GR130

#152

Thread Starter

No problem Gerald, but let’s get back to turbines. I‘m on the way of recreating the whole 2nd stage! Will design a new turbinewheel and a new NGV during my summer holidays. Much larger than the 85mm wheel. Airflow is the main problem!

I have the same problem like most of us: Too many ideas and no time

regards Lukacs

I have the same problem like most of us: Too many ideas and no time

regards Lukacs

The following users liked this post:

Gerald Rutten (07-20-2020)

#153

That's ambitious! Maybe try and contact Dieter from Jetmax and see if he would be interested? He has all the moulding and casting equipment available, worth a try?

Rgds,

Gerald

Rgds,

Gerald

#154

Thread Starter

Hi Gerald

As far as I know, he has no bigger wheels and NGVs. That was also the reason he sold me the 84mm NGV and wheel. But now I know because of different measurements and calculations it is too small. I've already some ideas for creating...

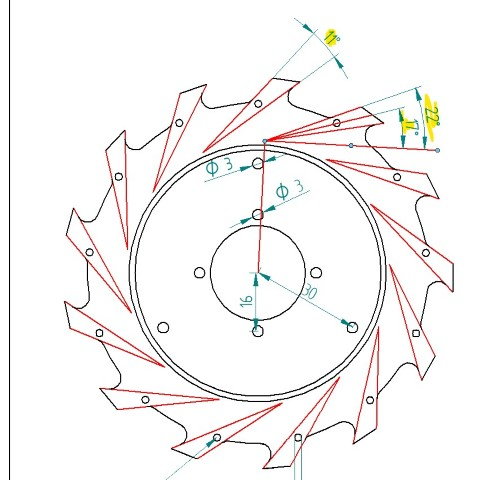

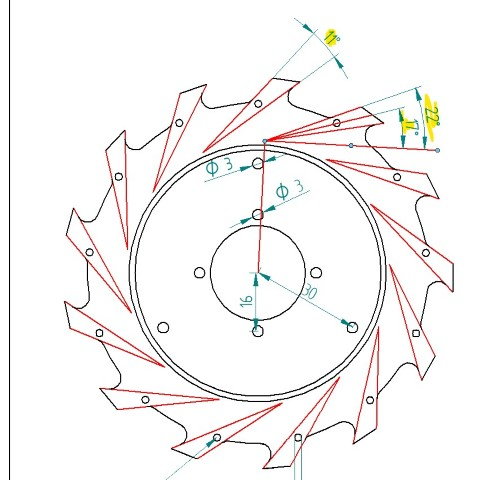

I would like to talk with you once more about your design of the diffusor. I have calculated the turbine on the basis of Thomas Kamps and there I get an angle of only 18.5° for the angle alpaha

Thomas Kamps also wrote in his book about “backward curved blades compressor“ and then to use an angle of 21° for angle alpha. For “vertical blades compressors” he recommends an angele of 18°. So the compressor I use is the same as you took.

Which amazes me is that you have even steeper angle of 22°? Or is it the angle bisector who counts?

Why do I ask? It's because I'm still fighting with rotating stall or surging when I make the compressor more effective by closing some holes and move the inlet closer to the compressor

Attached you find my drawing of your diffusor with additional angle information.

happy to hear from you

regards Lukacs

As far as I know, he has no bigger wheels and NGVs. That was also the reason he sold me the 84mm NGV and wheel. But now I know because of different measurements and calculations it is too small. I've already some ideas for creating...

I would like to talk with you once more about your design of the diffusor. I have calculated the turbine on the basis of Thomas Kamps and there I get an angle of only 18.5° for the angle alpaha

Thomas Kamps also wrote in his book about “backward curved blades compressor“ and then to use an angle of 21° for angle alpha. For “vertical blades compressors” he recommends an angele of 18°. So the compressor I use is the same as you took.

Which amazes me is that you have even steeper angle of 22°? Or is it the angle bisector who counts?

Why do I ask? It's because I'm still fighting with rotating stall or surging when I make the compressor more effective by closing some holes and move the inlet closer to the compressor

Attached you find my drawing of your diffusor with additional angle information.

happy to hear from you

regards Lukacs

Last edited by athome; 07-30-2020 at 09:08 PM.

#155

These guys have wheels and NGV up to 200mm, they will also produce from drawings.

yilicasting.com

Regards,

yilicasting.com

Regards,

Last edited by Halcyon66; 07-30-2020 at 01:23 PM.

#157

Which amazes me is that you have even steeper angle of 22°? Or is it the angle bisector who counts?

Why do I ask? It's because I'm still fighting with rotating stall or surging when I make the compressor more effective by closing some holes and move the inlet closer to the compressor

Why do I ask? It's because I'm still fighting with rotating stall or surging when I make the compressor more effective by closing some holes and move the inlet closer to the compressor

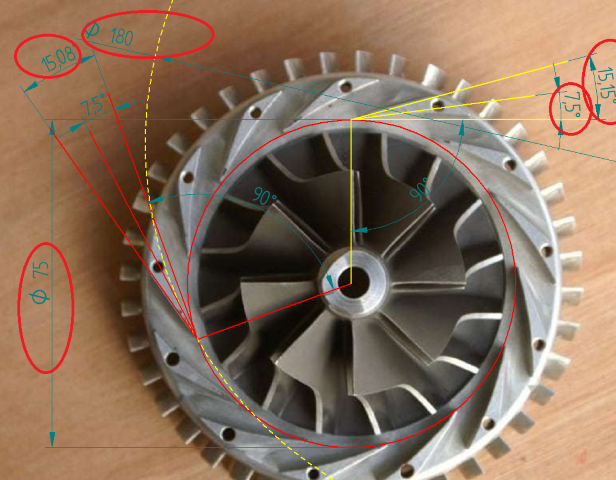

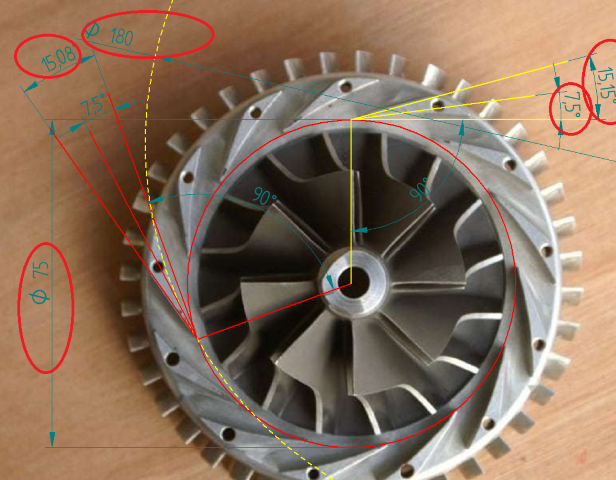

You are absolutely correct, again, I do have to point out this diffuser has never been tested by me and was a retro fit of the older JG100 double stage diffuser. This particular compressor has a different retro curve compared to most compressors and also compared to the one Thomas refers to in his calculations. So you're in a trial and error zone here. The original JG100 diffuser has different angles as well, see picture below. As the outflow angles of the T04B compressor wheel seems quite critical I tried to adopt the angles from the older diffuser but again, never tested these. I was asked to release the plans anyway to do some own testing.

Here the JG100 diffuser using same compressor;

Compared to my GR180 which is quite different;

These diffusers are a bit of a black art within gasturbine engines and sometimes it's difficult to find the sweet spot in all rpm region where all angles coincide with the best compromise. If I would have the time I would gladly make a few diffusers with different angles and try them out. I however would be tempted to go even 1 degree flatter using this compressor to let's say 16 degrees and give it a go. If you have cnc equipment maybe make two diffusers, one +1 and one -1 and see the difference.

I hope this information helps in deciding what direction to go, I would be glad in assisting you on any thought you have.

Kind regards,

Gerald

The following users liked this post:

athome (08-02-2020)

#158

Thread Starter

#159

Thread Starter

Hi Gerald

Thank you for this photo. I don’t know if a blueprint for the JG100 diffusor exists. If one exists I’m very interested to get it.

So I did a little bit reverse engineering. I found a lot of interesting things…

The alpha angle is probably 15° or 7.5° that’s quit flat. Flatter than Thomas recommends for “perpendicular blades compressors”

Then there is a bigger “blade free zone” probably 75mm which makes the diffusor less aggressive. It looks that the JG100 diffusor is strongly oriented on Thomas Kamps

My quintessence: Maybe I should build this compressor

Regards Lukacs

Thank you for this photo. I don’t know if a blueprint for the JG100 diffusor exists. If one exists I’m very interested to get it.

So I did a little bit reverse engineering. I found a lot of interesting things…

The alpha angle is probably 15° or 7.5° that’s quit flat. Flatter than Thomas recommends for “perpendicular blades compressors”

Then there is a bigger “blade free zone” probably 75mm which makes the diffusor less aggressive. It looks that the JG100 diffusor is strongly oriented on Thomas Kamps

My quintessence: Maybe I should build this compressor

Regards Lukacs

#160

I have no drawings for this diffuser, if I had I probably used this as reference for this engine as well... This diffuser is based on the KJ66 diffuser so outer blades would probably be almost the same, you have KJ66 drawings? I think the US built RAM1000 and the Australian TJT3000 from Chris Mounkley are identical so if you can find some info on those....

This diffuser is based on the KJ66 diffuser so outer blades would probably be almost the same, you have KJ66 drawings? I think the US built RAM1000 and the Australian TJT3000 from Chris Mounkley are identical so if you can find some info on those....

This diffuser is based on the KJ66 diffuser so outer blades would probably be almost the same, you have KJ66 drawings? I think the US built RAM1000 and the Australian TJT3000 from Chris Mounkley are identical so if you can find some info on those....

This diffuser is based on the KJ66 diffuser so outer blades would probably be almost the same, you have KJ66 drawings? I think the US built RAM1000 and the Australian TJT3000 from Chris Mounkley are identical so if you can find some info on those....

#163

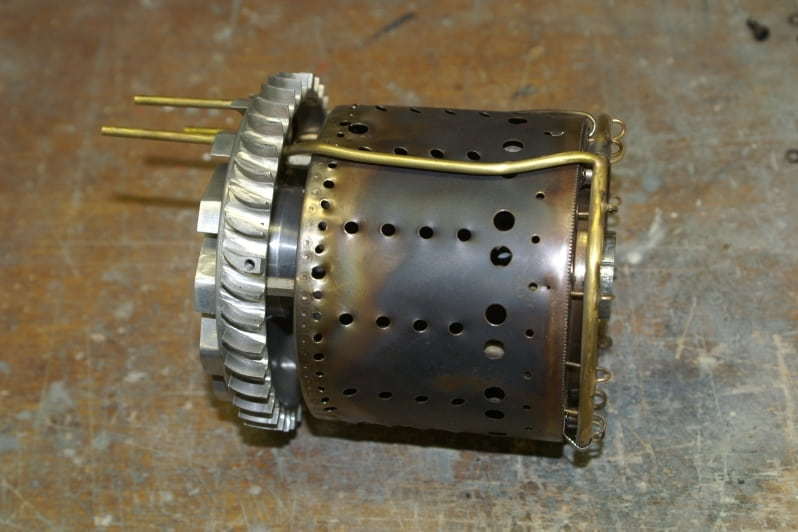

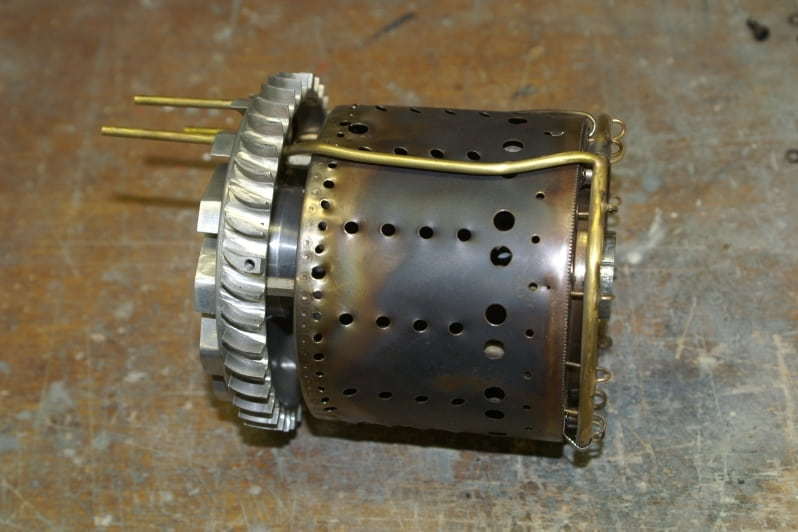

It's going to be installed in my new 1/6 Thunderstreak. I overhauled the engine two winters ago after removal from my Avonds F15.

This one uses the older 2 stage diffuser, as said, the new design never has been tested before. This is also the reason I'm not gonna release my "GR220" plans until I'm satisfied. The GR130 plans where just a theory developed design for experimentors but I found a lot of people complaining and not fully understand my philosophy of the drawings.

I expected the diffuser to run well but you never know until it's fully tested!

Here's my GR130 which flew a lot of flights on my Avonds F16 and F15. In all those years used 3 combustion chambers, the rest remains the same;

This one uses the older 2 stage diffuser, as said, the new design never has been tested before. This is also the reason I'm not gonna release my "GR220" plans until I'm satisfied. The GR130 plans where just a theory developed design for experimentors but I found a lot of people complaining and not fully understand my philosophy of the drawings.

I expected the diffuser to run well but you never know until it's fully tested!

Here's my GR130 which flew a lot of flights on my Avonds F16 and F15. In all those years used 3 combustion chambers, the rest remains the same;

Last edited by Gerald Rutten; 08-08-2020 at 11:40 AM.

The following users liked this post:

athome (08-08-2020)

#165

The FOD screen is just a simple kitchen strainer which is epoxied to the fiberglass housing.

Hope the picture helps;

#166

Thread Starter

Hey Gerald

I’m not complaining! Absolut amazing what you did. I mean it’s working! But for my purpose, there is optimization potential So I will try this diffusor redesigned by me.

So I will try this diffusor redesigned by me.

I did not find any drawings!

Thanks for your support and this design!

Regards Lukacs

I’m not complaining! Absolut amazing what you did. I mean it’s working! But for my purpose, there is optimization potential

So I will try this diffusor redesigned by me.

So I will try this diffusor redesigned by me.I did not find any drawings!

Thanks for your support and this design!

Regards Lukacs

#173

Join Date: Nov 2009

Location: London, UNITED KINGDOM

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Hi everyone, after years of looking I finaly found someone on Ebay selling 718 Inconell disks in small enough quantity for homwbuilders to make Turbine wheels.

The same person also sells 321 Grade Stainless Steel ideal for Combustion chamger and nozzle cone etc...

https://www.ebay.co.uk/itm/165193393...YAAOSwYj5hmXdY

https://www.ebay.co.uk/itm/165193094...oAAOSwzzZhmT3o

The same person also sells 321 Grade Stainless Steel ideal for Combustion chamger and nozzle cone etc...

https://www.ebay.co.uk/itm/165193393...YAAOSwYj5hmXdY

https://www.ebay.co.uk/itm/165193094...oAAOSwzzZhmT3o

#174

Junior Member

Nice to see that those ebay materials are still up for sale!

Is there a complete parts list for the whole build?

For my own purposes, I have completed an analytical calculation of the GR180, using Thomas Kamps book.

Unfortunately I keep getting a very low thrust value however.

If anyone could share the compressor map for the KTS S224 (schwitzer 316954), I would be most grateful!

I believe this is where my initial estimates are off.

Some compressor maps for BorgWarner are available, but I cant find the BorgWarner S200 (55.8/77.3) which is very close to the o.g. schwitzer wheel.

Ugh, bummer!!

Is there a complete parts list for the whole build?

For my own purposes, I have completed an analytical calculation of the GR180, using Thomas Kamps book.

Unfortunately I keep getting a very low thrust value however.

If anyone could share the compressor map for the KTS S224 (schwitzer 316954), I would be most grateful!

I believe this is where my initial estimates are off.

Some compressor maps for BorgWarner are available, but I cant find the BorgWarner S200 (55.8/77.3) which is very close to the o.g. schwitzer wheel.

Ugh, bummer!!

#175

Nice to see that those ebay materials are still up for sale!

Is there a complete parts list for the whole build?

For my own purposes, I have completed an analytical calculation of the GR180, using Thomas Kamps book.

Unfortunately I keep getting a very low thrust value however.

If anyone could share the compressor map for the KTS S224 (schwitzer 316954), I would be most grateful!

I believe this is where my initial estimates are off.

Some compressor maps for BorgWarner are available, but I cant find the BorgWarner S200 (55.8/77.3) which is very close to the o.g. schwitzer wheel.

Ugh, bummer!!

Is there a complete parts list for the whole build?

For my own purposes, I have completed an analytical calculation of the GR180, using Thomas Kamps book.

Unfortunately I keep getting a very low thrust value however.

If anyone could share the compressor map for the KTS S224 (schwitzer 316954), I would be most grateful!

I believe this is where my initial estimates are off.

Some compressor maps for BorgWarner are available, but I cant find the BorgWarner S200 (55.8/77.3) which is very close to the o.g. schwitzer wheel.

Ugh, bummer!!