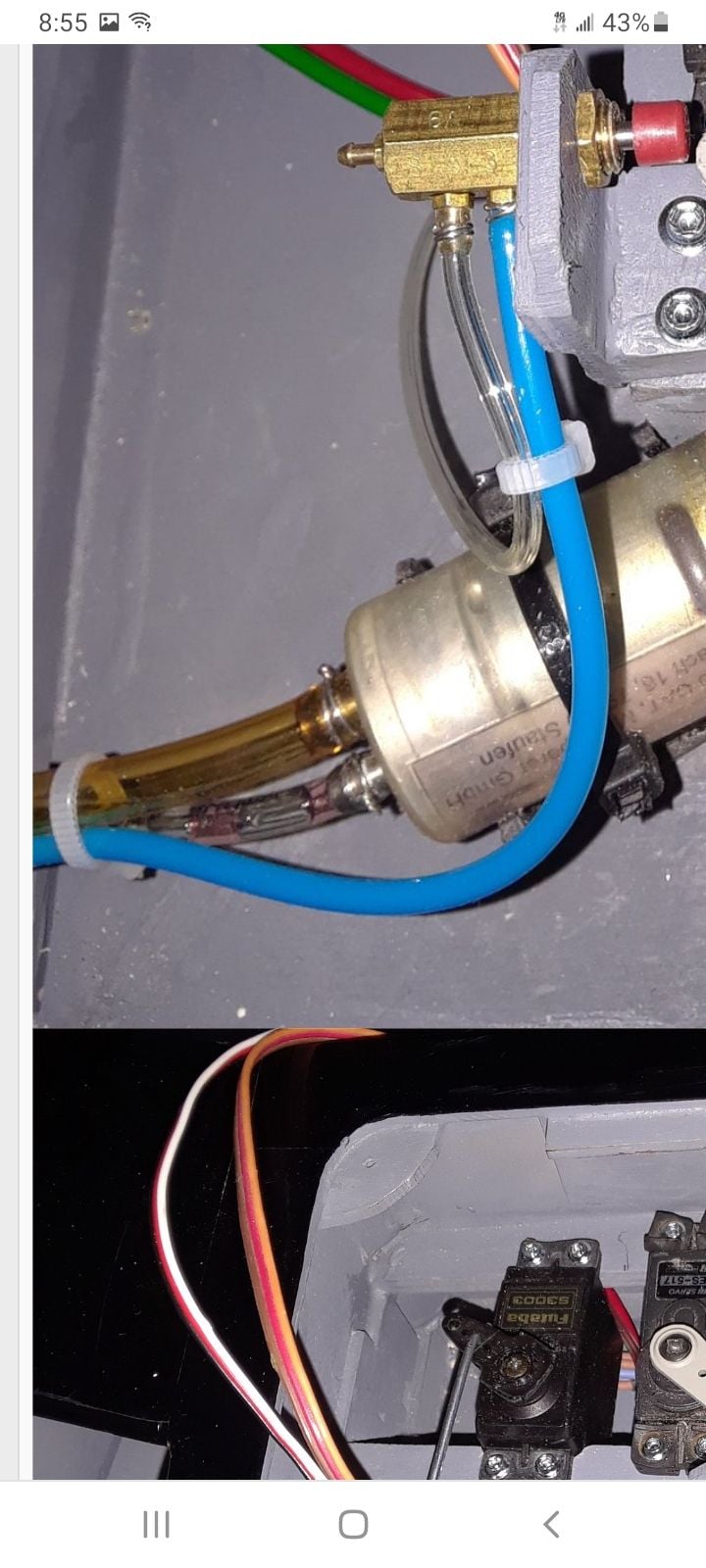

Was the JC filter easy to unscrew?

Tygon is not the best tube to use for outside the tank. 6mm o/d 4mm I/d SMC poly tube would be better. Tygon inside tank

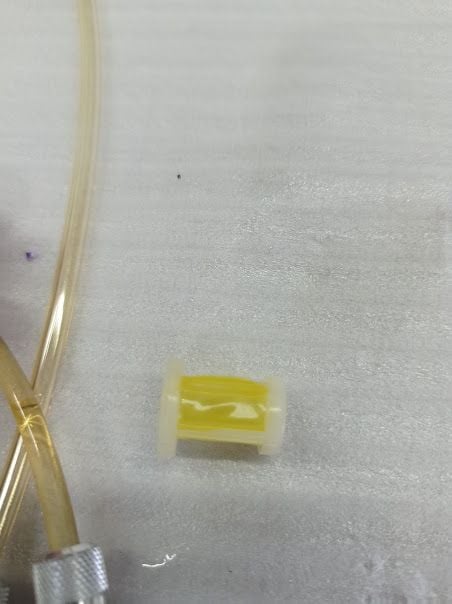

The Sintered pick up is not ideal in the bubble trap, we are starting to see issues with another type that uses those, they clog easily and more importantly don’t hold a ‘reserve’ of fuel in the filter.

No barbs on the main tank tubes either, was it lock wired down?

Dave

Tygon is not the best tube to use for outside the tank. 6mm o/d 4mm I/d SMC poly tube would be better. Tygon inside tank

The Sintered pick up is not ideal in the bubble trap, we are starting to see issues with another type that uses those, they clog easily and more importantly don’t hold a ‘reserve’ of fuel in the filter.

No barbs on the main tank tubes either, was it lock wired down?

Dave

#9

Member

Thread Starter

Yes jetcat filter easy to unscrew

Maybe I should press harder?

The main pipes no burrs and are not obstructed.-

Air trap checked and not clogged

The interior of both tanks are clean.

The system has no more than 18 flights and is all new.

Although it is not a guarantee of anything.-

I did tests on the ground after the video, the turbine shut down at maximum rpm.

No air see on the fuel line or UAT.-

But I believe in what dave says

The problem does not seem electronic but fuel because you see white smoke

Maybe I should press harder?

The main pipes no burrs and are not obstructed.-

Air trap checked and not clogged

The interior of both tanks are clean.

The system has no more than 18 flights and is all new.

Although it is not a guarantee of anything.-

I did tests on the ground after the video, the turbine shut down at maximum rpm.

No air see on the fuel line or UAT.-

But I believe in what dave says

The problem does not seem electronic but fuel because you see white smoke

#10

Member

Thread Starter

Dave

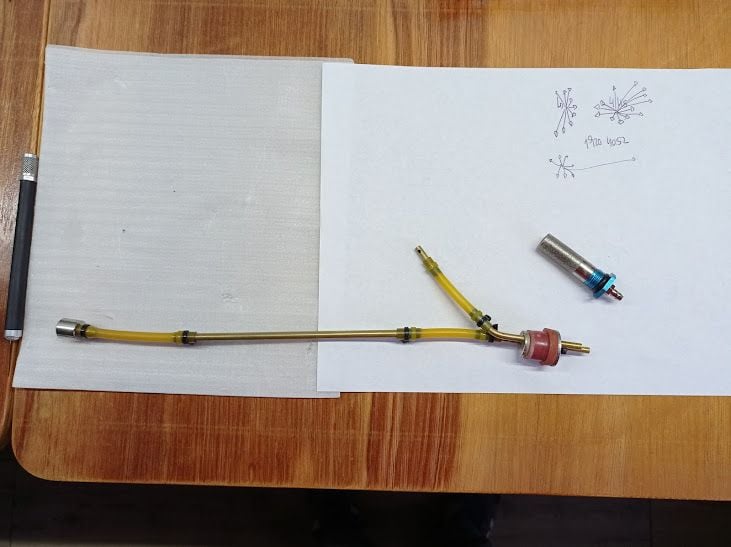

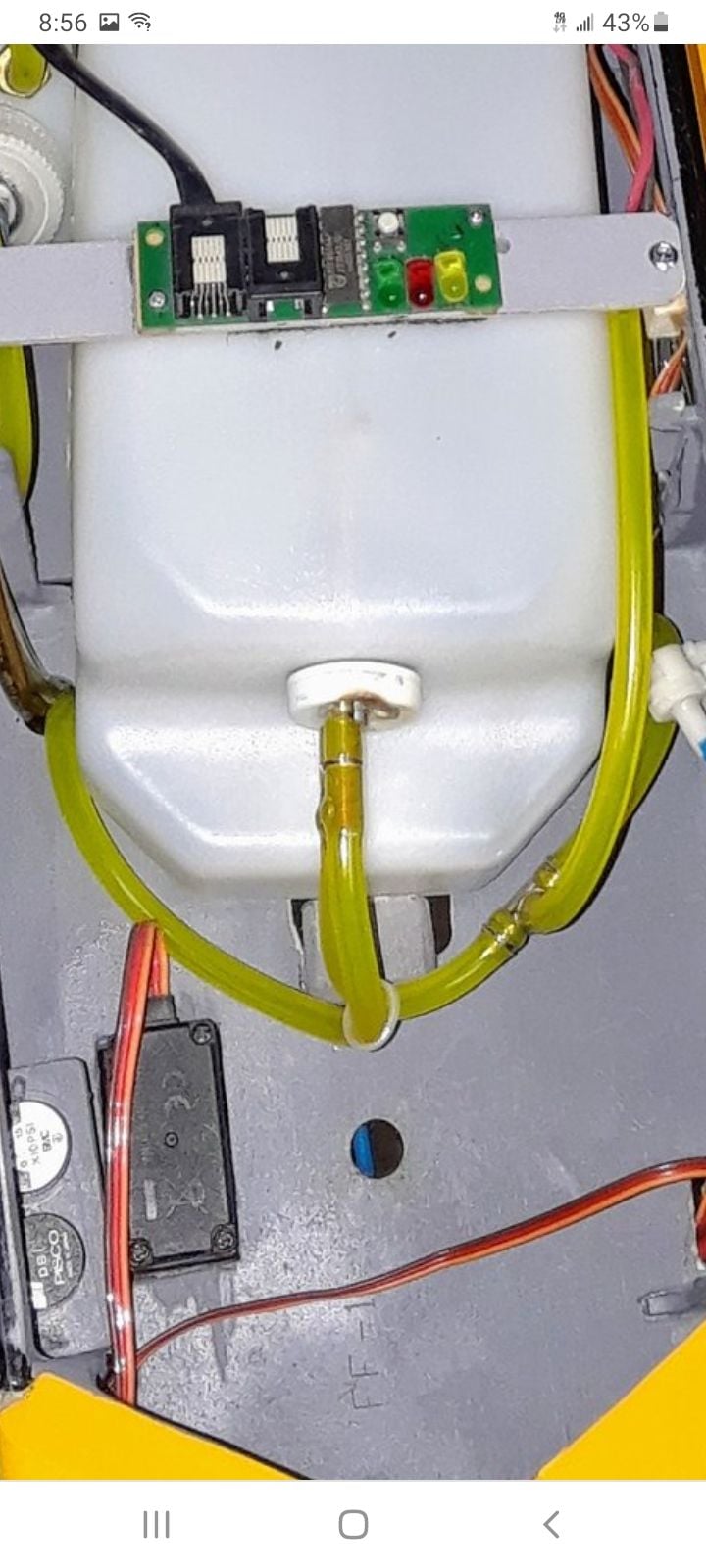

The tygon line out of fuel tank

I can change for you recomendation.-

6mm SMC poly

Main tank to UAT and UAT to PUMP

See the picture festo 6mm to 4mm is a good option? read on another thread and not recomended the brass nipple for the nipple ID is very small

The tygon line out of fuel tank

I can change for you recomendation.-

6mm SMC poly

Main tank to UAT and UAT to PUMP

See the picture festo 6mm to 4mm is a good option? read on another thread and not recomended the brass nipple for the nipple ID is very small

#16

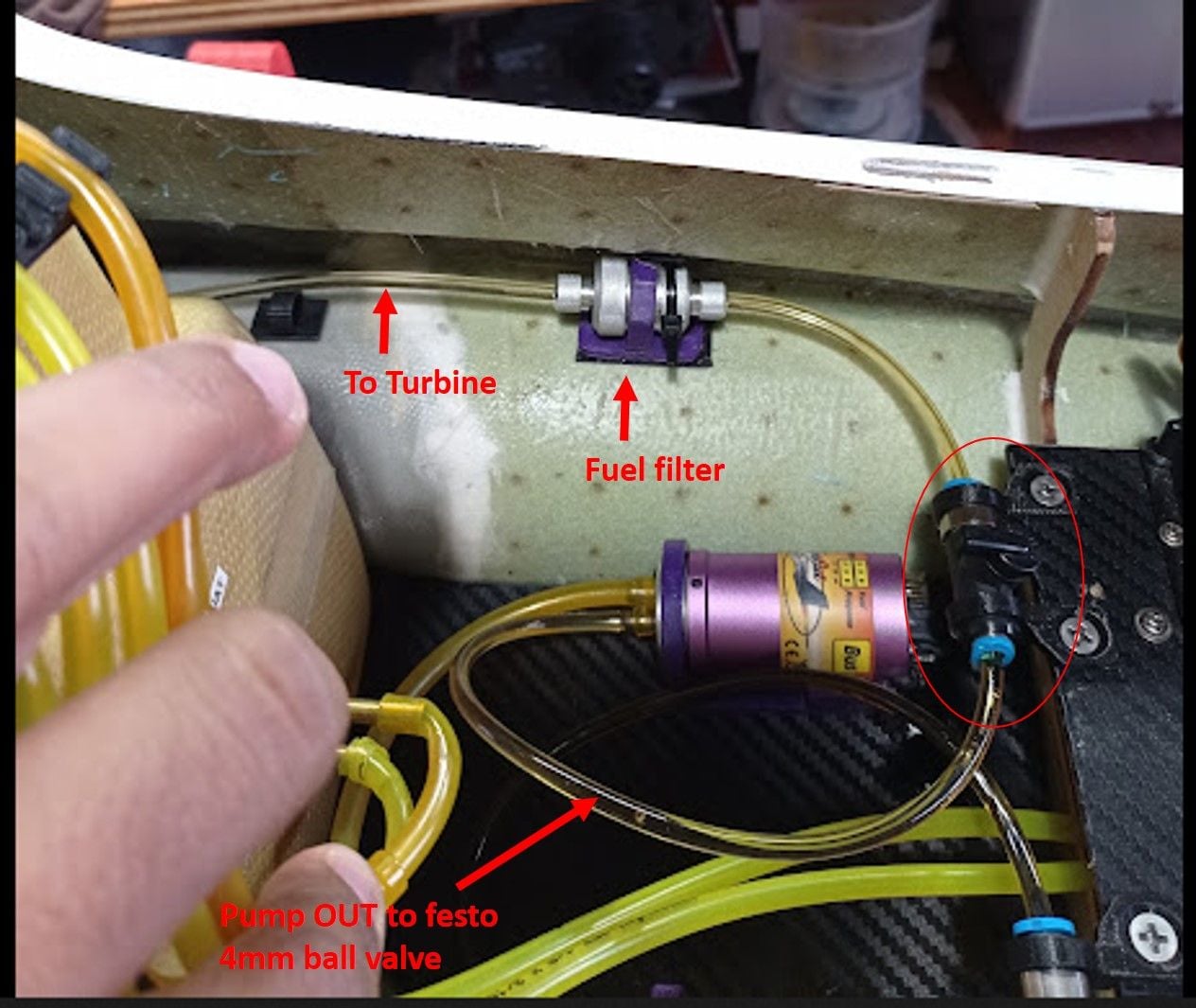

4-6 Festo causes no problem, I use just a short length of 4mm maybe 40mm.

The O ring in the JC filter relaxes after a few hours, then retighten cap. Normally an extra 3mm of turn is possible. After doing this once it stays tight for good.

The O ring in the JC filter relaxes after a few hours, then retighten cap. Normally an extra 3mm of turn is possible. After doing this once it stays tight for good.

#18

My Feedback: (1)

Looks like a Pilot RC Predator (or at least the tank from one). My predator developed a leak between the bottom of the UAT portion of the tank and the main tank which eventually led to a flame-out. You could actually see a stream of tiny bubbles come up from the bottom corner of the UAT if you ran the turbine on the ground with the main tank not full. I ended up bypassing the integral UAT and running a separate BVM high flow UAT. That integral UAT actually has a piece of fiberglass/kevlar glued between it and the main tank and believe it or not the glue and it's application are not of the best quality for this joint.

#19

Member

Thread Starter

Hi dccatl

Yes, is a Pilot PRedator 2.2M.-

I read another thread about the standar UAT,.-

I solved this problems pouring resin into the bottom of the UAT and sealing between the main tank and the UAT.-

I am attentive to air bubbles and I have not seen them.-

After the flight of the video where the turbine was turned off.

The next day I made two flights without problem or air in the UAT.- Then the third flight the turbine OFF on takeoff

I keep looking if the bubbles appear

Yes, is a Pilot PRedator 2.2M.-

I read another thread about the standar UAT,.-

I solved this problems pouring resin into the bottom of the UAT and sealing between the main tank and the UAT.-

I am attentive to air bubbles and I have not seen them.-

After the flight of the video where the turbine was turned off.

The next day I made two flights without problem or air in the UAT.- Then the third flight the turbine OFF on takeoff

I keep looking if the bubbles appear

#20

My Feedback: (21)

When I use JC Fuel Filters, I found that they will look free of any debris, but it can be very restricted. Try blowing through it. Or at least soak it in some alcohol and brush the outside of the filter with the alcohol and a small epoxy brush.

Also, I was always told to mount the filter in a vertical position to prevent any micro bubbles from collecting in the filter and releasing one bubble causing a flameout. Fuel in from the bottom and out to the turbine from the top.

Just saying what I have experienced with my JC's.

Also, I was always told to mount the filter in a vertical position to prevent any micro bubbles from collecting in the filter and releasing one bubble causing a flameout. Fuel in from the bottom and out to the turbine from the top.

Just saying what I have experienced with my JC's.

The following users liked this post:

Springbok Flyer (06-15-2022)

#21

Member

Thread Starter

Hi everyone

I am back with the problems of the P180RX.-

There are several points that can be more than one problem.

I ask you to read carefully

since I started this thread

1) Change the diameters of the hoses to make sure it is not a problem of restriction or cavitation due to restriction.-

2) Hoses inside the fueltank is tygon 3/16", hoses outside fueltank is PU 6MM and just to the 40mm aprox to pump use the festo 6mm-to-4mm

3) Connections with festo fitting and other parts use the safety wire.-

I did several tests on the ground and there are no air bubbles in the line, clean filter and system checked.-

But in fligth (straight and level fligth @88k RPM) agian the problems the turbine flame out (this case whitout white smoke) sudden flameout and error on GSU is LOW-RPM

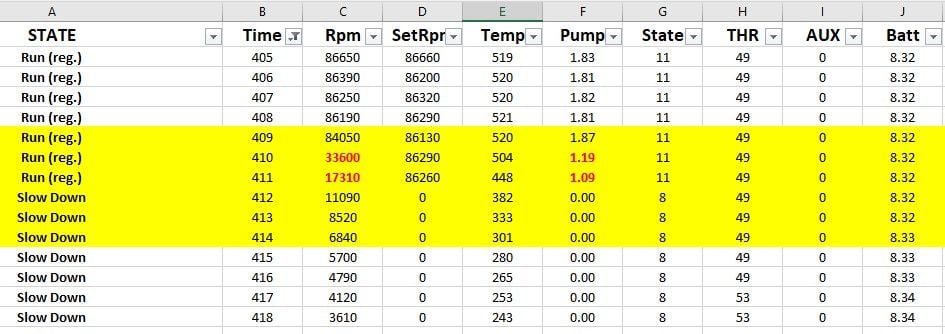

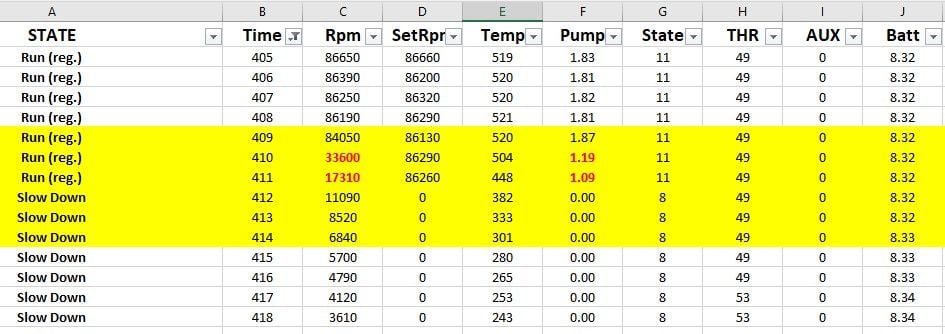

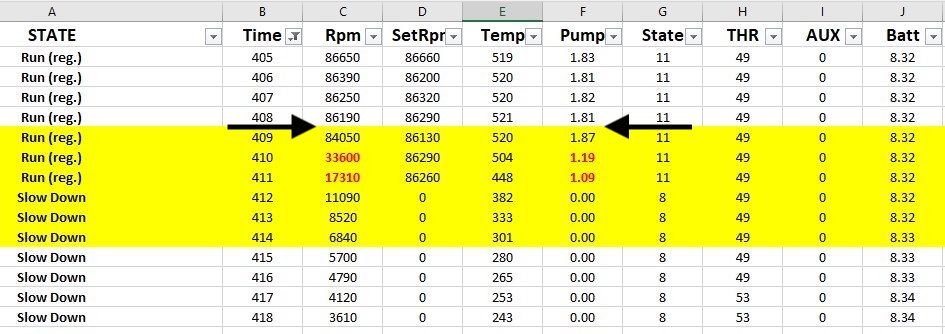

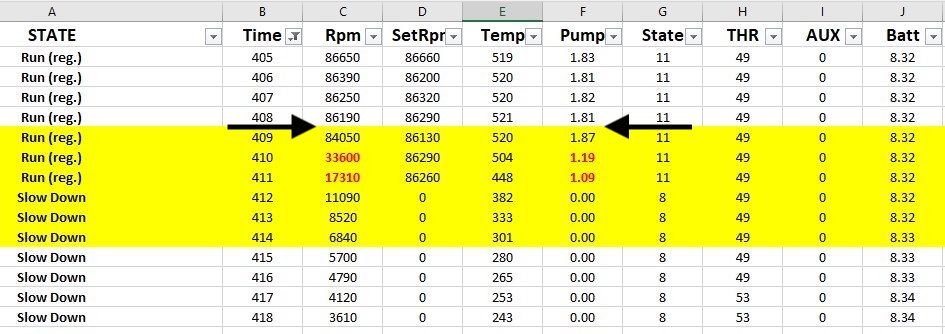

checking the logs fligth , i see the possible low RPM previos to flame out, and the fuel pump voltage also low voltage, but you don't see a drop from the RC the throttle is still at 49see logs analisys

Now what causes this drop in rpm that causes the turbine to shut down.

do you suspect?

1) RPM - SENSOR

2) FUEL VALVE

3) FUEL PUMP check the Fuel pump volt @IDLE 0.6v and @FULL 4.8v

I did several tests on the ground remove the turbine cover and check during a test

1) rpm sensor and the fuel valve I did not find false contacts.-

2) tests with the pump, slightly closing the fuel passage FESTO 4mm BALL VALVE, to make the pump work harder

(to detect high current consumption, disconnection or pump motor failure)

I not find any error

I am back with the problems of the P180RX.-

There are several points that can be more than one problem.

I ask you to read carefully

since I started this thread

1) Change the diameters of the hoses to make sure it is not a problem of restriction or cavitation due to restriction.-

2) Hoses inside the fueltank is tygon 3/16", hoses outside fueltank is PU 6MM and just to the 40mm aprox to pump use the festo 6mm-to-4mm

3) Connections with festo fitting and other parts use the safety wire.-

I did several tests on the ground and there are no air bubbles in the line, clean filter and system checked.-

But in fligth (straight and level fligth @88k RPM) agian the problems the turbine flame out (this case whitout white smoke) sudden flameout and error on GSU is LOW-RPM

checking the logs fligth , i see the possible low RPM previos to flame out, and the fuel pump voltage also low voltage, but you don't see a drop from the RC the throttle is still at 49see logs analisys

Now what causes this drop in rpm that causes the turbine to shut down.

do you suspect?

1) RPM - SENSOR

2) FUEL VALVE

3) FUEL PUMP check the Fuel pump volt @IDLE 0.6v and @FULL 4.8v

I did several tests on the ground remove the turbine cover and check during a test

1) rpm sensor and the fuel valve I did not find false contacts.-

2) tests with the pump, slightly closing the fuel passage FESTO 4mm BALL VALVE, to make the pump work harder

(to detect high current consumption, disconnection or pump motor failure)

I not find any error

#22

My Feedback: (57)

I don't think you said how many hours it had, or what happened between the time it was working and when it started shutting down (i.e. maintenance, hard landing, etc.), but I would guess the pump might be your problem, and would start there.

If you look at the left arrow in between 408 & 409 (I'm assuming these are one sec. intervals), you will see the RPM starting to drop. Now look at the right arrow, you will notice that the pump voltage increases to try and compensate, but is unsuccessful and starts shutting down (giving you OC: LOW RPM). If you had more granular data (less than 1 sec. intervals), it could give a better picture of exactly what's happening.

This is just my opinion of course!

If you look at the left arrow in between 408 & 409 (I'm assuming these are one sec. intervals), you will see the RPM starting to drop. Now look at the right arrow, you will notice that the pump voltage increases to try and compensate, but is unsuccessful and starts shutting down (giving you OC: LOW RPM). If you had more granular data (less than 1 sec. intervals), it could give a better picture of exactly what's happening.

This is just my opinion of course!

#23

Member

Thread Starter

Thank you

you are right there seems to be a good point.-

if I have noticed that the data is not so granular.-

Suspecting the pump, I'm trying another one that is new.-

But I have had problems with the starts, (Acceleration too slow) apparently the new pump requires a little more voltage.-

I did several tests with U-ACCEL1 and U-ACCEL2

Accel1 from 0.175 to 0.250

Accel2 from 0.8 to 1.0

the pump ilde is ok, 0.7

I don't always get start, some best on Accel-1=0.250 and Accel-2=1.0

Do you think that more pump voltage would be normal in a new one?

or maybe it is braked dirt or dry fuel

I understand new brushes and gears

one thing in new and another a little time of use

you are right there seems to be a good point.-

if I have noticed that the data is not so granular.-

Suspecting the pump, I'm trying another one that is new.-

But I have had problems with the starts, (Acceleration too slow) apparently the new pump requires a little more voltage.-

I did several tests with U-ACCEL1 and U-ACCEL2

Accel1 from 0.175 to 0.250

Accel2 from 0.8 to 1.0

the pump ilde is ok, 0.7

I don't always get start, some best on Accel-1=0.250 and Accel-2=1.0

Do you think that more pump voltage would be normal in a new one?

or maybe it is braked dirt or dry fuel

I understand new brushes and gears

one thing in new and another a little time of use

Last edited by jarizaga; 08-12-2022 at 10:37 AM.

#24

URL 1 just needs to be high enough to start the pump turning-no more. Url2 needs to be higher than U idle, but will adjust after each run anyway.

U idle at 0.7 is a common and good figure. When you get a start do you always open to full power to set the max rpm pump figure? You should.

If the ECU software older than 10.3 the new pump software might be incompatible ( too new)

George asked how many hours on the original pump?

So for now boot up the ECU and note the software & the Pump Software. When you change one item you should reset the whole system and re do learn RC. If you change one component on the Bus turbines you should always do a system reset to clear the previous logs

Dave

U idle at 0.7 is a common and good figure. When you get a start do you always open to full power to set the max rpm pump figure? You should.

If the ECU software older than 10.3 the new pump software might be incompatible ( too new)

George asked how many hours on the original pump?

So for now boot up the ECU and note the software & the Pump Software. When you change one item you should reset the whole system and re do learn RC. If you change one component on the Bus turbines you should always do a system reset to clear the previous logs

Dave

#25

Member

Thread Starter

I didn't answer George's question

1) Total Run-Time : 30258 is equal to-> 8h:40m right?

2) Flight time 4 minutes approx.

ECU jet-tronic 10.1W / Fuel pump C4 - V1.0F

Following the tests with the suspicion that the fault is the pump

I did tests on Friday and fail again, at the time i using another ECU jet-tronic 10.4P and the same Fuel pump C4 - V1.0F

failure after accelerated and error LoRpmPmp

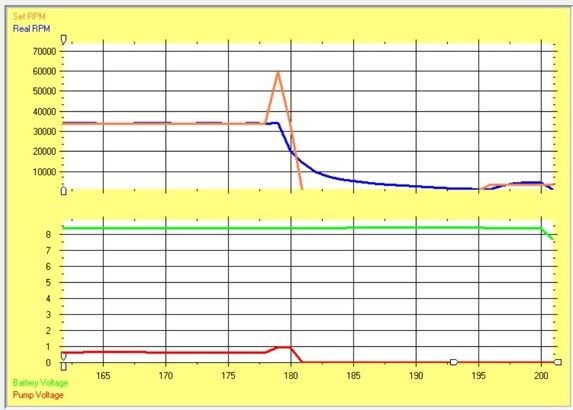

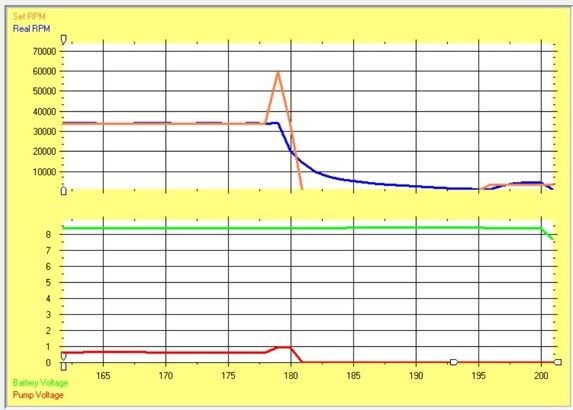

and this graph

I tell you the next step on Saturday I did 3 flights without problems with

the same turbine and another ECU and PUMP (jet-tronic 10.4P - Fuel pump C4 / V8.3)

1) Total Run-Time : 30258 is equal to-> 8h:40m right?

2) Flight time 4 minutes approx.

ECU jet-tronic 10.1W / Fuel pump C4 - V1.0F

Following the tests with the suspicion that the fault is the pump

I did tests on Friday and fail again, at the time i using another ECU jet-tronic 10.4P and the same Fuel pump C4 - V1.0F

failure after accelerated and error LoRpmPmp

and this graph

I tell you the next step on Saturday I did 3 flights without problems with

the same turbine and another ECU and PUMP (jet-tronic 10.4P - Fuel pump C4 / V8.3)