Sabre XLT A large scratch built flying wing sport jet

#126

Thread Starter

My Feedback: (20)

Sabre XLT Removing Glass Parts From Plugs

DEC 2015

Turtle deck removed from foam plug after sanding edged with sanding bar

Nozzle edged sanded before removing from plug

Nozzle edges smooth and straight

Foam cutter removing a layer of foam behind tape

Removing nozzle ring from plug

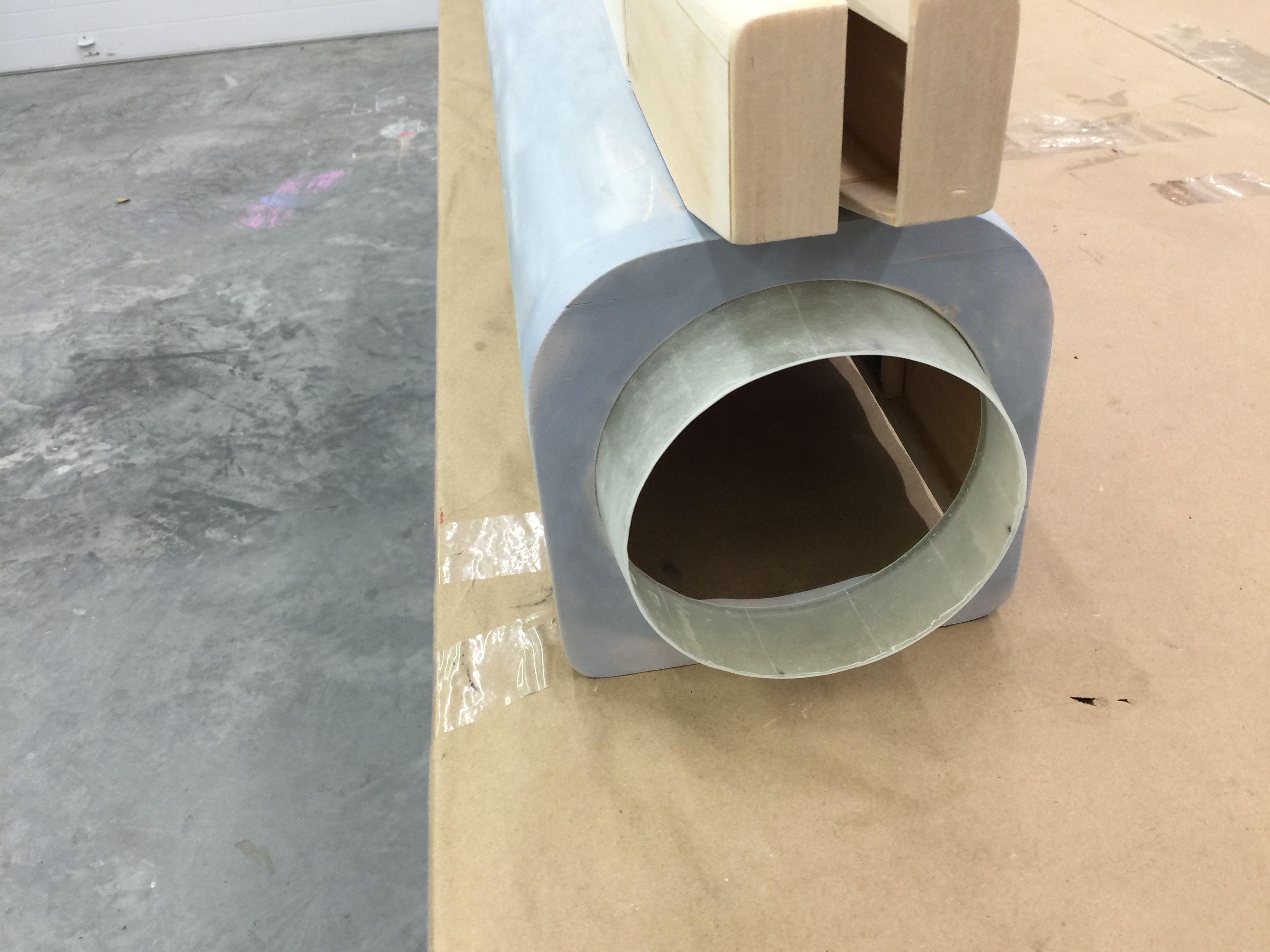

Nozzle ring dry fit in tail

Sanding edge of nose cone

Nose cone removed from plug by using lacquer thinner to dissolve foam

Foam plug remains pulled out

Packing tape removed from inside cone

Nose cone popped out clean

All glass parts ready for use

DEC 2015

Turtle deck removed from foam plug after sanding edged with sanding bar

Nozzle edged sanded before removing from plug

Nozzle edges smooth and straight

Foam cutter removing a layer of foam behind tape

Removing nozzle ring from plug

Nozzle ring dry fit in tail

Sanding edge of nose cone

Nose cone removed from plug by using lacquer thinner to dissolve foam

Foam plug remains pulled out

Packing tape removed from inside cone

Nose cone popped out clean

All glass parts ready for use

Last edited by Viper1GJ; 12-17-2015 at 06:31 PM.

#128

Thread Starter

My Feedback: (20)

Sabre XLT Fuse Mockup With Fiberglass Parts

DEC 2015

I have never made glass parts before and was very pleased with the first time results. I could have made the nose cone lighter with

less layers of glass but I will need weight in the nose anyway so I made it thicker and stronger. Turtle deck and nozzle are just right.

Note: The turtle deck only had 4 layers of 3oz glass. After finishing and sanding the turtle deck I could see the layers where the packing tape overlapped on the surface. Next time I would cover the foam with low temp film to avoid the lapping marks or use more layers of glass.

Fuse mock up with nose cone, turtle deck, and nozzle ring.

Gluing nose cone to front of fuse with hysol.

DEC 2015

I have never made glass parts before and was very pleased with the first time results. I could have made the nose cone lighter with

less layers of glass but I will need weight in the nose anyway so I made it thicker and stronger. Turtle deck and nozzle are just right.

Note: The turtle deck only had 4 layers of 3oz glass. After finishing and sanding the turtle deck I could see the layers where the packing tape overlapped on the surface. Next time I would cover the foam with low temp film to avoid the lapping marks or use more layers of glass.

Fuse mock up with nose cone, turtle deck, and nozzle ring.

Gluing nose cone to front of fuse with hysol.

Last edited by Viper1GJ; 01-08-2016 at 08:02 PM.

#130

Thread Starter

My Feedback: (20)

Sabre XLT Bodywork

DEC 2015

Spot priming balsa corner sand top for filling and sanding

Filling out edge of front hatch

Speading thinned epoxy on bottom of fuse floor to fuel proof against kerosene and smoke oil leaks

DEC 2015

Spot priming balsa corner sand top for filling and sanding

Filling out edge of front hatch

Speading thinned epoxy on bottom of fuse floor to fuel proof against kerosene and smoke oil leaks

Last edited by Viper1GJ; 01-08-2016 at 08:04 PM.

#131

Thread Starter

My Feedback: (20)

Sabre XLT Nose, Turtledeck, Nozzle

DEC 2015

Making cardboard pattern for turtle deck front former

Marking cut in turtle deck for rear hatch

Cutting turtle deck on scroll saw

Marking turtle deck rear hatch formers

Dry fit turtle deck before gluing to fuse and hatch

Turtle deck tac glued to hatch

Turtle deck tac glued to vertical fin

Nozzle ring glue in place using popsicle stick as gluing guides

Nose cone tip fabricated from balsa and 1/2" dowel. Inside tube is Sullivan Golden Rod outer tube for 1/8" brass pitot tube sliding inside

Nose balsa block rough cut with hand saw

Nose balsa sanded to rough form

Nose balsa hardened with thin CA

Epoxy putty for final shaping of nose block

DEC 2015

Making cardboard pattern for turtle deck front former

Marking cut in turtle deck for rear hatch

Cutting turtle deck on scroll saw

Marking turtle deck rear hatch formers

Dry fit turtle deck before gluing to fuse and hatch

Turtle deck tac glued to hatch

Turtle deck tac glued to vertical fin

Nozzle ring glue in place using popsicle stick as gluing guides

Nose cone tip fabricated from balsa and 1/2" dowel. Inside tube is Sullivan Golden Rod outer tube for 1/8" brass pitot tube sliding inside

Nose balsa block rough cut with hand saw

Nose balsa sanded to rough form

Nose balsa hardened with thin CA

Epoxy putty for final shaping of nose block

Last edited by Viper1GJ; 12-19-2015 at 06:11 PM.

#132

Thread Starter

My Feedback: (20)

Sabre XLT Finished Fuse Assembly

DEC 2015

Three years and 6 months after seeing Mike Osers' Dagger in Model Aviaton and two years and two month after starting to cut wood and foam the

fuse is finally fabricated and ready for finishing. The end of the build is finally insight.

DEC 2015

Three years and 6 months after seeing Mike Osers' Dagger in Model Aviaton and two years and two month after starting to cut wood and foam the

fuse is finally fabricated and ready for finishing. The end of the build is finally insight.

Last edited by Viper1GJ; 12-19-2015 at 06:17 PM.

#136

Join Date: Dec 2004

Location: lincoln park,

NJ

Posts: 201

Likes: 0

Received 0 Likes

on

0 Posts

Hi Dave, I want to build a Lancer and install a small turbine(wren 54) in the back fuselage. Could you please tell me the width of the fuselage, and the wing aera of the Lancer.Thank you, Mark

#137

Thread Starter

My Feedback: (20)

Hi Mark,

Plans for the Mike Oser's Lancer are here. Hope this helps.

http://www.rcgroups.com/forums/showt...ght=Lancer+.95

Gary

Plans for the Mike Oser's Lancer are here. Hope this helps.

http://www.rcgroups.com/forums/showt...ght=Lancer+.95

Gary

#138

Thread Starter

My Feedback: (20)

Sabre XLT First Mockup Assembly of the Sabre XLT

DEC 2015

First complete assembly on the landing gear of the Sabre XLT. Body work and finishing in progress.

Merry Christmas to all.

Gary

DEC 2015

First complete assembly on the landing gear of the Sabre XLT. Body work and finishing in progress.

Merry Christmas to all.

Gary

#139

Thread Starter

My Feedback: (20)

Sabre XLT Wing Fence and Spraying Sanding Sealer

JAN 2015

Cutting wing fences from plywood

Dry fitting wing fences on wings

Setting up homemade spray booth

Air exits from back side of spray booth through 12" duct

Air exhaust through partially raised garage door

Setting up spray racks for parts.

Spraying Zinsser's Seal Coat sanding sealer on wing to keep wood from warping and soaking up excess Polycrylic

Parts ready for spraying

Spraying wing tip rails

Parts drying after spraying

JAN 2015

Cutting wing fences from plywood

Dry fitting wing fences on wings

Setting up homemade spray booth

Air exits from back side of spray booth through 12" duct

Air exhaust through partially raised garage door

Setting up spray racks for parts.

Spraying Zinsser's Seal Coat sanding sealer on wing to keep wood from warping and soaking up excess Polycrylic

Parts ready for spraying

Spraying wing tip rails

Parts drying after spraying

Last edited by Viper1GJ; 01-06-2016 at 05:25 PM.

#140

Thread Starter

My Feedback: (20)

Sabre XLT Glassing With Polycrylic

JAN 2015

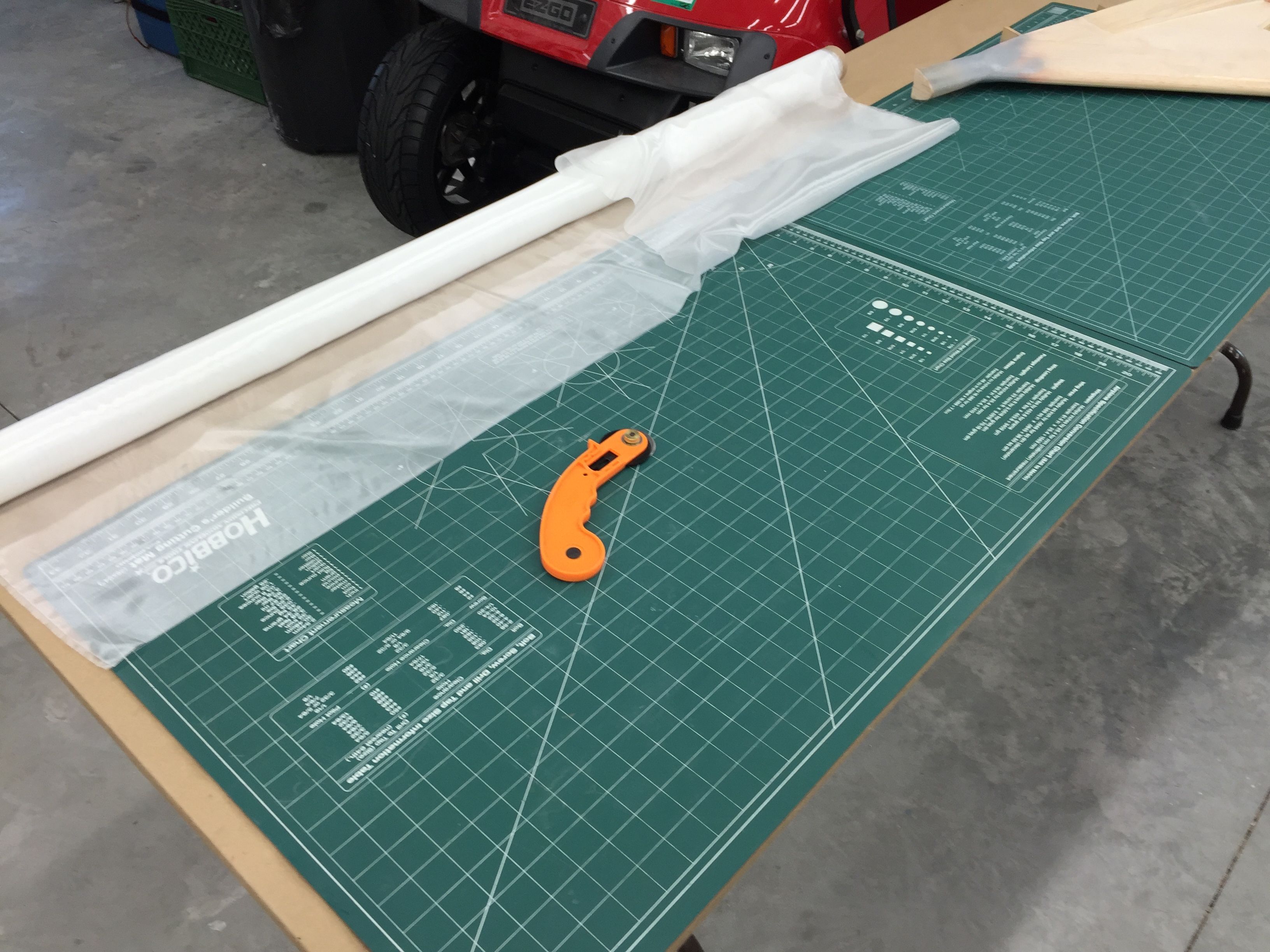

Fiberglass cutting on mat with rotary cutter

Rudder glassed first to see how it worked. Super easy, will never use epoxy again.

Trimming edge after poly dried with sharp blade.

Brushing out glass cloth on wing with a soft dry brush all strokes from center to outside edges

Starting application of Polycrylic from center to edges

Leading edge of wing coated, wing rotated to apply poly to trailing edge

Parts glassed on one side on drying racks

Trimming

Trimming some more…lots of trimming

Glass draped over aft end of fuse

Poly applied to top of fuse and then fuse rolled over to adhere sides

Glass draped over hatches ready for poly

Drying time for poly was about 1 hour

After trimming edges the edges were sanded with 220 paper and parts flipped over to glass the other side

Poly applied to aft hatch

Poly applied to front hatch

Glass laid on vertical fin

Speed brake panels getting glass

Trimming fuse glass edges

JAN 2015

Fiberglass cutting on mat with rotary cutter

Rudder glassed first to see how it worked. Super easy, will never use epoxy again.

Trimming edge after poly dried with sharp blade.

Brushing out glass cloth on wing with a soft dry brush all strokes from center to outside edges

Starting application of Polycrylic from center to edges

Leading edge of wing coated, wing rotated to apply poly to trailing edge

Parts glassed on one side on drying racks

Trimming

Trimming some more…lots of trimming

Glass draped over aft end of fuse

Poly applied to top of fuse and then fuse rolled over to adhere sides

Glass draped over hatches ready for poly

Drying time for poly was about 1 hour

After trimming edges the edges were sanded with 220 paper and parts flipped over to glass the other side

Poly applied to aft hatch

Poly applied to front hatch

Glass laid on vertical fin

Speed brake panels getting glass

Trimming fuse glass edges

Last edited by Viper1GJ; 01-06-2016 at 06:02 PM.

#142

Thread Starter

My Feedback: (20)

Sabre XLT Modifications of Canards, Tips, and Ventrals

JAN 2015

After I finished the main wing construction Mike Oser asked me to send him the exact measurements of the wing since it was slightly larger than the planned wing. The reason was that I cut the foam cores from the plan but did not account for balsa skin overlap at the TE and I used slightly larger wood where the elevons were hinged. The net result was about 3/4" extra chord on the wing.

Mike ran the exact measurements through his stability spread sheet and came back with the neutral point and recommended CG for optimum performance. The calculations required modifications to the surface areas of the canards, wing tips, and ventral fins to obtain the desired neutral point and keep the CG at the optimum position in relation to the main gear. The net result was shifting area forward by reducing the area of the ventral fins and wing tips and increasing the area of the canards. These calculations by Mike give me real confidence that the Sabre XLT will fly well.

I had totally forgotten the first calculations first made a year ago (ref. post #75) when I quickly made the canards in post #113 and ventrals in post #118 from the original Lancer blown up plans. Therefore I had to modify the existing canards and ventrals plus the tips. Mike gave me the new data and I started chopping wood. I was able to use all the existing parts with modifications.

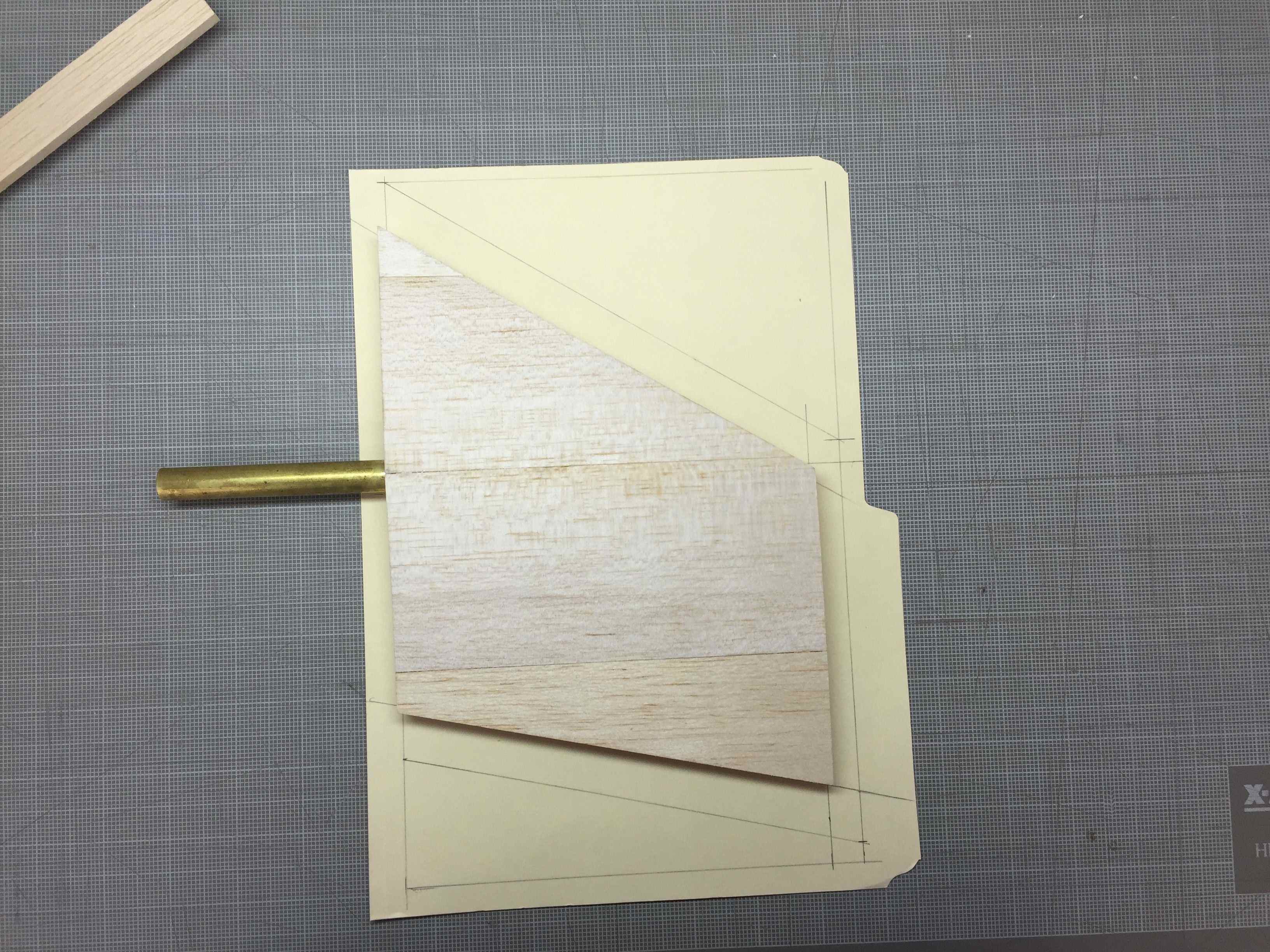

I plotted the new canard shape on file folder cardboard and cut skins from 3/32" balsa sheet

The new skins were glued on top of the existing canards. Then the old canard edges were trimmed to the new shape.

LE, TE, and tip edges of balsa were glued on the new canard frame

Canards were shaped with the Great Planes power planer, rotary sander with 80 grit pad, and final sanding

New canards after shaping

Canards test fit to fuse

New wing tip shape is shorter and more narrow than the original

Rear of old tip slots in the wing tip rail are filled in

New shape of ventral is more narrow that original parts

Ventral fins after cutting to new shape

Ventral fin dry fit to fuse

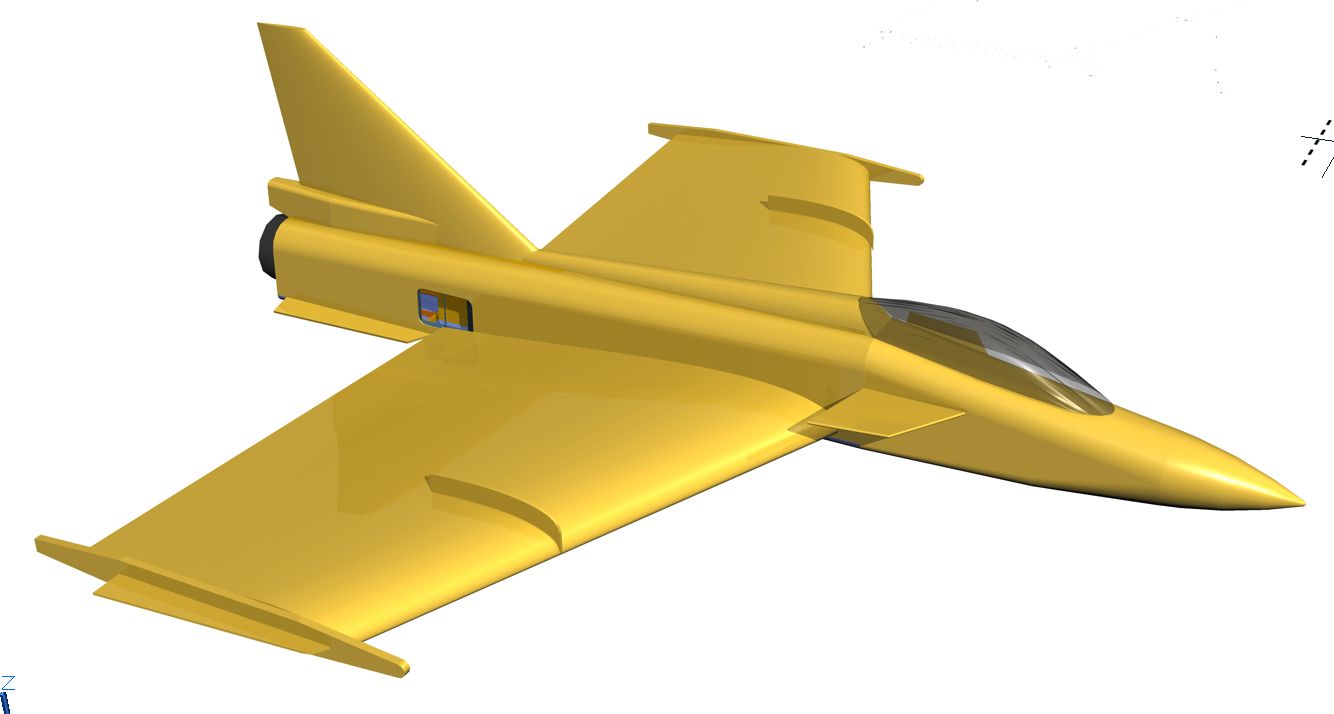

Mike produced a CAD 3D model of the new airframe with the new shaped canards, tip, and ventrals

JAN 2015

After I finished the main wing construction Mike Oser asked me to send him the exact measurements of the wing since it was slightly larger than the planned wing. The reason was that I cut the foam cores from the plan but did not account for balsa skin overlap at the TE and I used slightly larger wood where the elevons were hinged. The net result was about 3/4" extra chord on the wing.

Mike ran the exact measurements through his stability spread sheet and came back with the neutral point and recommended CG for optimum performance. The calculations required modifications to the surface areas of the canards, wing tips, and ventral fins to obtain the desired neutral point and keep the CG at the optimum position in relation to the main gear. The net result was shifting area forward by reducing the area of the ventral fins and wing tips and increasing the area of the canards. These calculations by Mike give me real confidence that the Sabre XLT will fly well.

I had totally forgotten the first calculations first made a year ago (ref. post #75) when I quickly made the canards in post #113 and ventrals in post #118 from the original Lancer blown up plans. Therefore I had to modify the existing canards and ventrals plus the tips. Mike gave me the new data and I started chopping wood. I was able to use all the existing parts with modifications.

I plotted the new canard shape on file folder cardboard and cut skins from 3/32" balsa sheet

The new skins were glued on top of the existing canards. Then the old canard edges were trimmed to the new shape.

LE, TE, and tip edges of balsa were glued on the new canard frame

Canards were shaped with the Great Planes power planer, rotary sander with 80 grit pad, and final sanding

New canards after shaping

Canards test fit to fuse

New wing tip shape is shorter and more narrow than the original

Rear of old tip slots in the wing tip rail are filled in

New shape of ventral is more narrow that original parts

Ventral fins after cutting to new shape

Ventral fin dry fit to fuse

Mike produced a CAD 3D model of the new airframe with the new shaped canards, tip, and ventrals

Last edited by Viper1GJ; 01-08-2016 at 08:08 PM.

#143

Thread Starter

My Feedback: (20)

Sabre XLT Spraying Polycrylic

JAN 2015

After the entire airframe was glassed with .73 oz/yd glass adhered with Minwax Polycrylic brushed on it was time to spray additional coats of poly.

Canopy rear bulkhead added before poly sprayed

Wing carrier and drying racks were made from scrap wood hot glued together with pads from pipe insulation foam scraps

Handles on racks make moving wet wings easy after spraying on one sideF

Fuse nose stand made from scrap wood hot glued together and bolted to NG mount on fuse bottom

Nose stand and foam block hold fuse for spraying

Poly sprayed right from can using gravity fed HVLP sprayer from Harbor Freight with 1.5 needle tip

Fuse is largest part and extends out of front of spray booth, most over spray still goes into the filters

The spray booth was built 20 years ago for smaller planes… the planes have out grown it!

Drying racks for parts in shop, two small space heaters keep shop warm for painting and drying

4 coats of poly sprayed on, sanding after 2nd and then again after 4th

Most fiberglass weave is filled after 4 coats and ready for primer

JAN 2015

After the entire airframe was glassed with .73 oz/yd glass adhered with Minwax Polycrylic brushed on it was time to spray additional coats of poly.

Canopy rear bulkhead added before poly sprayed

Wing carrier and drying racks were made from scrap wood hot glued together with pads from pipe insulation foam scraps

Handles on racks make moving wet wings easy after spraying on one sideF

Fuse nose stand made from scrap wood hot glued together and bolted to NG mount on fuse bottom

Nose stand and foam block hold fuse for spraying

Poly sprayed right from can using gravity fed HVLP sprayer from Harbor Freight with 1.5 needle tip

Fuse is largest part and extends out of front of spray booth, most over spray still goes into the filters

The spray booth was built 20 years ago for smaller planes… the planes have out grown it!

Drying racks for parts in shop, two small space heaters keep shop warm for painting and drying

4 coats of poly sprayed on, sanding after 2nd and then again after 4th

Most fiberglass weave is filled after 4 coats and ready for primer

Last edited by Viper1GJ; 01-08-2016 at 06:55 PM.

#146

Thread Starter

My Feedback: (20)

Sabre XLT Spraying Primer and Sanding

JAN 2015

My car painting buddy strongly suggested getting 2 part urethane primer for the job. I'm glad I listened as it is much better than spray can primer.

Fuse masked off for spraying

Primer was mixed 4-1-1 with fast reducer. Starting primer spraying on fuse nose

Completed fuse. Using the fast reducer at inside temp of 70° the primer flashed off and was dry to touch in about 5 min

Started on wheel well on bottom of wing

Front half of wing bottom sprayed.

Sprayed parts drying and curing

Wings completed

Parts sat over weekend to cure

Wet sanding table. With primer sprayed on thin and reduced 320 wet paper was good and finished with 400 wet.

All parts were wet sanded and wiped down with denatured alcohol to remove any remaining dust and grease or oils.

Planned color scheme. Yellow on top and blue on bottom based on the Northrup N-9M flying wing

JAN 2015

My car painting buddy strongly suggested getting 2 part urethane primer for the job. I'm glad I listened as it is much better than spray can primer.

Fuse masked off for spraying

Primer was mixed 4-1-1 with fast reducer. Starting primer spraying on fuse nose

Completed fuse. Using the fast reducer at inside temp of 70° the primer flashed off and was dry to touch in about 5 min

Started on wheel well on bottom of wing

Front half of wing bottom sprayed.

Sprayed parts drying and curing

Wings completed

Parts sat over weekend to cure

Wet sanding table. With primer sprayed on thin and reduced 320 wet paper was good and finished with 400 wet.

All parts were wet sanded and wiped down with denatured alcohol to remove any remaining dust and grease or oils.

Planned color scheme. Yellow on top and blue on bottom based on the Northrup N-9M flying wing

Last edited by Viper1GJ; 01-12-2016 at 06:02 PM.

#148

Thread Starter

My Feedback: (20)

Hi Joe,

The heaviest I have used is .56 and .73 oz/yd. The .73 was the easiest to work with. I could not much tell the difference after the application. It took each coat about 30 min to 1 hr to dry at about 70° inside temp. I see no reason why you could not go up to around 3 oz/yd if you wanted but i did have not done it.

I brushed on the first coat to adhere the glass and generally waited overnight to trim and feather sand the edges. I used 220 grit dry to do this. After glassing I sprayed on two coats and sanded with 220 grit again dry. Then sprayed on two more coats and sanded with 220 again. I had some runs I did not see till after they dried and the 220 block took them down fairly easily. I just don't like sanding.

Hope this helps.

What weight of glass were you thinking of?

Gary

The heaviest I have used is .56 and .73 oz/yd. The .73 was the easiest to work with. I could not much tell the difference after the application. It took each coat about 30 min to 1 hr to dry at about 70° inside temp. I see no reason why you could not go up to around 3 oz/yd if you wanted but i did have not done it.

I brushed on the first coat to adhere the glass and generally waited overnight to trim and feather sand the edges. I used 220 grit dry to do this. After glassing I sprayed on two coats and sanded with 220 grit again dry. Then sprayed on two more coats and sanded with 220 again. I had some runs I did not see till after they dried and the 220 block took them down fairly easily. I just don't like sanding.

Hope this helps.

What weight of glass were you thinking of?

Gary

#150

Thread Starter

My Feedback: (20)

Joe, I think the weave would be more difficult to fill and you may need to use some micro balloons or talc to help fill the heavier weave. I just used straight poly and after 4 sprayed coats and primer it is mostly filled. Lots of guys have done more that me. You may ask on the composites forum and get some more info.

Gary

Gary