Galeb G2 - new jet made in Serbia

#26

ORIGINAL: mirce

In last ten days many things happened with this project.

I exchanged more than 15 mails with Ali, and he told me many interesting things. Ali have an amazing experience, so any advice is very important to me. Thank you Ali...

Man I needed to make the wings of Styrofoam canceled the cooperation, so I returned to plan to made constructive wing. I need to draw again plans, but constructive wings are for me best option.

Few days ago I visit our sport airport and take down all measure I need to made final drawings for fuselage, wings and tail section.

When I come home and comparing measures I was very pleased when saw how much my drawings are precise.

With measure I take from airplane, I have now all I need to start making wing and elevator.

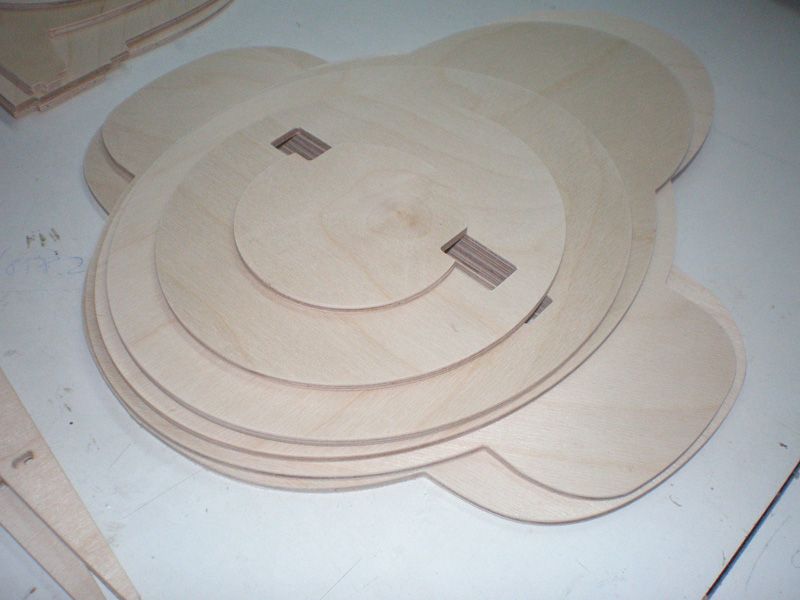

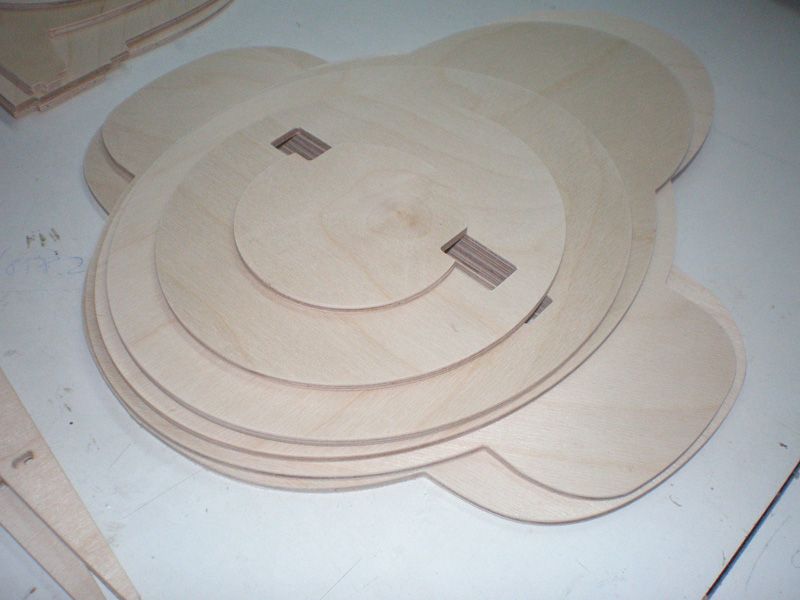

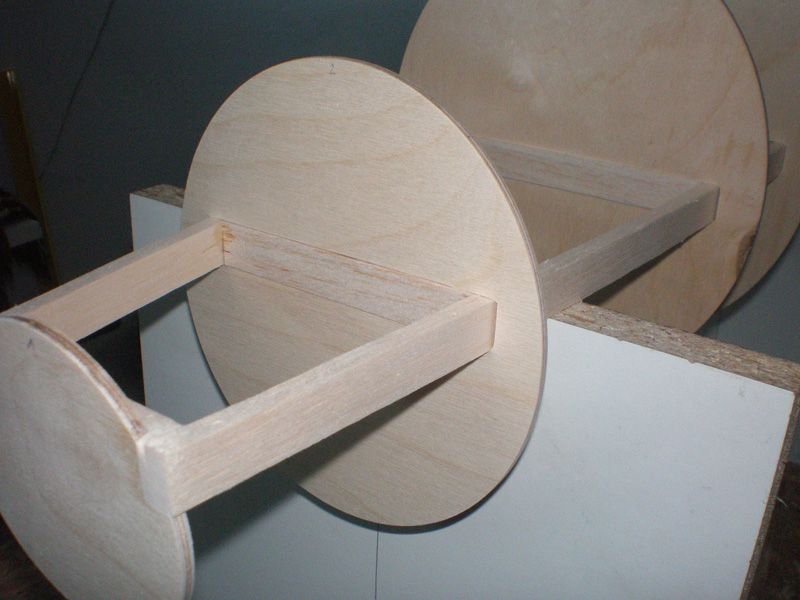

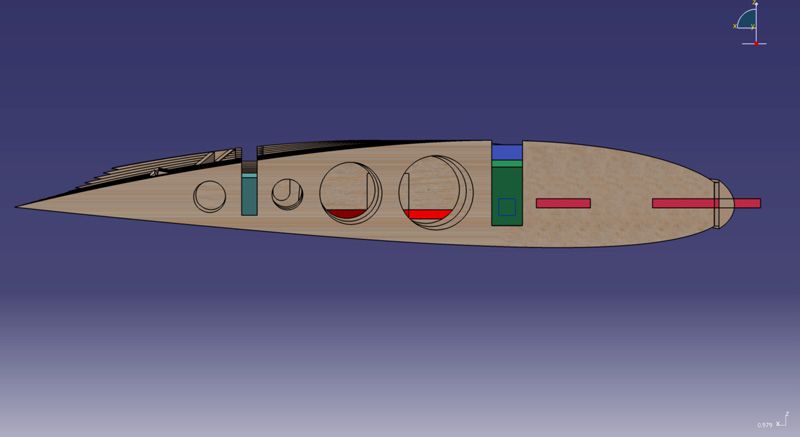

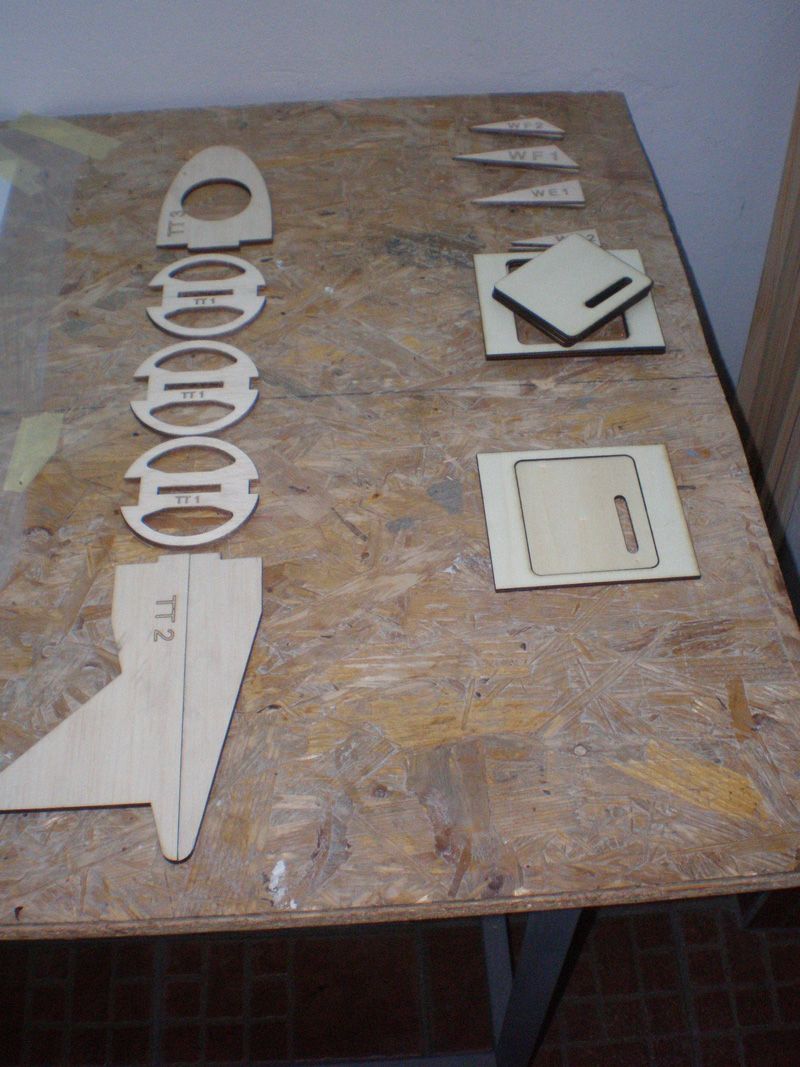

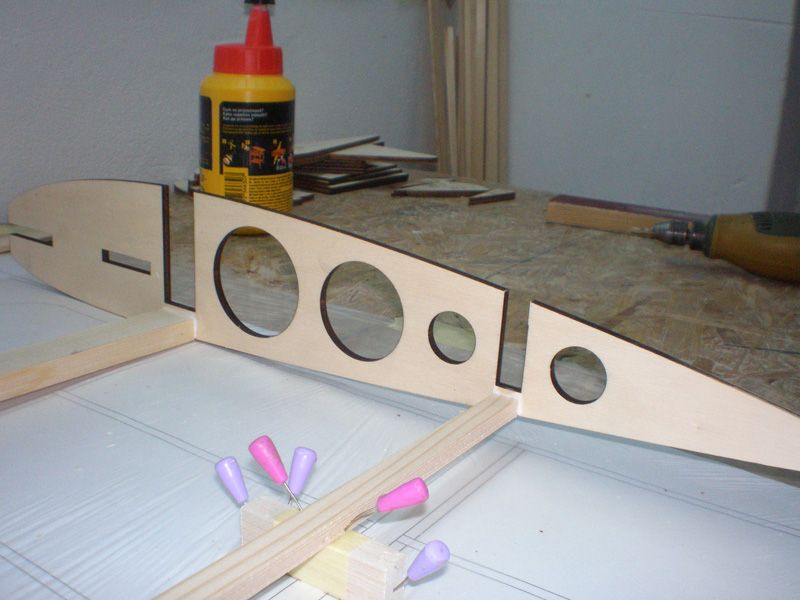

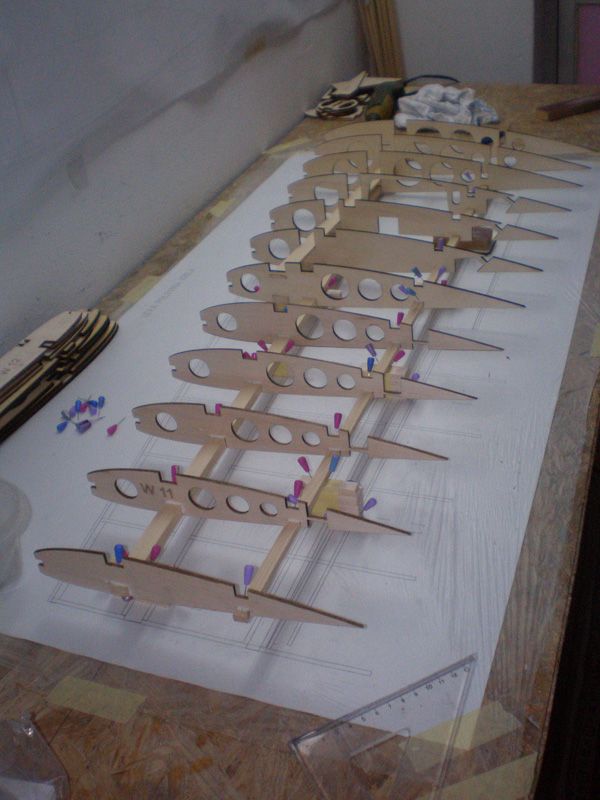

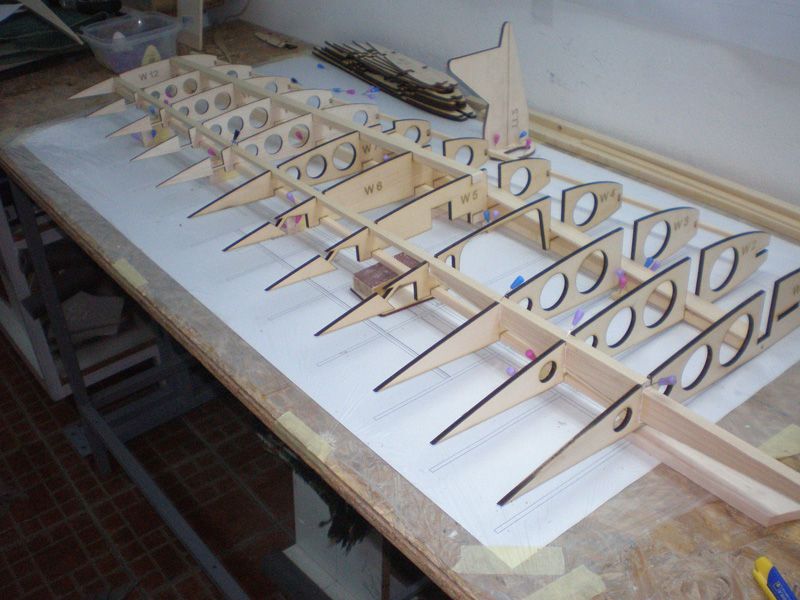

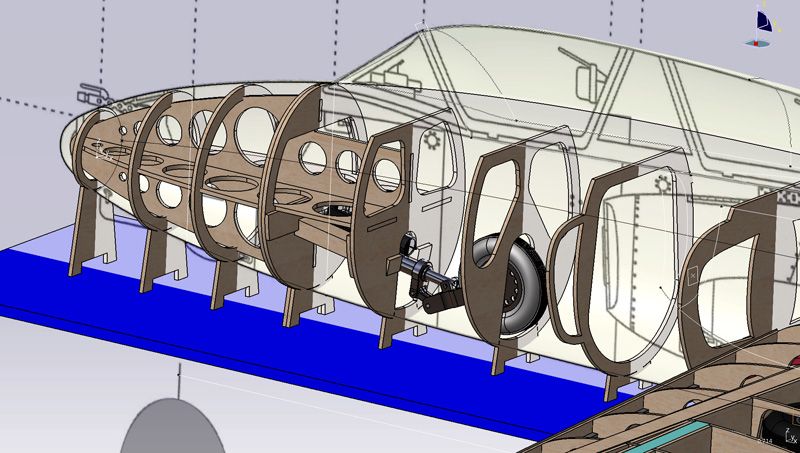

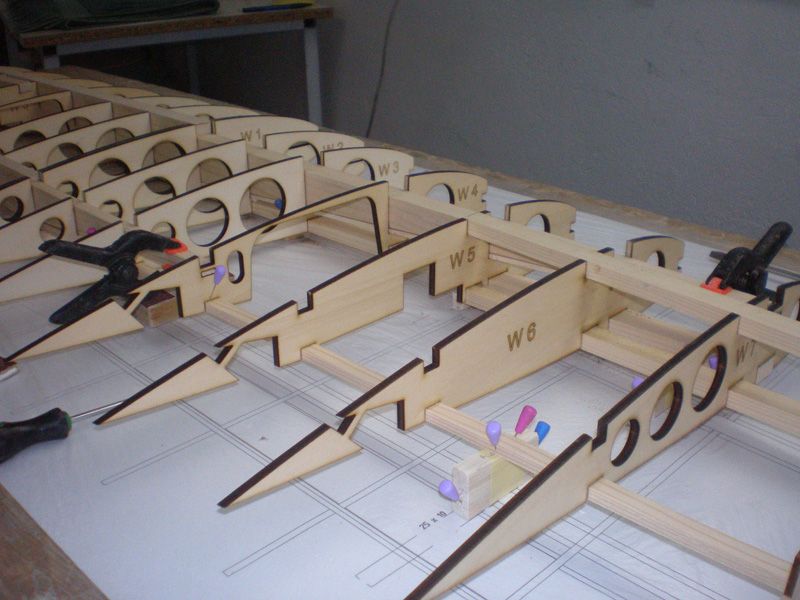

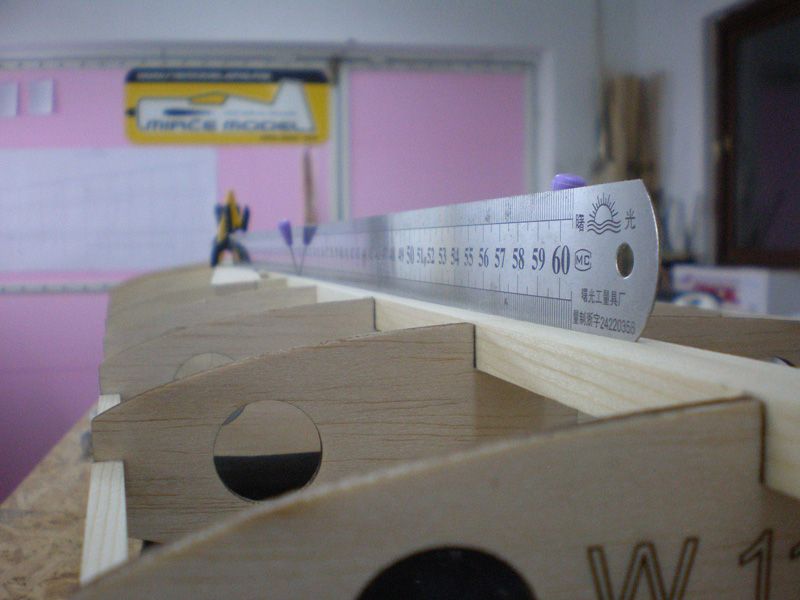

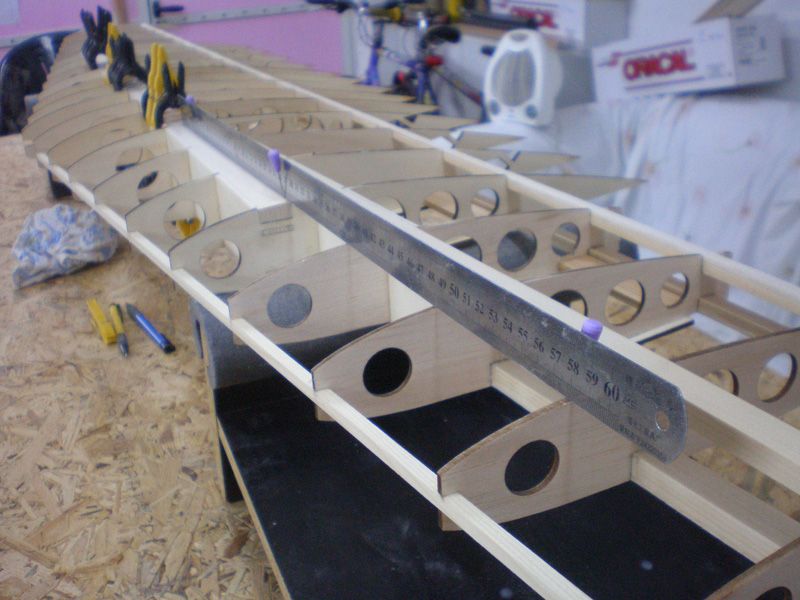

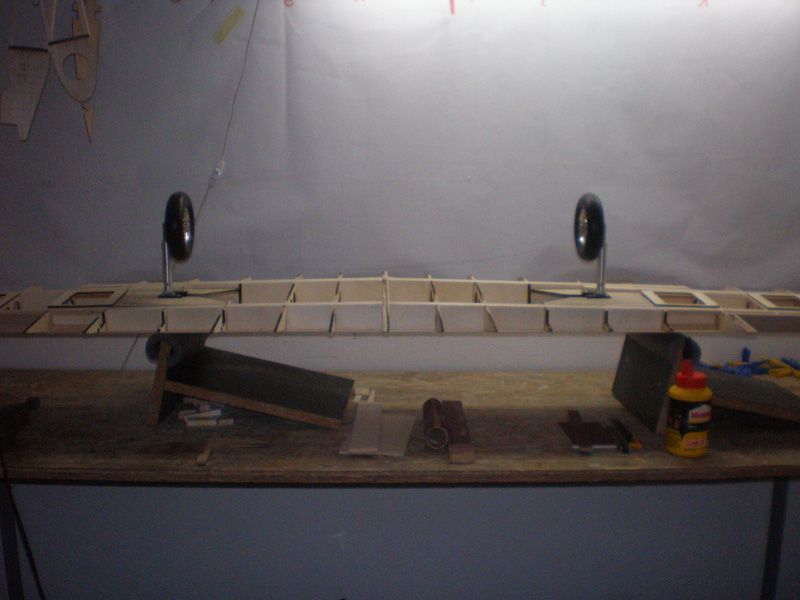

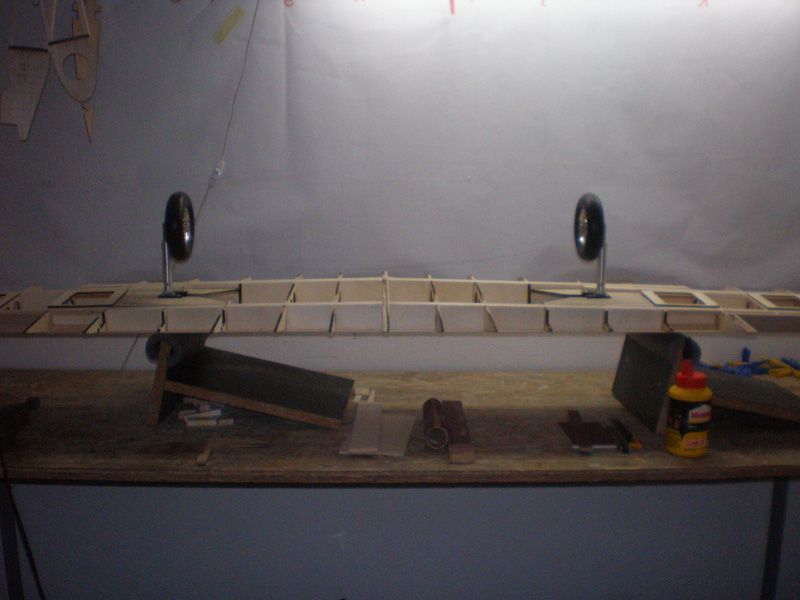

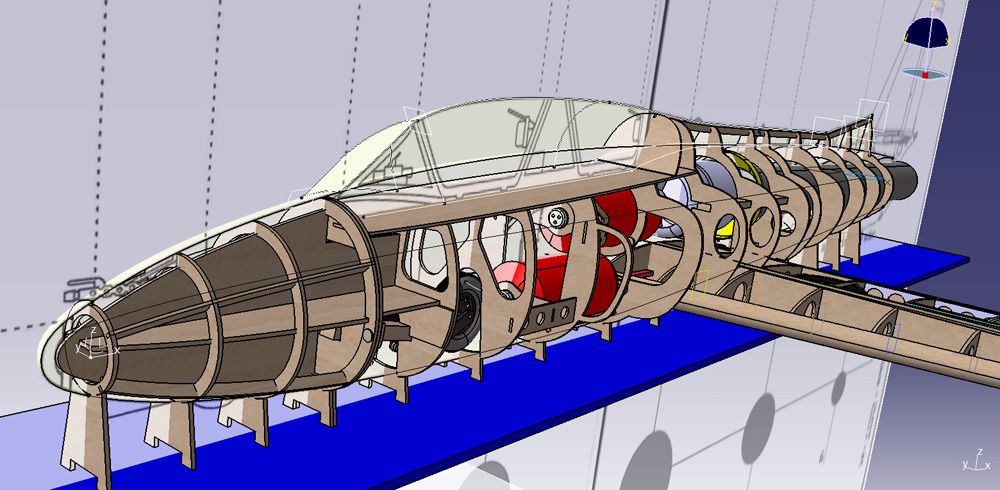

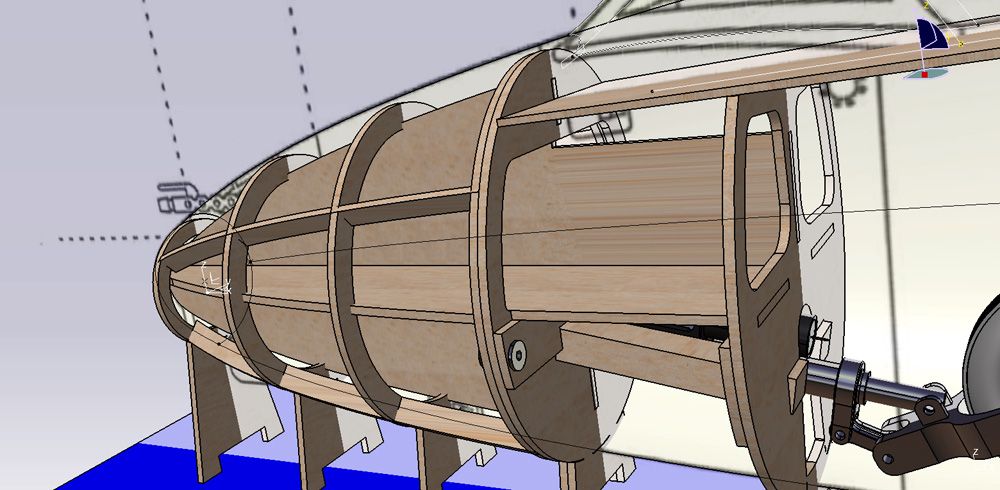

In meantime, I made all ribs for fuselage. This are ribs which I drew from JPG's I get for Galeb G2. I have invested a lot of work to set all parameters for fuselage. Of course, this is just first step, I must work on fuselage, and all I made to draw back on plan.

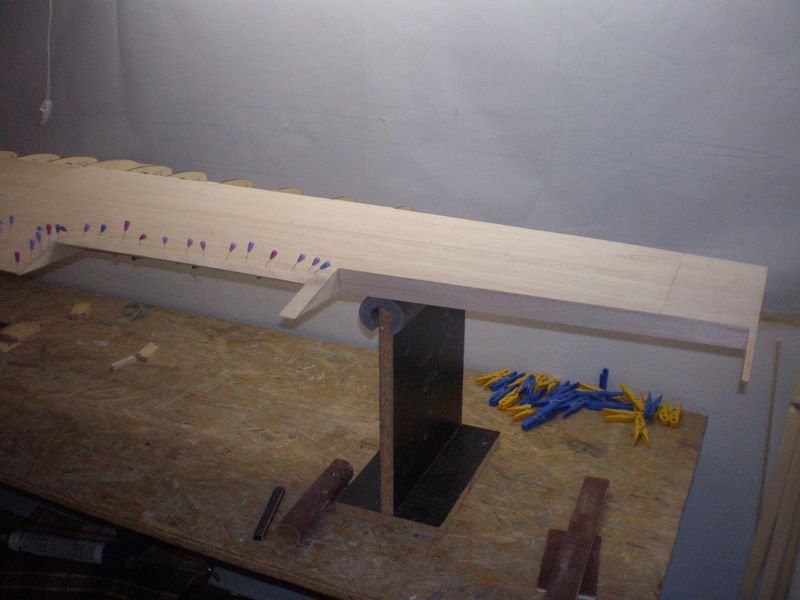

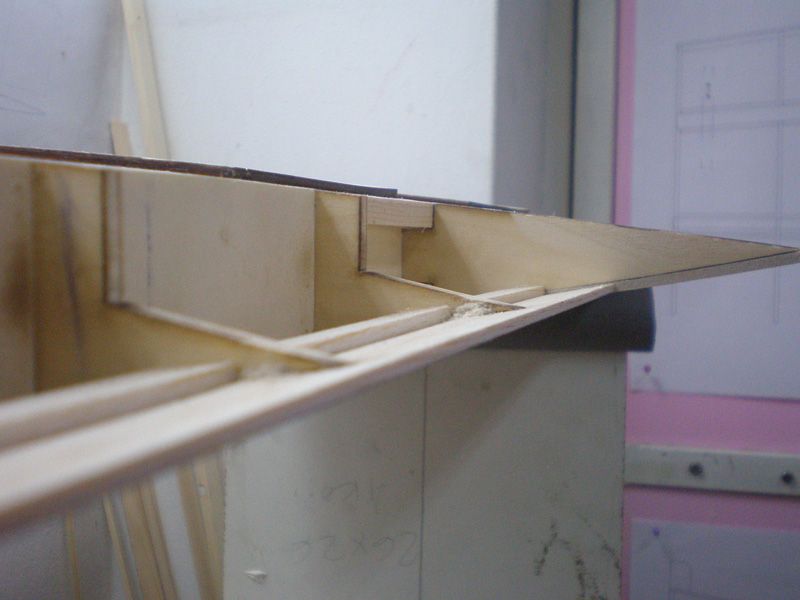

For now it look like this:

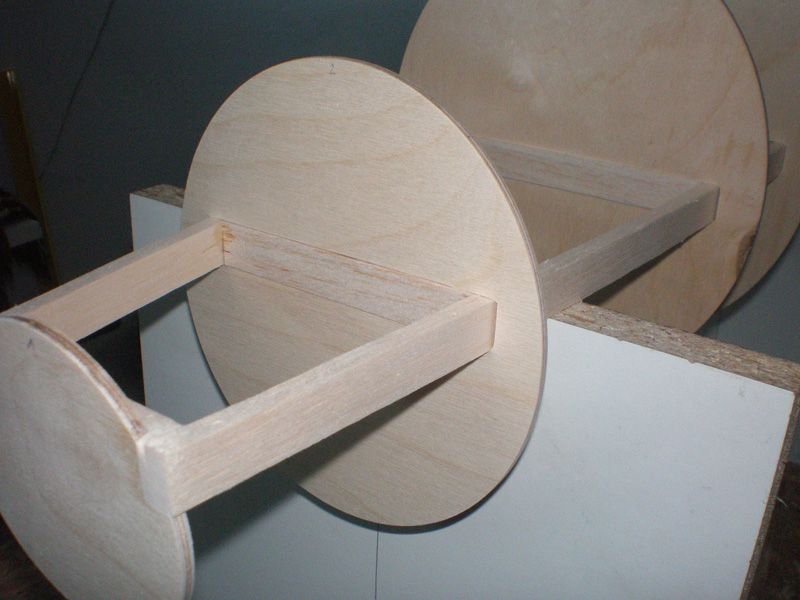

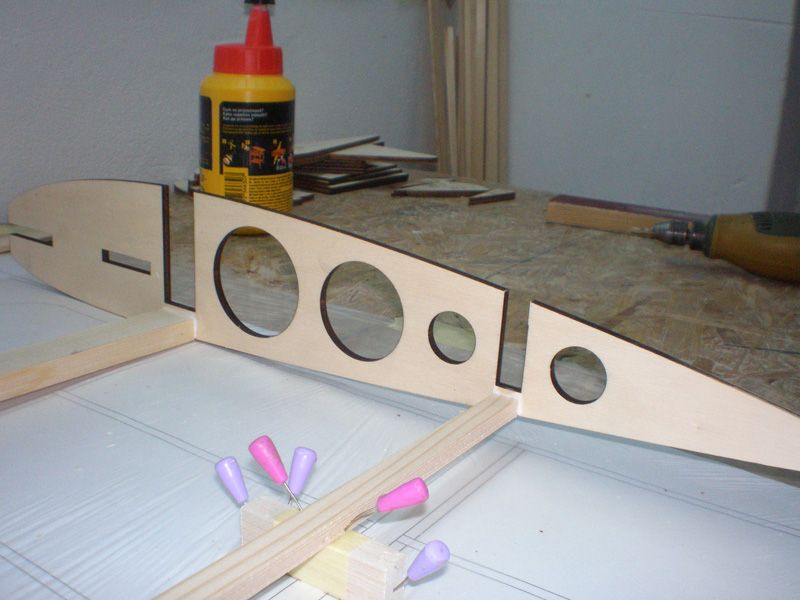

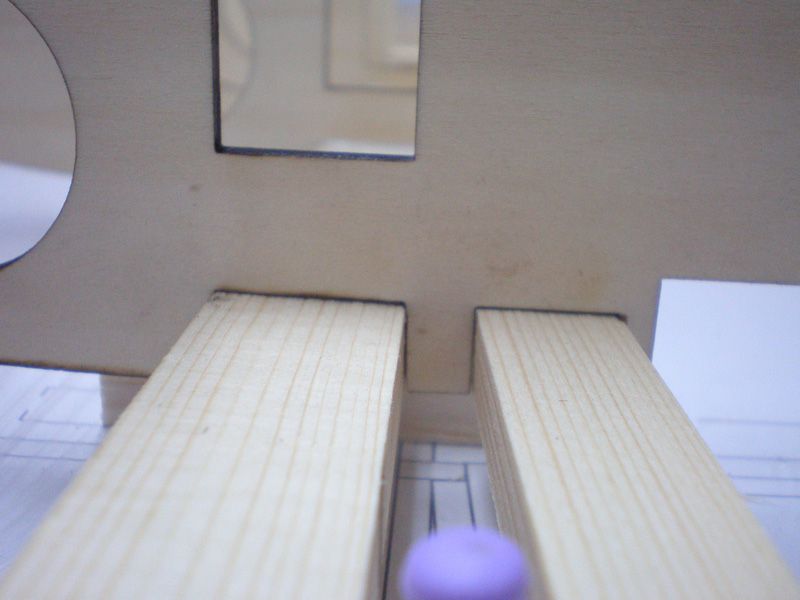

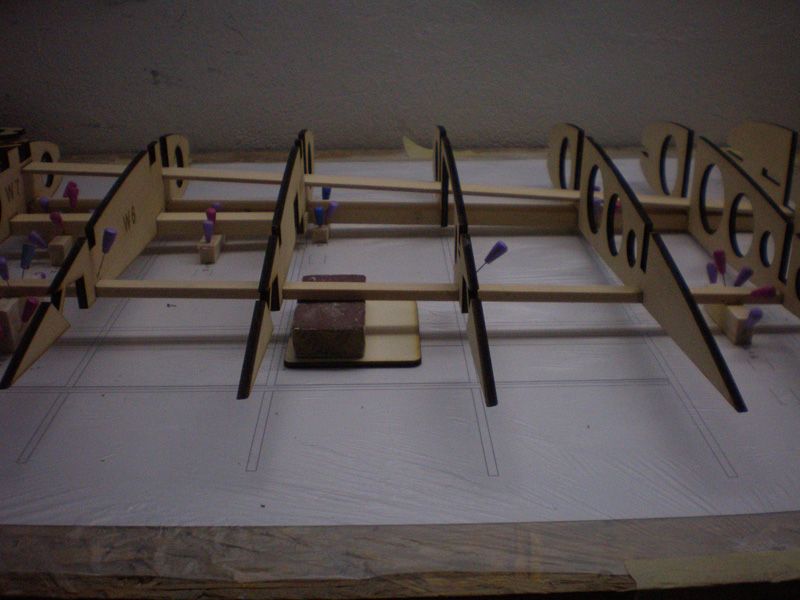

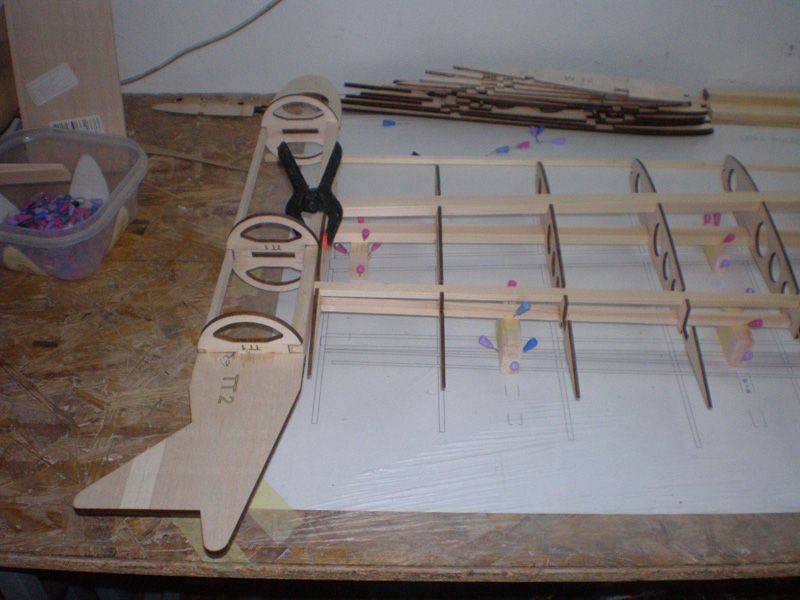

For ribs I made crutch...

When I put ribs on crutch, it fits perfectly...

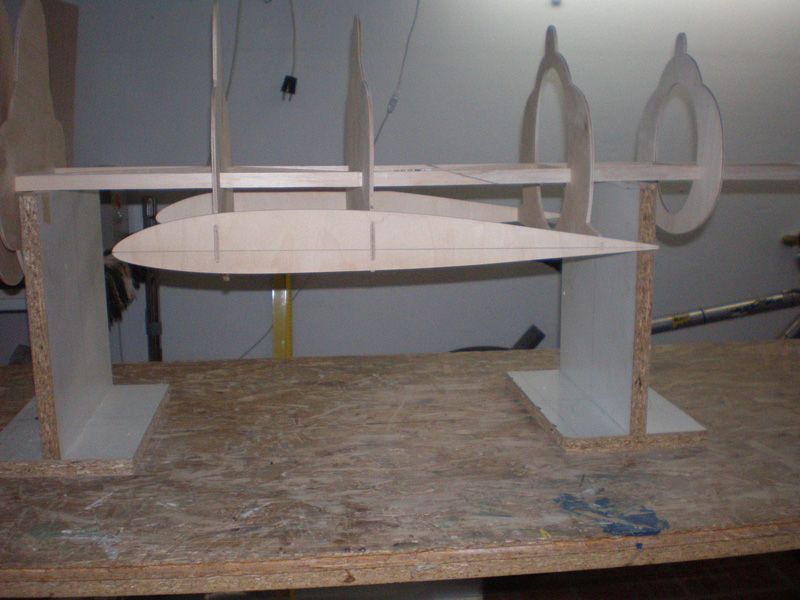

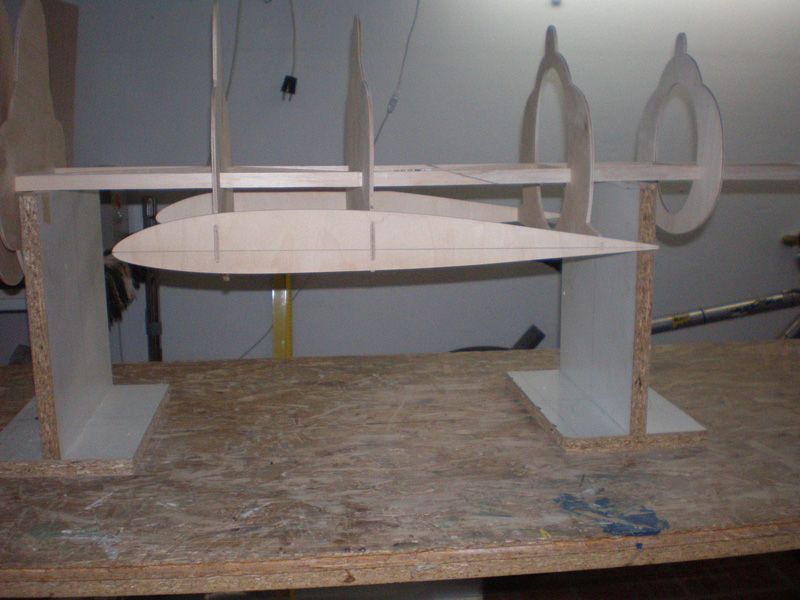

For now, this is fuselage...

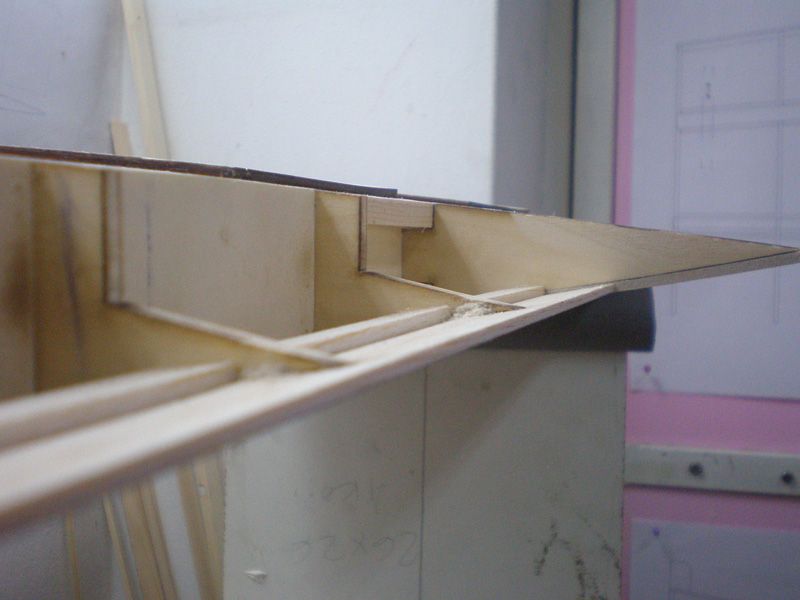

Wing angle of attack is already built...

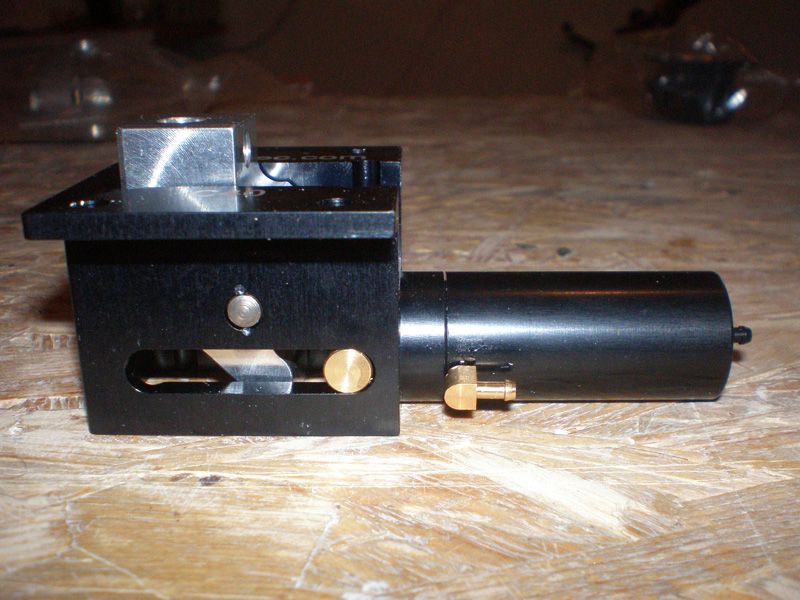

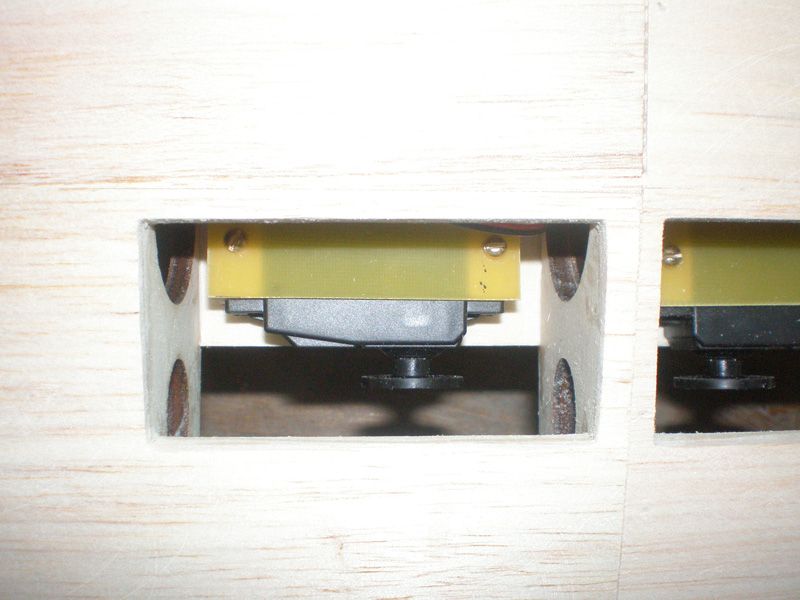

From German firm Behotec I ordered complete retract system. Plans for kit of this project, will be made for those retracts.

Behotec's retracts are high quality, and price is very acceptable...

Best regards

Mirce

In last ten days many things happened with this project.

I exchanged more than 15 mails with Ali, and he told me many interesting things. Ali have an amazing experience, so any advice is very important to me. Thank you Ali...

Man I needed to make the wings of Styrofoam canceled the cooperation, so I returned to plan to made constructive wing. I need to draw again plans, but constructive wings are for me best option.

Few days ago I visit our sport airport and take down all measure I need to made final drawings for fuselage, wings and tail section.

When I come home and comparing measures I was very pleased when saw how much my drawings are precise.

With measure I take from airplane, I have now all I need to start making wing and elevator.

In meantime, I made all ribs for fuselage. This are ribs which I drew from JPG's I get for Galeb G2. I have invested a lot of work to set all parameters for fuselage. Of course, this is just first step, I must work on fuselage, and all I made to draw back on plan.

For now it look like this:

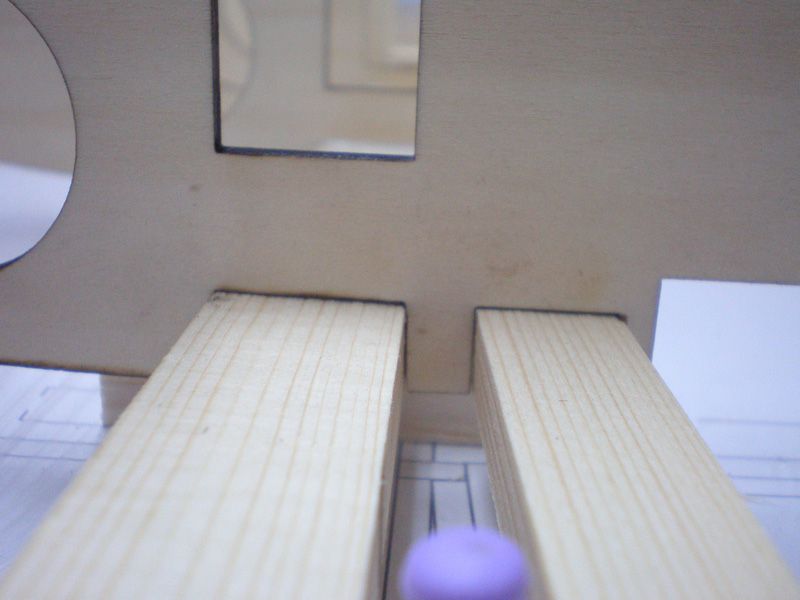

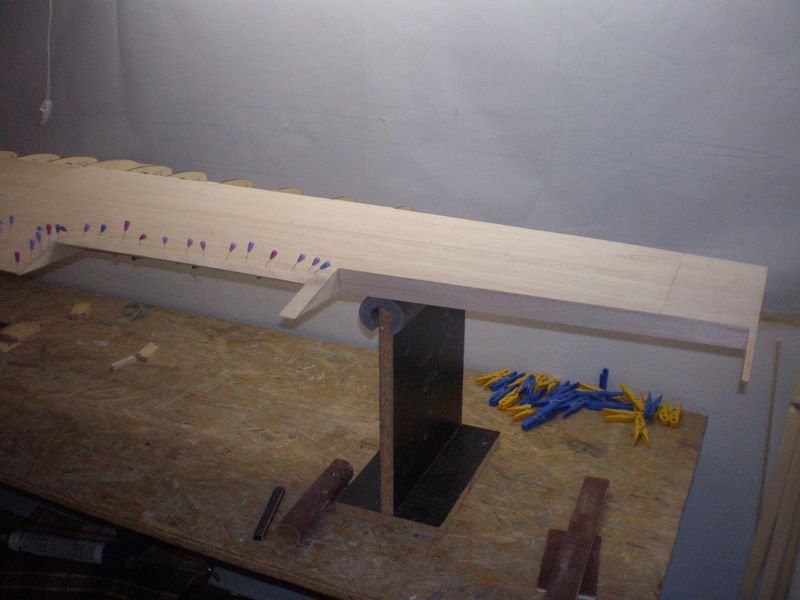

For ribs I made crutch...

When I put ribs on crutch, it fits perfectly...

For now, this is fuselage...

Wing angle of attack is already built...

From German firm Behotec I ordered complete retract system. Plans for kit of this project, will be made for those retracts.

Behotec's retracts are high quality, and price is very acceptable...

Best regards

Mirce

REGARDS

#27

Thread Starter

Hello again...

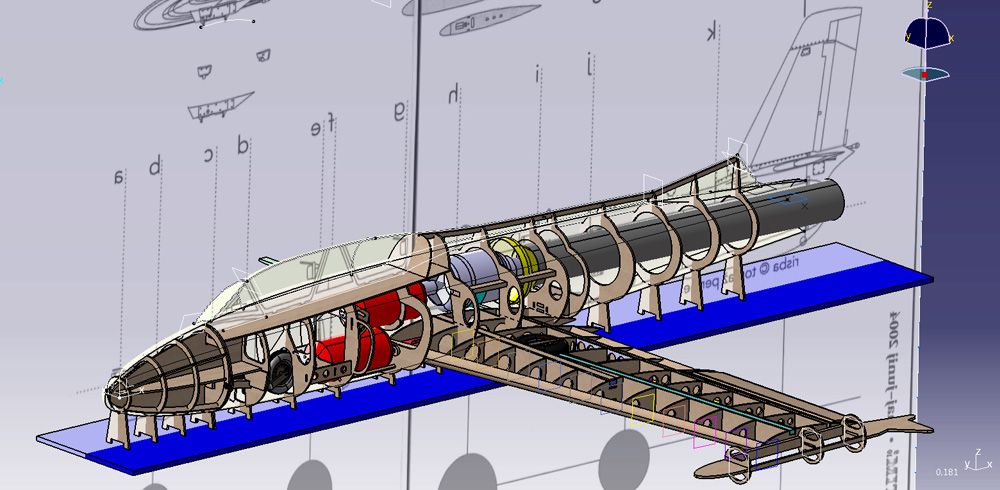

As you can see, I was nothing write about my Galeb G2 project until April.

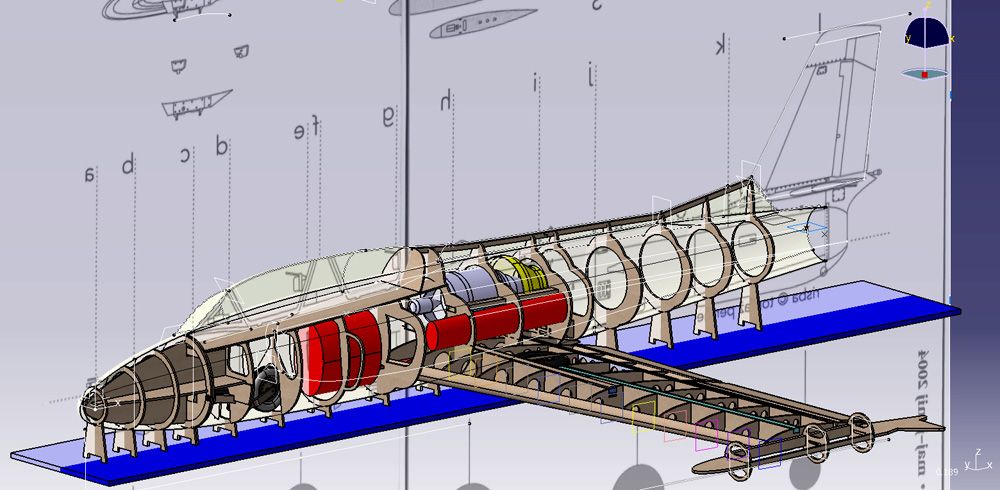

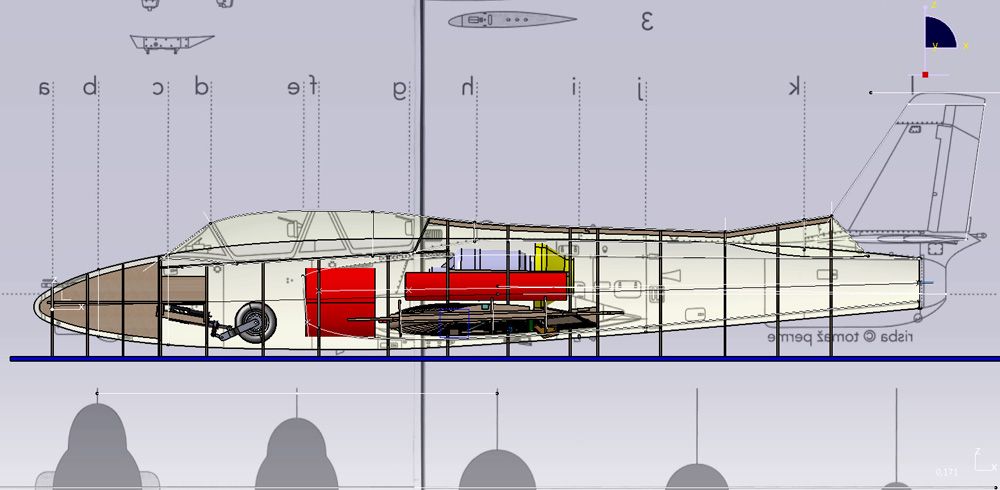

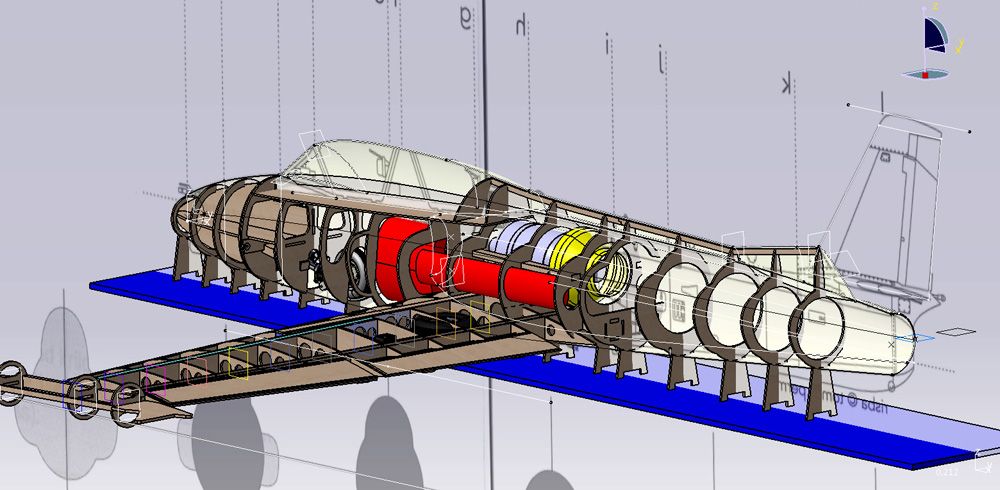

For it has few reasons, one is I want to finish my warbird model project I'm working on, and more important, I must find someone who will made good quality 3D drawing of Galeb G2.

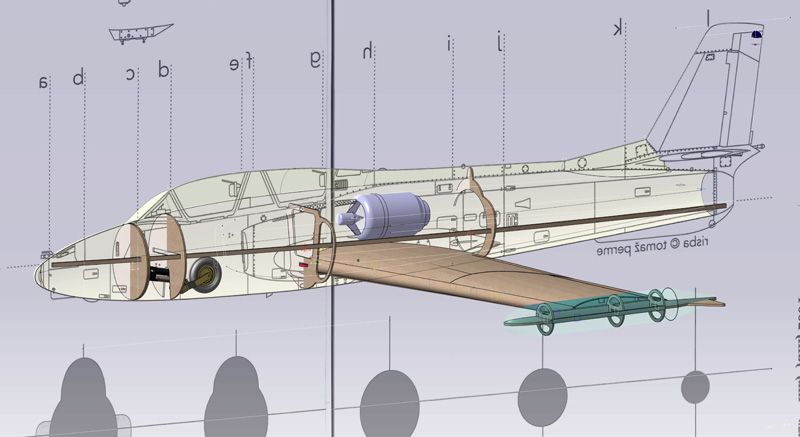

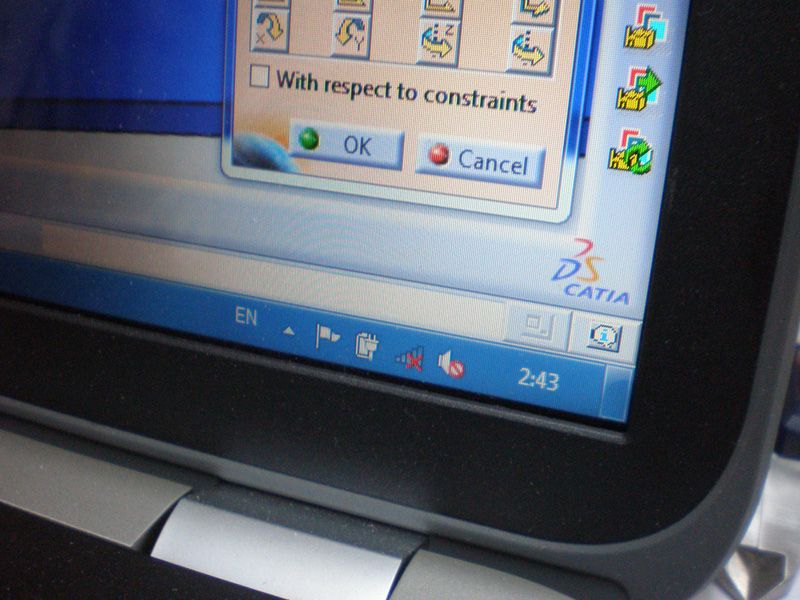

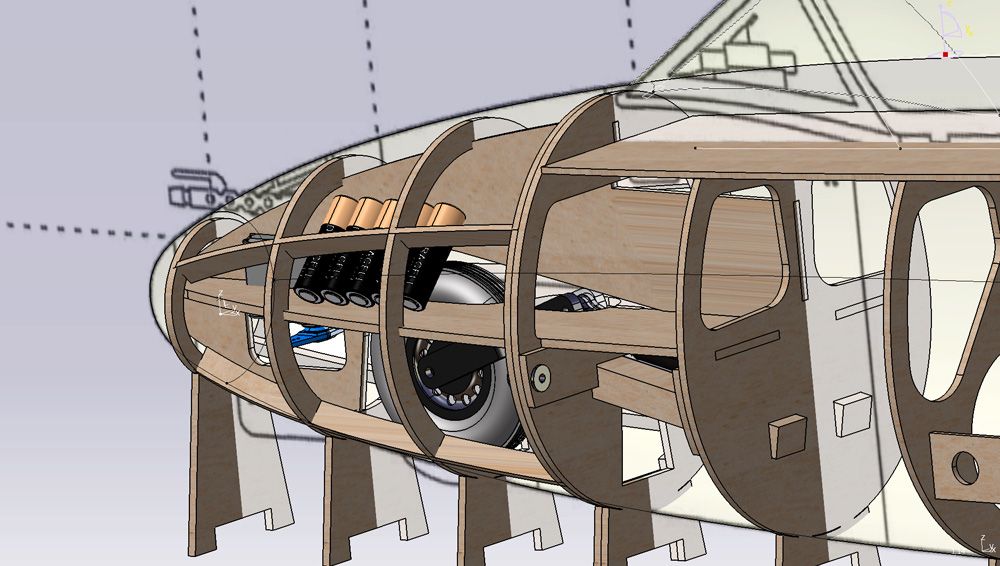

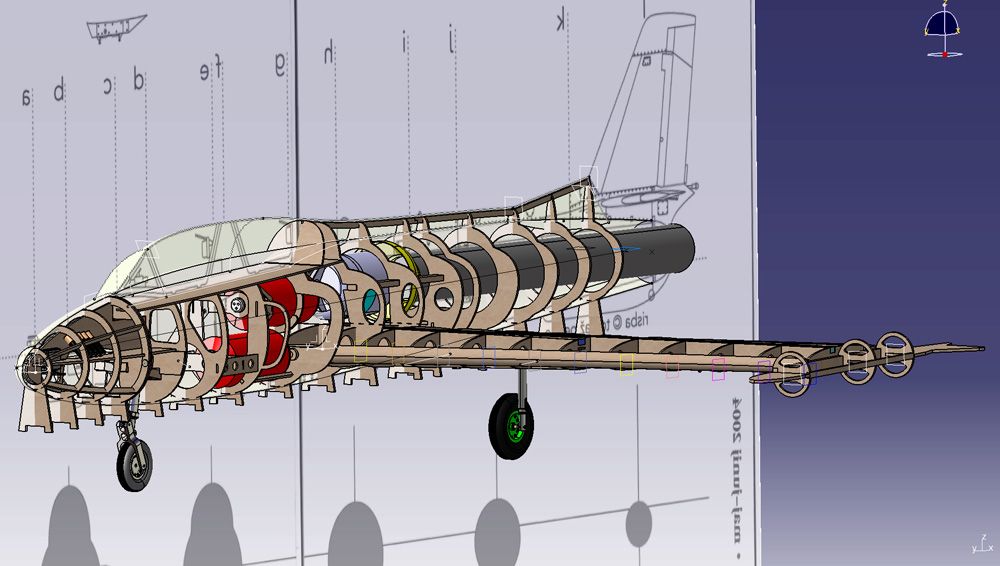

So, in meantime I get to know and start working with Martin, my new friend and fellow in this story.

Martin is wizard for Catia - 3D program... His regular job is making projects for firm in which he work, so he is more than capable to made high quality 3D drawings.

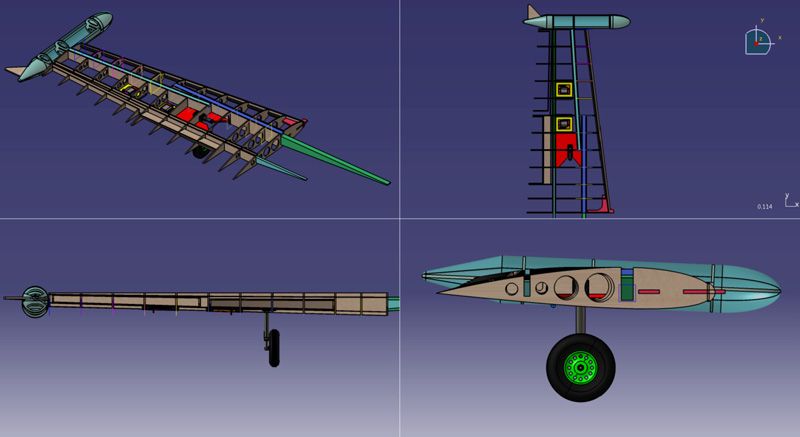

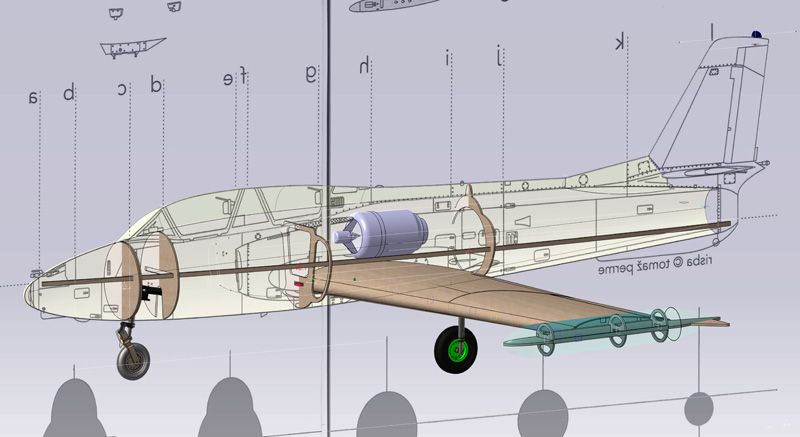

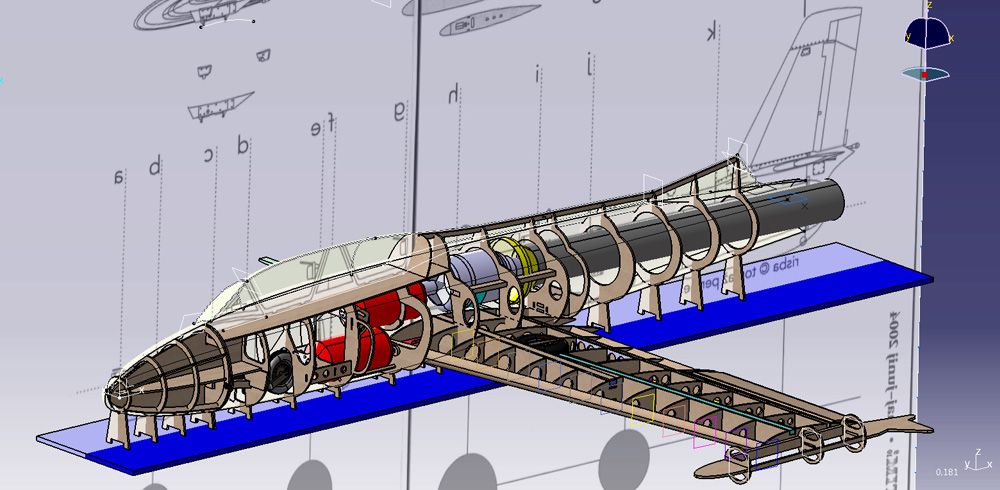

In last two months we are working on the Galeb G2 wing. If you remember, Galeb G2 will be exactly 1/5 scale of real airplane.

I have few conceptions how to made a wing, and finally with the help of friends, who are mechanical engineers, we find, I think best solutions.

Don't forget, I want to made and sell kit from this model, so I must thinking how modelers will be the easiest and most convenient to make this jet.

Galeb G2 will be wooden kit, with few plastic parts - canopy, wing tips...

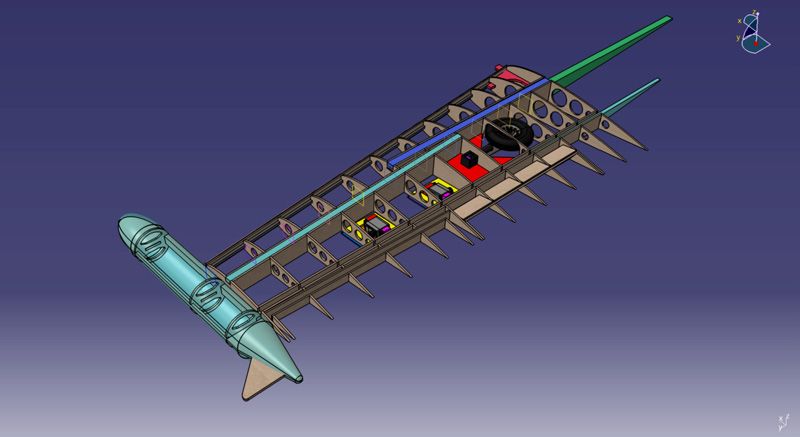

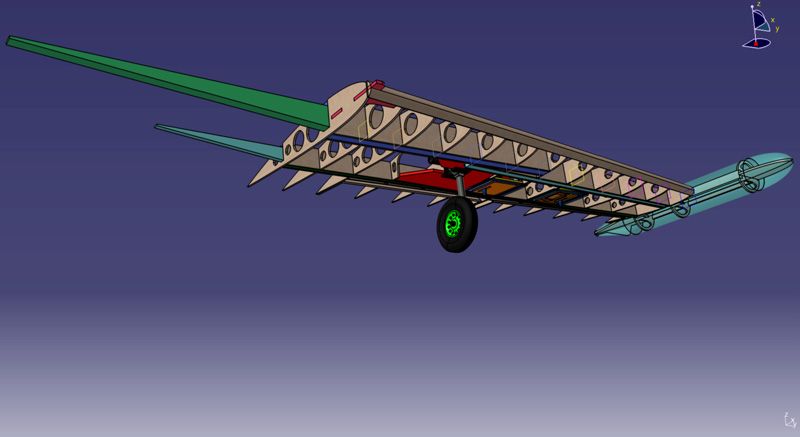

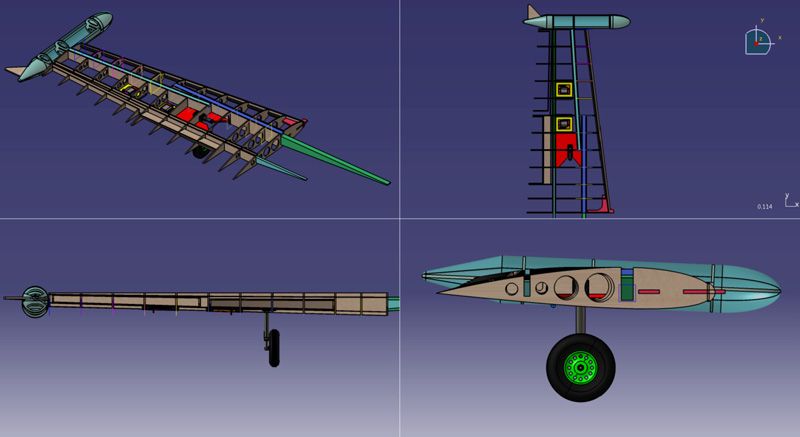

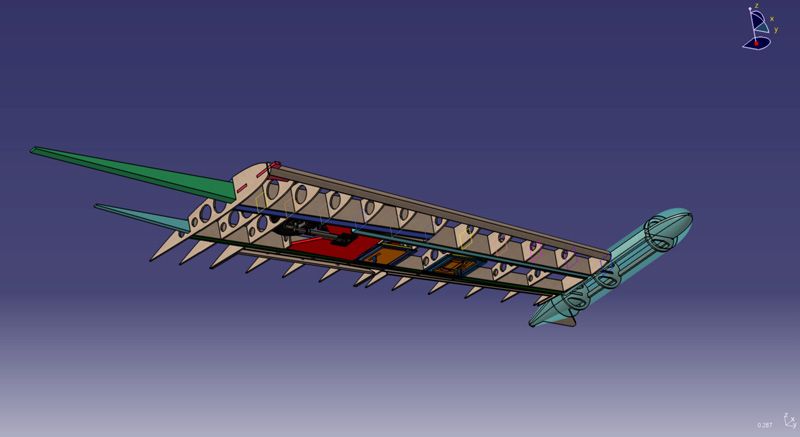

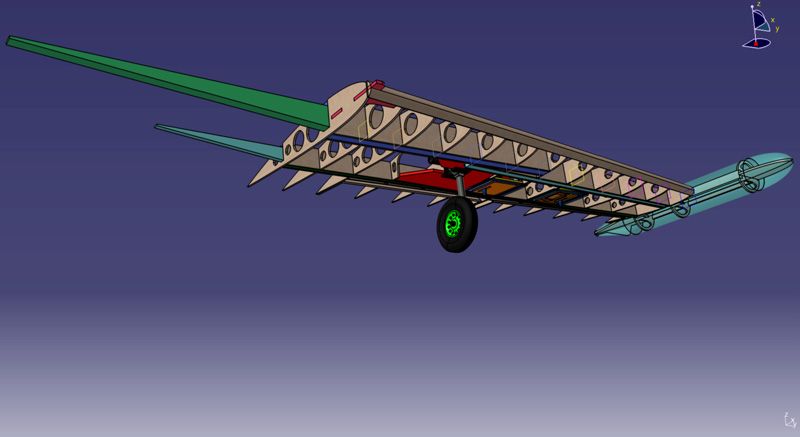

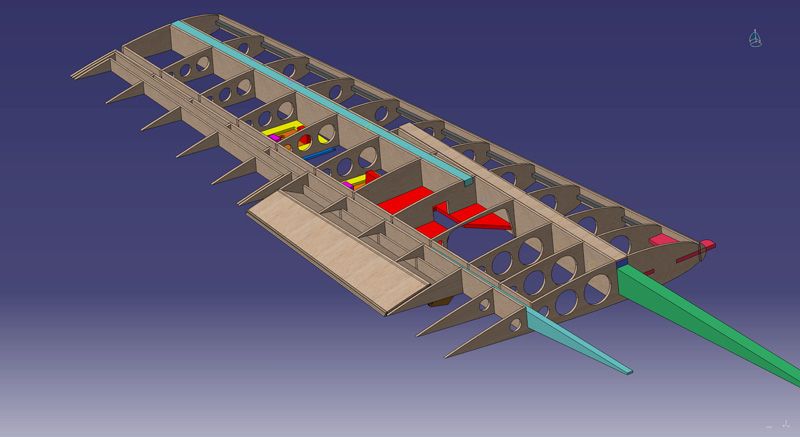

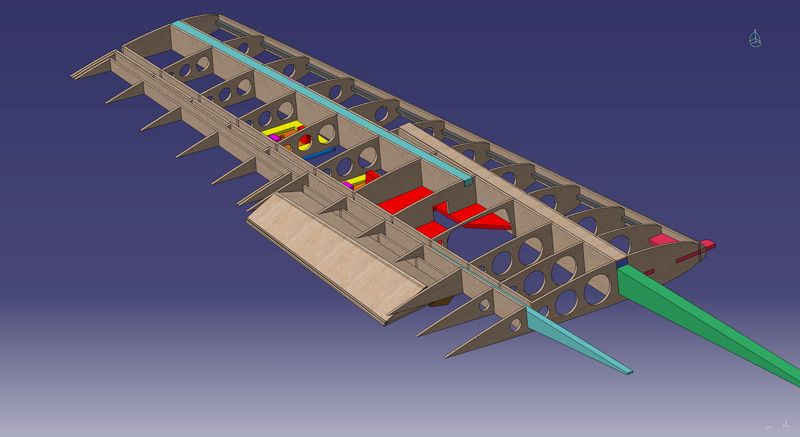

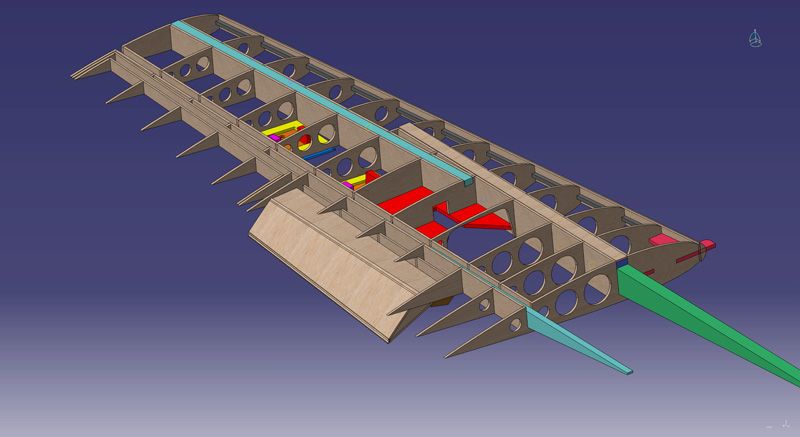

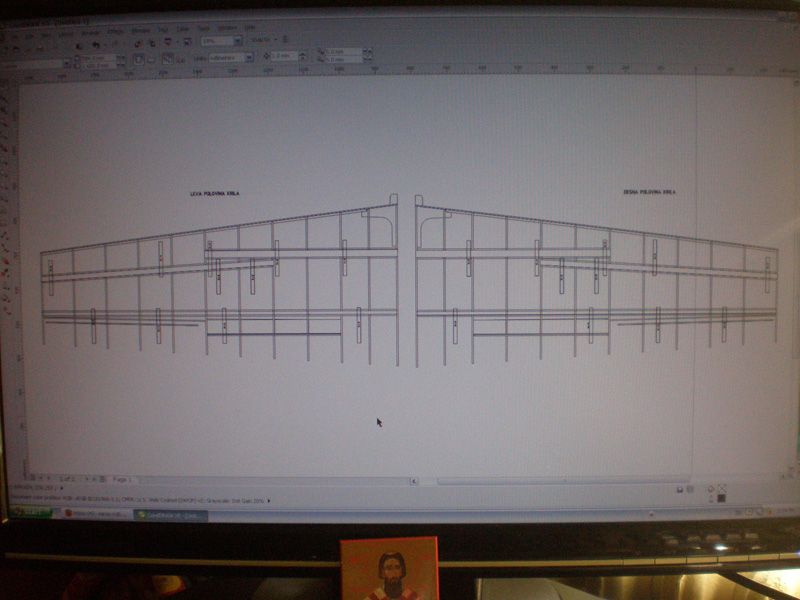

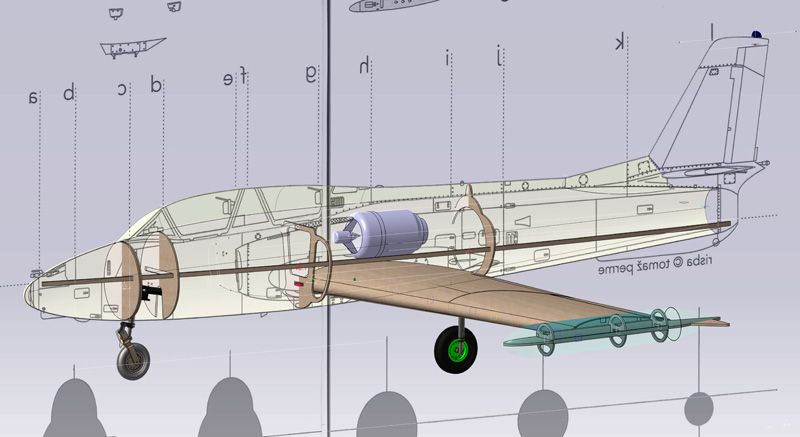

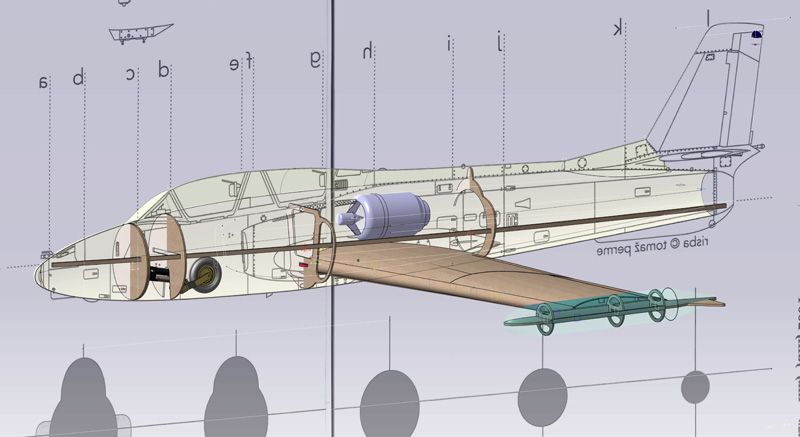

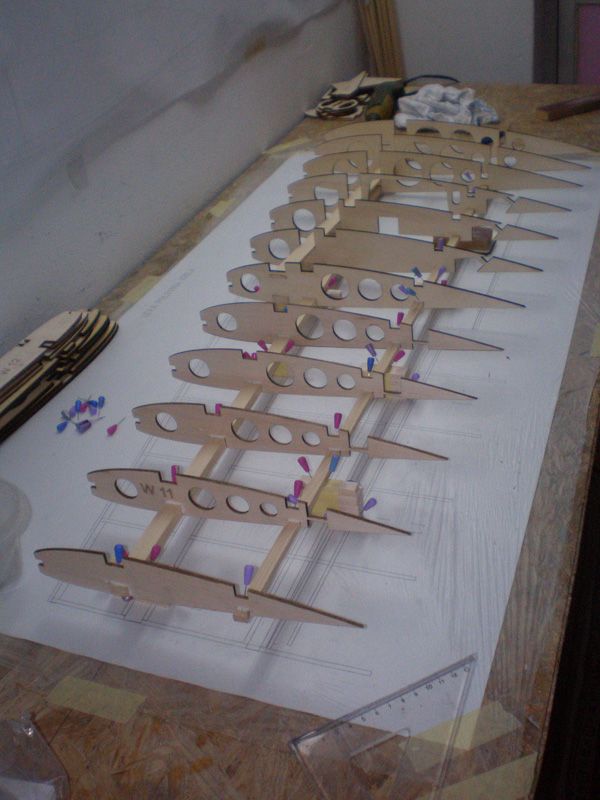

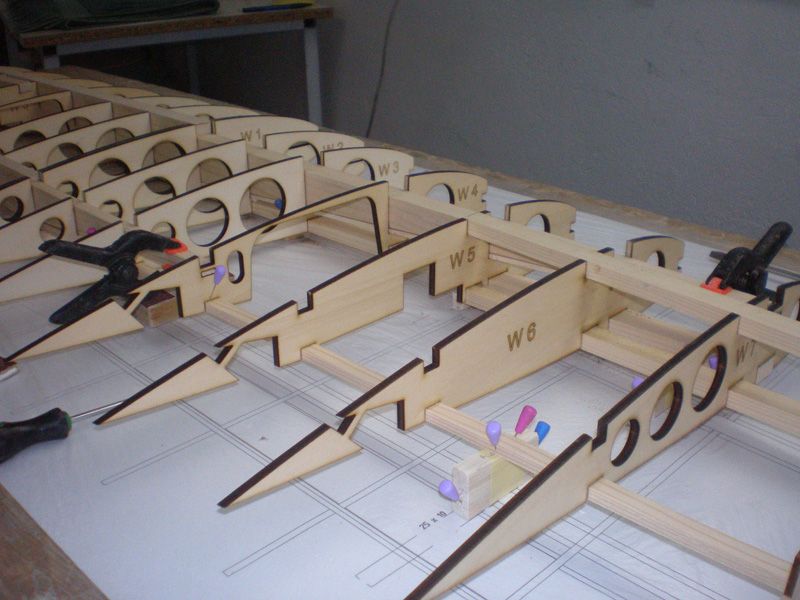

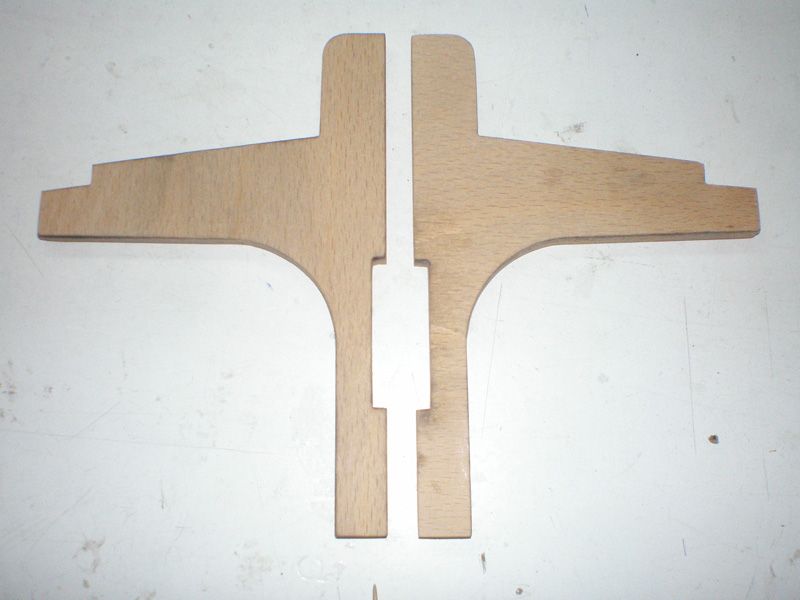

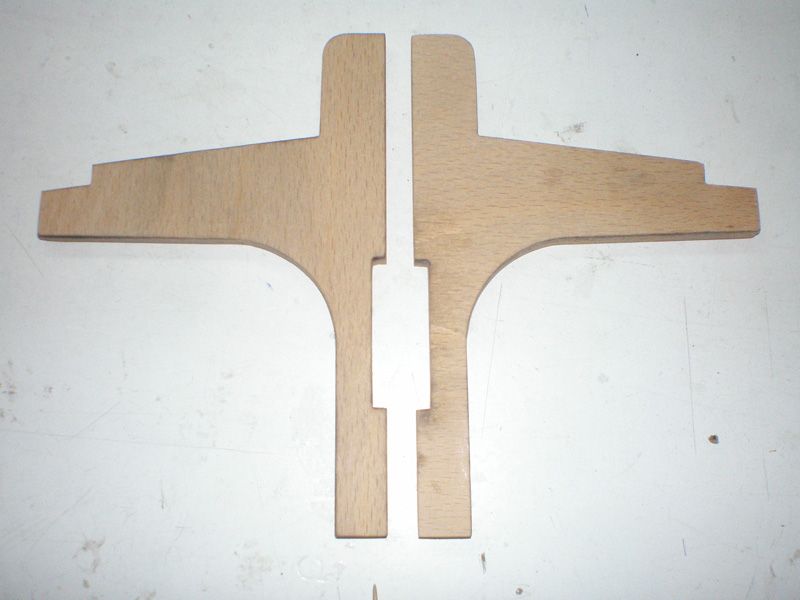

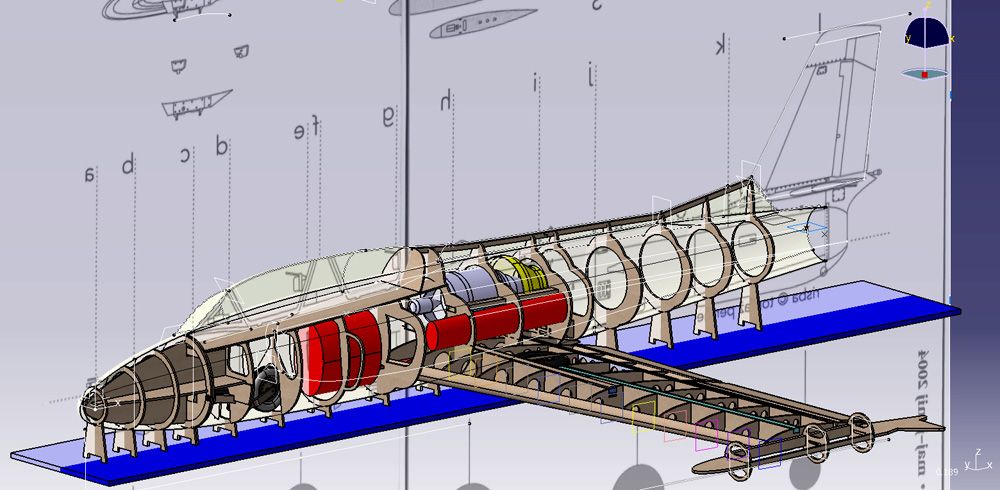

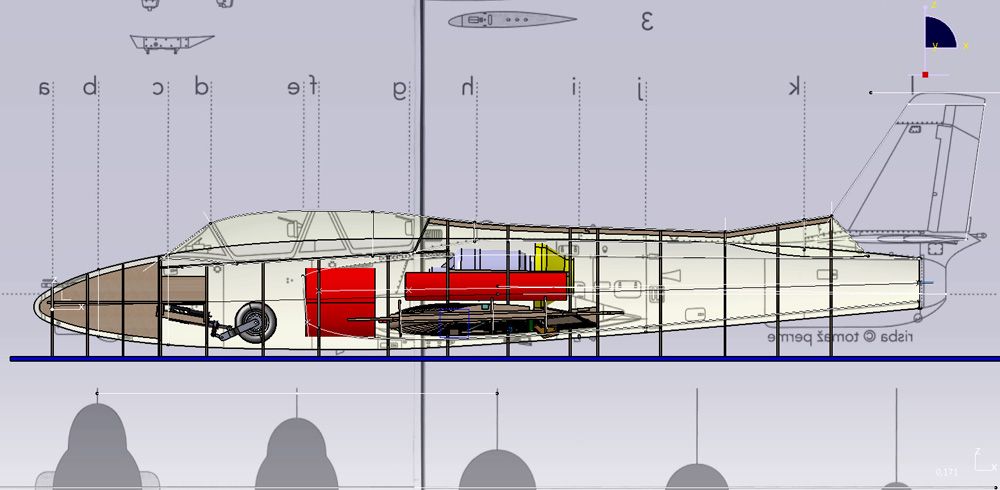

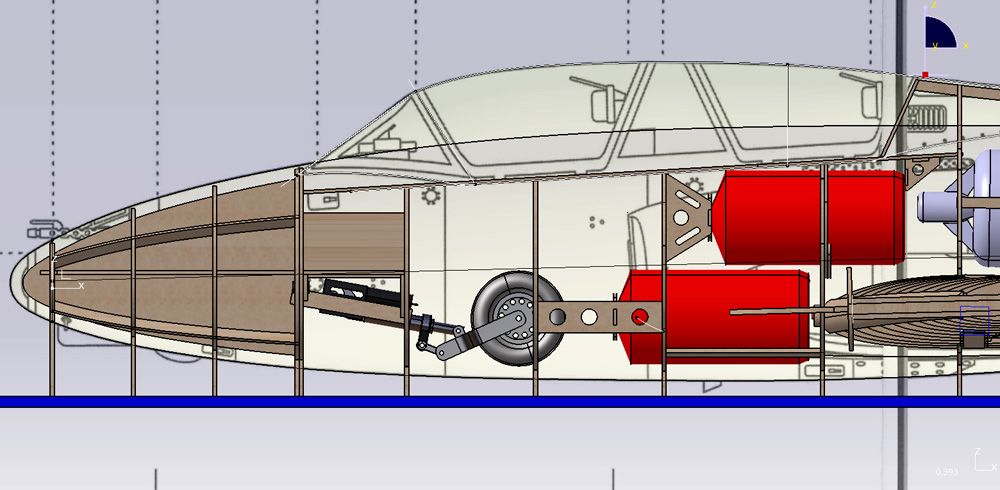

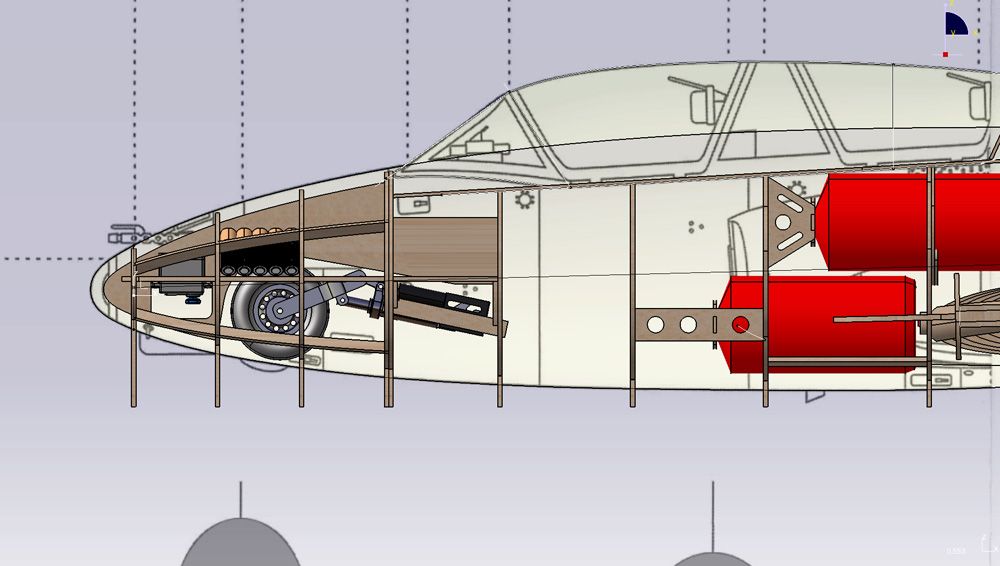

We are working on the wing first. Here is some pictures, how it look in this stage...

Wingspan is 81" or 2060 mm, with tip tanks 91,3" - 2320 mm.

Landing gears are in the middle of the wing, and they determine the structure of other parts. Because that, main spar will be two piece, with fold over three ribs.

In space between front main spar, will come big wooden wing joiner.

Small wooden wing joiner will be in the rear spar.

Ribs from the root of the wing to the end of the landing gear panel, will be from poplar plywood, and ribs to the end of the wing will be from balsa.

Space between spars will be closed with ply or balsa plates, and that will give stiff and strong construction.

Ribs will have washout for better stability on slow speed. Tip tanks will just increase that stability.

Tip tanks will be made from two part plastic. In kit will be balsa construction which will be glued on last wing rib. On that construction setting of the tip tank will be very easy job.

Landing gear plate will be made from 6 mm plywood and it will be glued on the front and rear ply which will connect upper and lower spars. That will give strong support and help with bad landings.

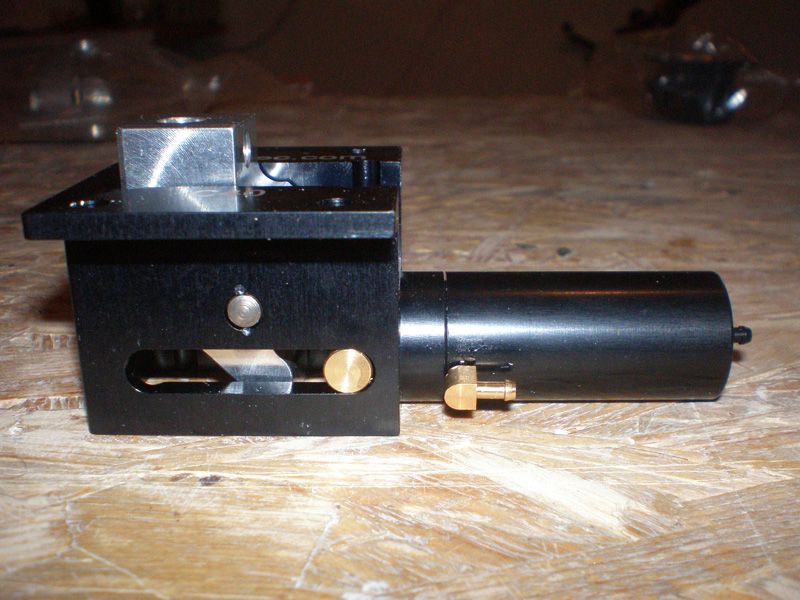

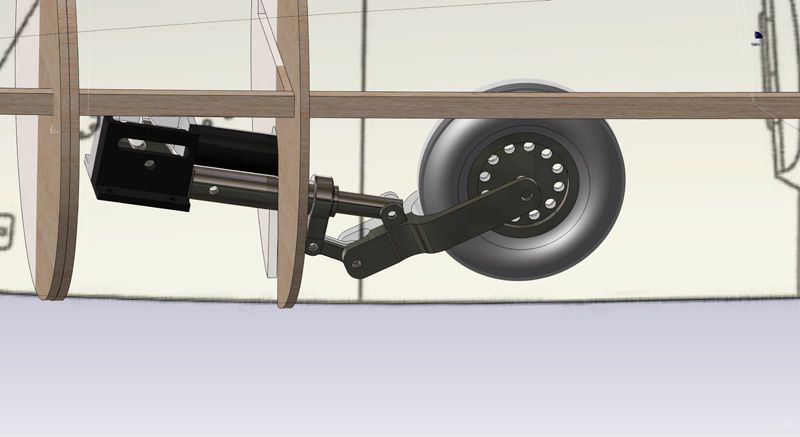

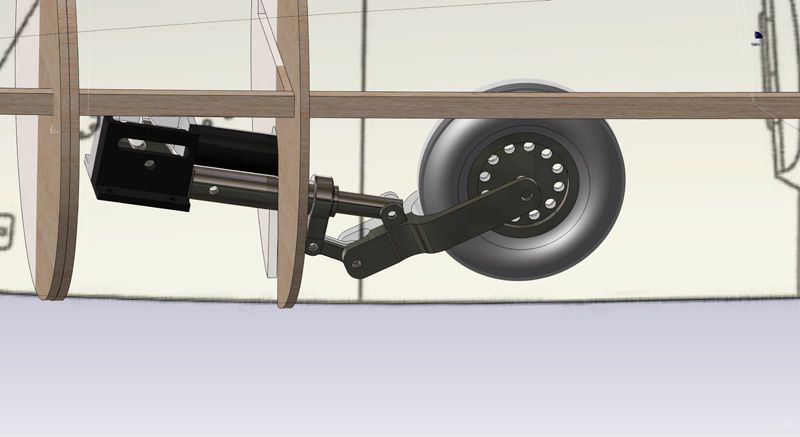

As I write earlier in this topic, I bought landing gears in German firm Behotec ( www.behotec.de ). They are top quality...

Front leg...

Main retracts...

And few pictures of difference in size between Ziroli Panther and Galeb retracts...

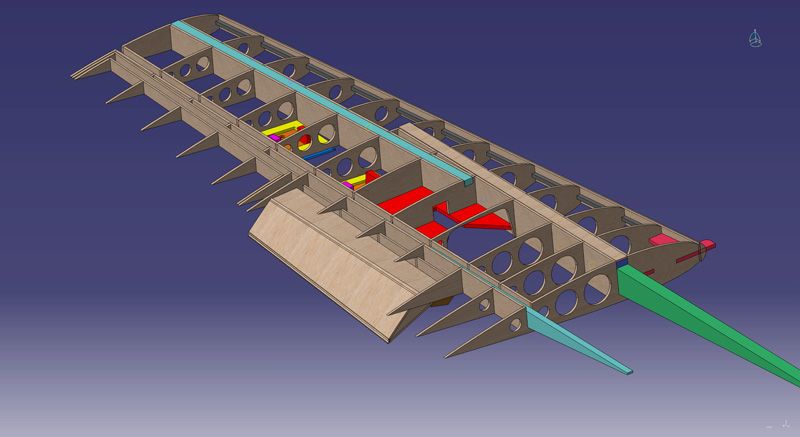

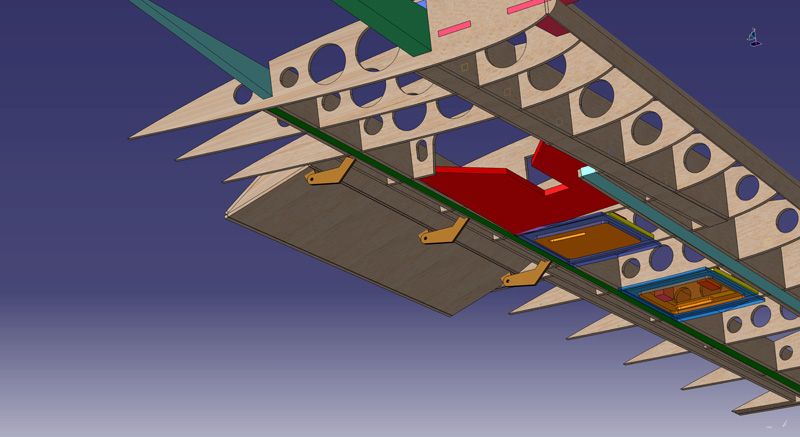

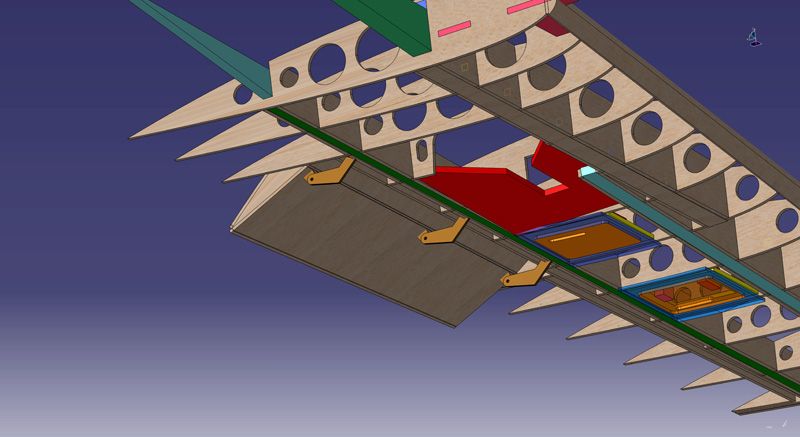

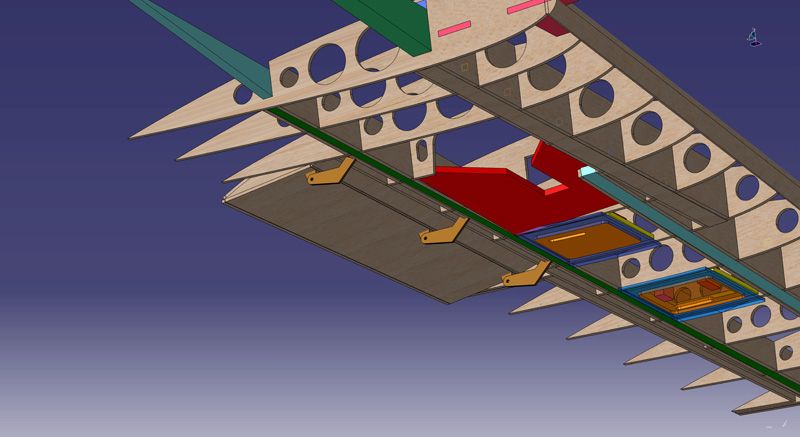

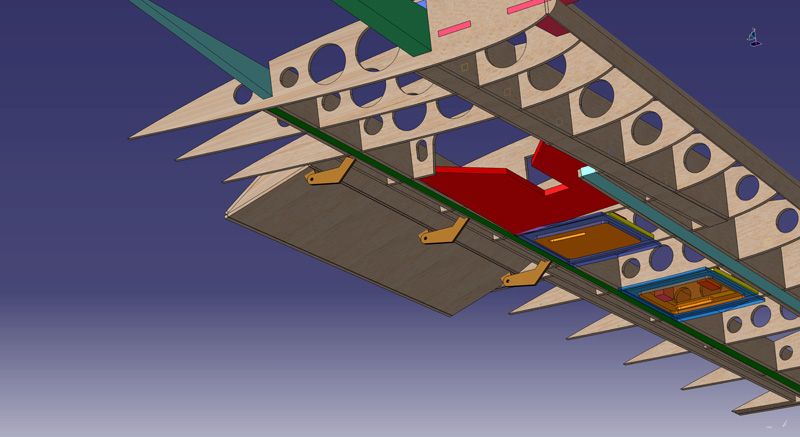

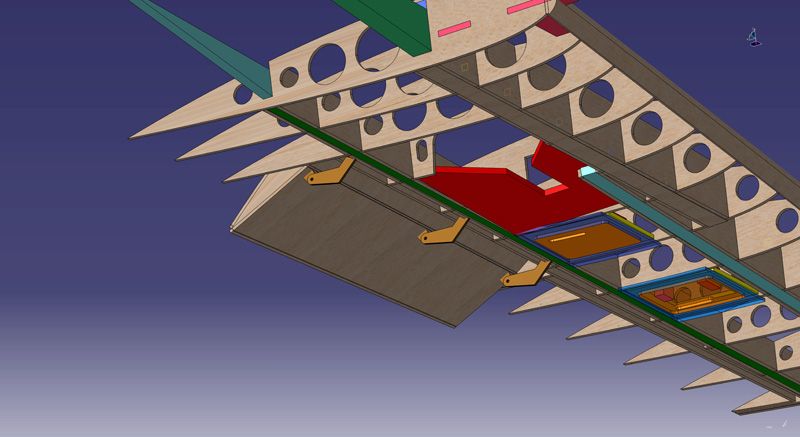

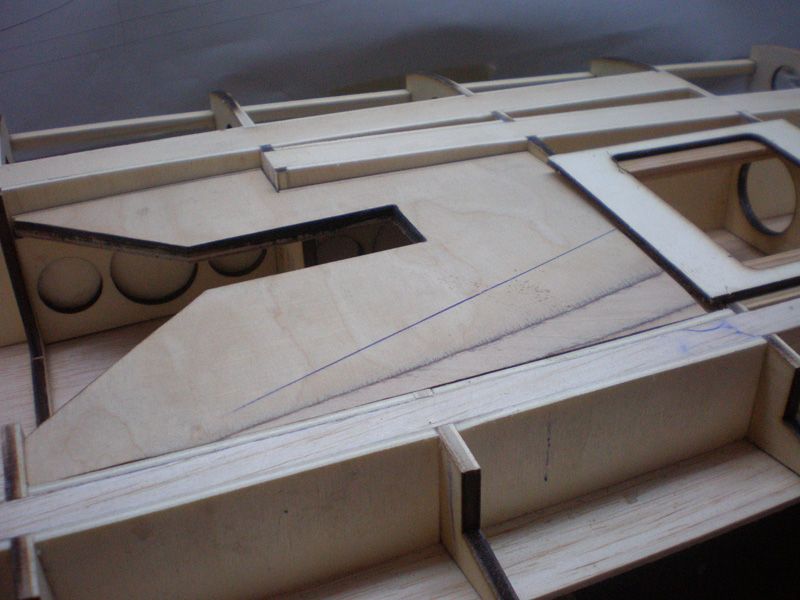

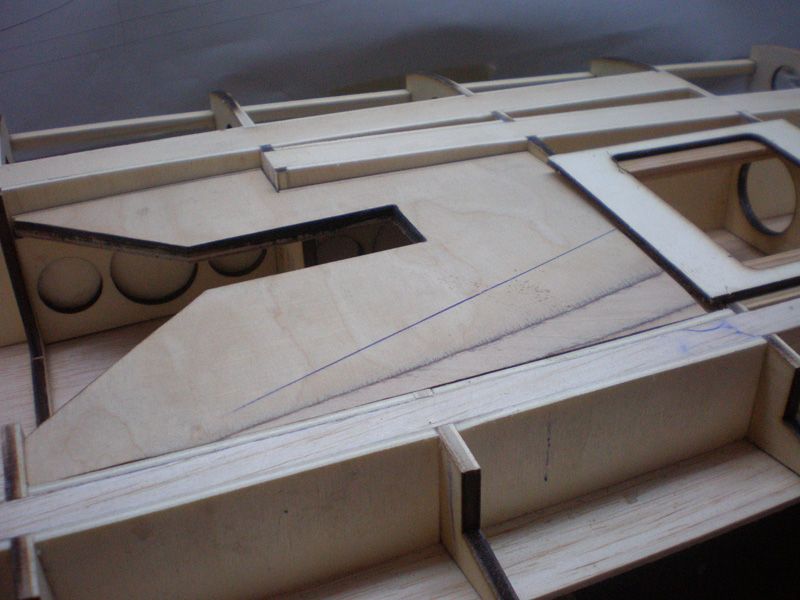

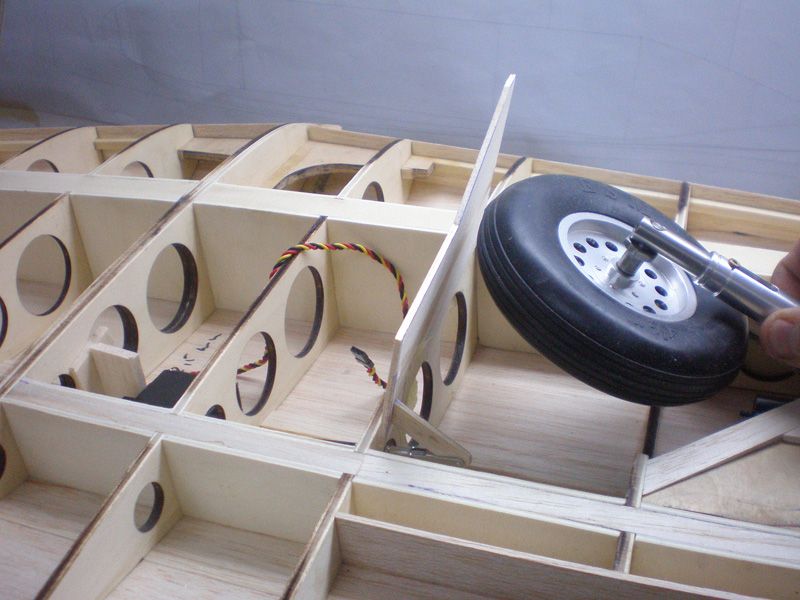

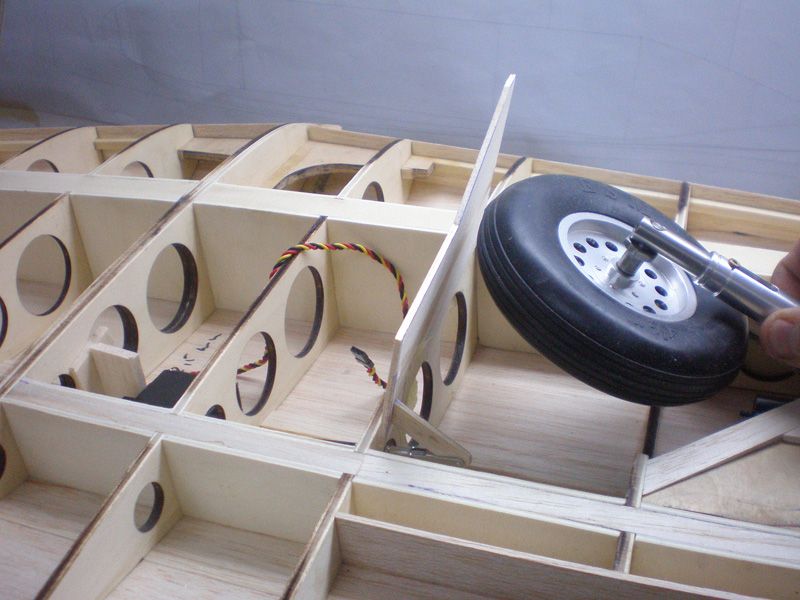

Here is pictures of wing & retract construction...

Galeb G2 have very short main legs, so I have a problem to find exactly 1/5 scale retracts. This Behotec is best option for that...

So this is it for now. In mean time Martin is almost finish everything on the wing, and now he is working on the fuselage. When he made drawing for wing - fuselage connect I'll start working on the wing.

Can't wait...

This topic will show all steps in that building, and it can be use like manual in the future...

Regards

Mirce

As you can see, I was nothing write about my Galeb G2 project until April.

For it has few reasons, one is I want to finish my warbird model project I'm working on, and more important, I must find someone who will made good quality 3D drawing of Galeb G2.

So, in meantime I get to know and start working with Martin, my new friend and fellow in this story.

Martin is wizard for Catia - 3D program... His regular job is making projects for firm in which he work, so he is more than capable to made high quality 3D drawings.

In last two months we are working on the Galeb G2 wing. If you remember, Galeb G2 will be exactly 1/5 scale of real airplane.

I have few conceptions how to made a wing, and finally with the help of friends, who are mechanical engineers, we find, I think best solutions.

Don't forget, I want to made and sell kit from this model, so I must thinking how modelers will be the easiest and most convenient to make this jet.

Galeb G2 will be wooden kit, with few plastic parts - canopy, wing tips...

We are working on the wing first. Here is some pictures, how it look in this stage...

Wingspan is 81" or 2060 mm, with tip tanks 91,3" - 2320 mm.

Landing gears are in the middle of the wing, and they determine the structure of other parts. Because that, main spar will be two piece, with fold over three ribs.

In space between front main spar, will come big wooden wing joiner.

Small wooden wing joiner will be in the rear spar.

Ribs from the root of the wing to the end of the landing gear panel, will be from poplar plywood, and ribs to the end of the wing will be from balsa.

Space between spars will be closed with ply or balsa plates, and that will give stiff and strong construction.

Ribs will have washout for better stability on slow speed. Tip tanks will just increase that stability.

Tip tanks will be made from two part plastic. In kit will be balsa construction which will be glued on last wing rib. On that construction setting of the tip tank will be very easy job.

Landing gear plate will be made from 6 mm plywood and it will be glued on the front and rear ply which will connect upper and lower spars. That will give strong support and help with bad landings.

As I write earlier in this topic, I bought landing gears in German firm Behotec ( www.behotec.de ). They are top quality...

Front leg...

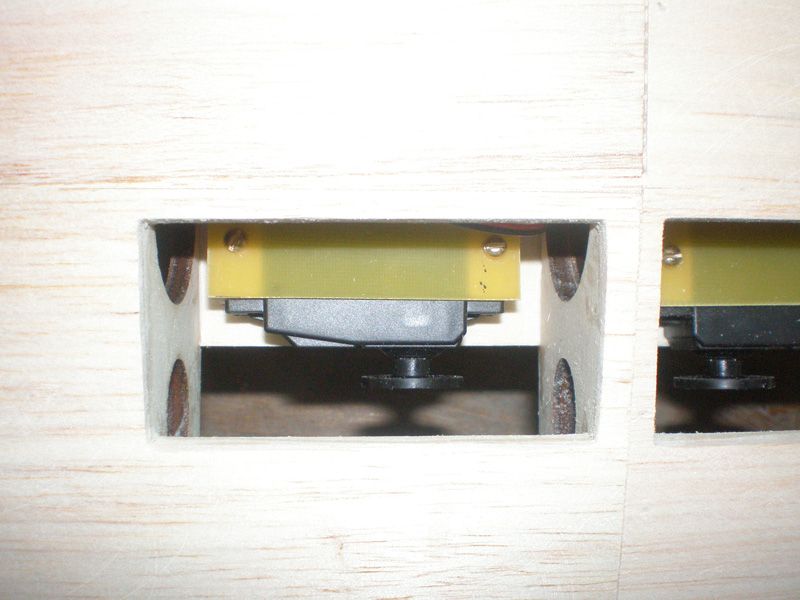

Main retracts...

And few pictures of difference in size between Ziroli Panther and Galeb retracts...

Here is pictures of wing & retract construction...

Galeb G2 have very short main legs, so I have a problem to find exactly 1/5 scale retracts. This Behotec is best option for that...

So this is it for now. In mean time Martin is almost finish everything on the wing, and now he is working on the fuselage. When he made drawing for wing - fuselage connect I'll start working on the wing.

Can't wait...

This topic will show all steps in that building, and it can be use like manual in the future...

Regards

Mirce

#28

Thread Starter

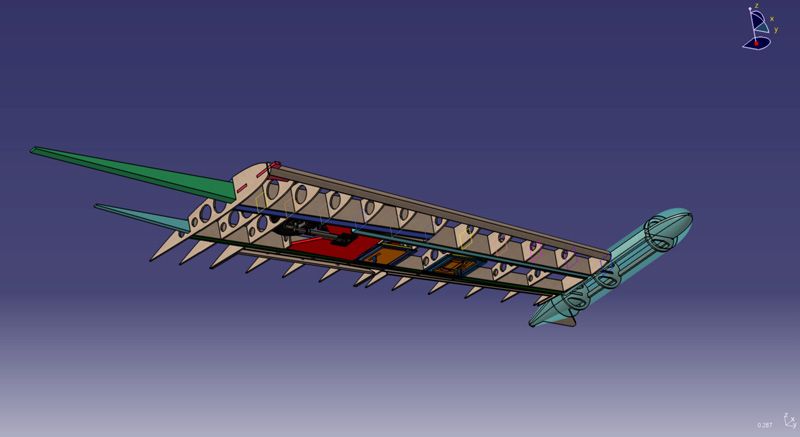

Few more pictures...

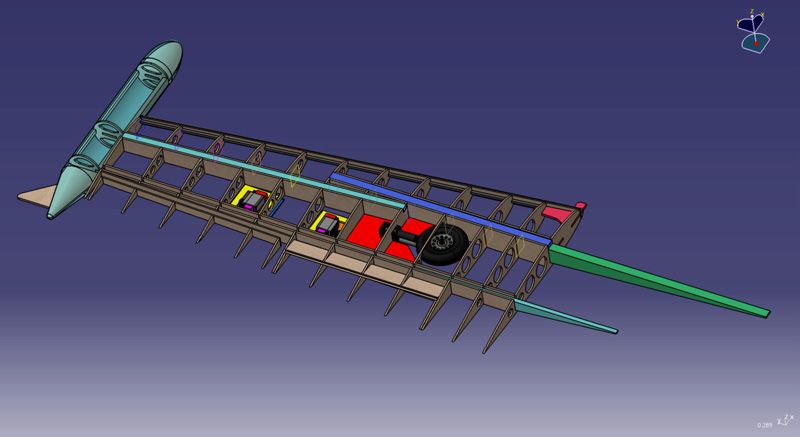

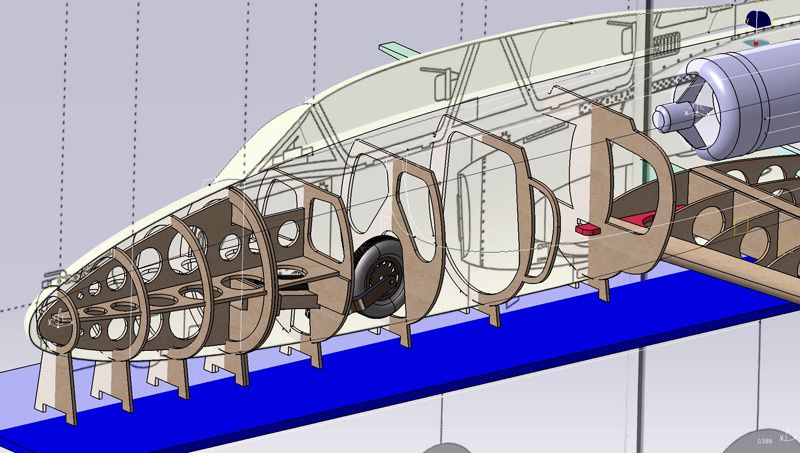

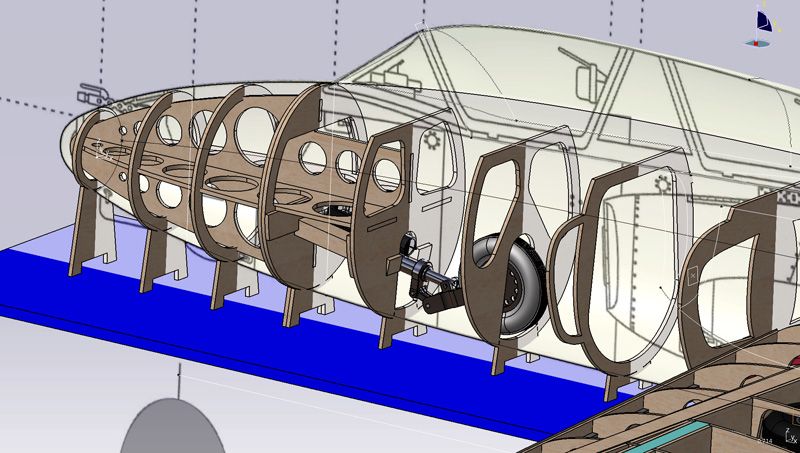

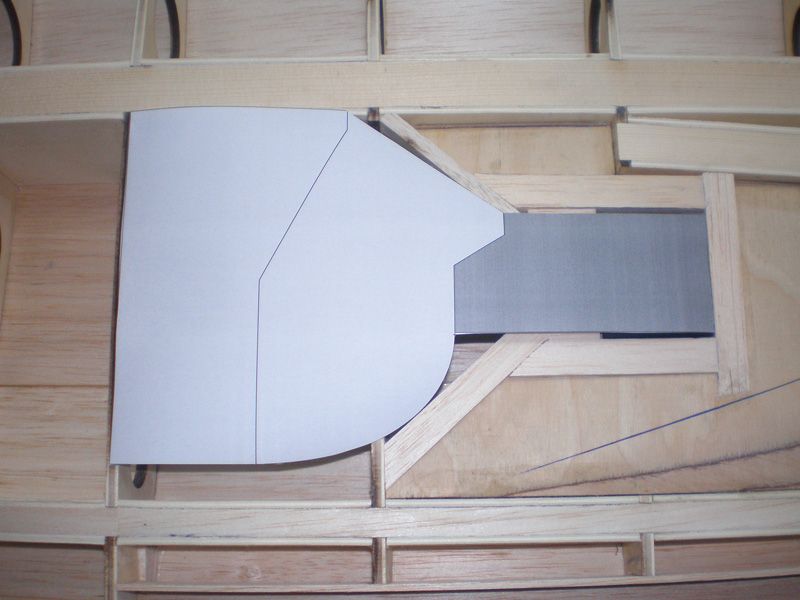

Martin started work on the fuselage and wings blend...

Flaps...

From other angle...

Flaps is similar like on P 47. When flap goes in down position between flap and wing is opening gutter for air flow. That give better stability on low speed when flap is in lower position...

To be continued...

Mirce

Martin started work on the fuselage and wings blend...

Flaps...

From other angle...

Flaps is similar like on P 47. When flap goes in down position between flap and wing is opening gutter for air flow. That give better stability on low speed when flap is in lower position...

To be continued...

Mirce

#30

Thread Starter

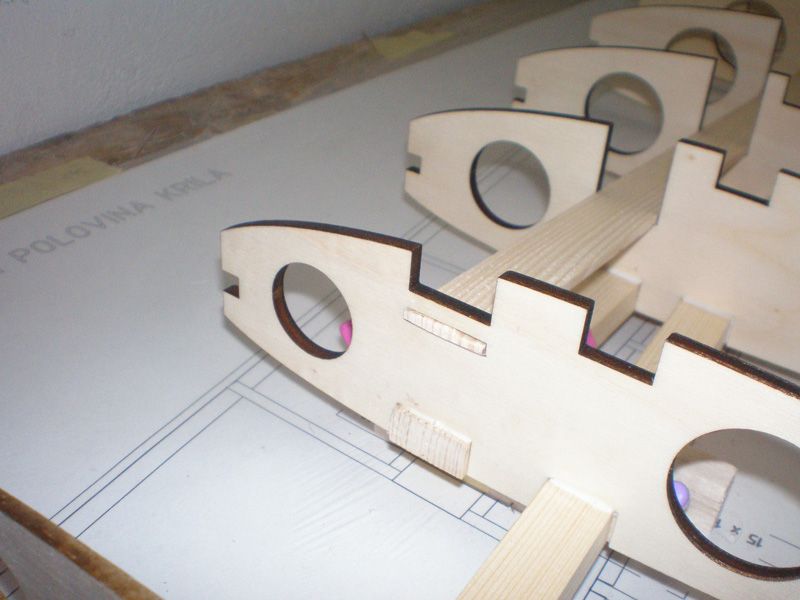

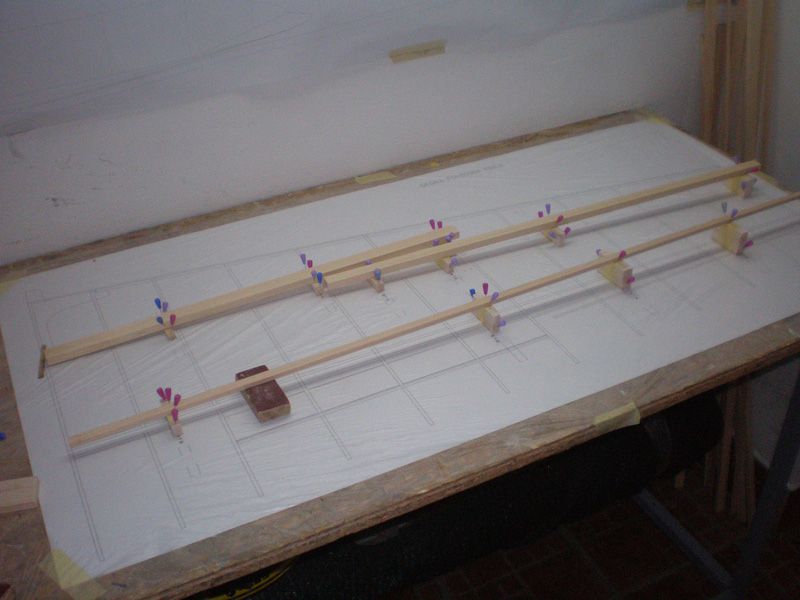

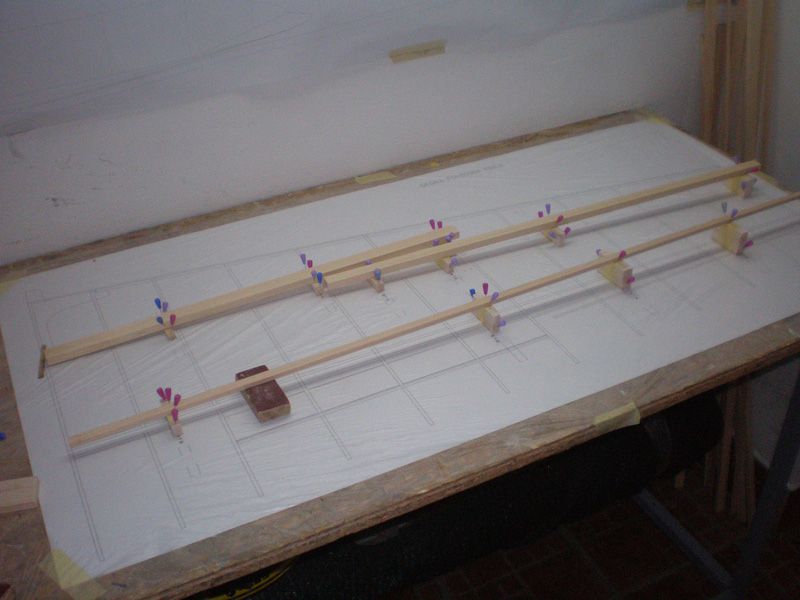

Few days ago first parts of Galeb G2 project arrived in work shop.

My friend send me all fir slats for spars, and some other wing parts. Of course, he send me 3 time more than I need....

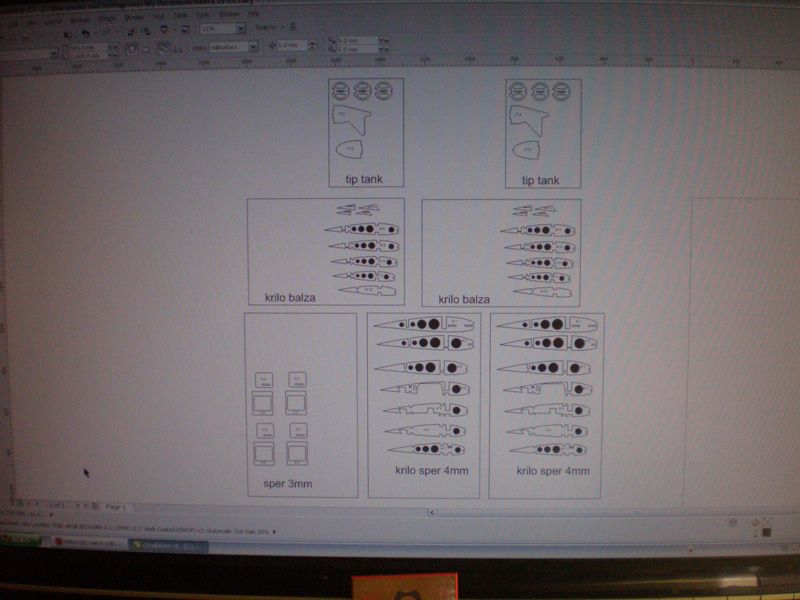

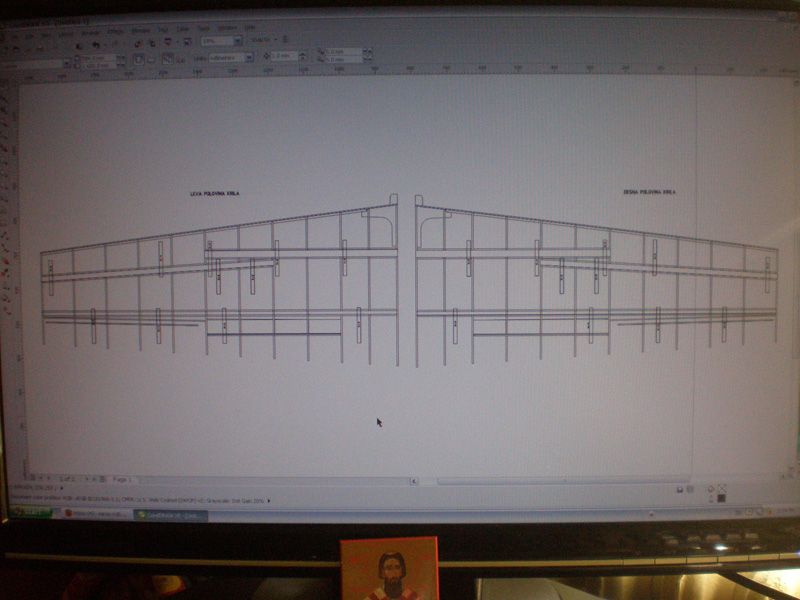

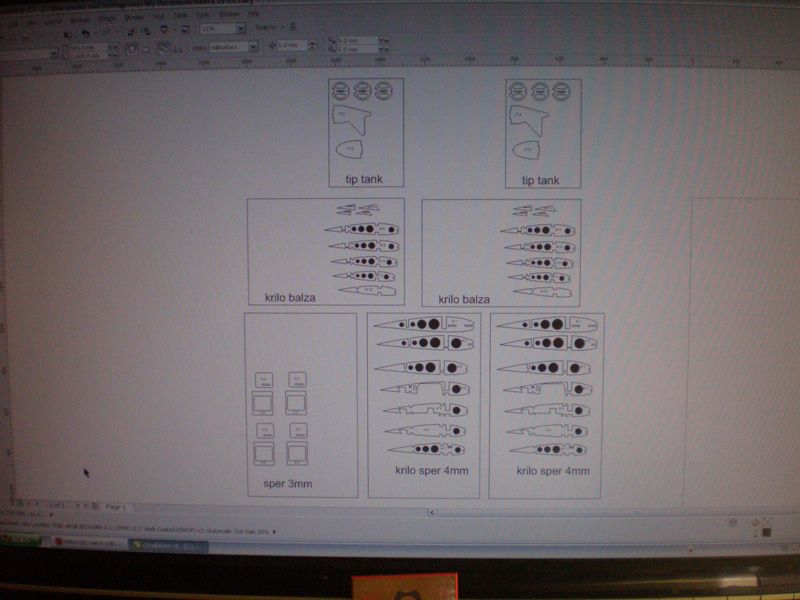

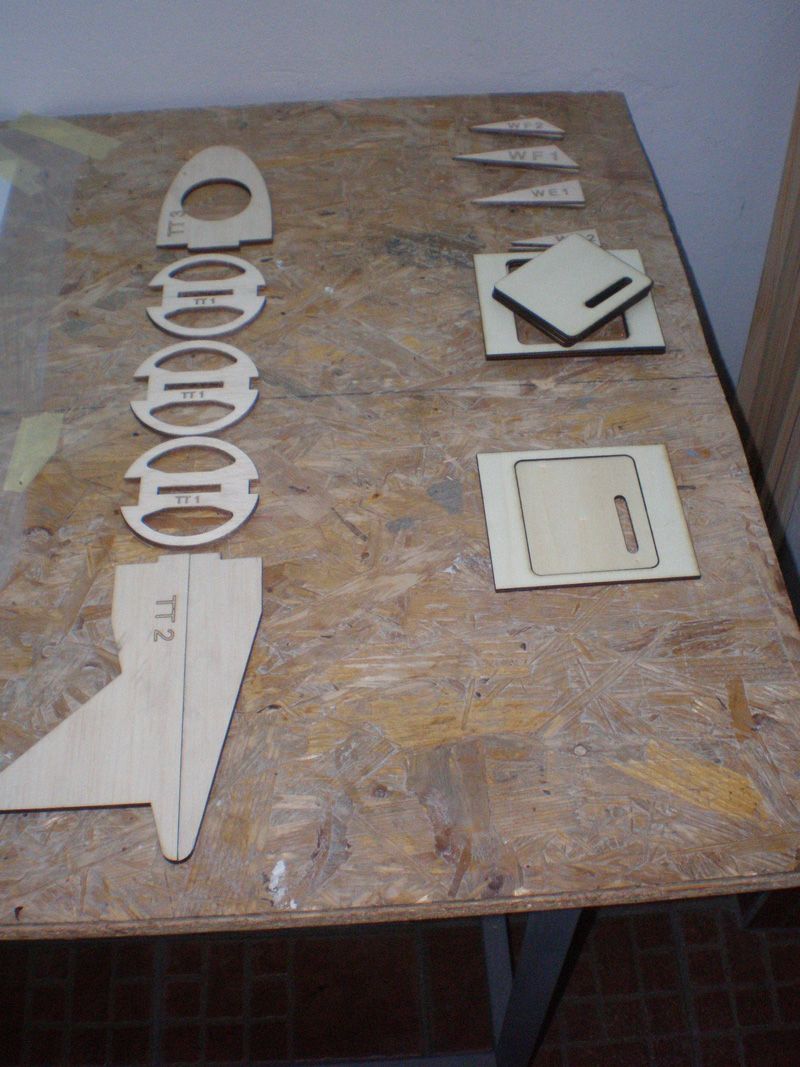

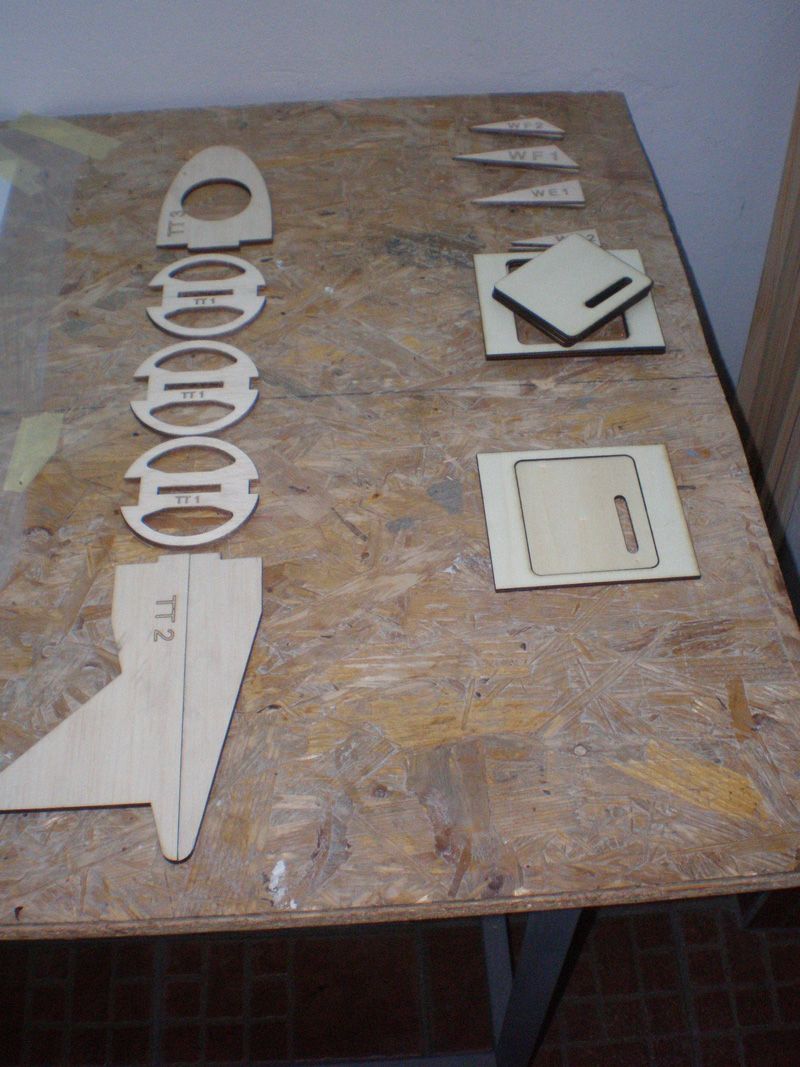

Martin, guy who made 3D drawings, send me first files of wing and wing ribs...

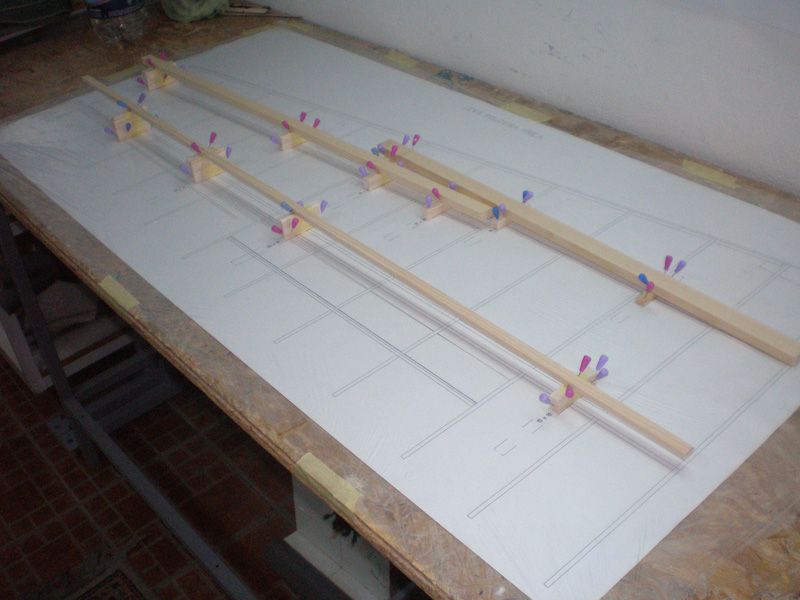

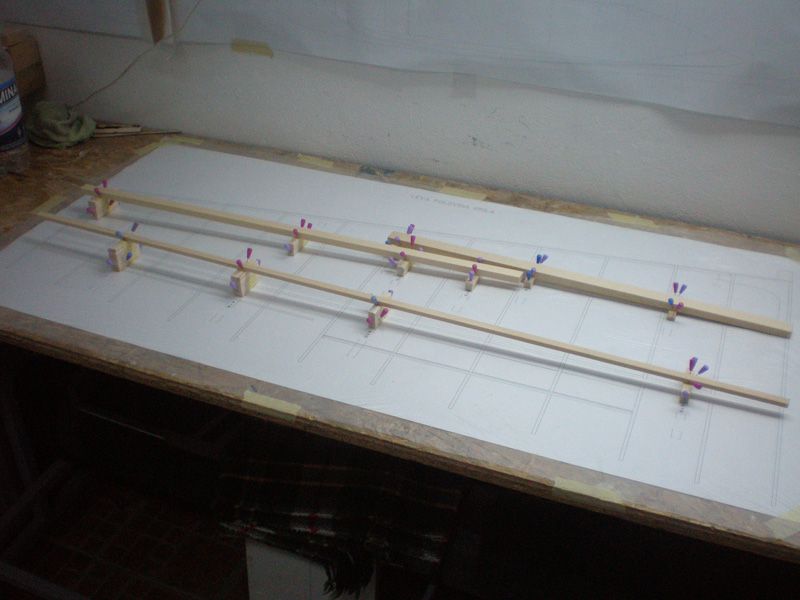

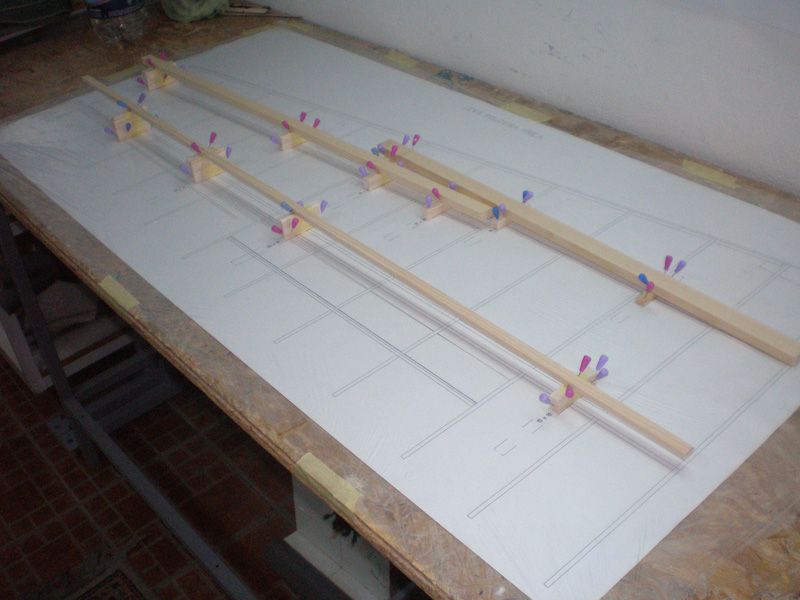

Wing files I send to print shop, and soon I'll have plan of left wing side on my work table...

This is first plan, with out any details, but good for me to start making wing. Plans which will be sell with kit of Galeb G2, will have much more details, and many drawings of the ribs and some wing sets...

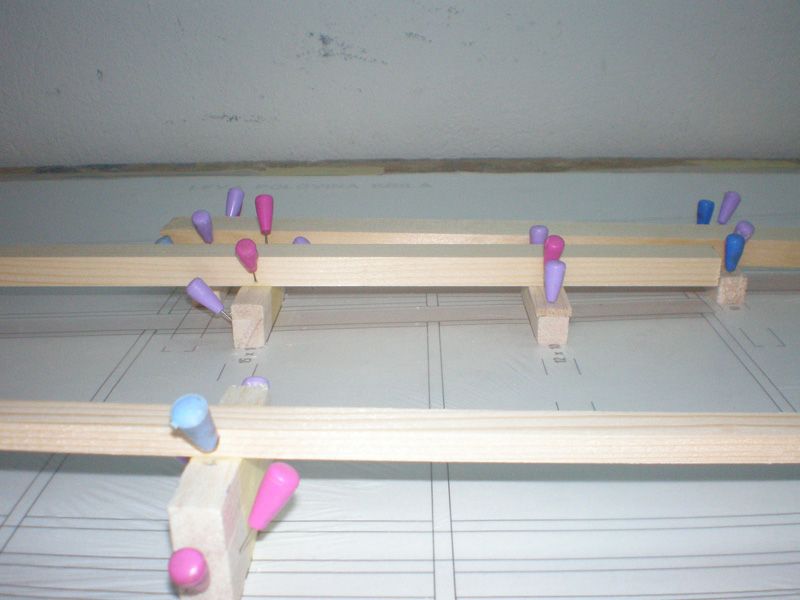

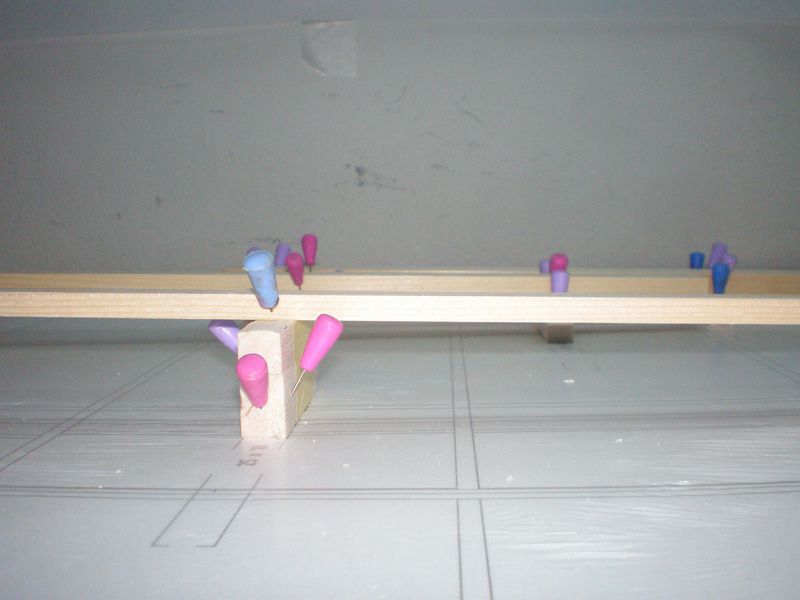

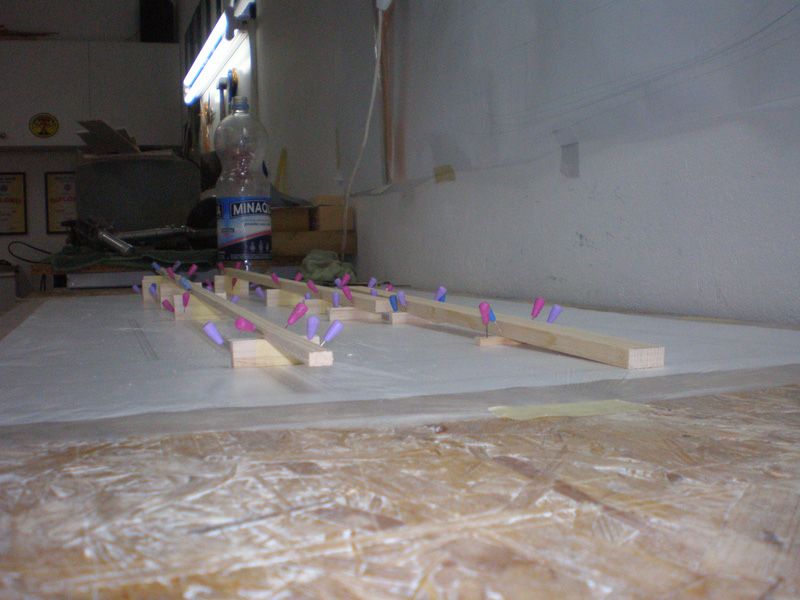

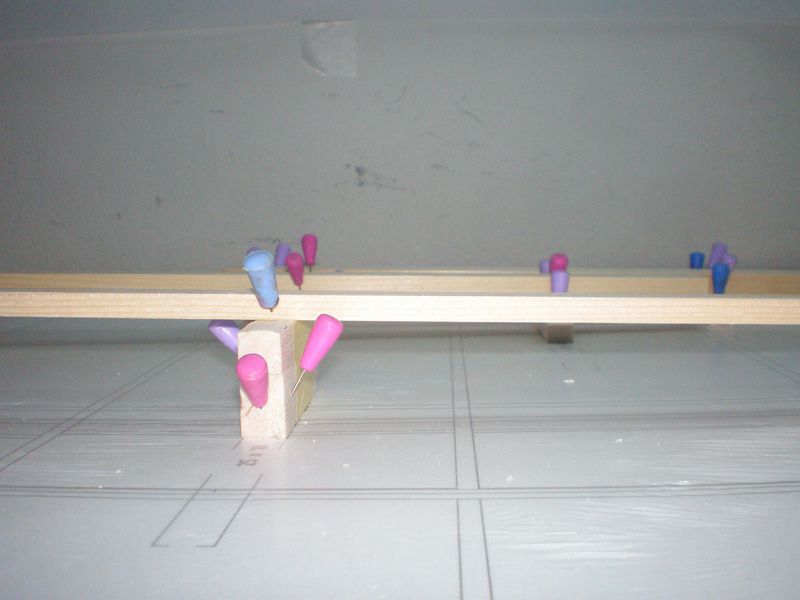

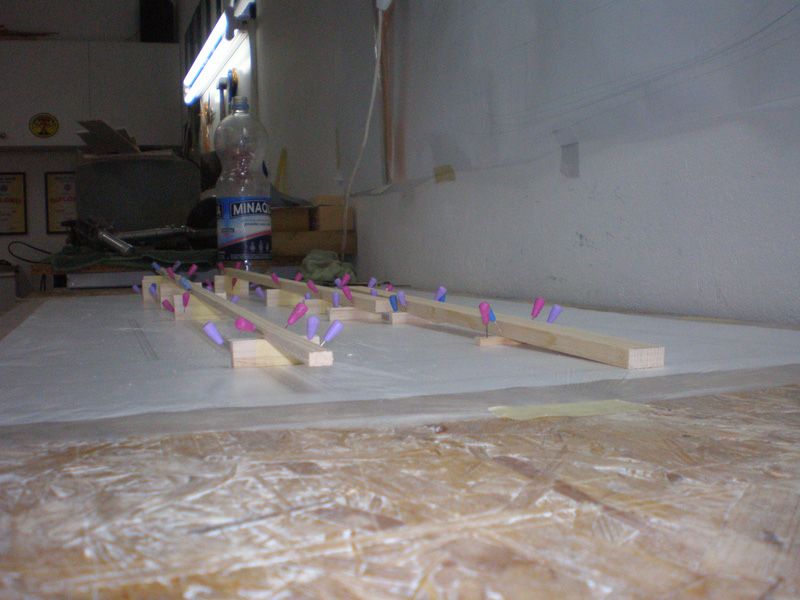

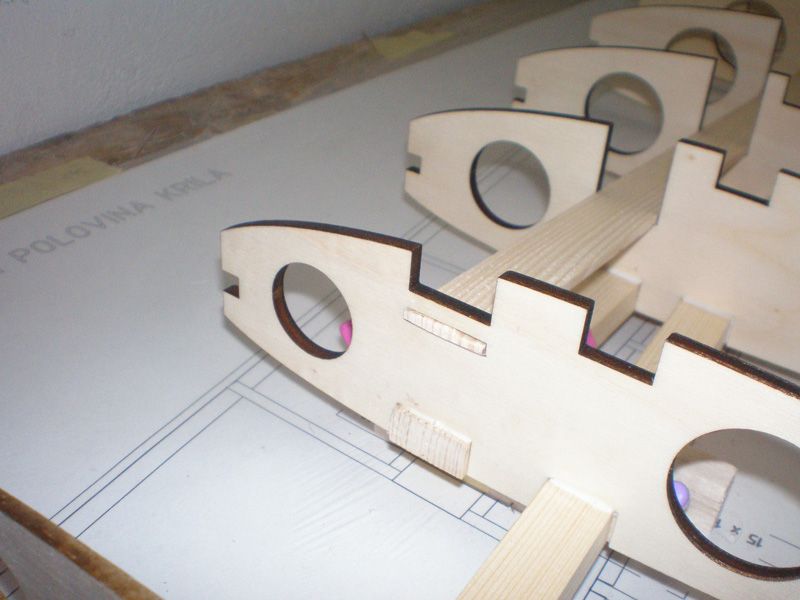

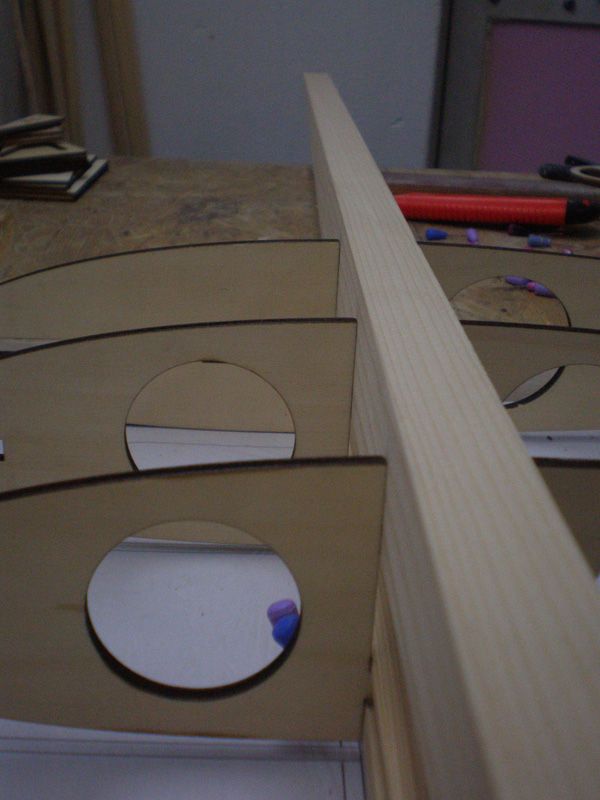

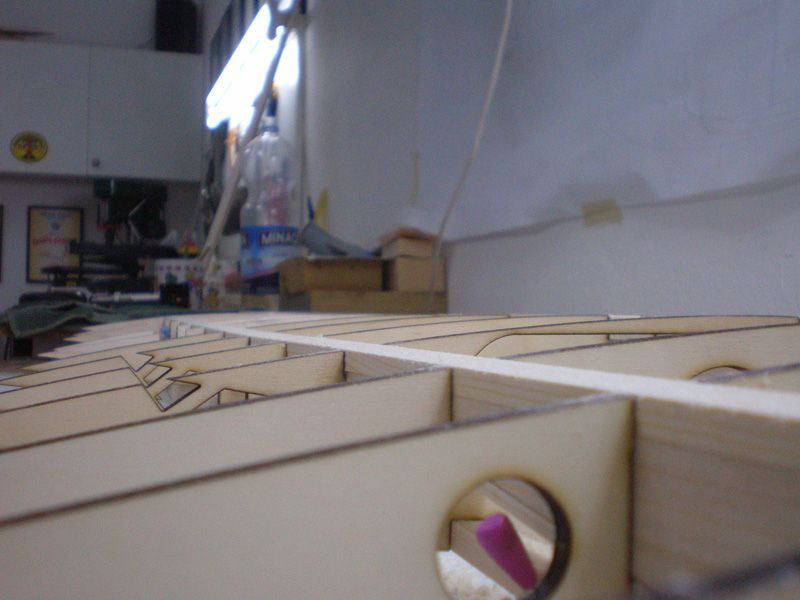

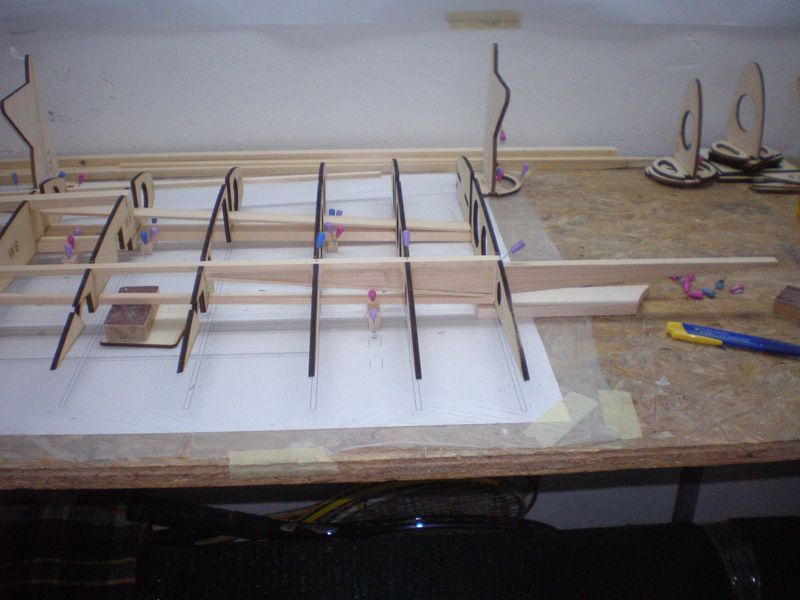

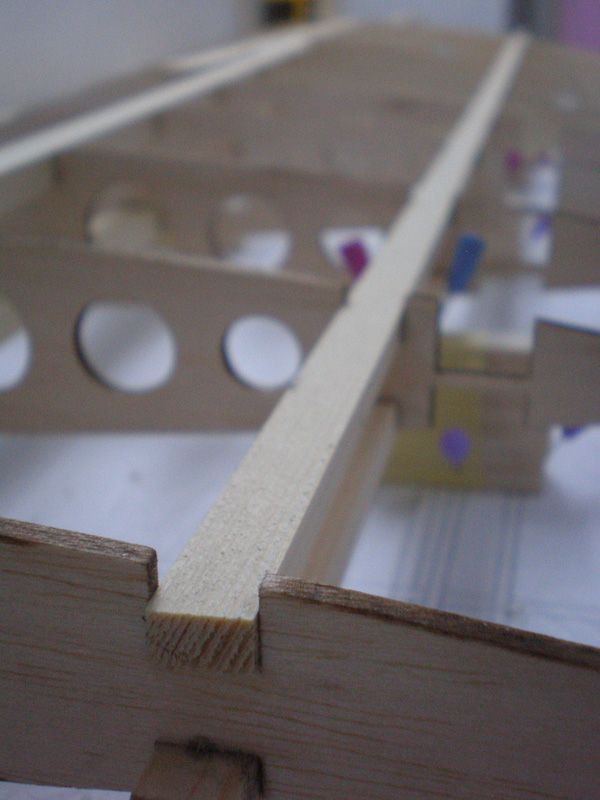

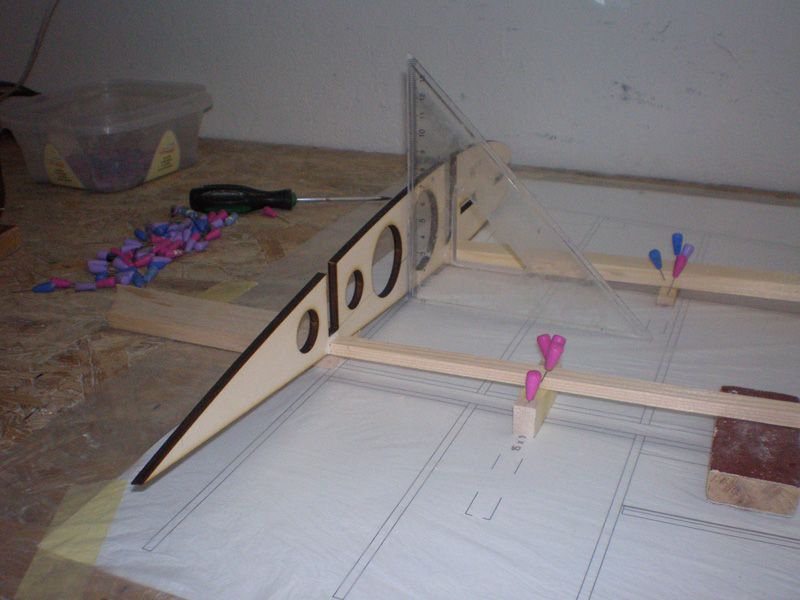

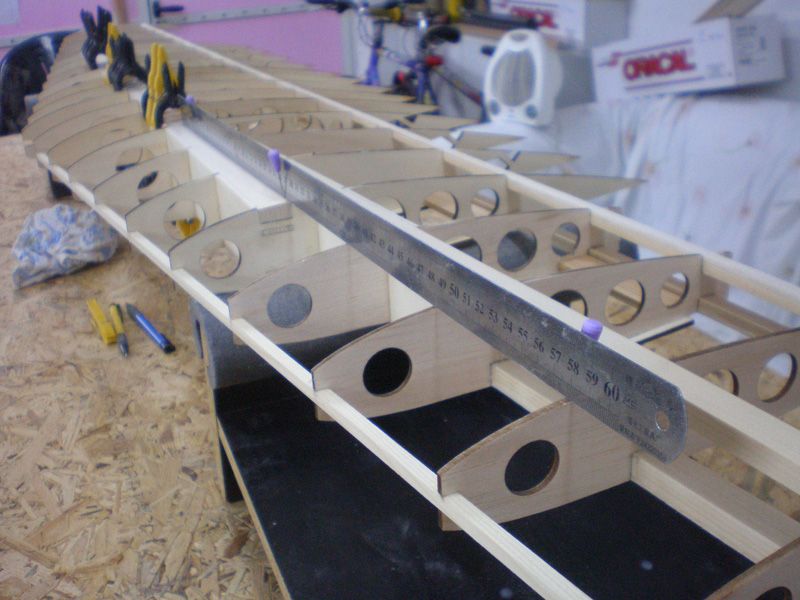

Because specific wing spars, I place some spacers on exactly places under wing spars...

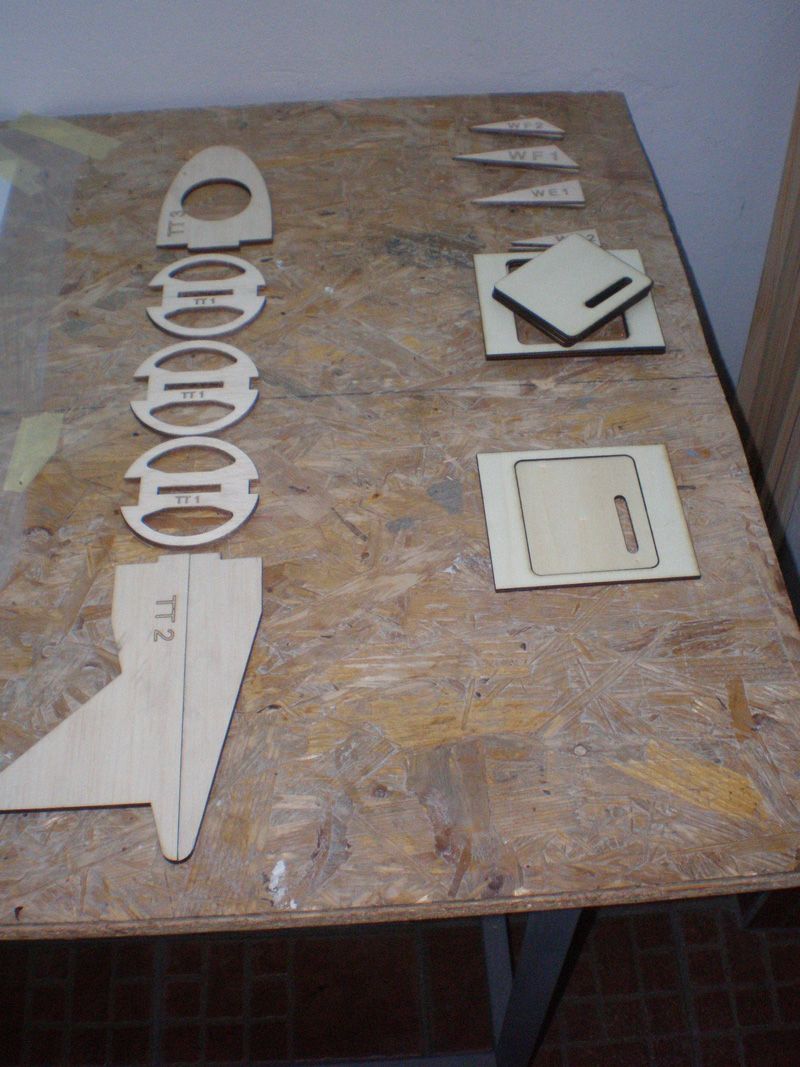

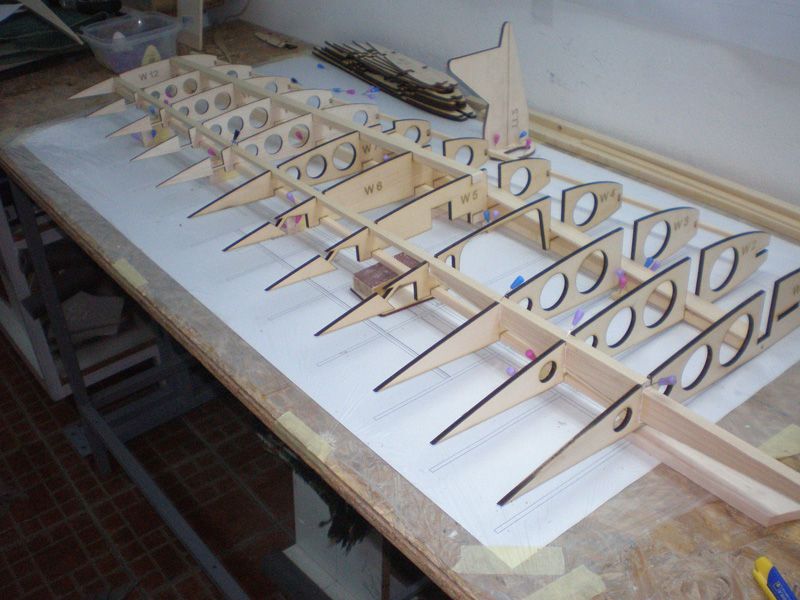

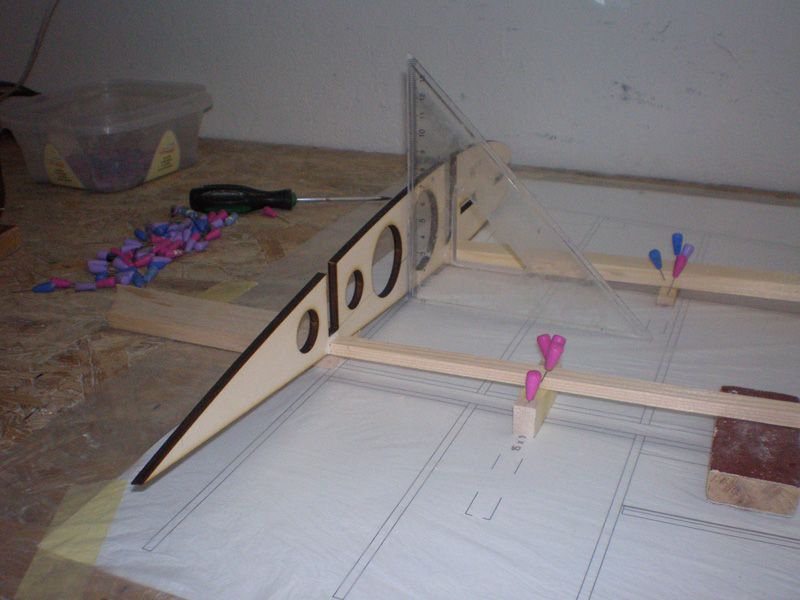

Yesterday I received wing ribs and few other parts from my friend who has laser cut machine.

First seven ribs in the wing are made from 4 mm wide poplar ply...

Other five ribs are from 3 mm balsa...

From balsa, but thicker, are parts for tip tanks...

Servo plates are made from 3 mm ply, same thickness as will be the wing plank...

Before first gluing parts, Martin and me planted small seedlings of aronia berry...

Symbolically, aronia is now as small as our project, but it will grow and be big and strong...

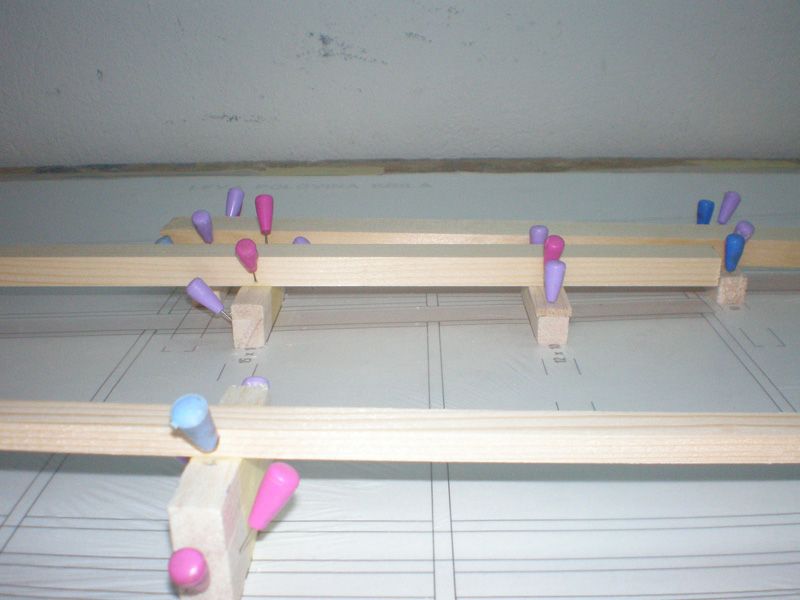

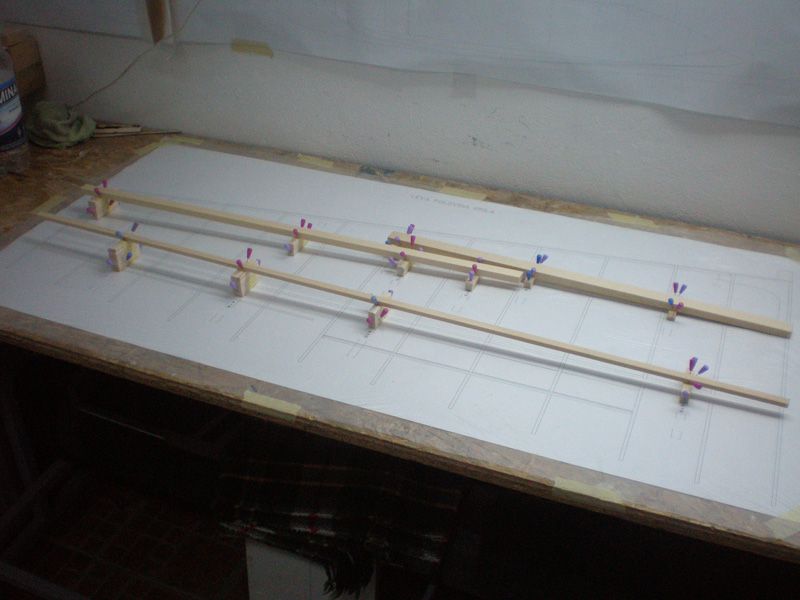

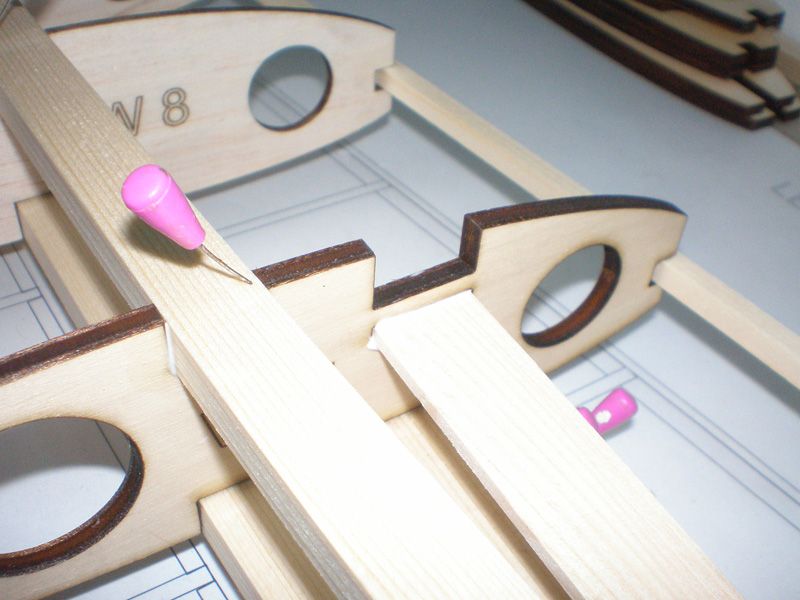

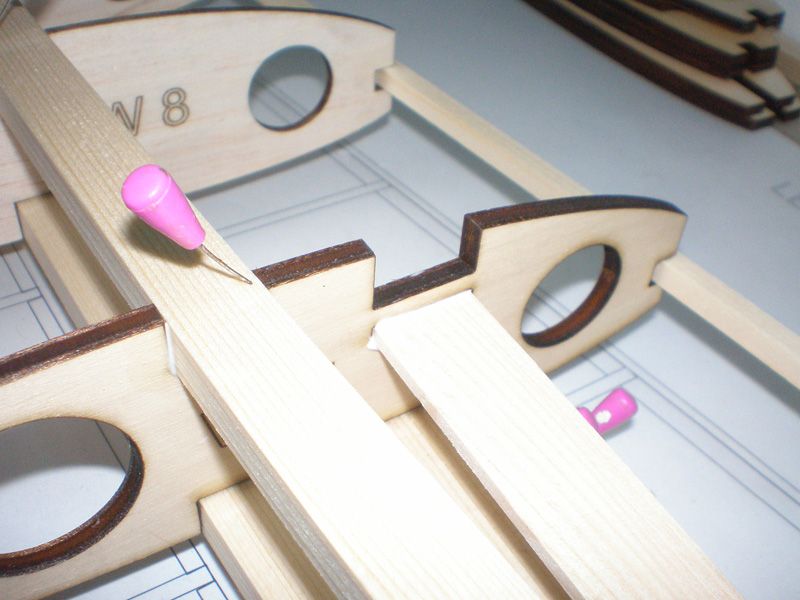

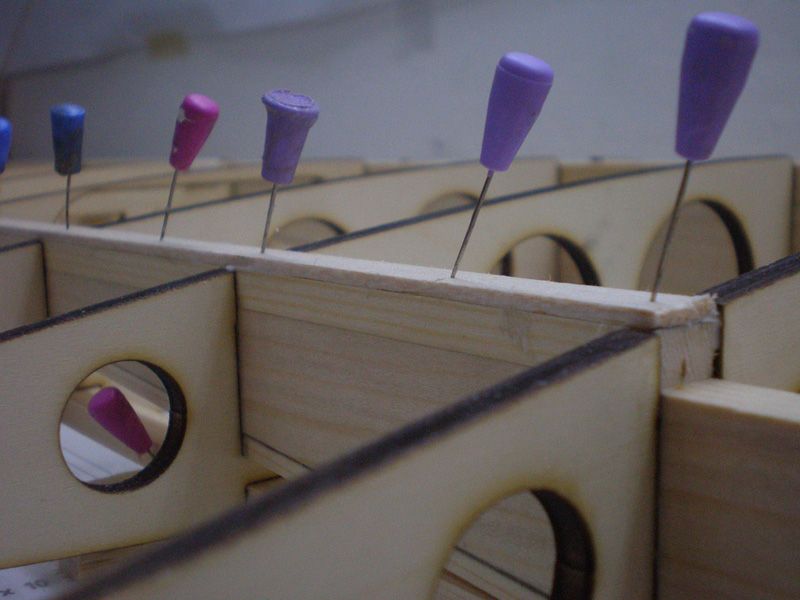

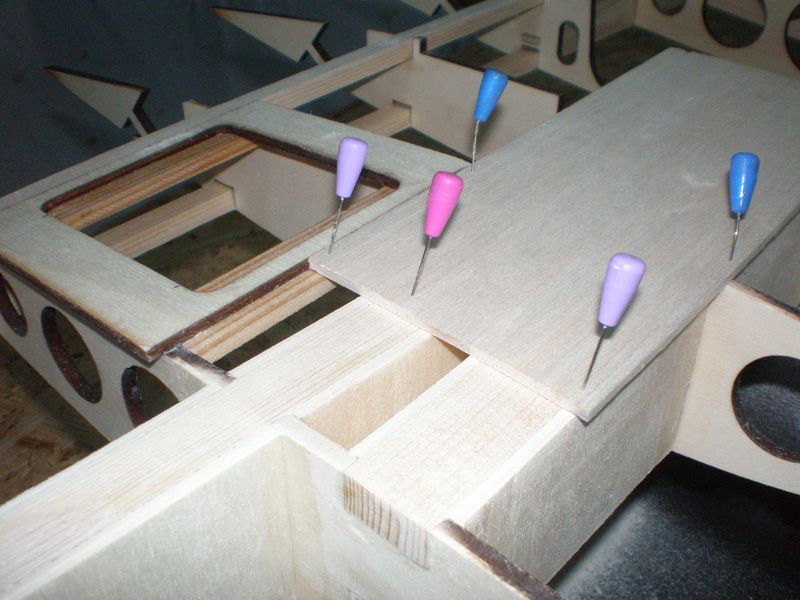

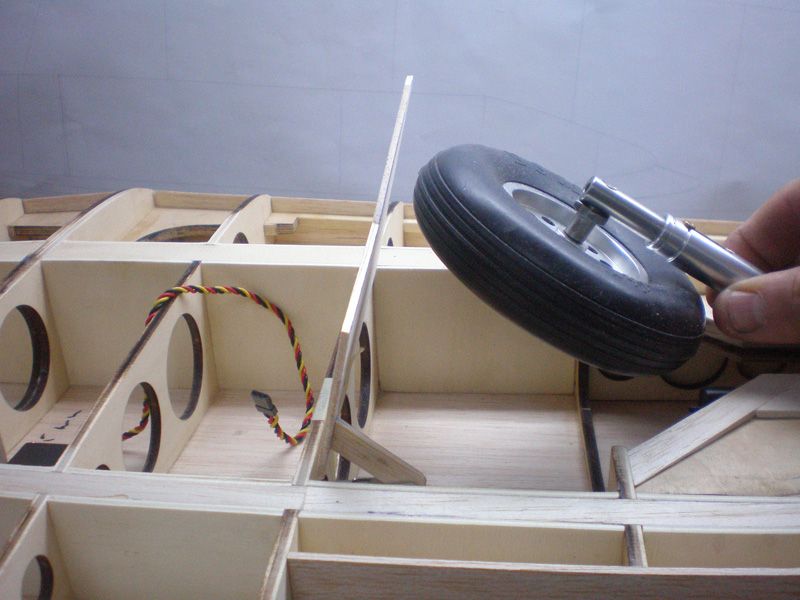

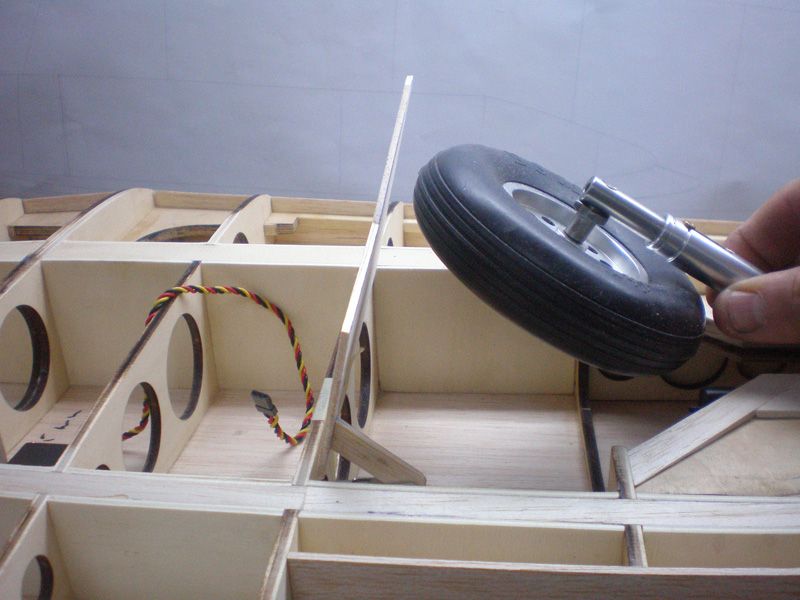

Last evening I start working on the wing. First I glued rib one, which is just lean on the wing spar. Because that I fix that rib with two small screws, until glue get dry. Latter I'll take out those screws...

Gap between rib and spars are perfect...

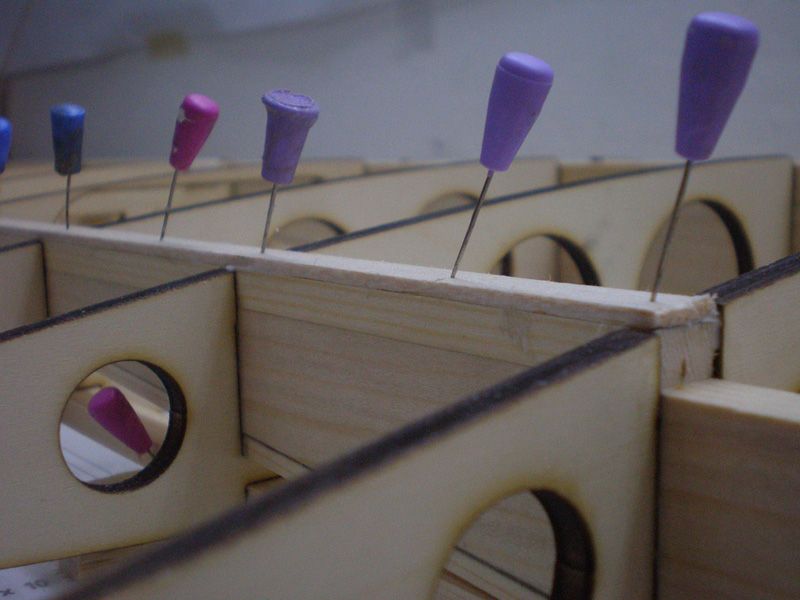

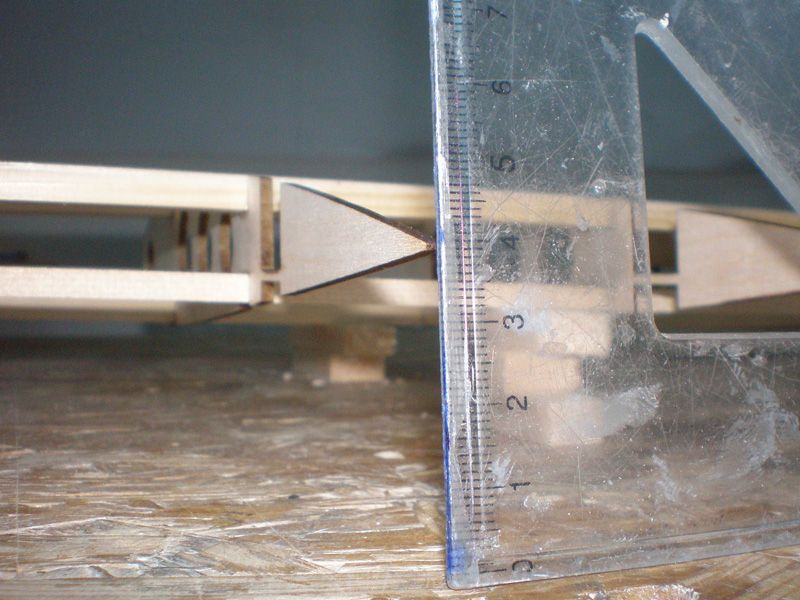

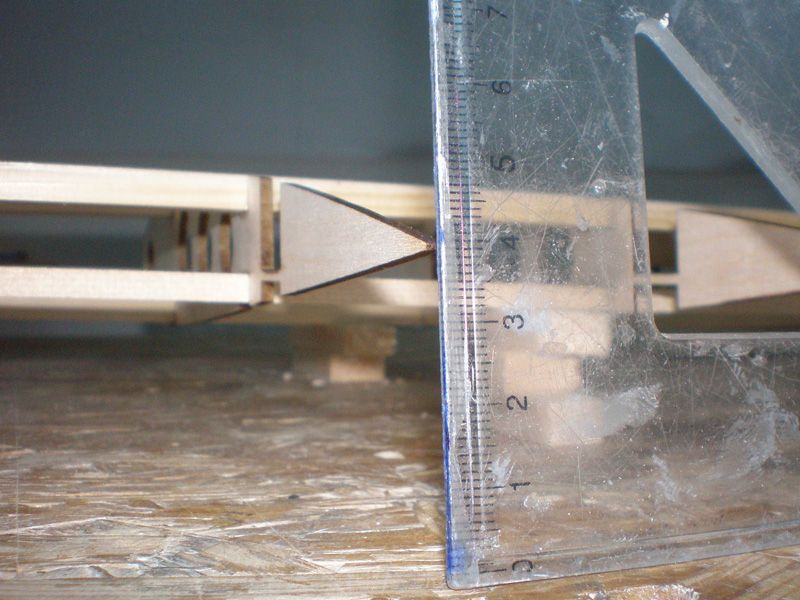

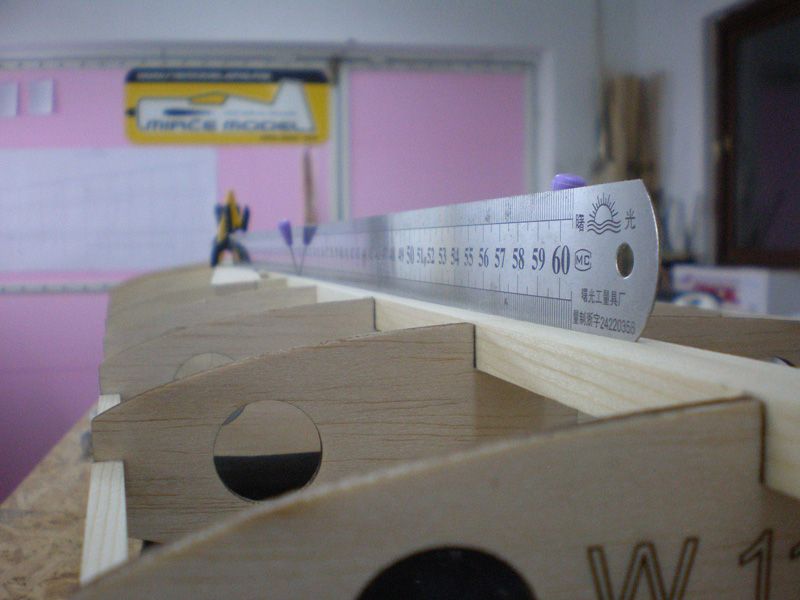

All ribs are at 90 degrees to the work bench...

Because all ribs are fit perfectly I wasn't need to use sand paper to fit it to the spars, and gluing was pretty fast...

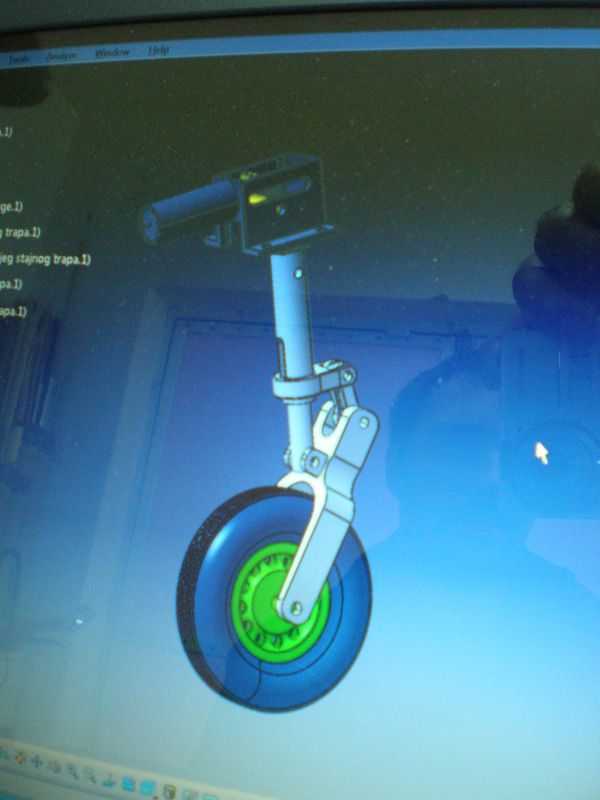

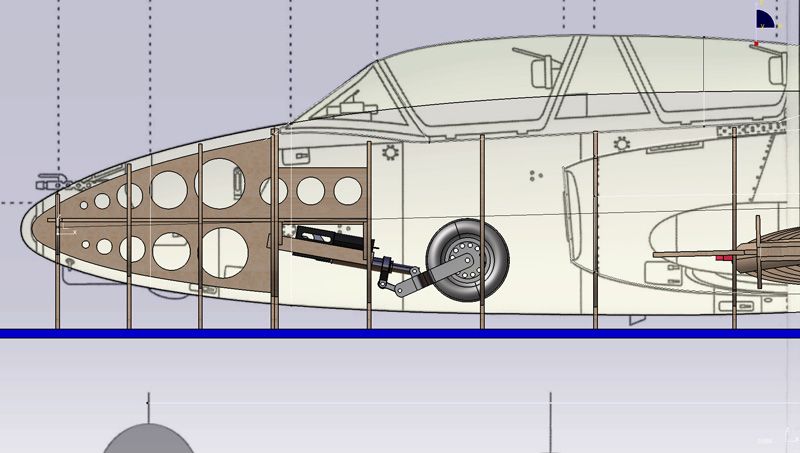

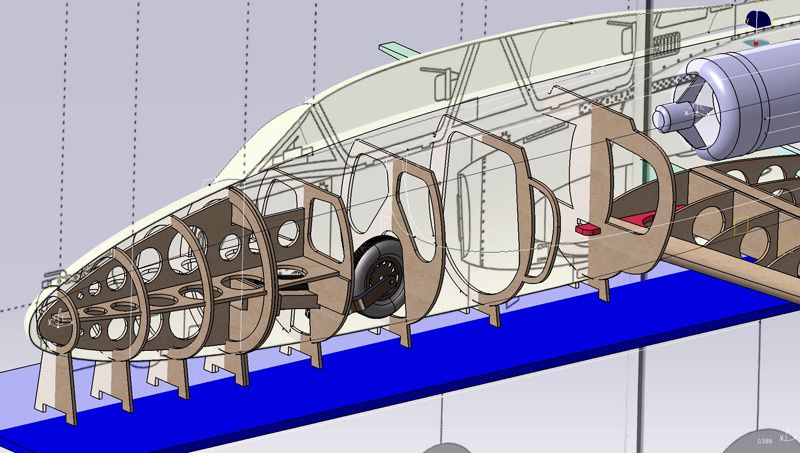

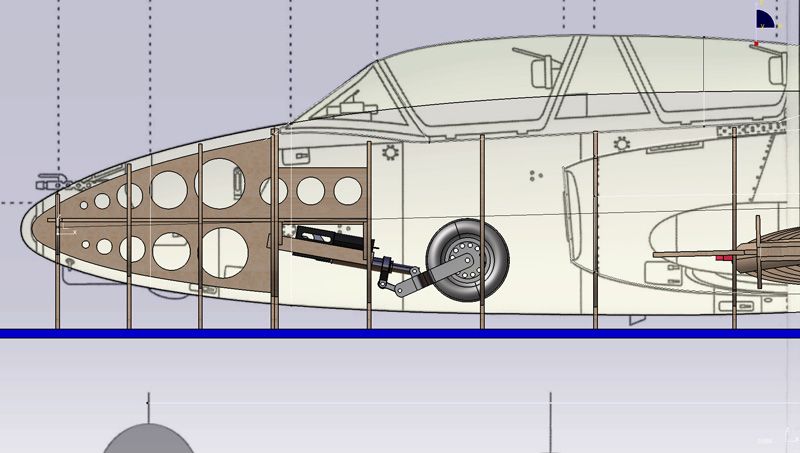

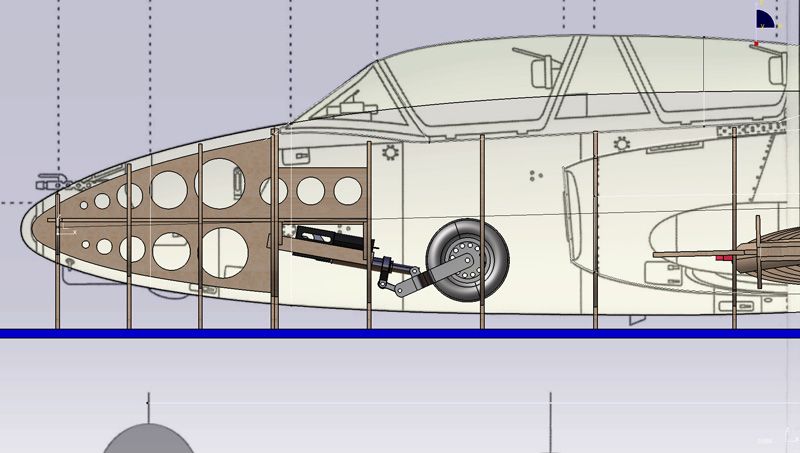

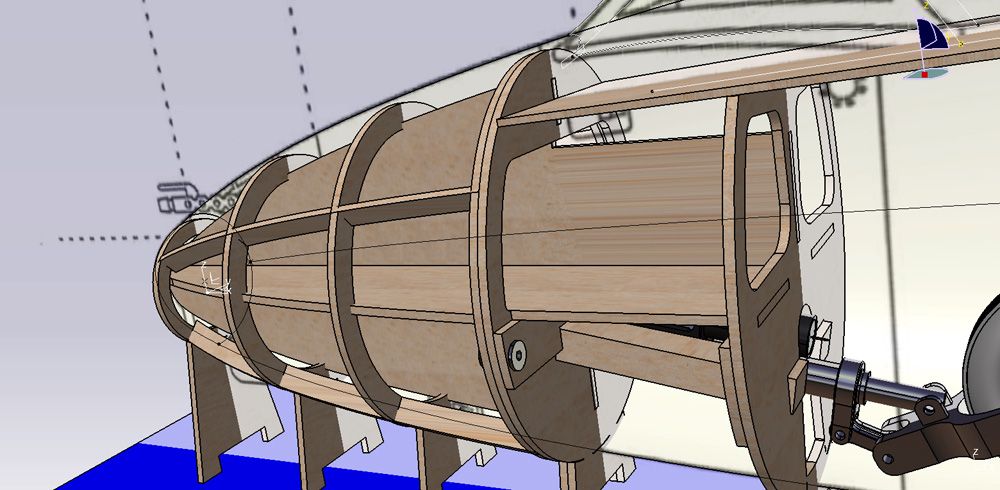

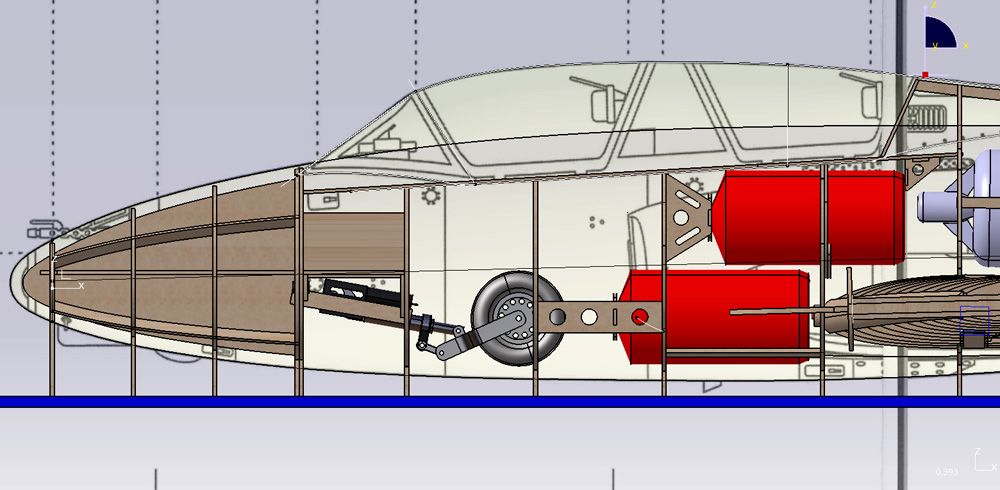

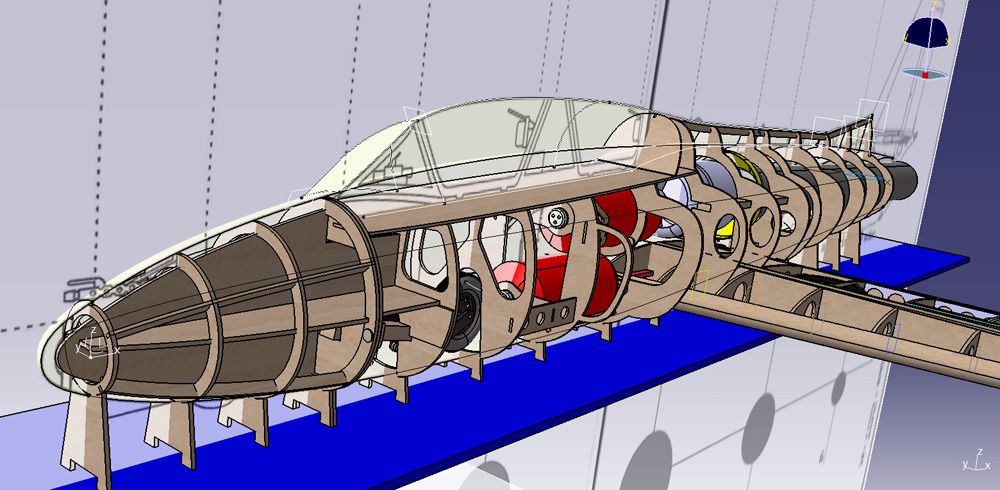

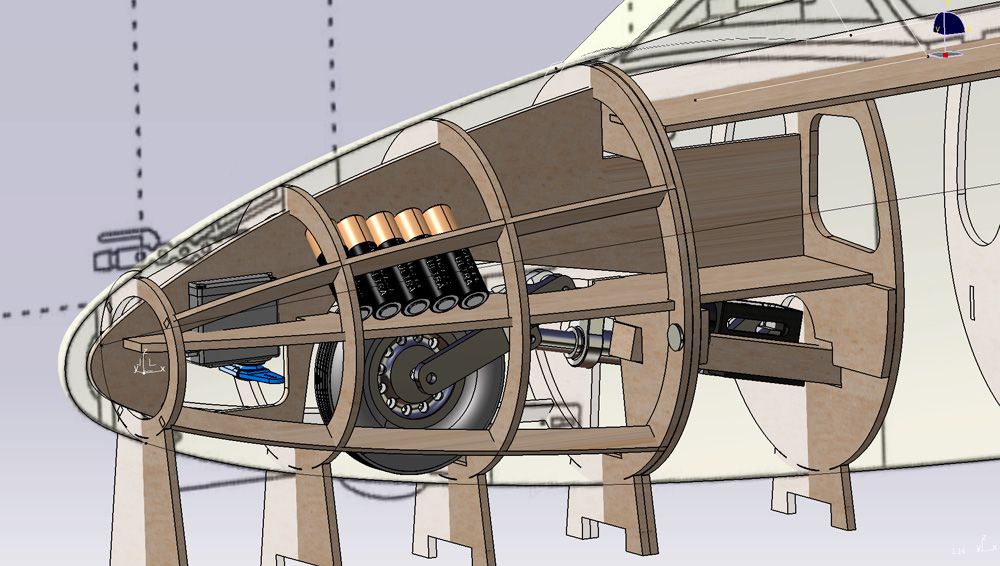

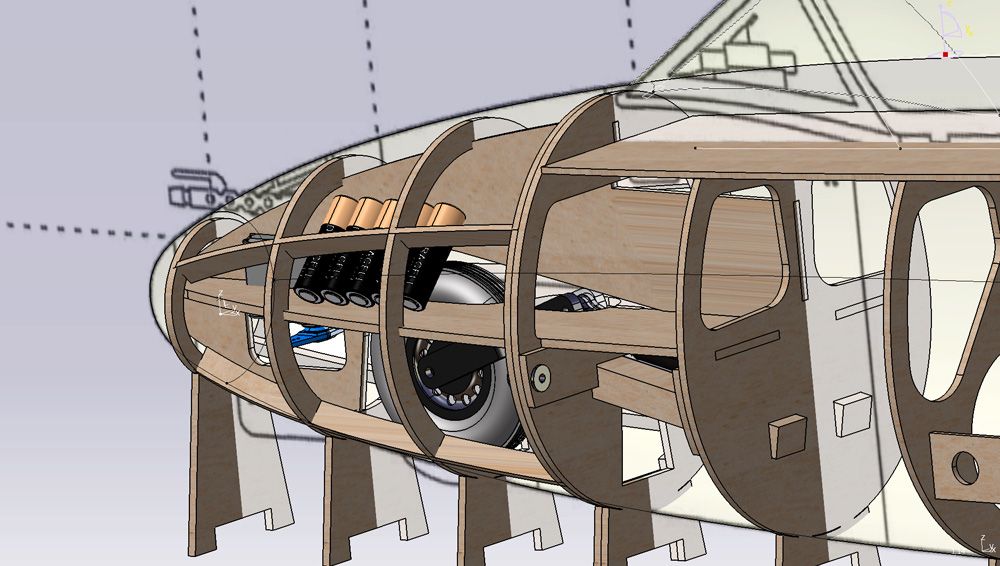

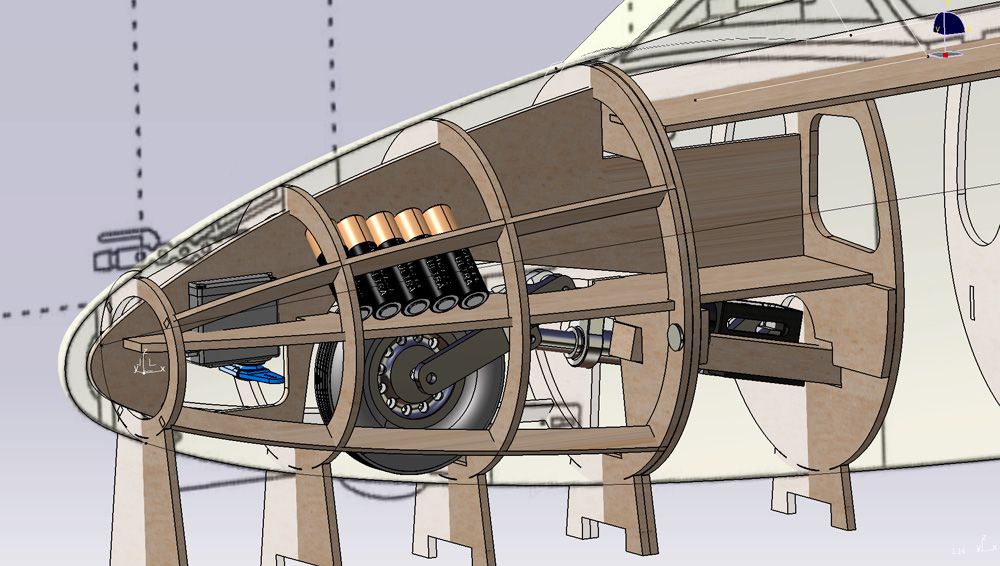

While I worked on the wing, Martin was working on the fuselage of Galeb G2.

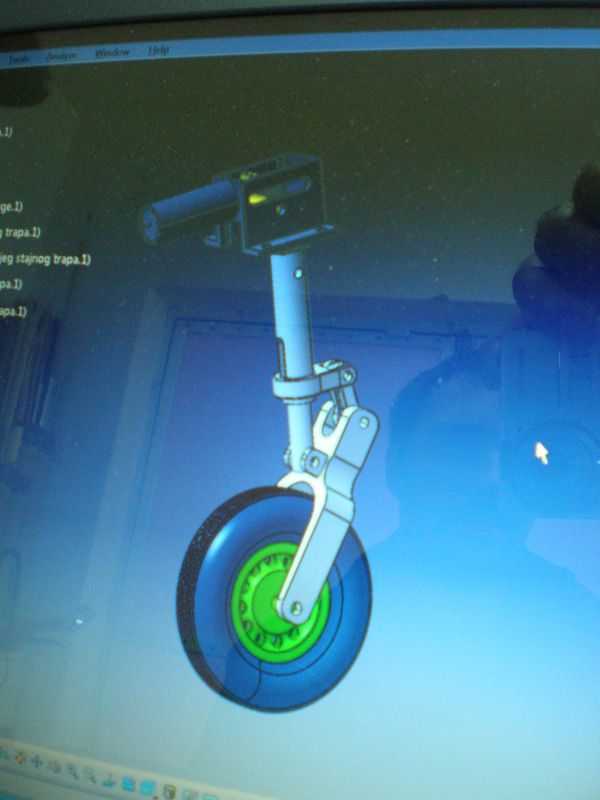

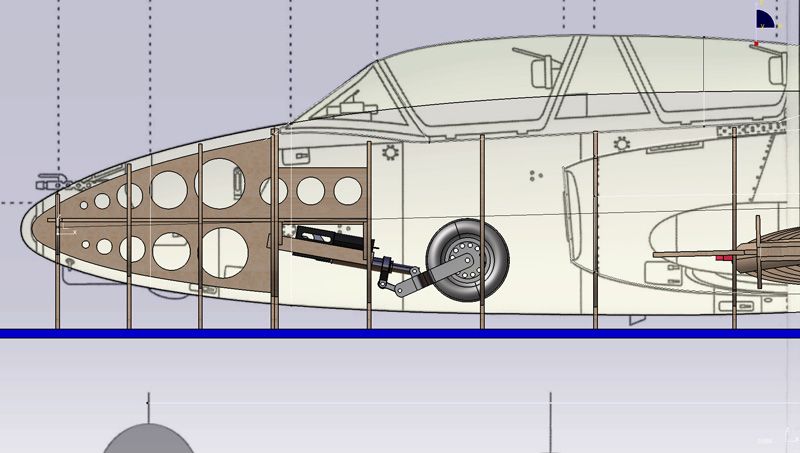

First, he made draw of nose wheel...

... and later he put that draw on the fuselage draw...

Right now this is pretty early stage of fuselage drawings, but I hope in next month - two fuselage will be ready for building too...

Regards

Mirce

My friend send me all fir slats for spars, and some other wing parts. Of course, he send me 3 time more than I need....

Martin, guy who made 3D drawings, send me first files of wing and wing ribs...

Wing files I send to print shop, and soon I'll have plan of left wing side on my work table...

This is first plan, with out any details, but good for me to start making wing. Plans which will be sell with kit of Galeb G2, will have much more details, and many drawings of the ribs and some wing sets...

Because specific wing spars, I place some spacers on exactly places under wing spars...

Yesterday I received wing ribs and few other parts from my friend who has laser cut machine.

First seven ribs in the wing are made from 4 mm wide poplar ply...

Other five ribs are from 3 mm balsa...

From balsa, but thicker, are parts for tip tanks...

Servo plates are made from 3 mm ply, same thickness as will be the wing plank...

Before first gluing parts, Martin and me planted small seedlings of aronia berry...

Symbolically, aronia is now as small as our project, but it will grow and be big and strong...

Last evening I start working on the wing. First I glued rib one, which is just lean on the wing spar. Because that I fix that rib with two small screws, until glue get dry. Latter I'll take out those screws...

Gap between rib and spars are perfect...

All ribs are at 90 degrees to the work bench...

Because all ribs are fit perfectly I wasn't need to use sand paper to fit it to the spars, and gluing was pretty fast...

While I worked on the wing, Martin was working on the fuselage of Galeb G2.

First, he made draw of nose wheel...

... and later he put that draw on the fuselage draw...

Right now this is pretty early stage of fuselage drawings, but I hope in next month - two fuselage will be ready for building too...

Regards

Mirce

#31

Join Date: Jan 2007

Location: farnborough, , UNITED KINGDOM

Posts: 3,294

Likes: 0

Received 1 Like

on

1 Post

Nice work my friend, lovely to see drawings come to life and classic build techniques - I'll be watching as I am starting another 'interesting' jet project soon too

marcs

marcs

#32

Thread Starter

Thank you Mark...

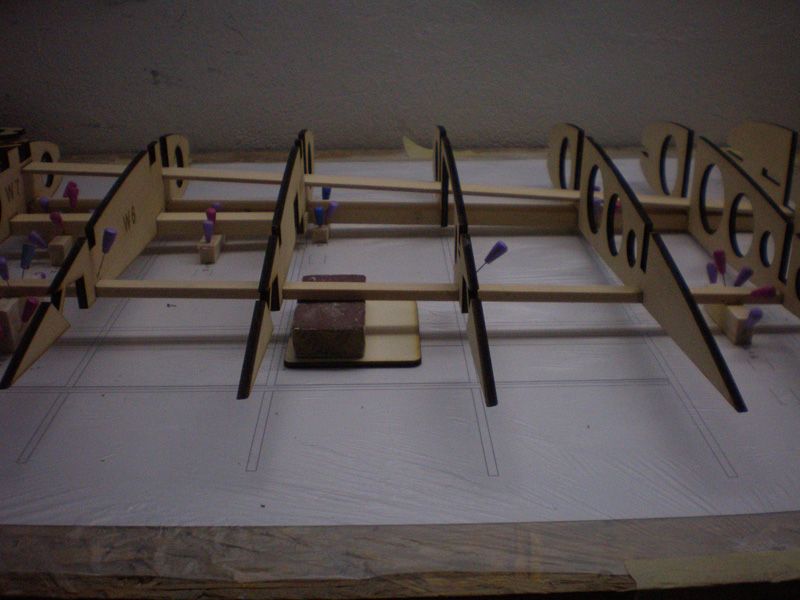

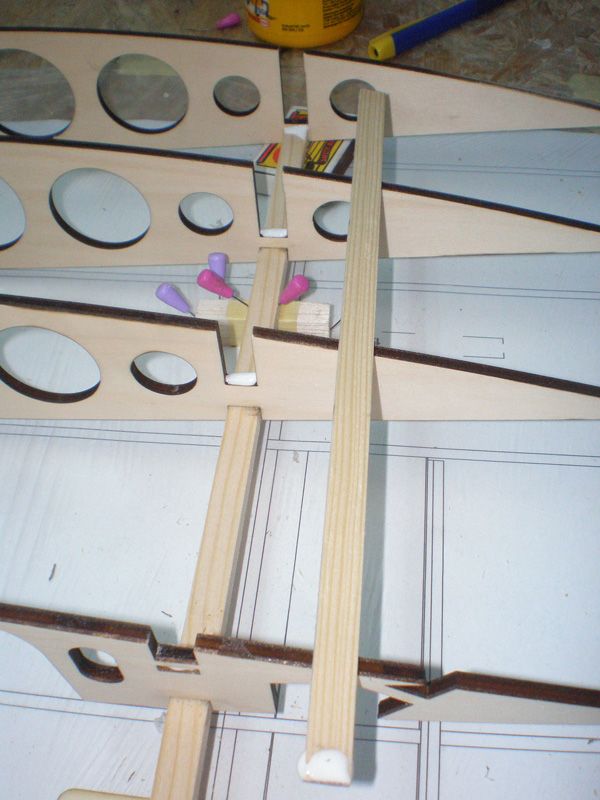

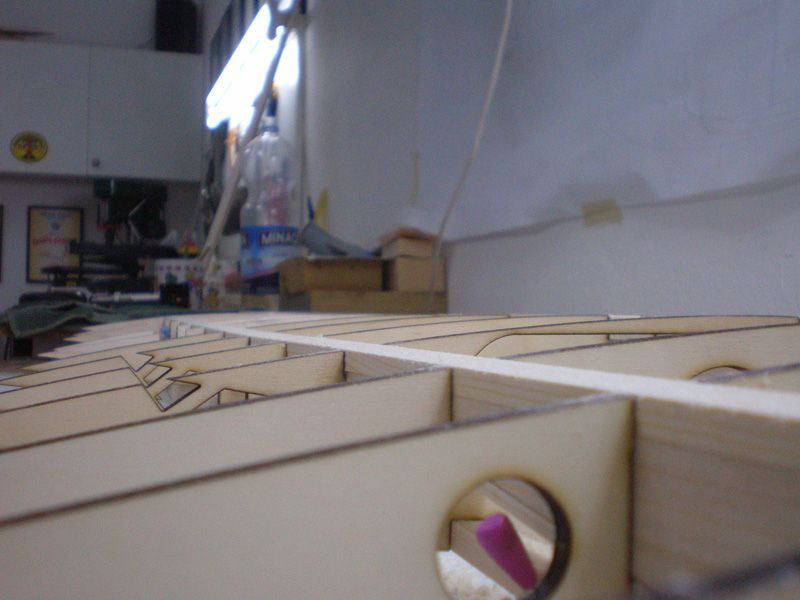

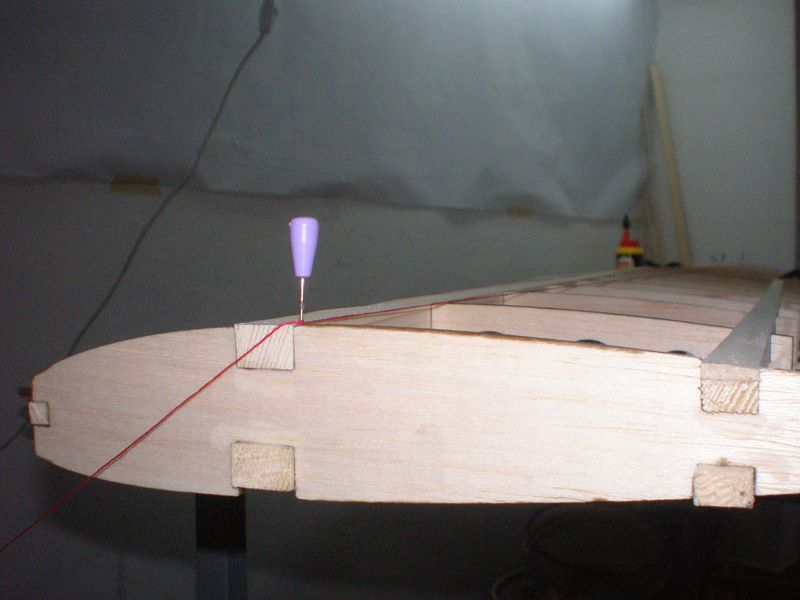

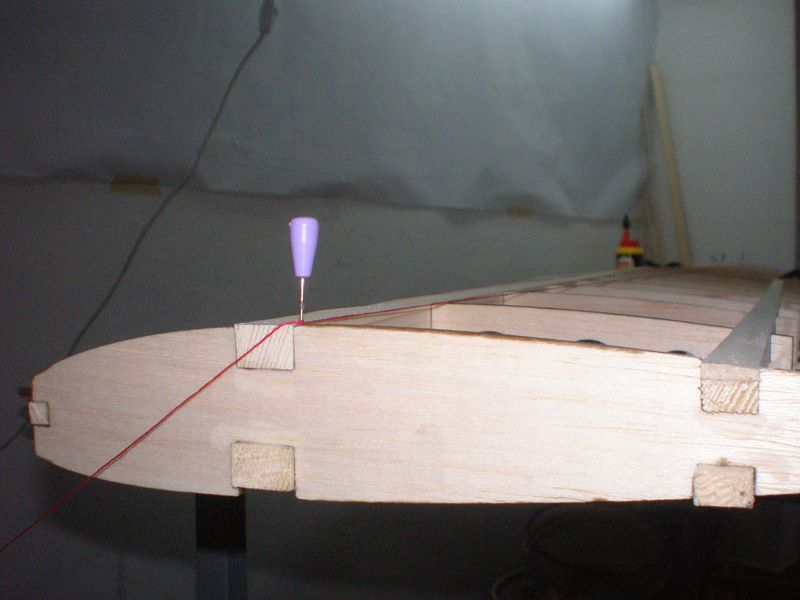

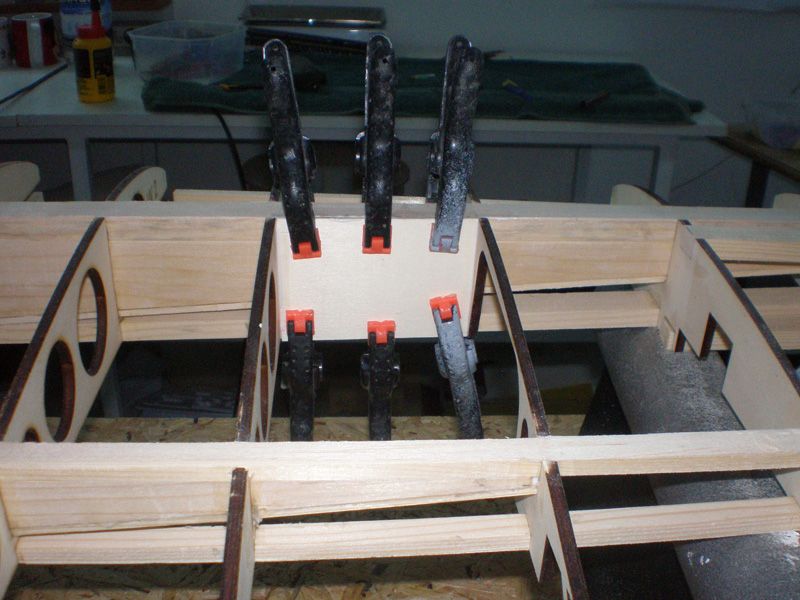

Last night I spent some more time on G2 wing.

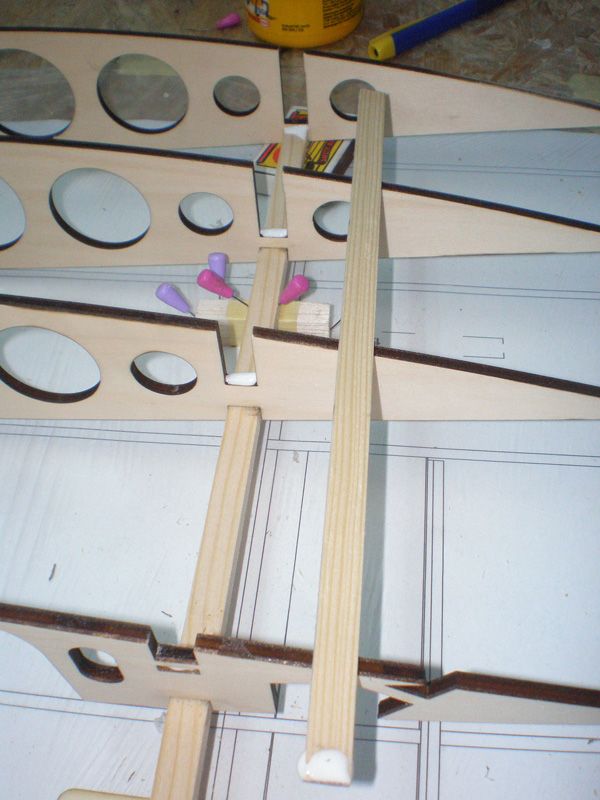

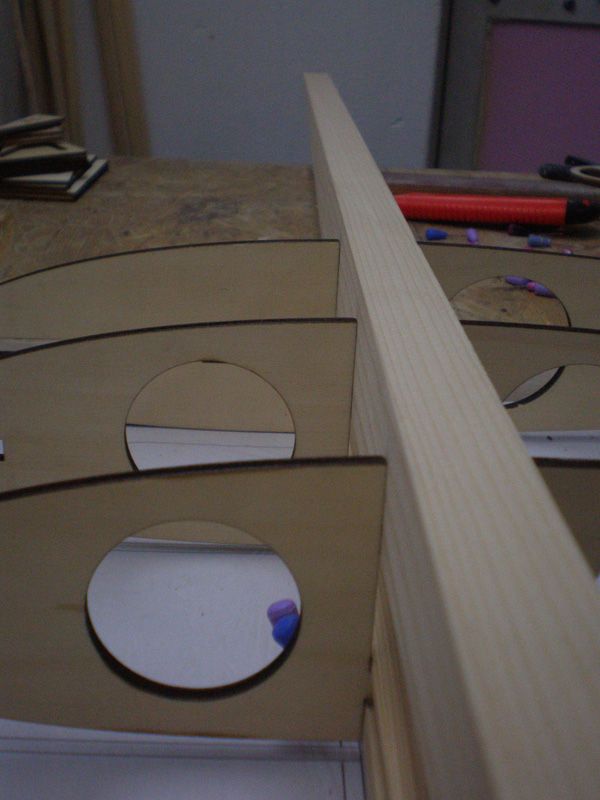

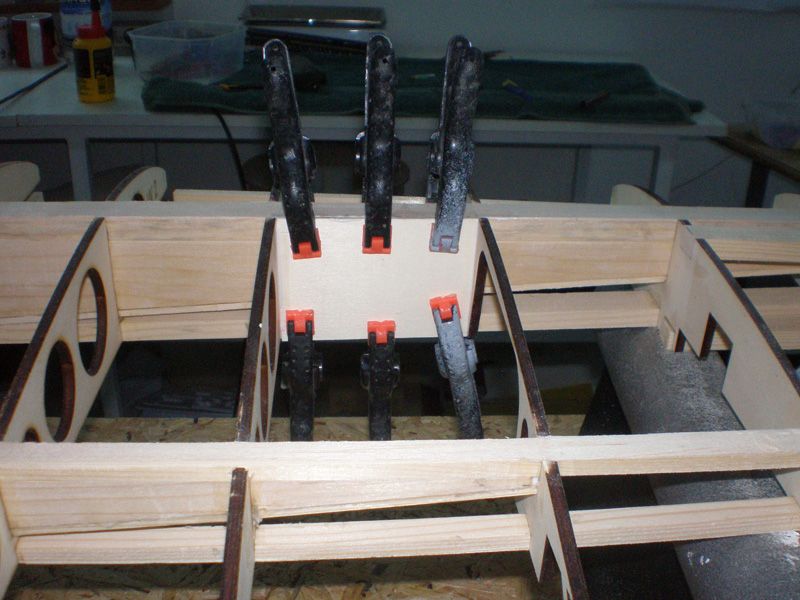

First I glued all ribs...

Next was to put auxiliary spar on position. On that spar will come wooden wing joiners. Hope I'll get it today...

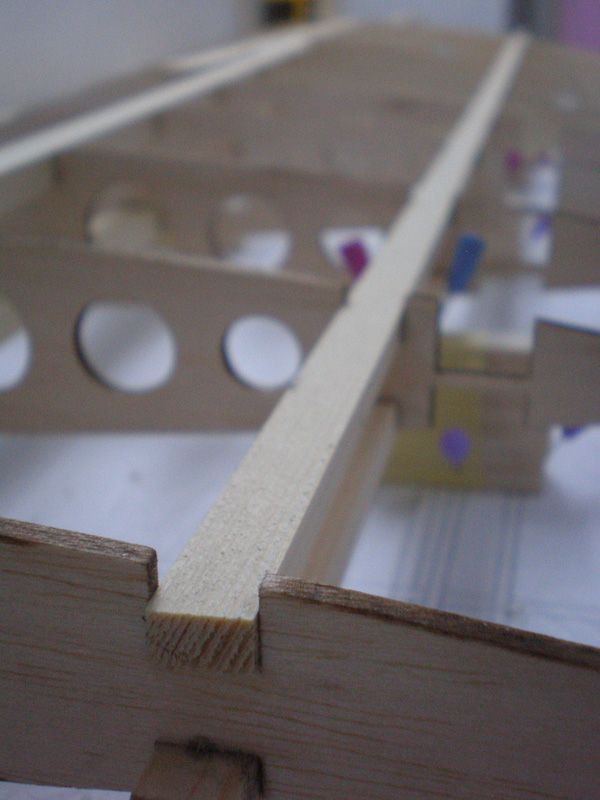

When I saw that everything fit perfectly I glued it. Same was doing with upper external spar...

Finally for last night was to glued few pieces of tip tank cantilever...

And last picture for this post, angle of ribs trailing edges. You can see washout...

Continue tonight...

Regards

Mirce

Last night I spent some more time on G2 wing.

First I glued all ribs...

Next was to put auxiliary spar on position. On that spar will come wooden wing joiners. Hope I'll get it today...

When I saw that everything fit perfectly I glued it. Same was doing with upper external spar...

Finally for last night was to glued few pieces of tip tank cantilever...

And last picture for this post, angle of ribs trailing edges. You can see washout...

Continue tonight...

Regards

Mirce

#35

Thread Starter

Thank you guys...

Last night Martin was here so we are working until early morning and I haven't time to add more pictures about G2 progress.

Yesterday I got wing joiners from my friend Milan... Before installation I put it on scales and measured it...

Scales show 220 gr...

I want to compare it with aluminum wing joiners about same size...

Next step was to prepare and glue rear auxiliary spar for small wing joiner...

While the glue dries, I made tip tank balsa base...

Than I lean it to the wings last rib...

When I lean main wing joiner in the ribs gutters I saw - no gaps... Seating is perfectly...

Because everything fits so good, I glued wing joiner and upper spar. I want to made one piece wing, but it can be done in two pieces also...

As everything, alignment of the front and rear spar is very good...

Since spar must be in parallel with bayonets, the profile curvature appeared the great difference in front and behind the bayonet.

We can made higher spars, but in that case modeler must sand hard wood. So, decision was to put balsa in that gap, because balsa is much easier to work with...

Than sanding...

Fine tuning...

... and finally it looks like this...

... and when come plank it will be like this...

After this operation I take off left wing half from the work table. I have immediately two impressions, first how stiff and strong is construction, and second, how light is it.

Again I used scale, add few wing parts, few balsa planks...

and scale show exactly 1010 gr...

Than I measured Panther wing panel...

... and scale show 940 gr...

But, check this...

Now I will change plans a little bit, because wing is so strong that I'll not need so many reinforcement. Also, I think to add thinner balsa cover...

Regards

Mirce

Last night Martin was here so we are working until early morning and I haven't time to add more pictures about G2 progress.

Yesterday I got wing joiners from my friend Milan... Before installation I put it on scales and measured it...

Scales show 220 gr...

I want to compare it with aluminum wing joiners about same size...

Next step was to prepare and glue rear auxiliary spar for small wing joiner...

While the glue dries, I made tip tank balsa base...

Than I lean it to the wings last rib...

When I lean main wing joiner in the ribs gutters I saw - no gaps... Seating is perfectly...

Because everything fits so good, I glued wing joiner and upper spar. I want to made one piece wing, but it can be done in two pieces also...

As everything, alignment of the front and rear spar is very good...

Since spar must be in parallel with bayonets, the profile curvature appeared the great difference in front and behind the bayonet.

We can made higher spars, but in that case modeler must sand hard wood. So, decision was to put balsa in that gap, because balsa is much easier to work with...

Than sanding...

Fine tuning...

... and finally it looks like this...

... and when come plank it will be like this...

After this operation I take off left wing half from the work table. I have immediately two impressions, first how stiff and strong is construction, and second, how light is it.

Again I used scale, add few wing parts, few balsa planks...

and scale show exactly 1010 gr...

Than I measured Panther wing panel...

... and scale show 940 gr...

But, check this...

Now I will change plans a little bit, because wing is so strong that I'll not need so many reinforcement. Also, I think to add thinner balsa cover...

Regards

Mirce

#36

Thread Starter

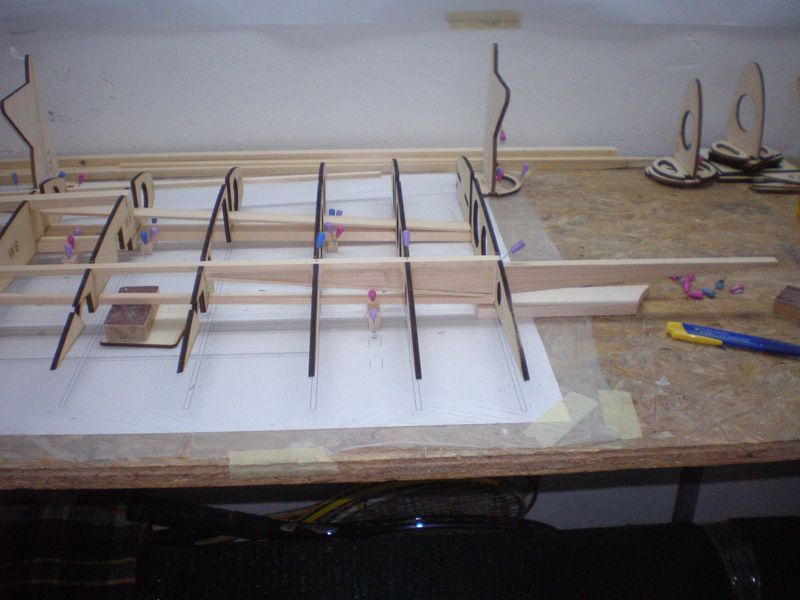

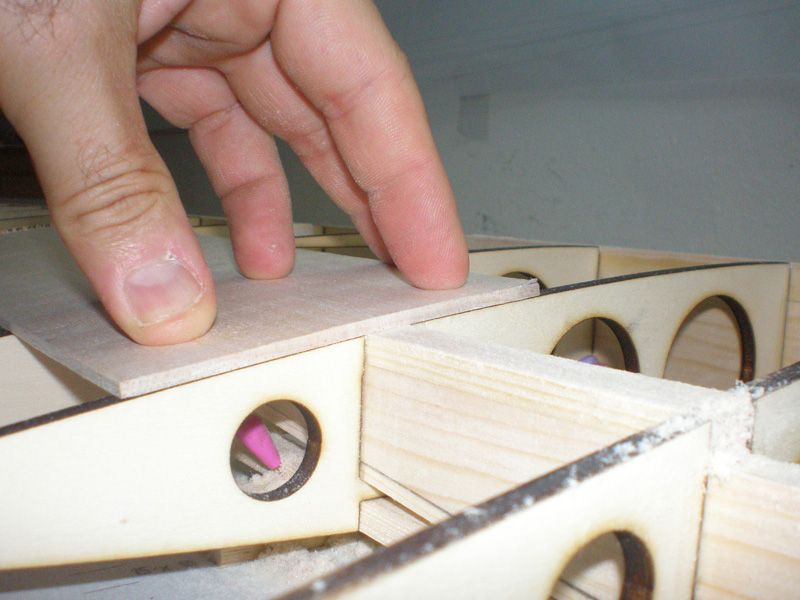

Yesterday I spent almost all day in my work shop.

I start working on right wing side...

... and because everything fit well, after 45 minutes, right wing panel was in this stage...

I must just a little bit sand slots for wooden wing joiners...

...and then i put left wing side in position, for now without glue, just to check is everything OK...

Than I add glue...

After few hours I took off wing from the work table. In spar slots, on the bottom side I add balsa strips, same as I worked on upper surface...

... than sanding, and all transitions from ribs on spar was nice and smooth...

Next step will be to add 3 mm plywood plates between spars and ribs. This will be boring job...

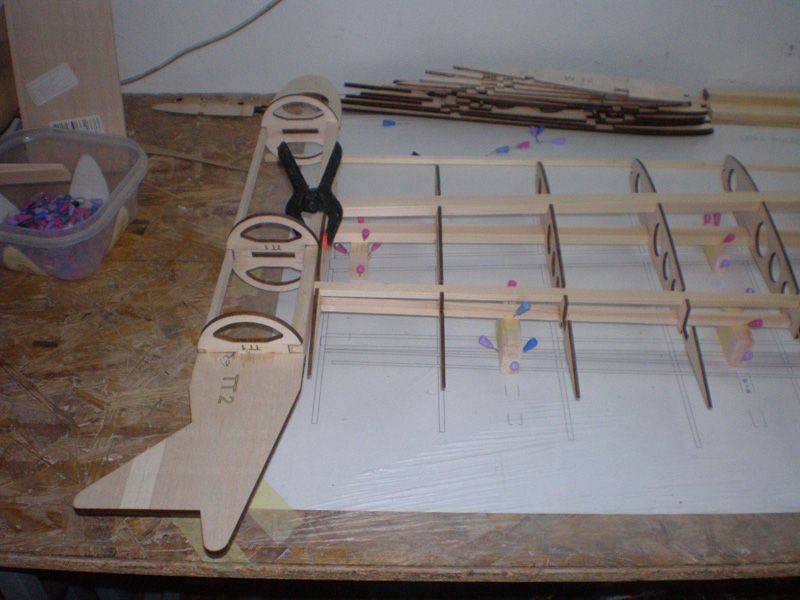

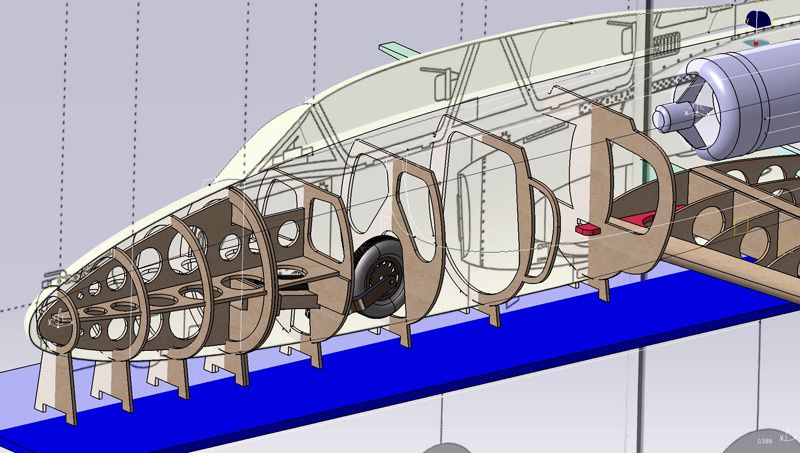

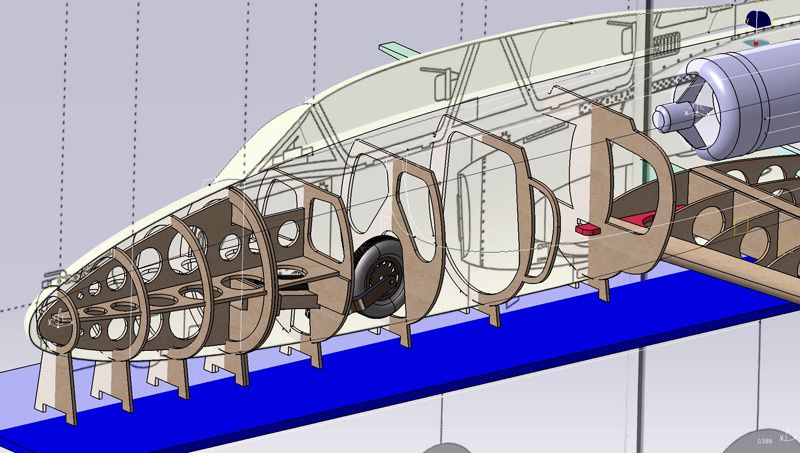

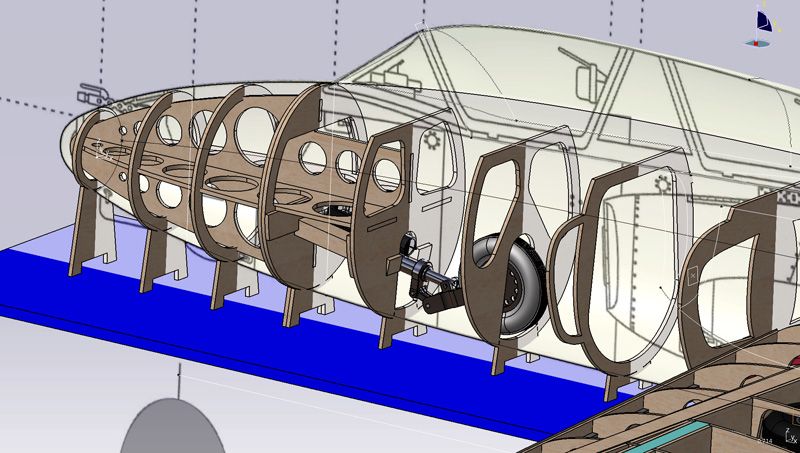

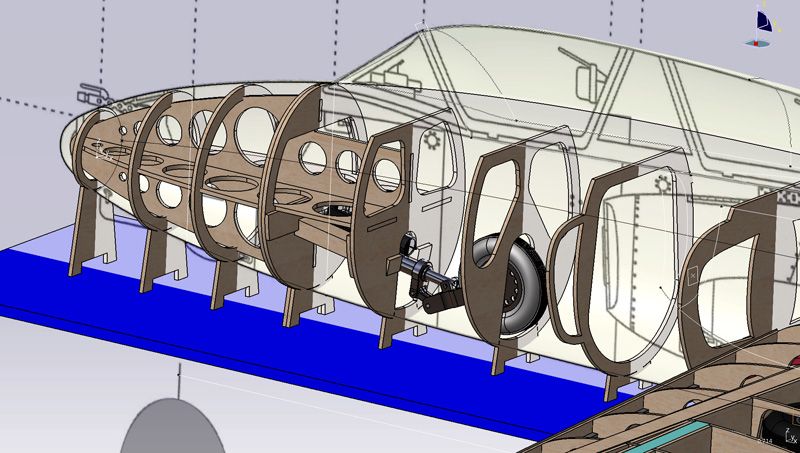

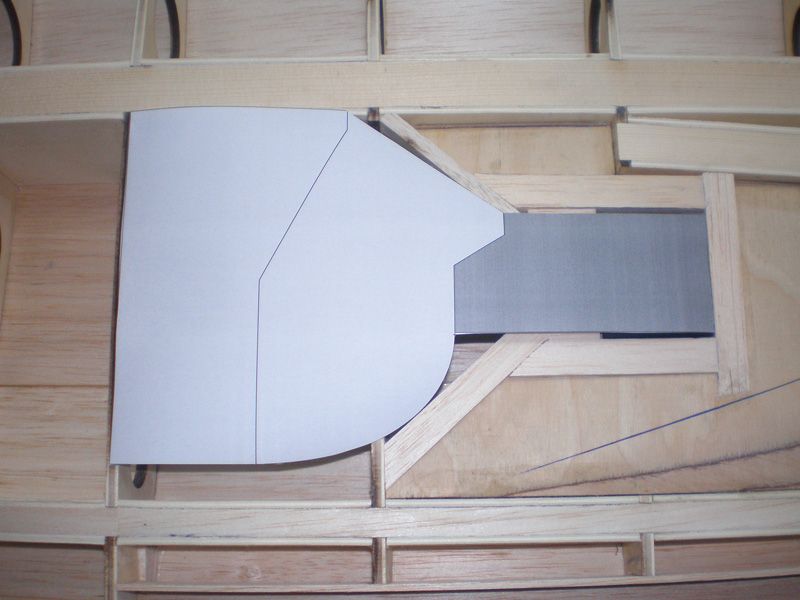

While I was working in the workshop, Martin began to draw fuselage ribs... This is just first few ribs, of course here will be some changes...

Plan is to front fuselage section, be moveable, and when you take it down, on horizontal and vertical plates will have space for batteries and other parts.

Regards

Mirce

I start working on right wing side...

... and because everything fit well, after 45 minutes, right wing panel was in this stage...

I must just a little bit sand slots for wooden wing joiners...

...and then i put left wing side in position, for now without glue, just to check is everything OK...

Than I add glue...

After few hours I took off wing from the work table. In spar slots, on the bottom side I add balsa strips, same as I worked on upper surface...

... than sanding, and all transitions from ribs on spar was nice and smooth...

Next step will be to add 3 mm plywood plates between spars and ribs. This will be boring job...

While I was working in the workshop, Martin began to draw fuselage ribs... This is just first few ribs, of course here will be some changes...

Plan is to front fuselage section, be moveable, and when you take it down, on horizontal and vertical plates will have space for batteries and other parts.

Regards

Mirce

#38

Thread Starter

#39

Thread Starter

In last few days I made all ply plates between ribs and spars. As I told, that was boring job, but must be done.

Because this is first Galeb G 2 model, prototype, I find some things which can be changed.

One of these will be this part of building, making plates between ribs and spars. Martin change drawings and now this plates will be in one piece in which will come every rib, something like "comb". That construction will immediately position every rib exactly on place and will close space between ribs and spars...

Of course, few more little changes will be done in construction, but that is just details...

As I told I made plates...

I chack how balsa will lie down on wing...

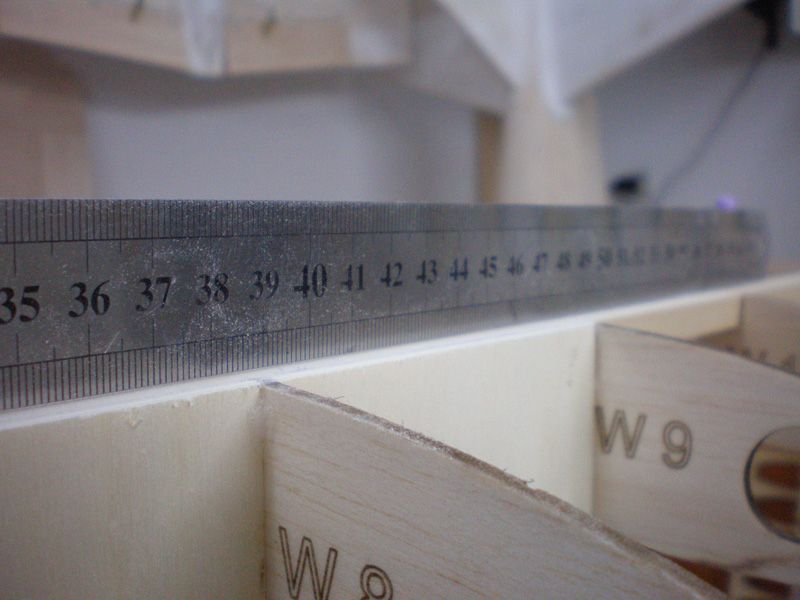

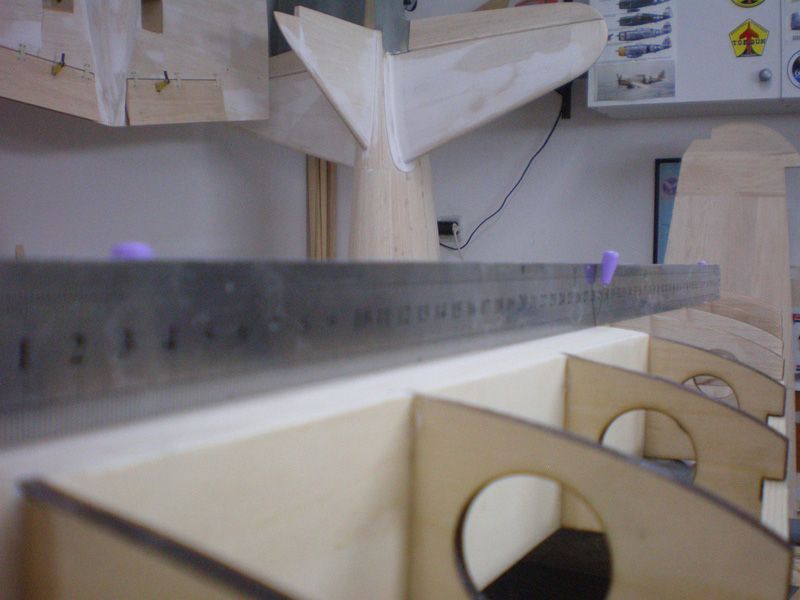

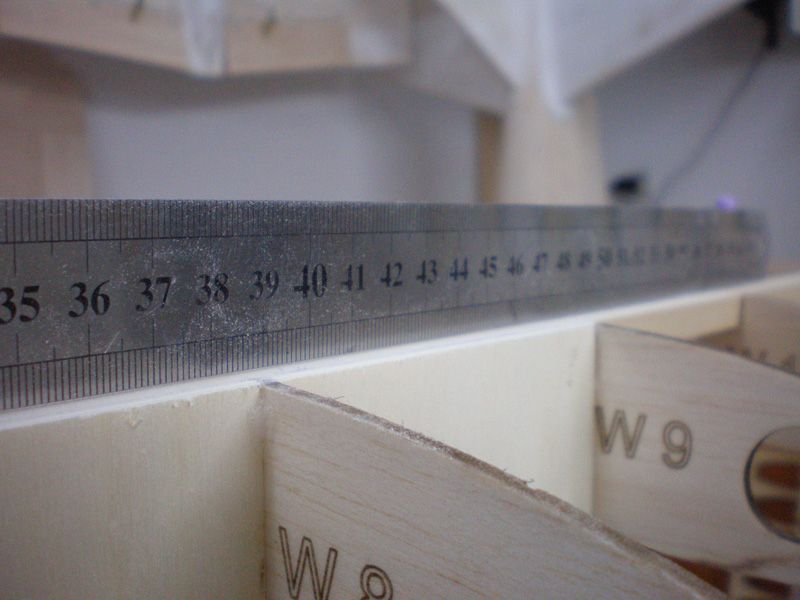

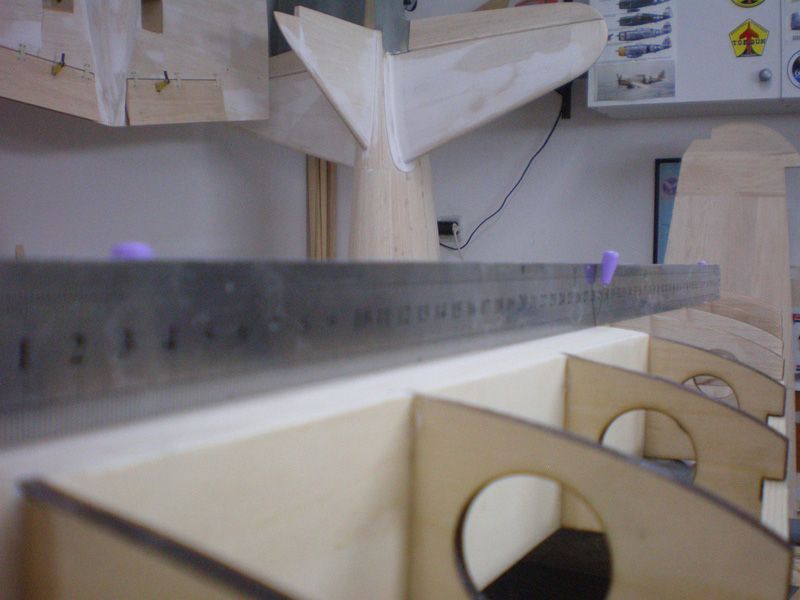

Other test was be with ruler...

I sand all spars at the end...

I glued outer servo plate...

Few picture of the wing before sheeting...

In this stage I must admit that wing is extreme strong. I measured everything and weight is maybe little higher, bur in case to use smaller spars, thinner ply ribs and few other details wing will be maybe 300 - 400 gr lighter.

My goal is to made strong model which I will fly from pretty rough terrain we have here on our airfield.

Don't forget position of the wheels in the wing that must withstand the occasional rough landing...

All in all, I'm pleased with the results so far...

First balsa plates on the upper side...

Regards

Mirce

Because this is first Galeb G 2 model, prototype, I find some things which can be changed.

One of these will be this part of building, making plates between ribs and spars. Martin change drawings and now this plates will be in one piece in which will come every rib, something like "comb". That construction will immediately position every rib exactly on place and will close space between ribs and spars...

Of course, few more little changes will be done in construction, but that is just details...

As I told I made plates...

I chack how balsa will lie down on wing...

Other test was be with ruler...

I sand all spars at the end...

I glued outer servo plate...

Few picture of the wing before sheeting...

In this stage I must admit that wing is extreme strong. I measured everything and weight is maybe little higher, bur in case to use smaller spars, thinner ply ribs and few other details wing will be maybe 300 - 400 gr lighter.

My goal is to made strong model which I will fly from pretty rough terrain we have here on our airfield.

Don't forget position of the wheels in the wing that must withstand the occasional rough landing...

All in all, I'm pleased with the results so far...

First balsa plates on the upper side...

Regards

Mirce

#40

Thread Starter

In last few days I was "slow down" my work on Galeb, because I have some renovations in the house, and I was hanging out with the masons, electricians, plumbers, carpenters ...

But, at evening, I find some time to little work on model...

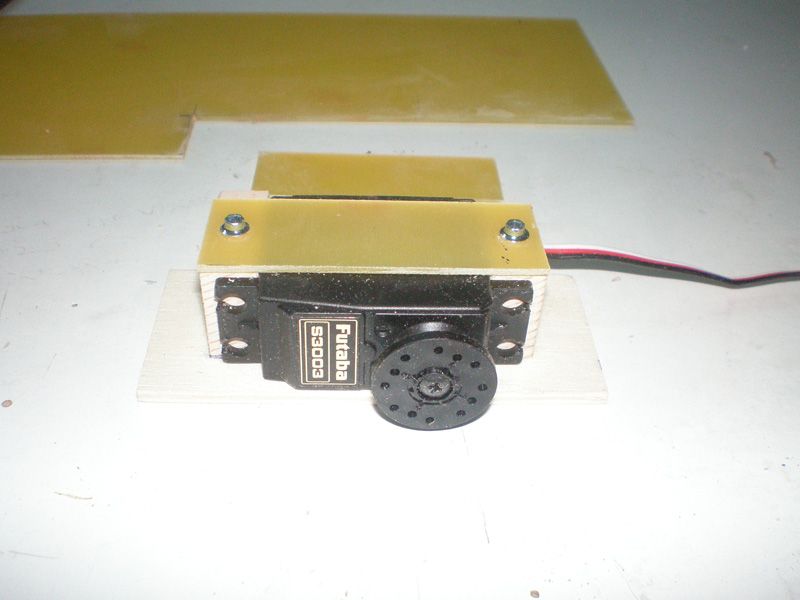

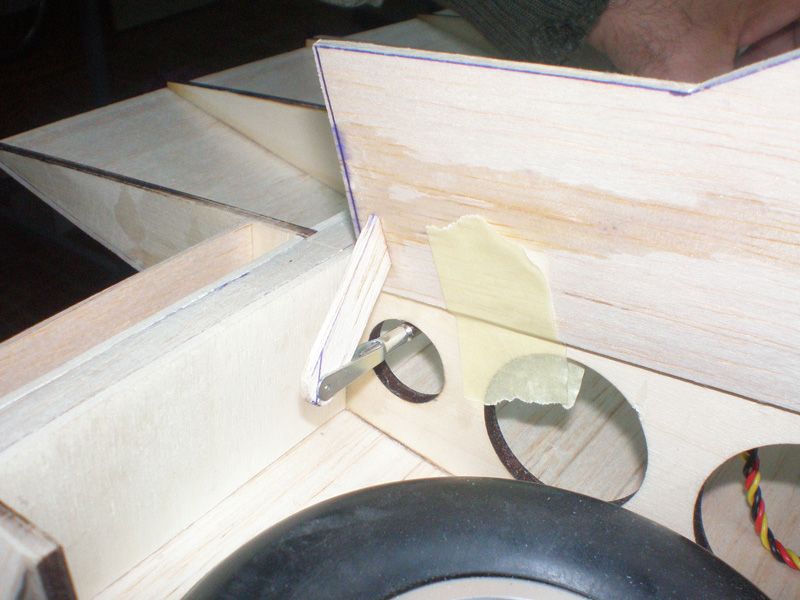

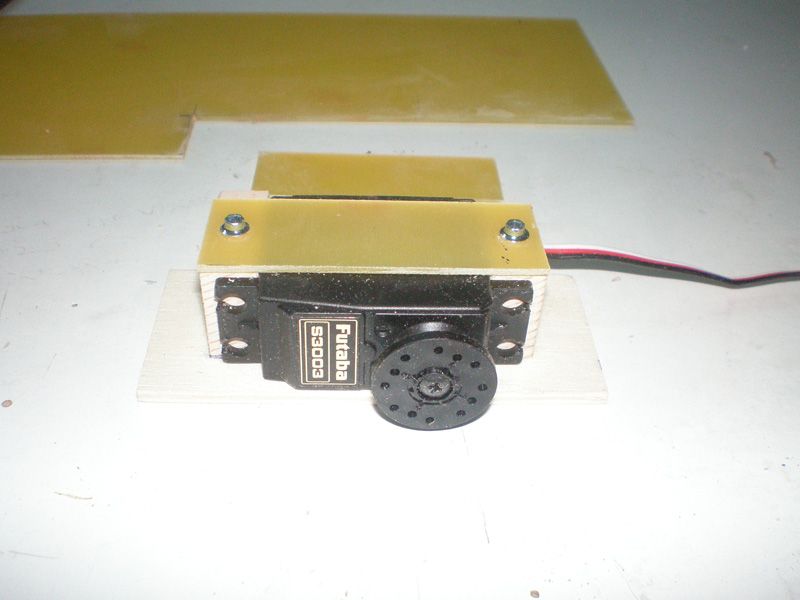

Martin, guy who work on 3D project, and Dragan, who have laser cut machine, made few new parts. Martin made drawings, and Dragan cut 6 mm thick ply plates for landing gears.

He also made 4 pieces of 3 mm multilayer beech plywood, which is very, very strong, for front wing pin.

When I got those parts, I first glued 2 of those 3 mm ply in one piece. For this I used epoxy glue...

New parts fit in the wing very good...

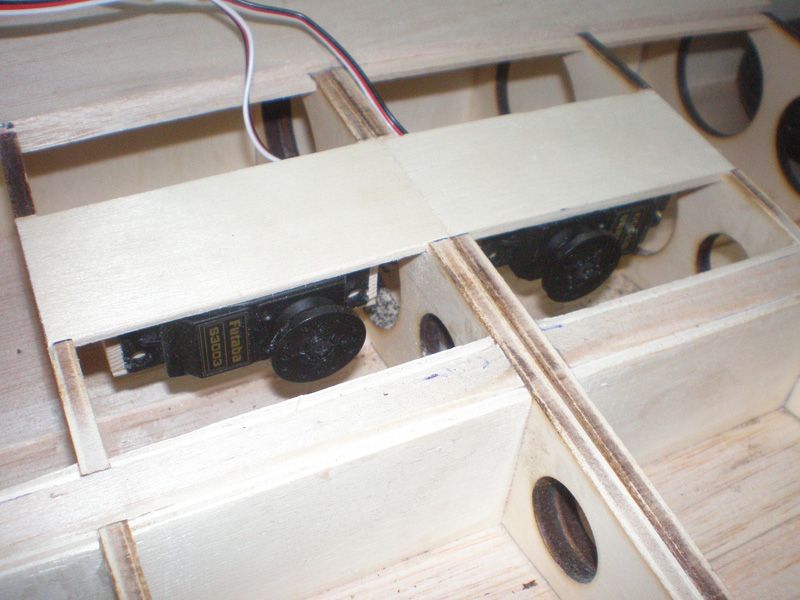

Same story is with landing gear plates...

I set landing gear on plate, fix it with screws, and set all together on the wing...

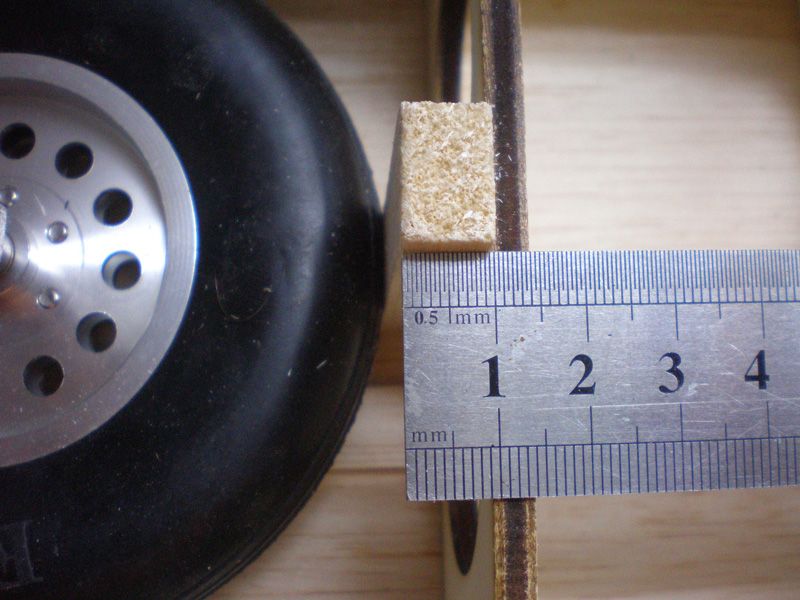

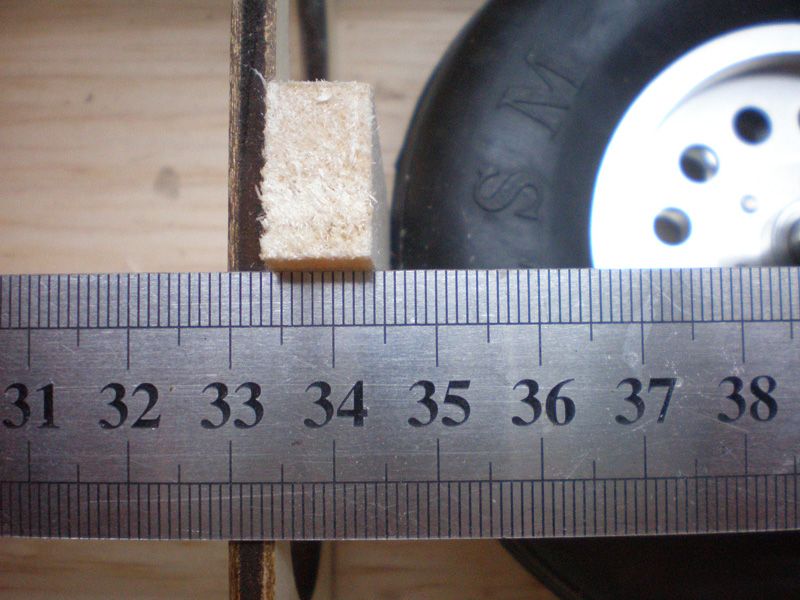

Landing gears come from German firm Bechotec, and they are for models up to 16 kg (Bechotec - C 40)...

Under landing gear plate I made support ribs to which the plate rests. Martin again made drawings, and Dragan cut parts...

We have dilemma whether to make plate from 4 or 6 mm ply. Decision was made to be thicker, but in that case, because landing gear angle, I need to sand down one corner of the plate.

That was done in 5 minutes...

When balsa come above, it will be like this...

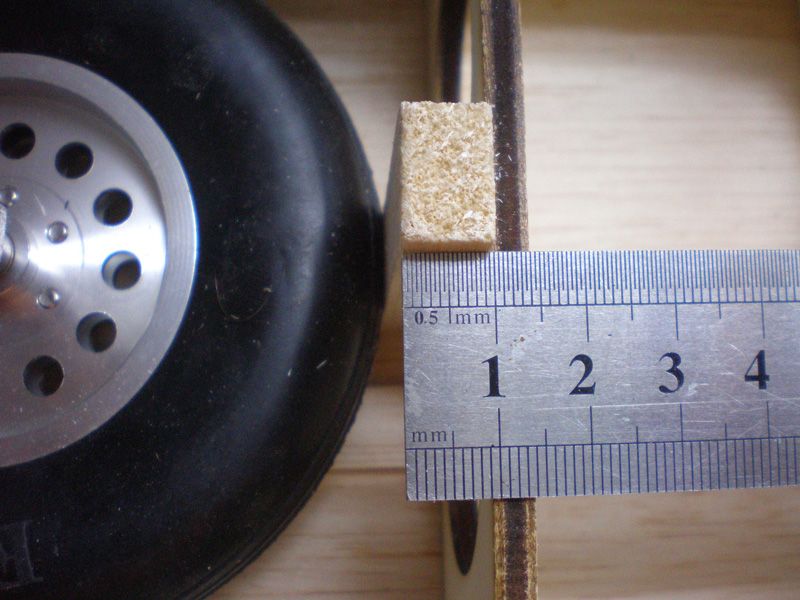

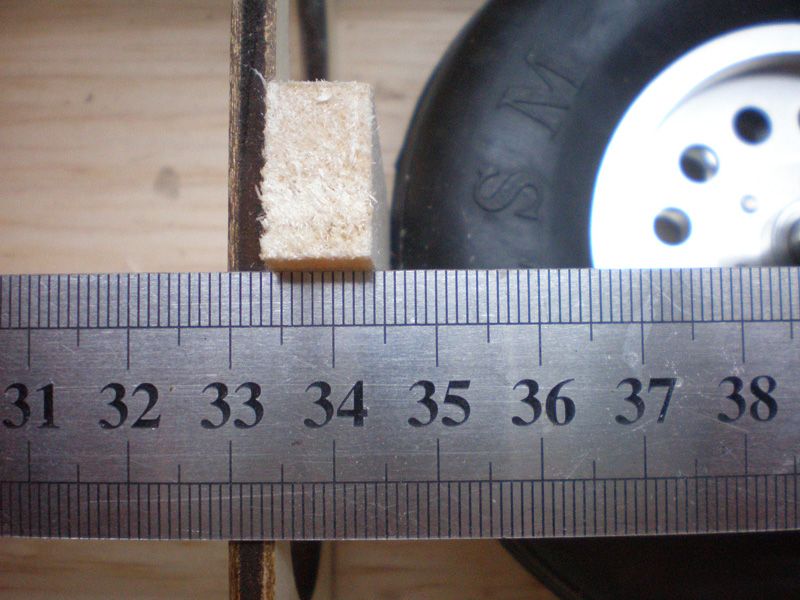

Next step was to glue everything in the place. Before that I made final measuring...

I put one 10 mm balsa on each side to get exactly distance between wheel and rib...

Ruler show exactly same distance in the middle of the wing...

Than I squeezed landing gear...

On the sides of the servo plates I add thin balsa strip on which will recline balsa cower...

I start work on ailerons. Between aileron and flap, on big Galeb G2 was 105 mm, so I made 21 mm distance ( 1/5 scale )...

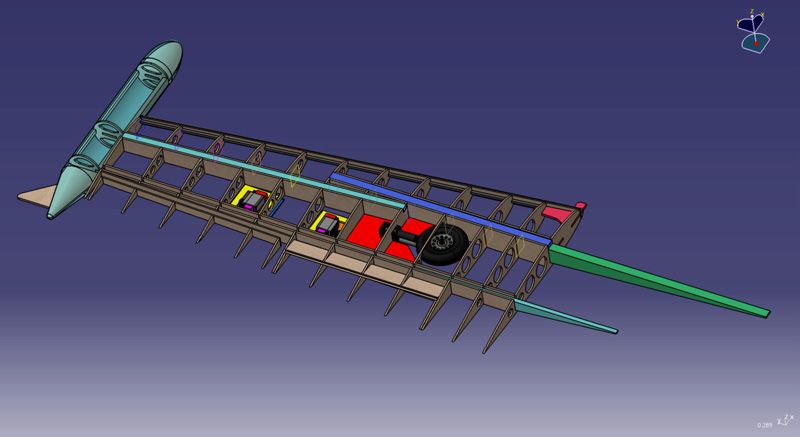

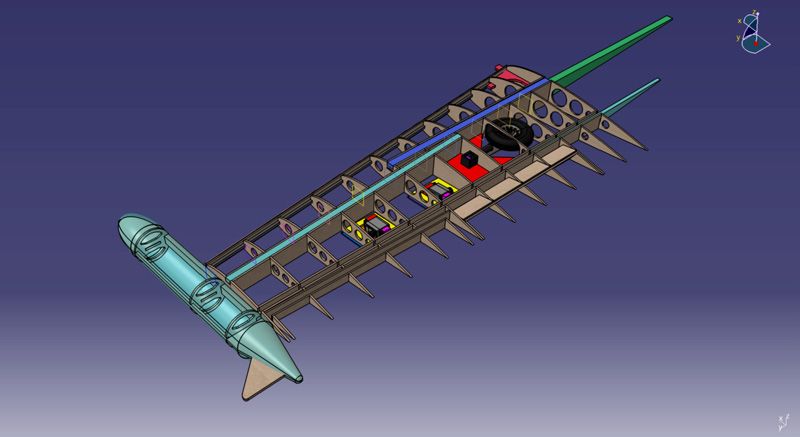

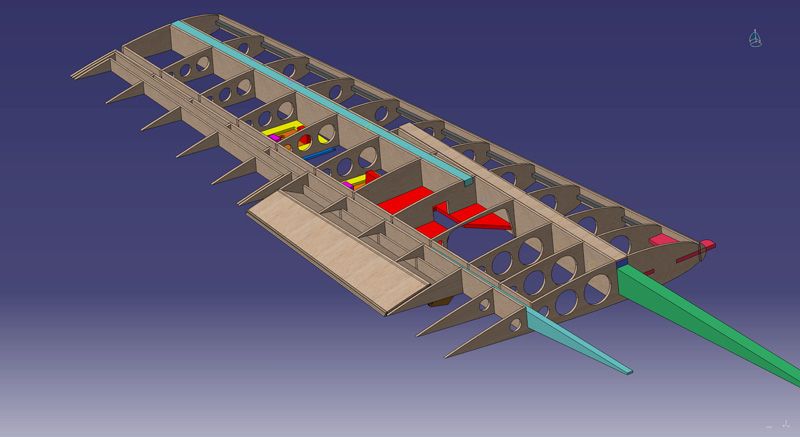

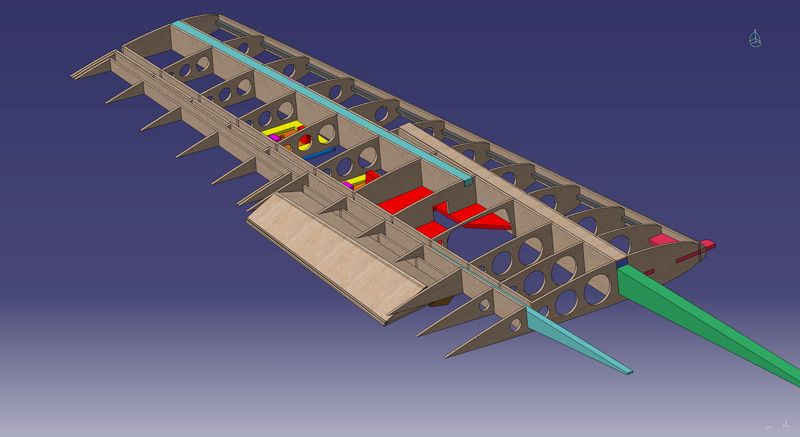

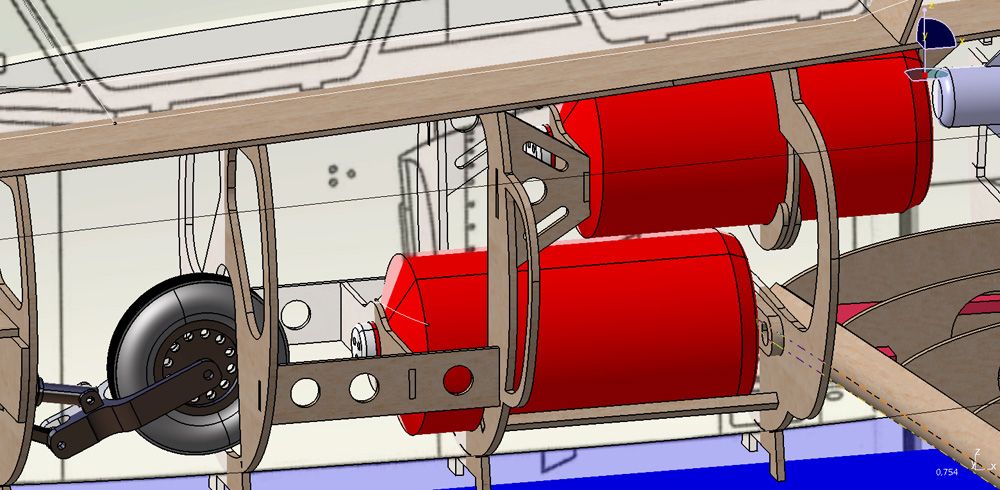

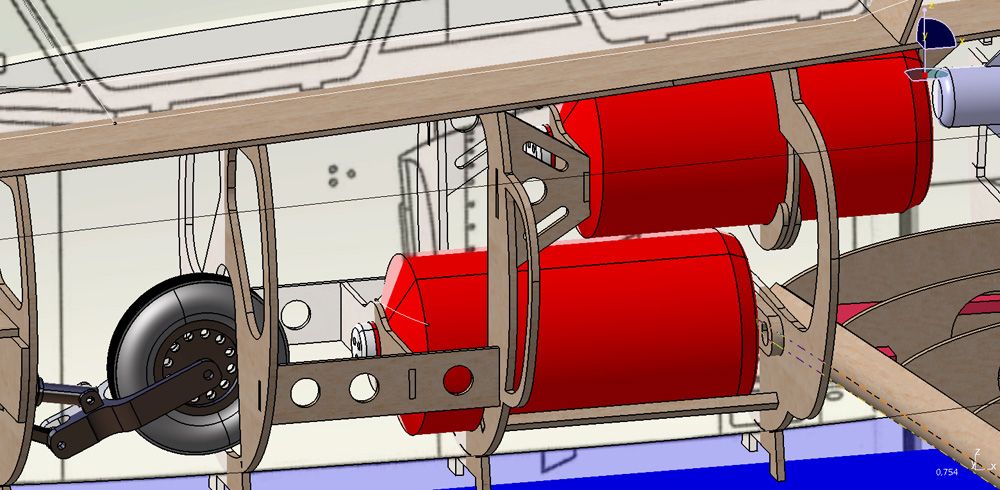

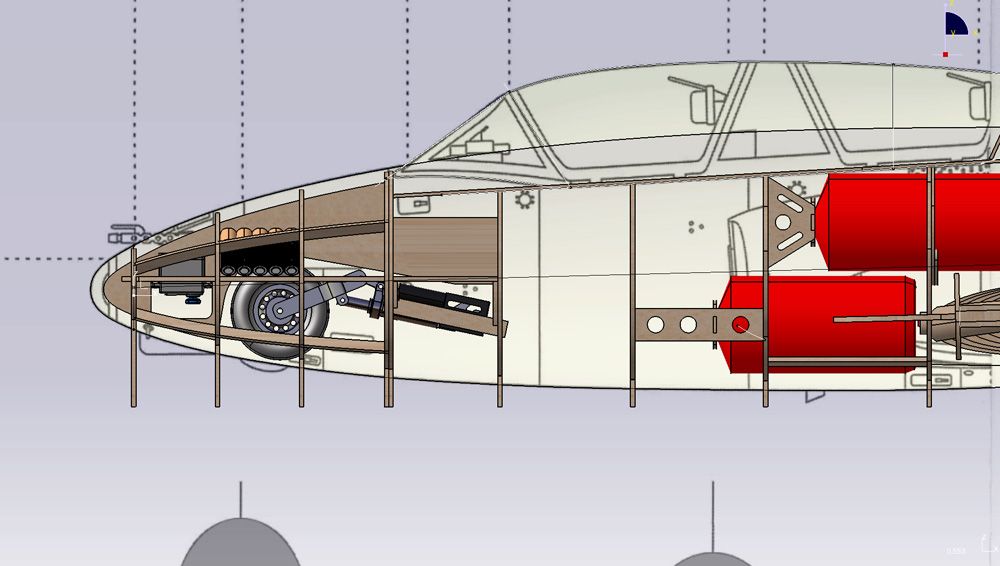

At the end, few pictures of progress on fuselage...

I think that Martin invested so far more than 100 hours in 3D drawings. I was lucky when find him and start this project. Without so quality 3D drawings final product would not have been this good.

On my this year visit Top Gun event, I have opportunity to meet owner of "Da Vinci" firm, which have many CNC machines. From conversation I heard that hour of work in Auto Cad cost 60,00$ !!!

Fortunately for me, here is different story...

Good 3D drawings, laser cut machine and good wood selection give great final product.

Until now I'm very, very satisfied with quality and to be honest, I wasn't expect that all parts fit so good, and everything will be on this level.

Best regards

Mirce

But, at evening, I find some time to little work on model...

Martin, guy who work on 3D project, and Dragan, who have laser cut machine, made few new parts. Martin made drawings, and Dragan cut 6 mm thick ply plates for landing gears.

He also made 4 pieces of 3 mm multilayer beech plywood, which is very, very strong, for front wing pin.

When I got those parts, I first glued 2 of those 3 mm ply in one piece. For this I used epoxy glue...

New parts fit in the wing very good...

Same story is with landing gear plates...

I set landing gear on plate, fix it with screws, and set all together on the wing...

Landing gears come from German firm Bechotec, and they are for models up to 16 kg (Bechotec - C 40)...

Under landing gear plate I made support ribs to which the plate rests. Martin again made drawings, and Dragan cut parts...

We have dilemma whether to make plate from 4 or 6 mm ply. Decision was made to be thicker, but in that case, because landing gear angle, I need to sand down one corner of the plate.

That was done in 5 minutes...

When balsa come above, it will be like this...

Next step was to glue everything in the place. Before that I made final measuring...

I put one 10 mm balsa on each side to get exactly distance between wheel and rib...

Ruler show exactly same distance in the middle of the wing...

Than I squeezed landing gear...

On the sides of the servo plates I add thin balsa strip on which will recline balsa cower...

I start work on ailerons. Between aileron and flap, on big Galeb G2 was 105 mm, so I made 21 mm distance ( 1/5 scale )...

At the end, few pictures of progress on fuselage...

I think that Martin invested so far more than 100 hours in 3D drawings. I was lucky when find him and start this project. Without so quality 3D drawings final product would not have been this good.

On my this year visit Top Gun event, I have opportunity to meet owner of "Da Vinci" firm, which have many CNC machines. From conversation I heard that hour of work in Auto Cad cost 60,00$ !!!

Fortunately for me, here is different story...

Good 3D drawings, laser cut machine and good wood selection give great final product.

Until now I'm very, very satisfied with quality and to be honest, I wasn't expect that all parts fit so good, and everything will be on this level.

Best regards

Mirce

#41

Mirce

Have you thought of covering the wings in Fibreglass sheet? would make the painting/finishing much easier and would not cause a world shortage of building pins. LOL

Mike

Have you thought of covering the wings in Fibreglass sheet? would make the painting/finishing much easier and would not cause a world shortage of building pins. LOL

Mike

#42

Join Date: Jan 2007

Location: farnborough, , UNITED KINGDOM

Posts: 3,294

Likes: 0

Received 1 Like

on

1 Post

Mike looking at his construction and the fact he has left the thickness of the balse sheet in all the ribs and servo plates using G10 or FR4 sheet will mean he has to adjust all these which I would suspect is a truck load of work - its a superb build though and that wing is going to be bullet proof and almost certainly stronger than a composite version I would suspect.

Great work Mirce and as you say to have friends who can draw in CAD (and have the free time!) and another with a laser cutter your a lucky man!

marcs

Great work Mirce and as you say to have friends who can draw in CAD (and have the free time!) and another with a laser cutter your a lucky man!

marcs

#43

Agreed Mark, but with 3D drawing and laser cutting the adjustment would be easy to accomodate on a second build, also agree this is a superb job, I just love the way correctly laser cut ribs and spars slot together so accurately, its a pleasure to see the pics, looking forward the fus build.

Mike

Mike

#44

Thread Starter

Thank you for kind words...

I will cover wing with balsa sheet and above will go 25 gr glass cloth with epoxy resin...

Than I'll made same technology like on all other my models: Mirce Finish Set for panel lines and rivets, details on wing and fuselage and finally paint...

I have now very good crew, we cover all building stages, so I now haven't problem to made entire model from 3D drawings to paint in final clear cote...

Best regards

Mirce

I will cover wing with balsa sheet and above will go 25 gr glass cloth with epoxy resin...

Than I'll made same technology like on all other my models: Mirce Finish Set for panel lines and rivets, details on wing and fuselage and finally paint...

I have now very good crew, we cover all building stages, so I now haven't problem to made entire model from 3D drawings to paint in final clear cote...

Best regards

Mirce

#45

Thread Starter

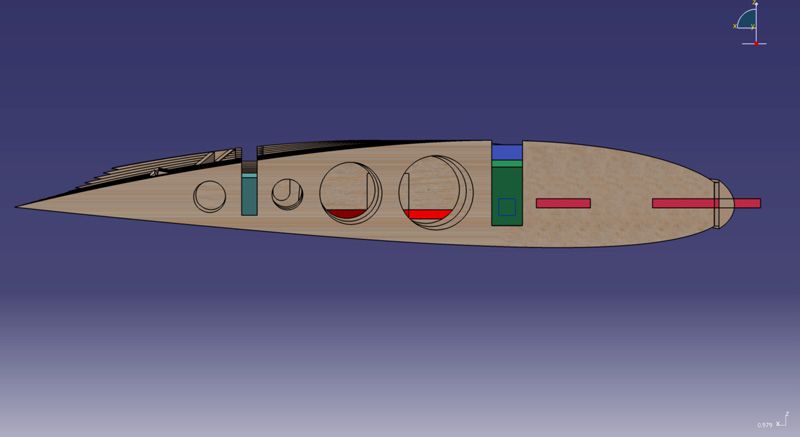

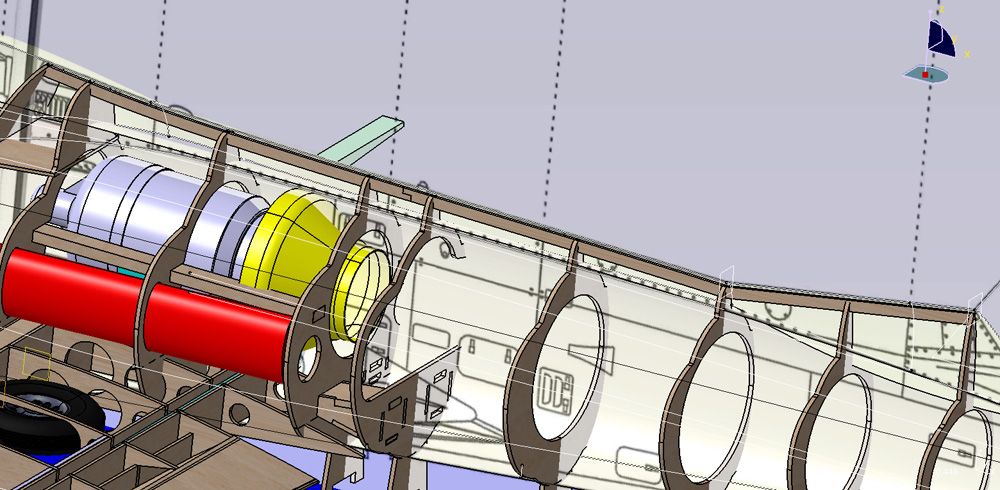

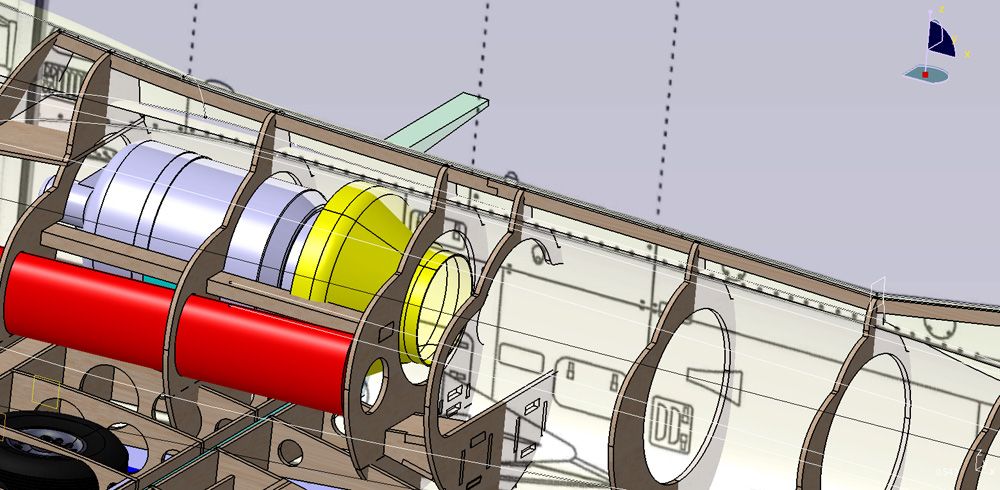

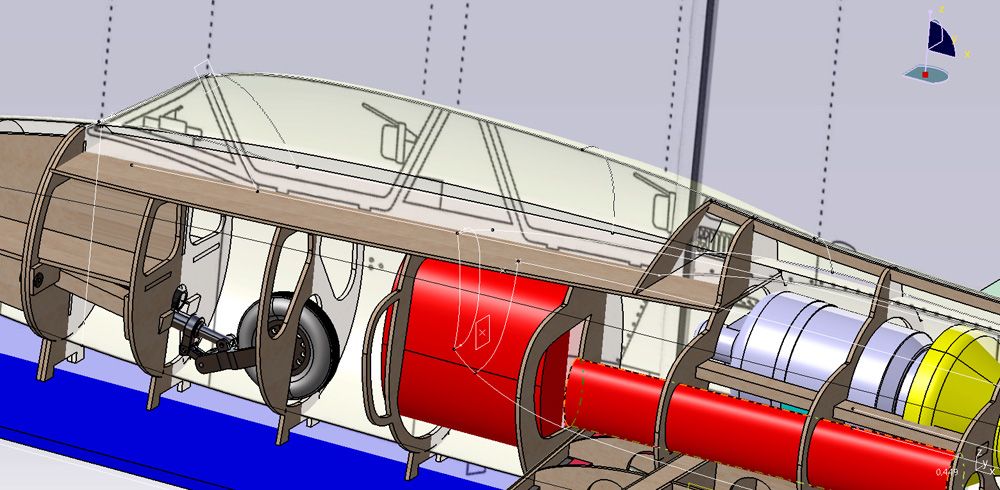

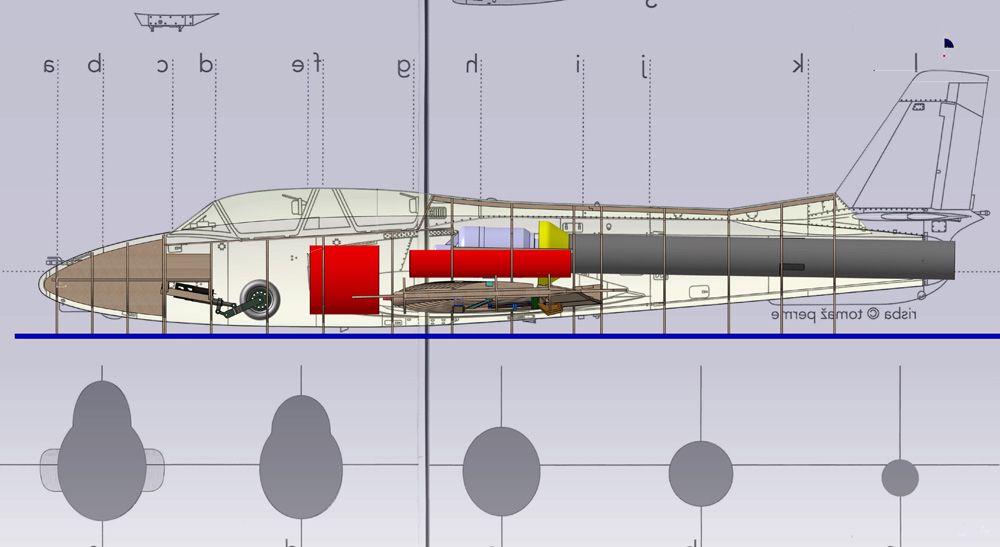

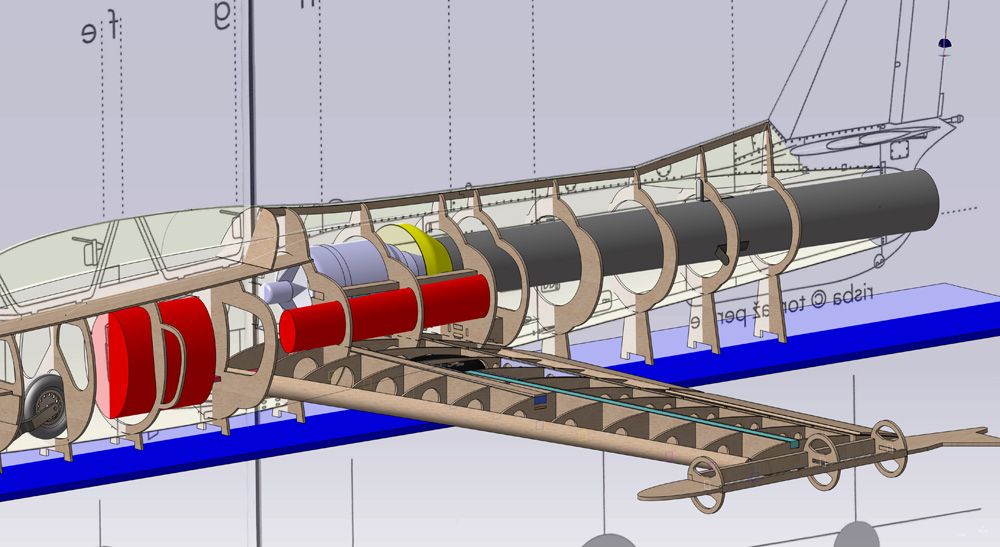

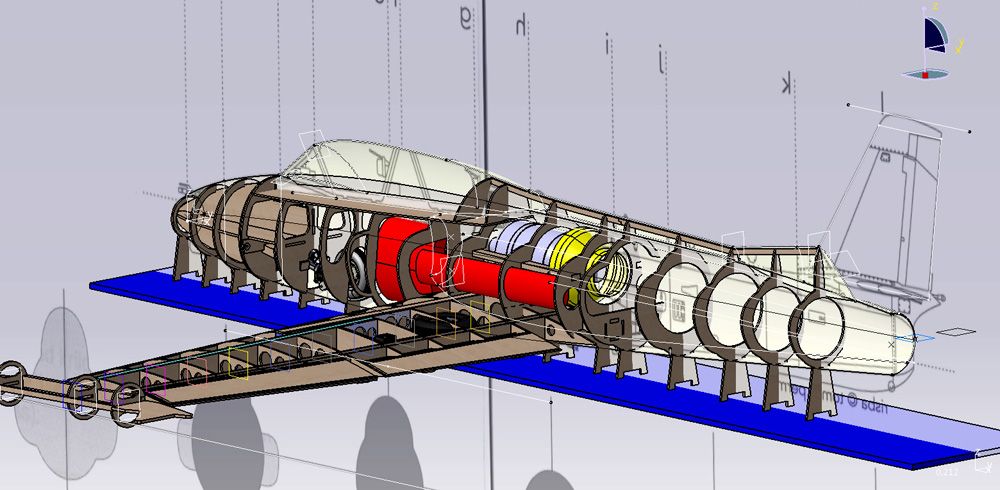

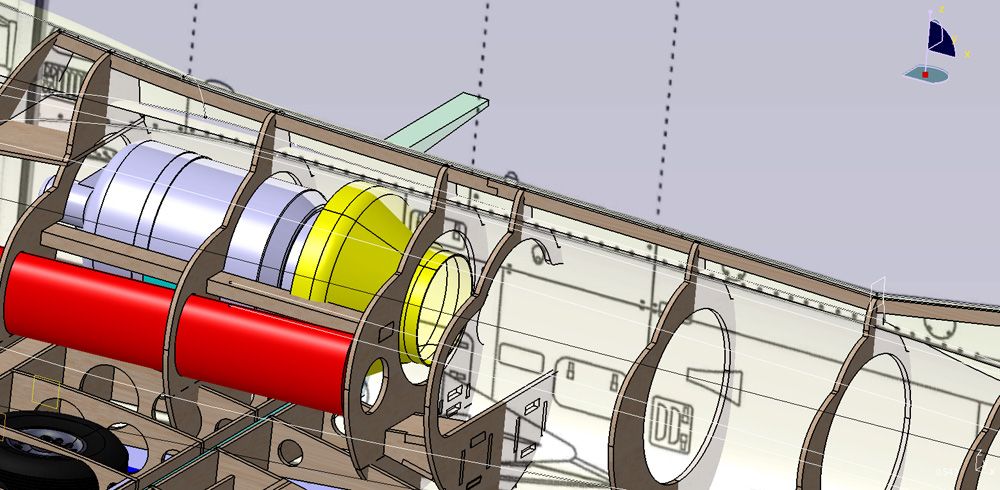

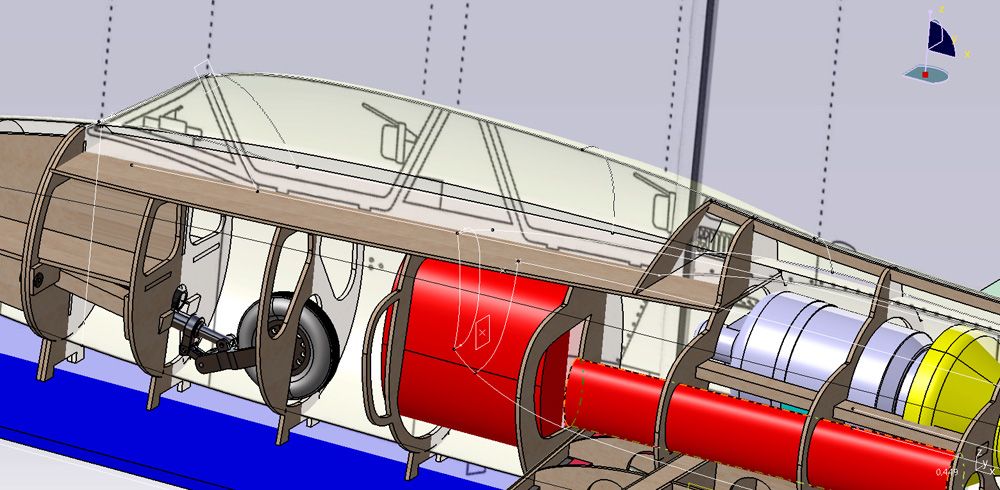

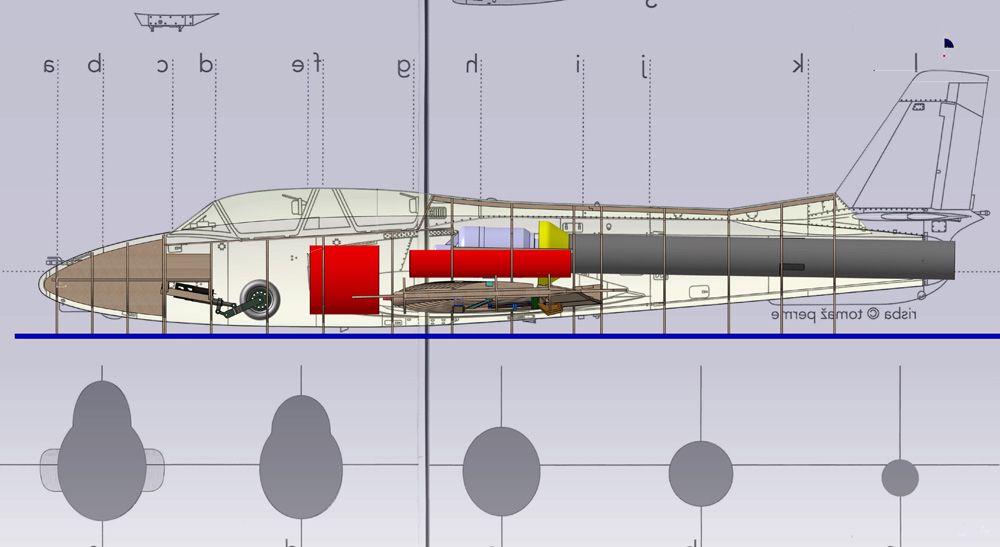

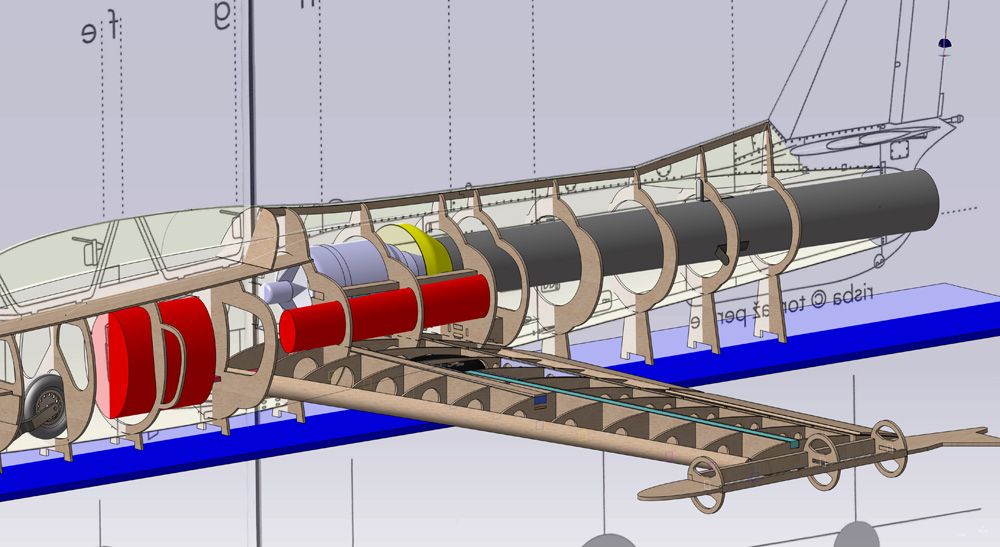

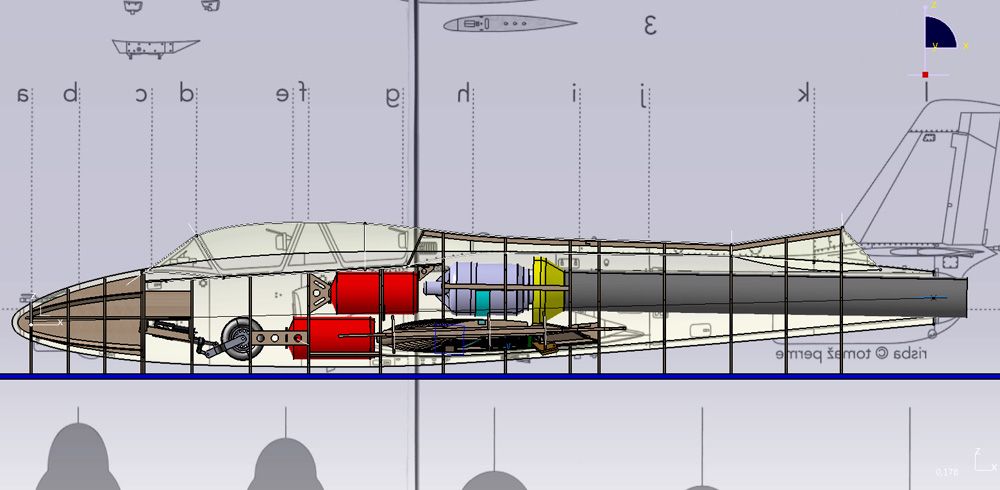

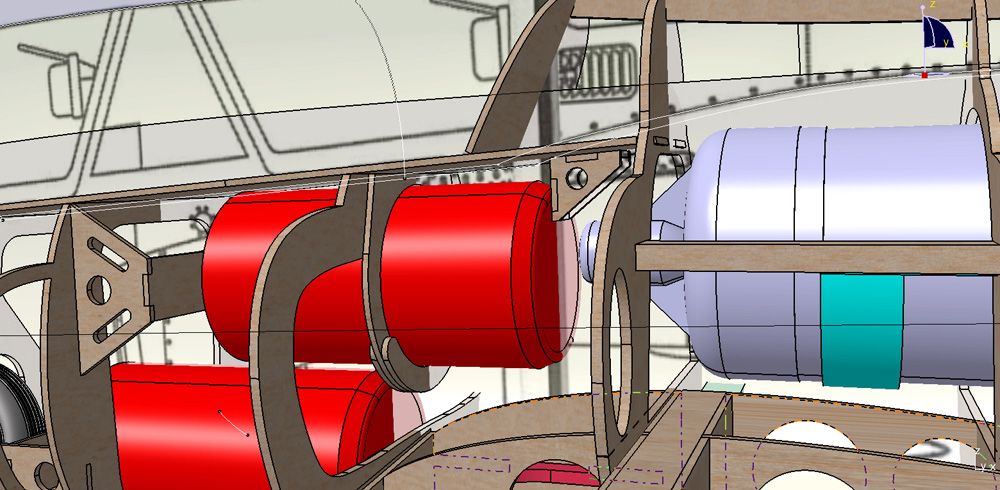

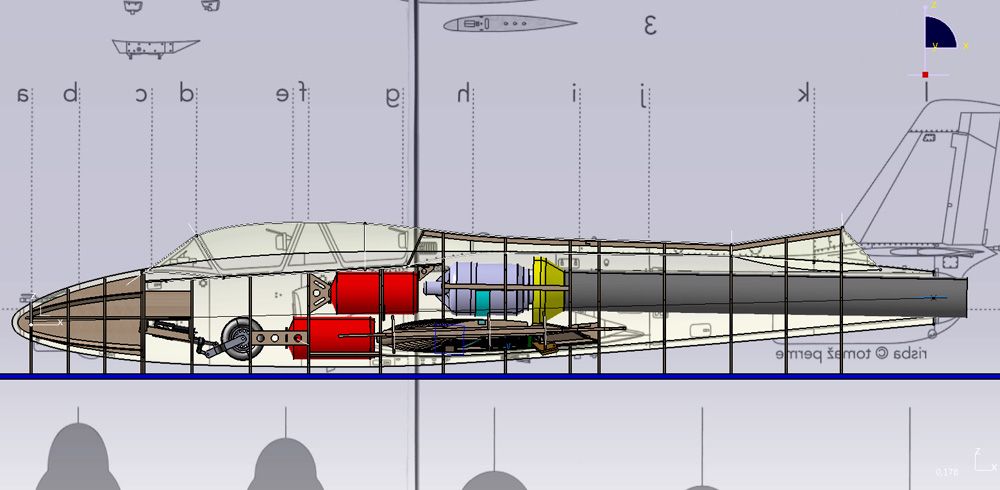

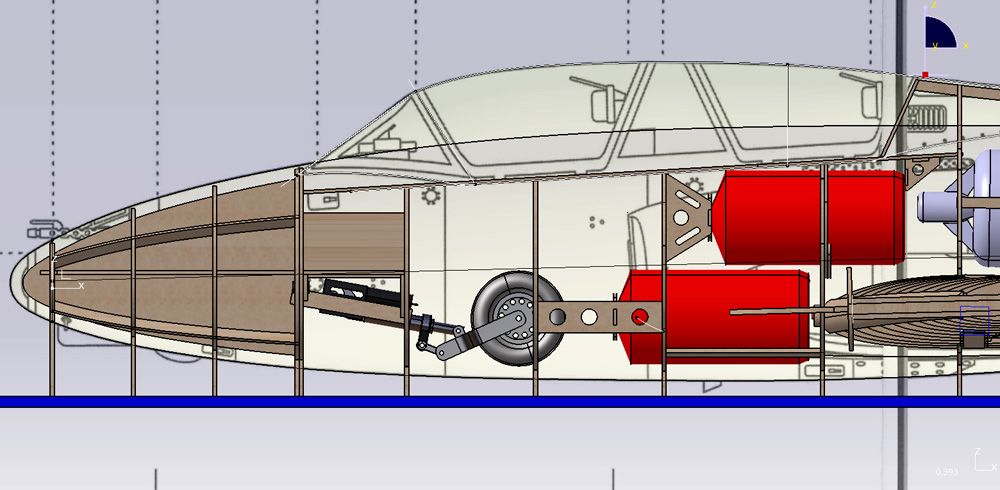

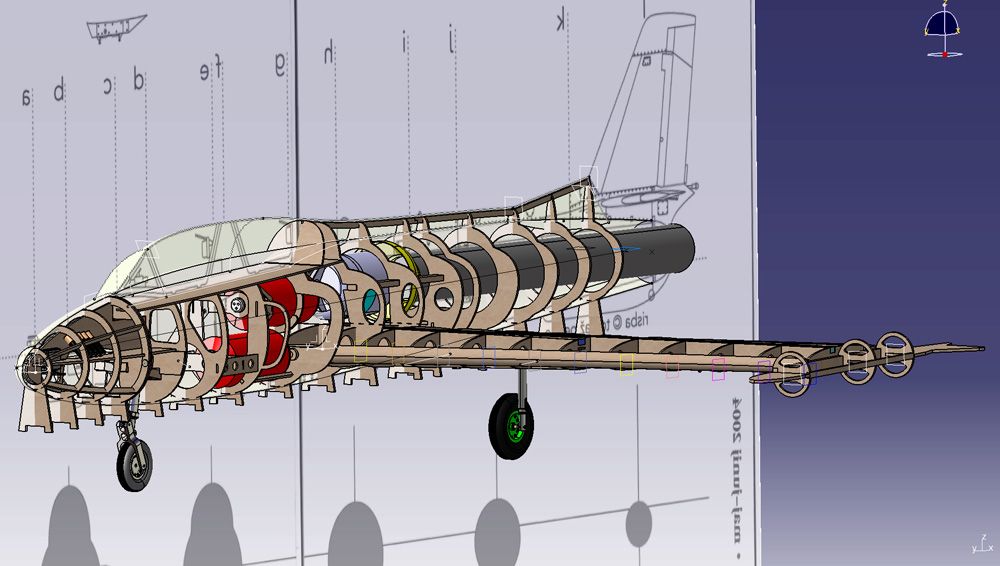

Martin was here yesterday, and whole evening we used for working on fuselage drawings. Of course, it's not finished yet, but progress is visible...

I think to made three tanks + uat. Sides tanks are 0,6 l each, and main tank is 1,2 liter (on picture is bigger 2 liter)

Side tanks are in and little behind CG, but front tank is forward, so everything near CG.

First will be used fuel from side tanks, and than from the front tank.

Side tank size and shape don't need to be like this, because now I must find similar tank which I can install in the fuselage.

If someone have idea where to try to find it, please let me know.

It is not important to be 100% same like this on drawings, but it must fit in this fuselage area...

I saw on RC Universe that someone made tanks, maybe I can get address and try to ask for price and order tanks for my model.

Ribs for fuselage will have "legs" which will aligned all ribs in line and good height. On every fuselage side ribs will have parts which will connect ribs together. On every rib, and on part for connection, will be slot and those parts will fit and join perfectly.

Right now Martin draw only upper part from back of the cockpit to the rudder. It's pretty long, so it is made from two parts ( I must think about shipping too ).

Martin made cockpit plate too...

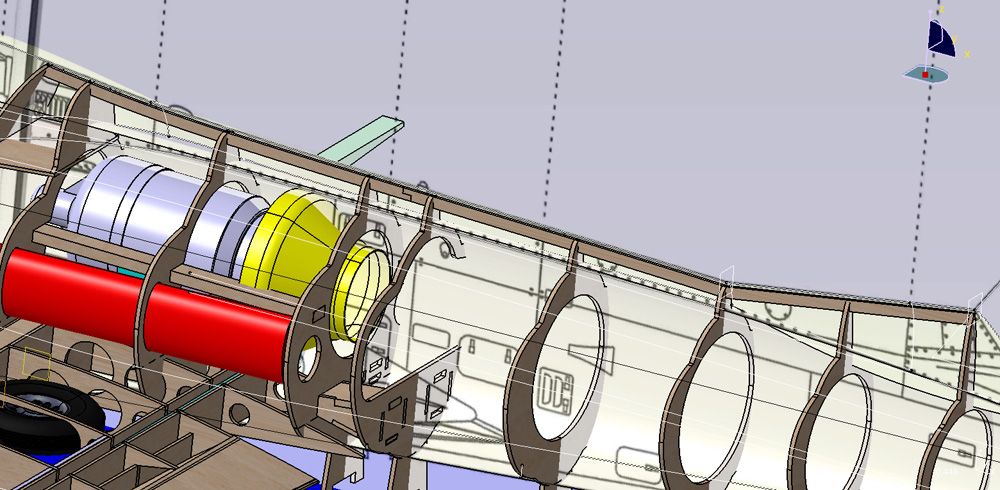

We made plates for turbine. Plates are long, so modelers have opportunity to move engine forward or backward. I put turbine pretty forward, almost in the CG.

Thrust tube is in this case 840 mm long...

I speak today with Jet Cat, and got the information that they can made thrust tube for this model. I will made single wall tube, to reduce weight, but diameter of last rib if big enough for double side tube also.

Inner diameter for P 80 is 85 mm and on this length is constant from turbine to rear end.

To be continued...

Regards

Mirce

I think to made three tanks + uat. Sides tanks are 0,6 l each, and main tank is 1,2 liter (on picture is bigger 2 liter)

Side tanks are in and little behind CG, but front tank is forward, so everything near CG.

First will be used fuel from side tanks, and than from the front tank.

Side tank size and shape don't need to be like this, because now I must find similar tank which I can install in the fuselage.

If someone have idea where to try to find it, please let me know.

It is not important to be 100% same like this on drawings, but it must fit in this fuselage area...

I saw on RC Universe that someone made tanks, maybe I can get address and try to ask for price and order tanks for my model.

Ribs for fuselage will have "legs" which will aligned all ribs in line and good height. On every fuselage side ribs will have parts which will connect ribs together. On every rib, and on part for connection, will be slot and those parts will fit and join perfectly.

Right now Martin draw only upper part from back of the cockpit to the rudder. It's pretty long, so it is made from two parts ( I must think about shipping too ).

Martin made cockpit plate too...

We made plates for turbine. Plates are long, so modelers have opportunity to move engine forward or backward. I put turbine pretty forward, almost in the CG.

Thrust tube is in this case 840 mm long...

I speak today with Jet Cat, and got the information that they can made thrust tube for this model. I will made single wall tube, to reduce weight, but diameter of last rib if big enough for double side tube also.

Inner diameter for P 80 is 85 mm and on this length is constant from turbine to rear end.

To be continued...

Regards

Mirce

#46

Good luck with your project, it's looking great.

I'm part way through a true scratch build & I can appreciate the work involved.

Unlike yourself I haven't the skills to use CAD software so I'm stuck with drawing

& designing on paper.

I can't wait to see your's (and mine ) finished & flying. John.

) finished & flying. John.

I'm part way through a true scratch build & I can appreciate the work involved.

Unlike yourself I haven't the skills to use CAD software so I'm stuck with drawing

& designing on paper.

I can't wait to see your's (and mine

) finished & flying. John.

) finished & flying. John.

#47

Thread Starter

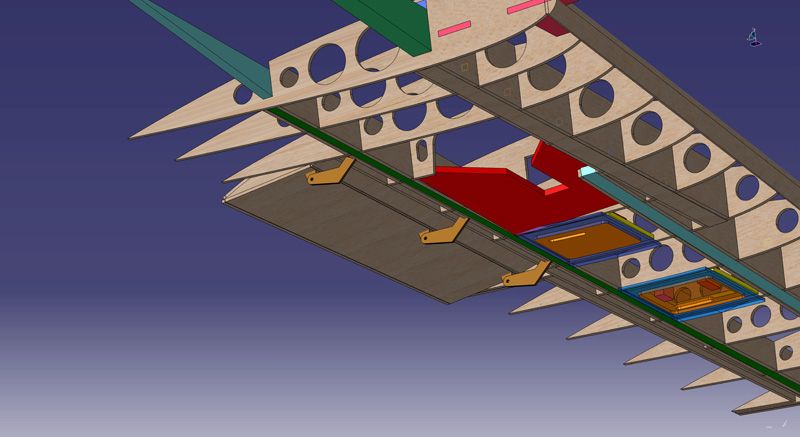

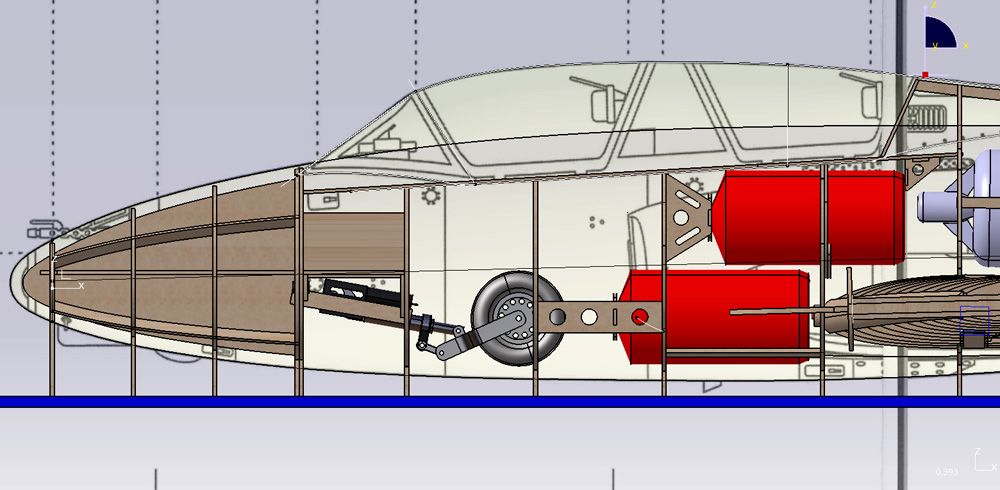

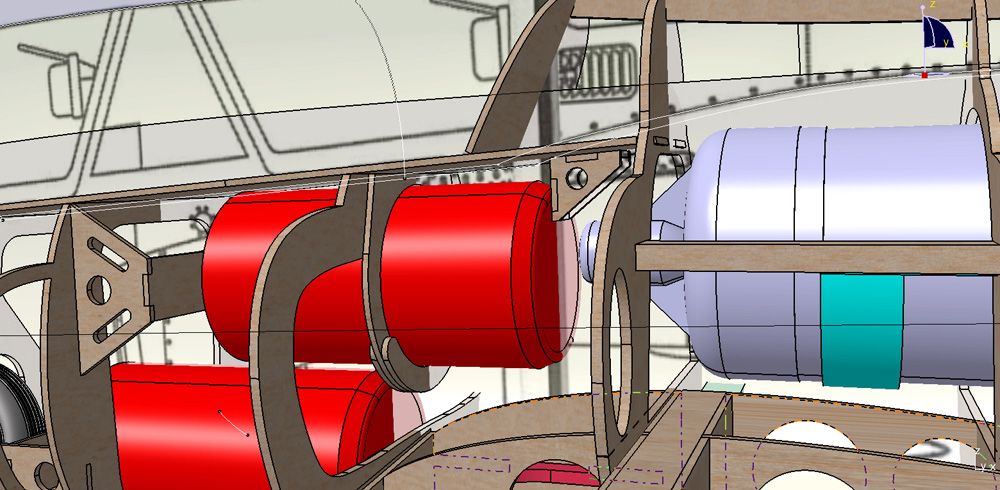

Last evening Martin and I was working on Galeb G2 drawings until early morning hours.

As usual, he worked on virtual 3D and I on real model...

Decision about tanks are made, on G2 will be used same tanks like on my Ziroli F9F model. But up grade is fact that I can put on that tank plug from Dubro tank.

Tanks will be 2 liters of volume + 0.1 liter of UAT. On Panther, with Jet Cat P 80, that is enough for start engine and 8 minutes of flying.

We are trying to made all as simple as possible, so every fuel tank have own bracket. Everything is very easy to instal and service...

Main tank is those closer to turbine...

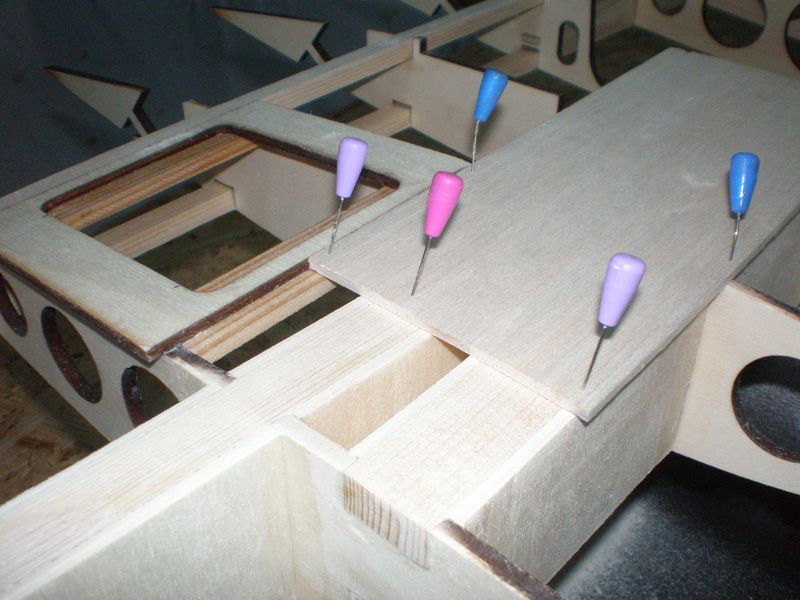

When Martin finished that, he start to work on front, removable part, making 4 pieces which will connect first 4 ribs.

Because ribs will have slot to come on horizontal and vertical plates, pieces are on 45 degrees...

On my side of the workshop I was working on front pin which is now glued in position.

I glued all balsa plates on rear part of the wings upper side...

Than I sand openings in which will come ailerons...

I think that tomorrow, from Jet Cat, will order thrust tube, and those aluminum part which come on tube front.

Tube is 840 mm long...

Regards

Mirce

As usual, he worked on virtual 3D and I on real model...

Decision about tanks are made, on G2 will be used same tanks like on my Ziroli F9F model. But up grade is fact that I can put on that tank plug from Dubro tank.

Tanks will be 2 liters of volume + 0.1 liter of UAT. On Panther, with Jet Cat P 80, that is enough for start engine and 8 minutes of flying.

We are trying to made all as simple as possible, so every fuel tank have own bracket. Everything is very easy to instal and service...

Main tank is those closer to turbine...

When Martin finished that, he start to work on front, removable part, making 4 pieces which will connect first 4 ribs.

Because ribs will have slot to come on horizontal and vertical plates, pieces are on 45 degrees...

On my side of the workshop I was working on front pin which is now glued in position.

I glued all balsa plates on rear part of the wings upper side...

Than I sand openings in which will come ailerons...

I think that tomorrow, from Jet Cat, will order thrust tube, and those aluminum part which come on tube front.

Tube is 840 mm long...

Regards

Mirce

#48

Thread Starter

Since the last writing I made few things on Galeb G2...

Complete upper surface is covered with balsa, but first I must on the front of the ribs glue vertical balsa plate...

Than I prepared upper and lower edges to be same like rib...

Balsa plates for covering was weted with hot water...

...next was glue...

...and when everything get dry I send edges on upper surface...

I almost don't need to sand surface, just a little connections between balsa plates.

Now I start work on lower wing side. I prepare areas for flaps.

First, I sand surplus on the ribs from rear rib flap part...

Next was to sand trailing edge and made two small ribs on the both area sides...

Than I glued vertical balsa plate...

Ruler was used for perfect direction...

With horizontal plate work was done. I used two harder wood plates to fix trailing edge to stay flat...

After light sanding, wing look like this...

I put this story on my web site too, and few days ago, one my friend send me e-mail, and told that everything is nice, but front wheel, when come in fuselage is not go backward but forward...

I check it and that was right...[X(]

So, Martin need to made change in 3D drawing...

Before:

Now:

Thank God, this was easy to amend. In this scale Galeb is pretty big model, so in front of the fuselage is still a lot of space for battery and other parts.

I must told again, drawings I put here are not finished yet, we made every day some changes...

Form Jet Cat I ordered thrust tube and aluminum inlet for Galeb G2 and P-80. Hope parts will come before New year.

And something that has nothing to do with this topic, yesterday come my daughters class to visit my work shop...

I showed them some my models, "secrets" from workshop...

Their eyes shone, and kids asked many questions...

Finally, we made some noise. I started Zenoah GT 80 on Hellcat and Jet Cat turbine on Panther...

At the end group photo...

All effort I invest in my models worth for this smiles and such a pleasure... Kids was full of impressions...

That's all for today...

Best regards

Mirce

Complete upper surface is covered with balsa, but first I must on the front of the ribs glue vertical balsa plate...

Than I prepared upper and lower edges to be same like rib...

Balsa plates for covering was weted with hot water...

...next was glue...

...and when everything get dry I send edges on upper surface...

I almost don't need to sand surface, just a little connections between balsa plates.

Now I start work on lower wing side. I prepare areas for flaps.

First, I sand surplus on the ribs from rear rib flap part...

Next was to sand trailing edge and made two small ribs on the both area sides...

Than I glued vertical balsa plate...

Ruler was used for perfect direction...

With horizontal plate work was done. I used two harder wood plates to fix trailing edge to stay flat...

After light sanding, wing look like this...

I put this story on my web site too, and few days ago, one my friend send me e-mail, and told that everything is nice, but front wheel, when come in fuselage is not go backward but forward...

I check it and that was right...[X(]

So, Martin need to made change in 3D drawing...

Before:

Now:

Thank God, this was easy to amend. In this scale Galeb is pretty big model, so in front of the fuselage is still a lot of space for battery and other parts.

I must told again, drawings I put here are not finished yet, we made every day some changes...

Form Jet Cat I ordered thrust tube and aluminum inlet for Galeb G2 and P-80. Hope parts will come before New year.

And something that has nothing to do with this topic, yesterday come my daughters class to visit my work shop...

I showed them some my models, "secrets" from workshop...

Their eyes shone, and kids asked many questions...

Finally, we made some noise. I started Zenoah GT 80 on Hellcat and Jet Cat turbine on Panther...

At the end group photo...

All effort I invest in my models worth for this smiles and such a pleasure... Kids was full of impressions...

That's all for today...

Best regards

Mirce

#50

Thread Starter

Thanks Kimhey...

In last few day I made many small works before I add balsa plates on lower wing side.

Around landing gear hole I add balsa parts... I must sand it to get right curve for wing surface...

For ailerons hinges I add balsa blocks...

Next was work on landing gear doors. First I check how the doors looks on the real Galeb G2..

Than I made template from paper and balsa...

For inner door for opening I'll use servo. I must find position for servo, and right movement for door...

Of course, this balsa parts are just templates...

Than next door...

After that I start adding balsa on lower side of the wing. First plate was come in front of the landing gear area...

Check alignment... Here is nothing sanding yet...

Same was made on the other wing side...

Now come time to add plates for screw for wing fixing on the fuselage. I made those plates from 6 mm ply. I made by hand gutter on wing ribs for this plates, but Martin immediately change 3D drawing and add those gutter.

I made holes now, because, when come balsa skin find right middle of the plate will be difficult...

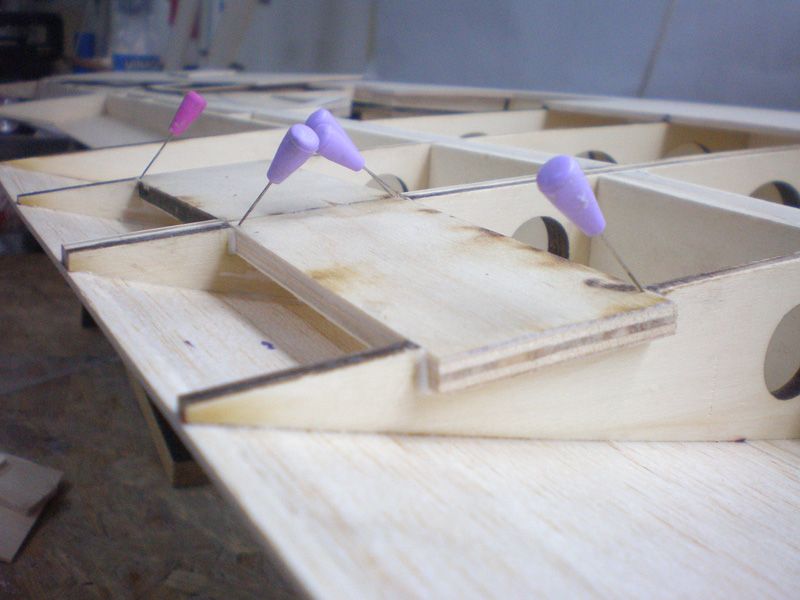

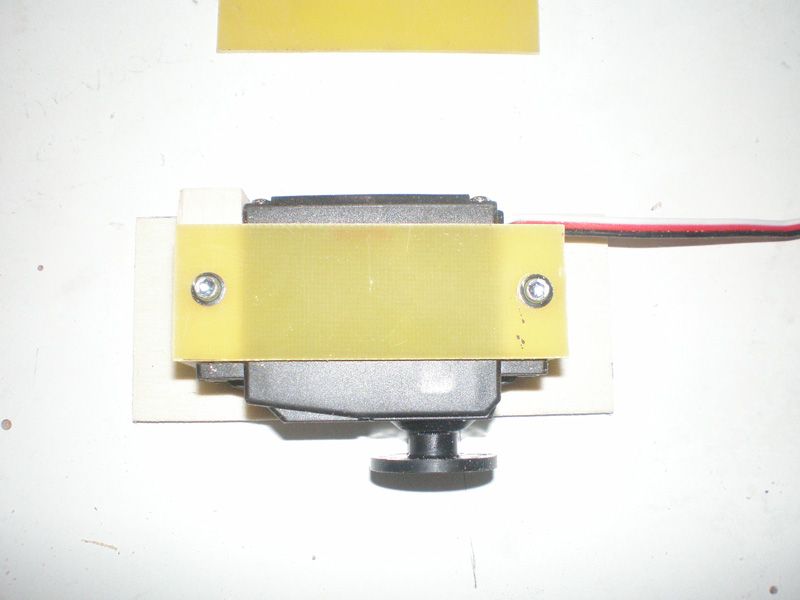

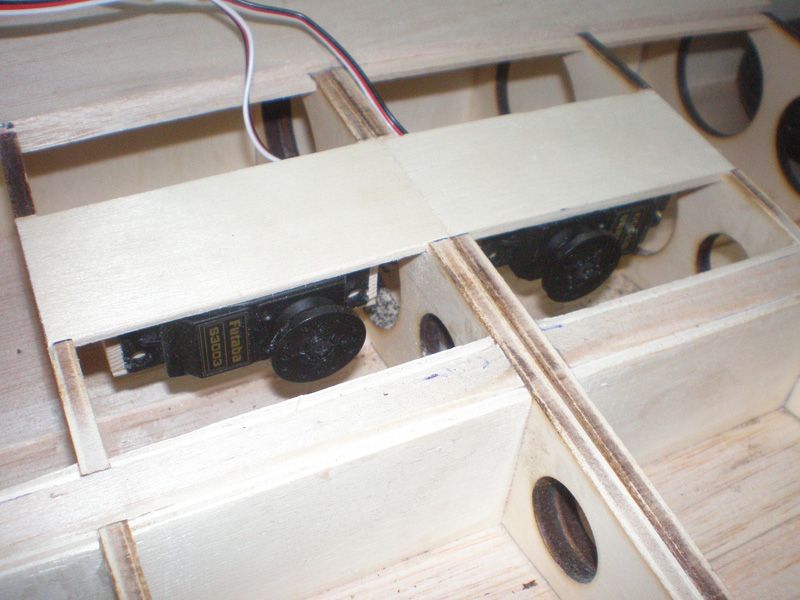

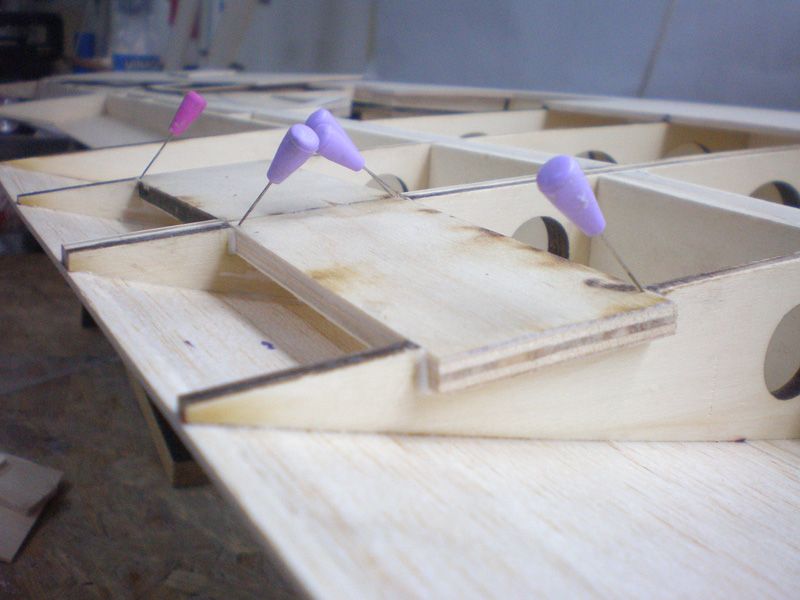

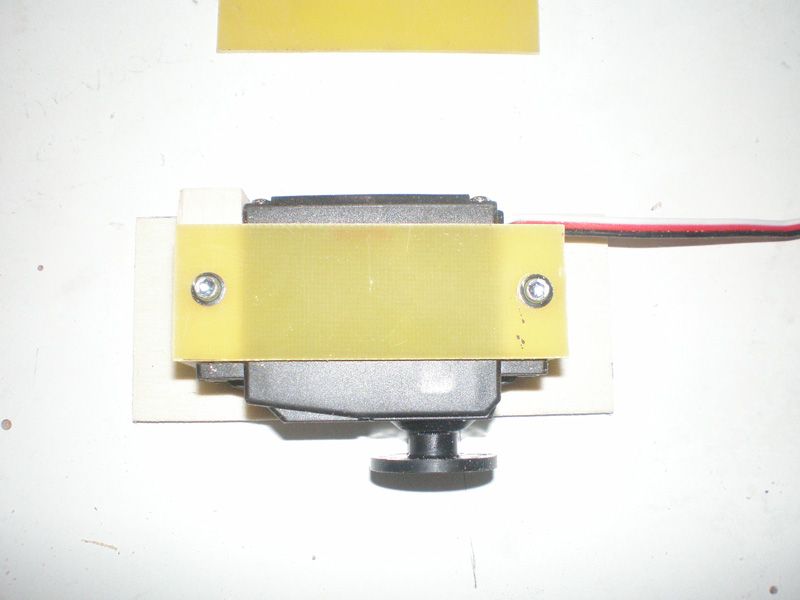

I made plates with servo holder for servos for inner gear doors...

G 10 plate will hold servo in position...

Everything was made same like for screw plates. Martin add this details on drawings also...

Small but important part...

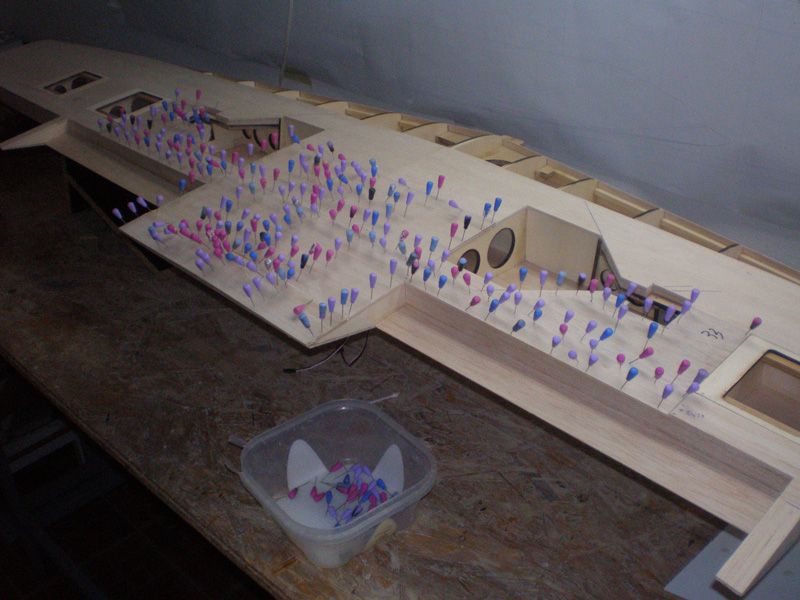

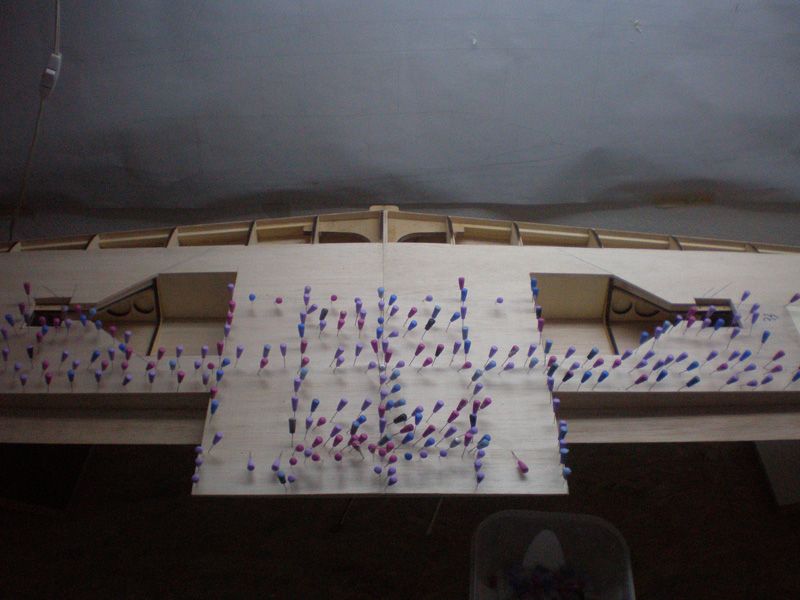

Now everything is ready to continue covering process...

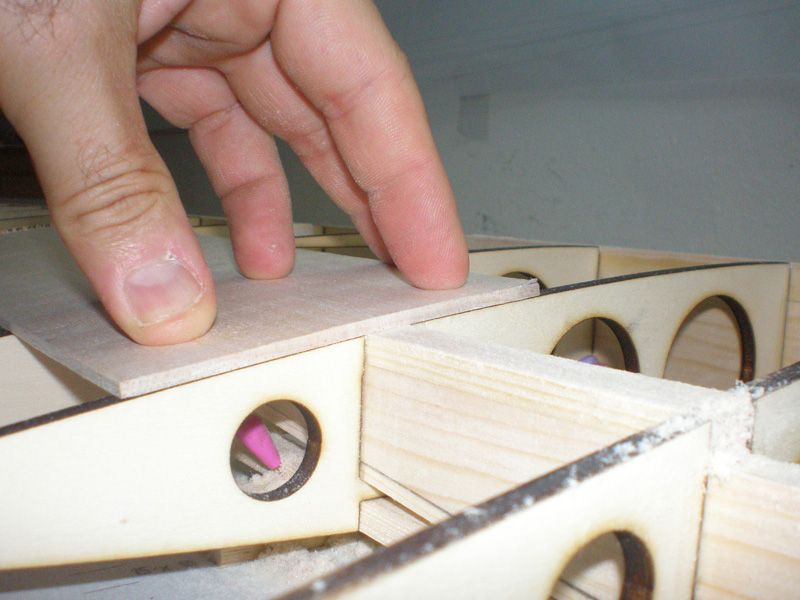

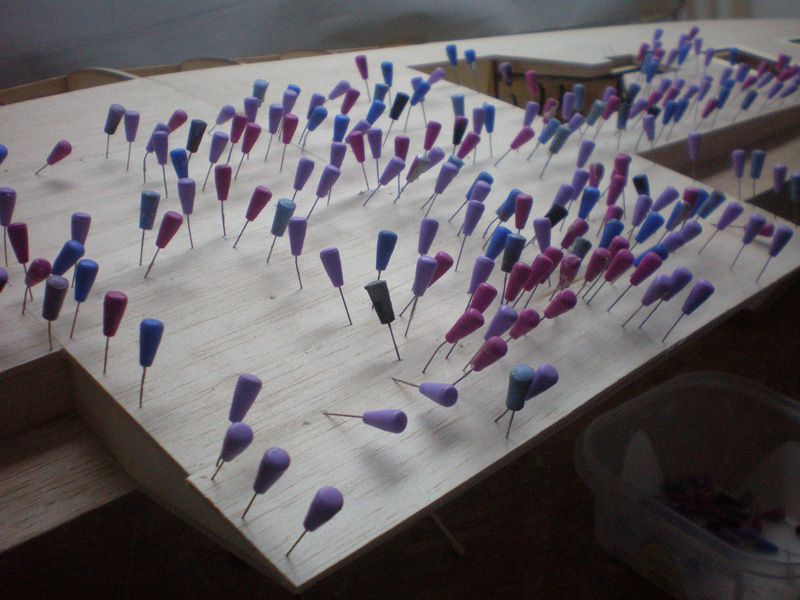

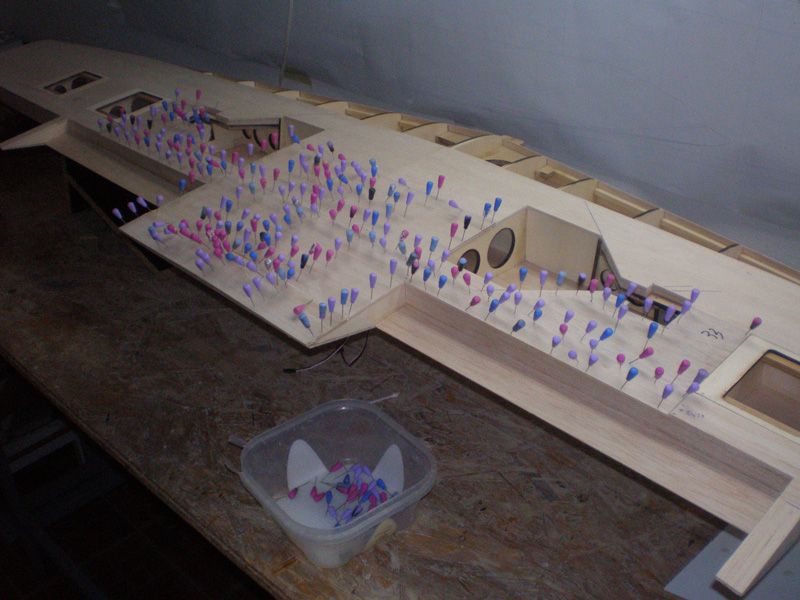

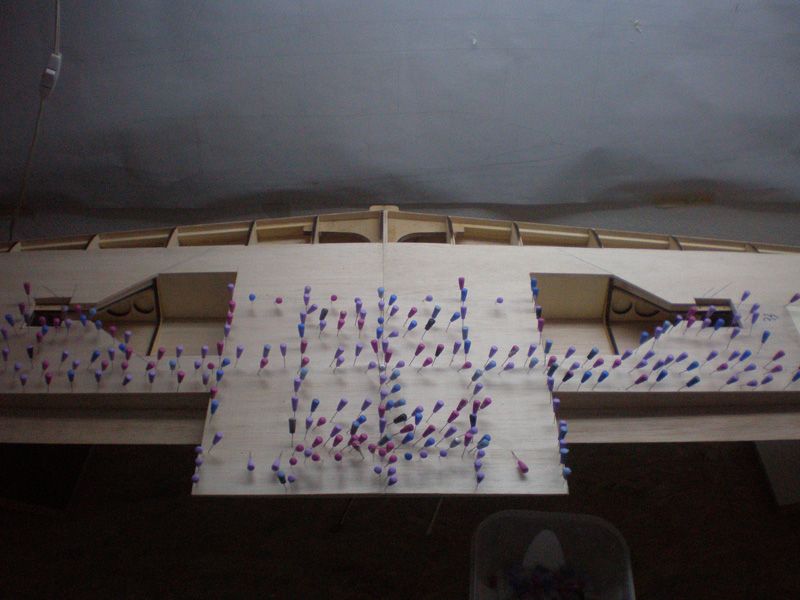

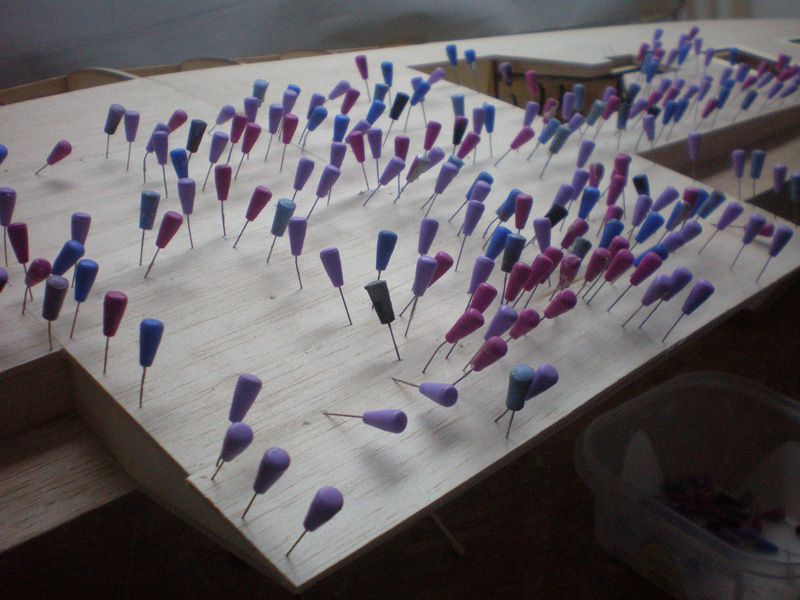

He, he, check this pictures... Like porcupine skin...

For front wing skin I must wet balsa plates...

I made holes on the upper wing surface for opening for inner landing gear servos. This parts in kit will be change too, and will be made from ply, similar like parts for servo openings on the wing bottom side... Martin add this to plan too...

Yesterday weather was here like in spring, so I used it to sand wing and add acrylic filler on the surface.

I need to buy bigger and bigger packaging...

This is acrylic filler I used... It's very easy to sand down...

This filler you must add in very thin layers.

After surface get dry, I add filler on other side too...

Than... O man... I sand wing almost two hours...

First with sand paper grade 100, and after with 240...

After cleaning, wing is smoother than baby ass...

And edges?

Now just to made leading edges, ailerons and flaps. For that I will need about two three days.

As you can see, it took me about three weeks to make a wing.

Don't forget, I wasn't work every day, my calculation is that I spent about 40 - 50 hours for wing in this stage...

Regards

Mirce

In last few day I made many small works before I add balsa plates on lower wing side.

Around landing gear hole I add balsa parts... I must sand it to get right curve for wing surface...

For ailerons hinges I add balsa blocks...

Next was work on landing gear doors. First I check how the doors looks on the real Galeb G2..

Than I made template from paper and balsa...

For inner door for opening I'll use servo. I must find position for servo, and right movement for door...

Of course, this balsa parts are just templates...

Than next door...

After that I start adding balsa on lower side of the wing. First plate was come in front of the landing gear area...

Check alignment... Here is nothing sanding yet...

Same was made on the other wing side...

Now come time to add plates for screw for wing fixing on the fuselage. I made those plates from 6 mm ply. I made by hand gutter on wing ribs for this plates, but Martin immediately change 3D drawing and add those gutter.

I made holes now, because, when come balsa skin find right middle of the plate will be difficult...

I made plates with servo holder for servos for inner gear doors...

G 10 plate will hold servo in position...

Everything was made same like for screw plates. Martin add this details on drawings also...

Small but important part...

Now everything is ready to continue covering process...

He, he, check this pictures... Like porcupine skin...

For front wing skin I must wet balsa plates...

I made holes on the upper wing surface for opening for inner landing gear servos. This parts in kit will be change too, and will be made from ply, similar like parts for servo openings on the wing bottom side... Martin add this to plan too...

Yesterday weather was here like in spring, so I used it to sand wing and add acrylic filler on the surface.

I need to buy bigger and bigger packaging...

This is acrylic filler I used... It's very easy to sand down...

This filler you must add in very thin layers.

After surface get dry, I add filler on other side too...

Than... O man... I sand wing almost two hours...

First with sand paper grade 100, and after with 240...

After cleaning, wing is smoother than baby ass...

And edges?

Now just to made leading edges, ailerons and flaps. For that I will need about two three days.

As you can see, it took me about three weeks to make a wing.

Don't forget, I wasn't work every day, my calculation is that I spent about 40 - 50 hours for wing in this stage...

Regards

Mirce