FEJ 1:6 scale f-18 build thred

#1

[h=2]FEJ 1:6 F-18 build thread[/h]

OK so I have this big f-18 and I'm going to finish it up with the best way to get it safe .so first I'm going to work on the elevators support taking the paper honeycomb inner skin and cover with carbon tow and carbon fiber to make it super stiff + all the plywood will be covered with the carbon tow for stiffness .The main thing is that the actual elevators are not honeycomb there are made by b1-bob with the same material he was using to build his thunder chef .Please don't bully me for doing this jet I'm just stock with so just wanted to finish it up.

#4

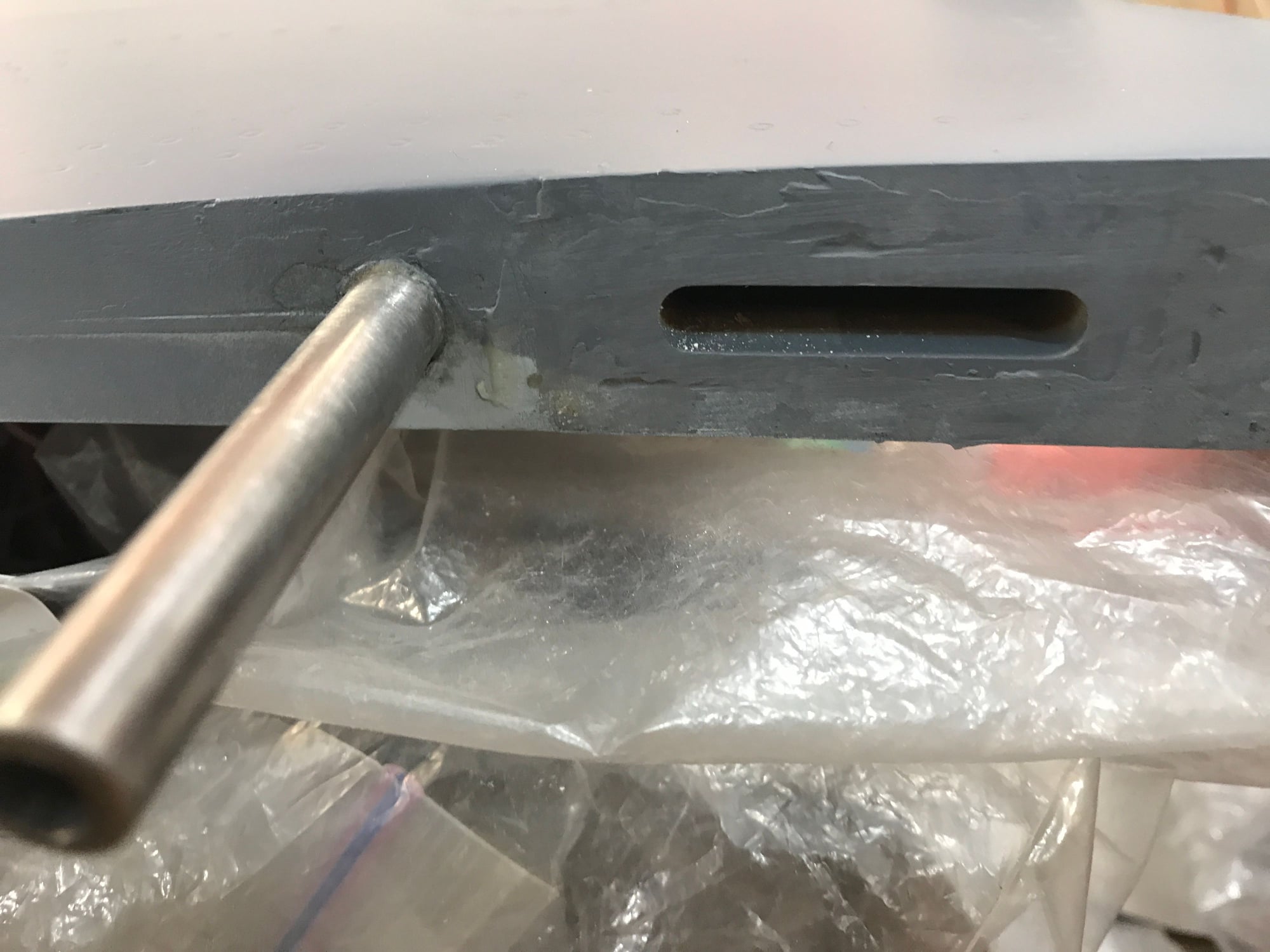

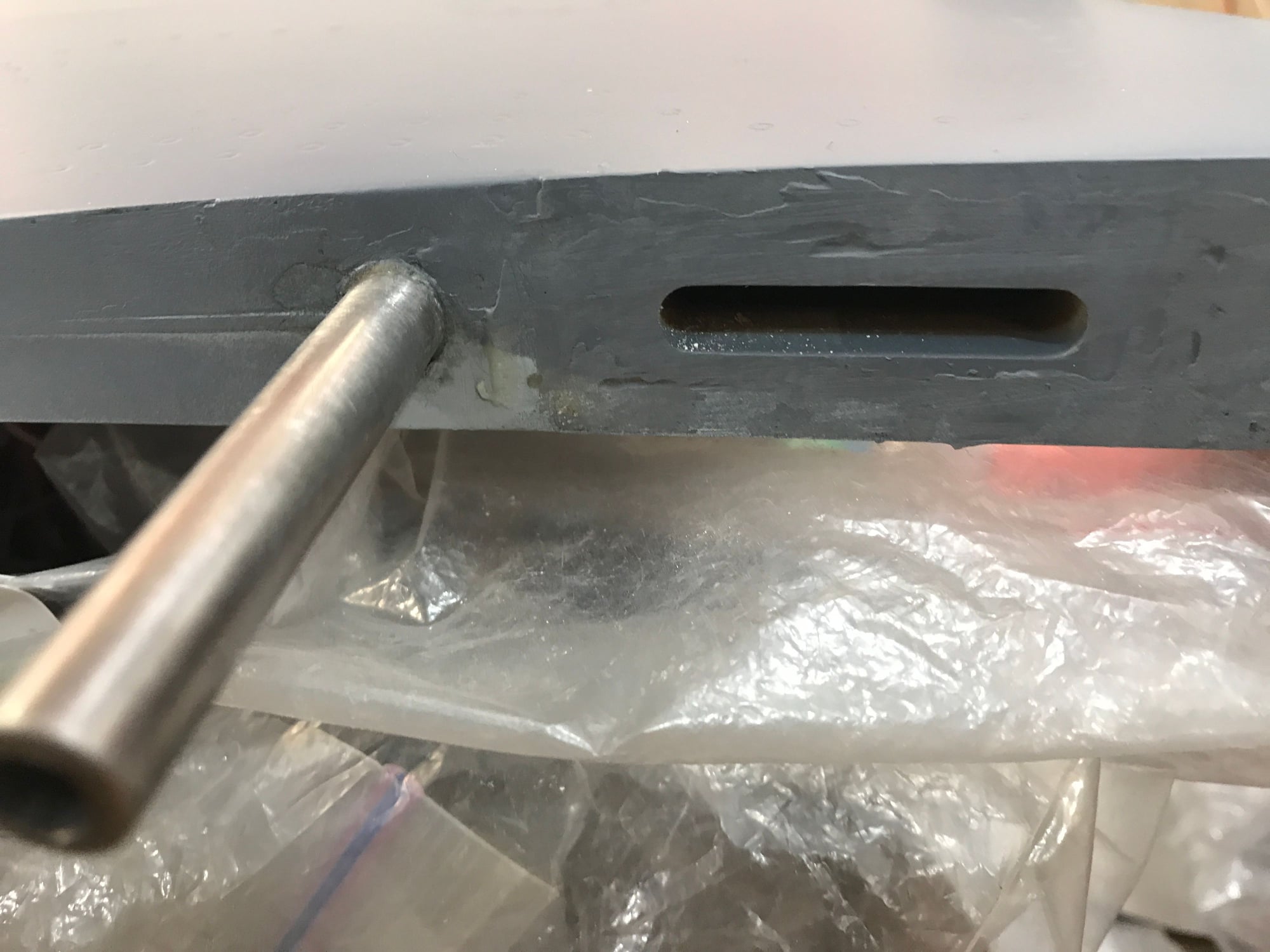

Doing more reinforcement for the elevators the servo plates have not been glued to the fuselage so I cut away the opening to do it with the glue and carbon fiber tow + I'm going to install the servos from outside with spacers to have the arms as close as possible to the elevator to minimize flexing .

notice that the carbon fiber cloth by fej have absolutely no glue .

notice that the carbon fiber cloth by fej have absolutely no glue .

#6

Not a lot more work than trying fitting wing servos in my skymaster mig-29 and other things to make is finish ,yes call me crazy but I'm not reckless so before the maiden flight I will make sure that it will be safe area to do the and the build will be strong and sound ,I know the all about FEJ reputation but I have the jet and I'm not going to just let it collect dust specially no one will buy it from me.

#11

So after little break have been working on the motor month and have the main support glued to upper rails and made the lower support made from solid 1"◊1" with channel for the vertical former support this will connect the actual motor support platform with the lower rails for strong turbine support.

#17

Okay so I just received the brass elevators bearings from my friend Vladimir so this is what I designed to reinforce the plastic fej bearing not so perfect fit and not very tide .The new one totally eliminated the wobble of the elevator shaft.

the two brass plates will be squeeze with 4 long screws to the plastic bearing and than epoxy all around.

the two brass plates will be squeeze with 4 long screws to the plastic bearing and than epoxy all around.

#19

Ok so itís been a while since I touched the f-18 but I decided to finish her up ! This is a long process but I hope that it will reward me for the time I spend with,so the wings are finished with flap servos berried inside the wings and ailerons standard ways,the rudders will have regular way with push rots just like ailerons no heavy mechanism from FEJ,finely I have the right pipe but to fit in the fuselage I decided to cut away the back of the nozzles fuselage and fit perfectly 😀 I donít care about the super scale look just wanted to make it functional and light as possible,please comment if you like thanks for looking.

#22

This is the plan! The jet was a twin version with absolutely no way of installing the long Y pipe and Iím probably going on to use my 230 Newton P-200 sx a lots more power than the K-210 ,the most important thing is that I eliminated all the Frankenstein FEJ rudders and elevators systems they heavy and donít work as supposed,I almost tried to install two k-170 Ďs but all the weight so I decided to go single and p-200 and thatís why I cut away the back part of the jet,will post more stuff about the assembling thanks for watching at the progress.

#24

Iím watching your build and the recent YouTube video,I was about to comment about the flaps servo horns but you fixed it right ,the push rot should be berried inside the wing and push the top of the flap this way the geometry works much better than the standard way ,good job fender and thank for watching.

#25

Iím watching your build and the recent YouTube video,I was about to comment about the flaps servo horns but you fixed it right ,the push rot should be berried inside the wing and push the top of the flap this way the geometry works much better than the standard way ,good job fender and thank for watching.