Thrust Tube dimensions???

#1

Thread Starter

Good Day all you jet fans. I am sure that this thread already exists, but I will give it a try anyway. I am trying to gather all of my materials and start scratch building a few jets with glow engines (Rossi .81, OS .77, .91) and I need your help. Does anyone have or does there exist a formula or rule of thumb concerning the dimensions of the thrust tube??? I need all of the dimensions, such a length, inlet diameter, exit diameter, suggested materials, etc. I need it all!!! Your help in this matter will be greatly appreciated. Thanks...

#2

Length will be down to the aircraft choice, but the ideal is probably no shorter than 20" if it's a fast machine.

work out the fan swept area and that will give you a circle diameter, I'd then reduce the diameter 10% on faster flying models! leave it the same on slower. There are so many variables, inlet area and length has a huge influence on overall performance.

You need to give a whole load more info if you want things pinned down more.

work out the fan swept area and that will give you a circle diameter, I'd then reduce the diameter 10% on faster flying models! leave it the same on slower. There are so many variables, inlet area and length has a huge influence on overall performance.

You need to give a whole load more info if you want things pinned down more.

#3

My Feedback: (1)

Length will be down to the aircraft choice, but the ideal is probably no shorter than 20" if it's a fast machine. work out the fan swept area and that will give you a circle diameter, I'd then reduce the diameter 10% on faster flying models! leave it the same on slower. There are so many variables, inlet area and length has a huge influence on overall performance. You need to give a whole load more info if you want things pinned down more.

#5

My Feedback: (57)

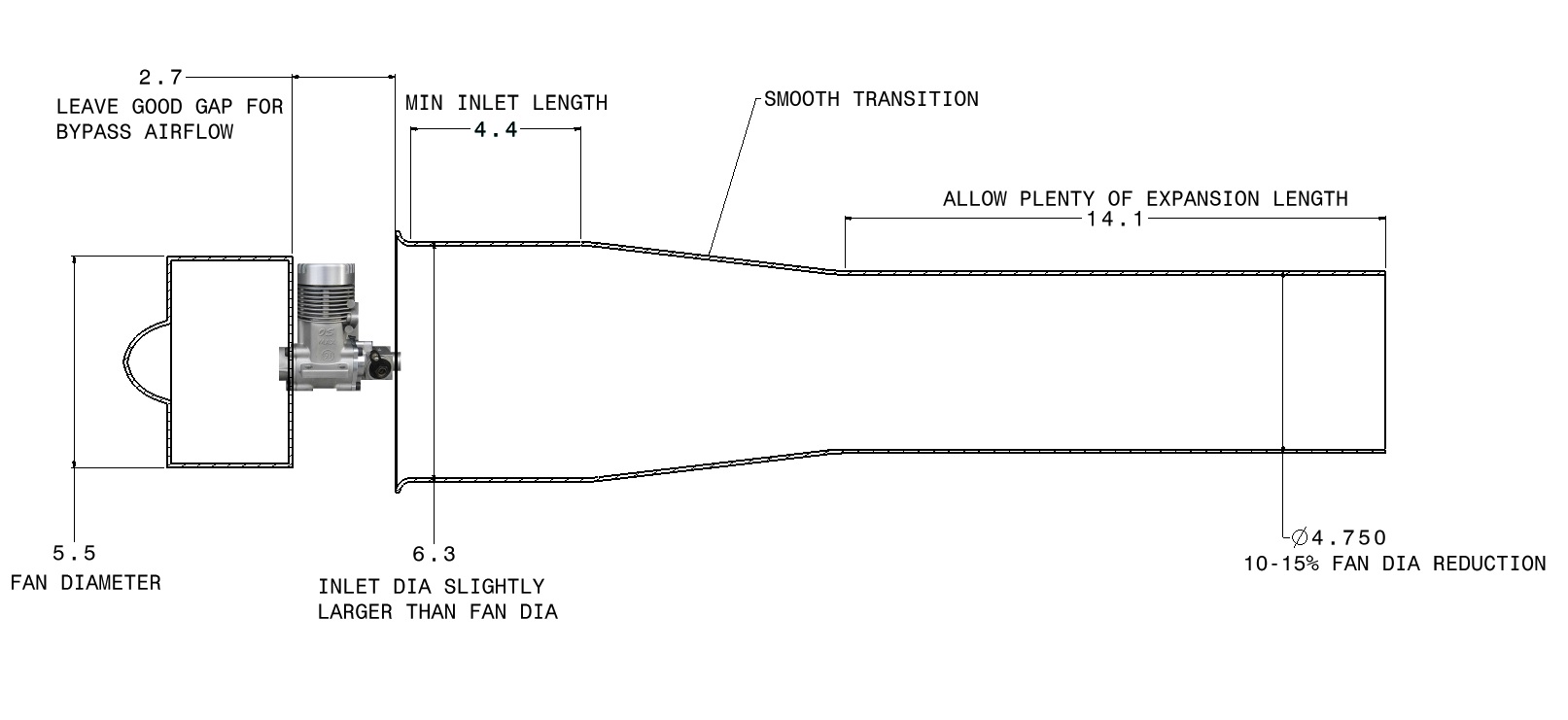

All the above info is good. i'll give some additional pointers from a purist standpoint.

DFs have very little power. The fan has very little pressure drop allowance, therefore even though it is important to compress the airflow to increase exhaust velocity, you have to take care not to increase the back pressure too much as it will quickly degrade performance. Ideally you want to capture as much air from the fan as possible (hence why a fully ducted typically performs better) and then accelerate it using a smooth throat. Not much you can do regarding exhaust tube length, as it will be determined by the design of the model/location of the engine.

I've made a small sketch for you. Don't pay attention to the numbers, but to the concept. In reality the only way to size an exhaust duct is to analyze it. But if you follow the idea you should get "good enough" results. Hope it helps.

DFs have very little power. The fan has very little pressure drop allowance, therefore even though it is important to compress the airflow to increase exhaust velocity, you have to take care not to increase the back pressure too much as it will quickly degrade performance. Ideally you want to capture as much air from the fan as possible (hence why a fully ducted typically performs better) and then accelerate it using a smooth throat. Not much you can do regarding exhaust tube length, as it will be determined by the design of the model/location of the engine.

I've made a small sketch for you. Don't pay attention to the numbers, but to the concept. In reality the only way to size an exhaust duct is to analyze it. But if you follow the idea you should get "good enough" results. Hope it helps.