Preferred Wing Tube/Sleeve

#26

Banned

I had actually thought about that but I as yet do not know enough about the subject. I just know the direction of the fibers plays into not only the strength of the tube but in what way that strength is available. Would be nice if someone with the smarts on this would provide an explanation for dummies on the matter.

I am about to start my first 'Big" model. The plans show a traditional ply blade type spar/wing joiner. Since I'm planning on going with the scale airfoil, which necessitate all new ribs, I was contemplating going with a tube spar. But how big and what type tubes? I think carbon would be ideal for the weight savings but again, just which way to go?

Last edited by Appowner; 01-25-2019 at 04:10 AM.

#27

My understanding is that pultruded tubes have fibres running along the tube and give max reistance to bending loads. They are less tollerant of crushing.

Cross weave has fibres running in several directions, perhaps not so strong in bending but more resistant to crushing !

My Blanik wing tube is cross weave. It is 73 cm long, 23mm diameter with a wall thickness of 2.5 mm. It weighs 176 gm.

In comparison an alloy tube of same length , dia 25 mm, wall thickness 1.5 mm weighs 225 gm.

I have not tested scientifically BUT I think the lighter carbon tube is vastly stronger but lighter than the equivalent alloy item.

It is, however, more expensive !

Cross weave has fibres running in several directions, perhaps not so strong in bending but more resistant to crushing !

My Blanik wing tube is cross weave. It is 73 cm long, 23mm diameter with a wall thickness of 2.5 mm. It weighs 176 gm.

In comparison an alloy tube of same length , dia 25 mm, wall thickness 1.5 mm weighs 225 gm.

I have not tested scientifically BUT I think the lighter carbon tube is vastly stronger but lighter than the equivalent alloy item.

It is, however, more expensive !

Last edited by David Gladwin; 01-25-2019 at 04:48 AM.

#28

Banned

My understanding is that pultruded tubes have fibres running along the tubeand give max reistance to bending loads. They are less tollerant if crushing.

Cross weave has fibres running in several directions, perhaps not so strong in bending but more resistant to crushing !

My Blanik wing tube is cross weave. It is 73 cm long, 23mm diameter with a wall thickness of 2.5 mm. It weighs 176 gm.

In comparison an alloy tube of same length , dia 25 mm, wall thickness 1.5 mm weighs 225 gm.

I have not tested scientifically BUT I think the lighter carbon tube is vastly stronger but lighter than the equivalent alloy item.

It is, however, more expensive !

Cross weave has fibres running in several directions, perhaps not so strong in bending but more resistant to crushing !

My Blanik wing tube is cross weave. It is 73 cm long, 23mm diameter with a wall thickness of 2.5 mm. It weighs 176 gm.

In comparison an alloy tube of same length , dia 25 mm, wall thickness 1.5 mm weighs 225 gm.

I have not tested scientifically BUT I think the lighter carbon tube is vastly stronger but lighter than the equivalent alloy item.

It is, however, more expensive !

#29

No, not at all, but may be a factor for some. I guess the use of aluminium tubes by kit manufacturers is basically a cost issue.

For me carbon fibre is the very best Material for high stress applications, such as wing structure just as it is now with Airbus and Boeing and many other fullsize manufacturers who know its properties.

Whatever you decide, good luck with your large model project

Anyway back to the workshop getting ready for the new season and to start work on my Vailly Tempest ( which will have much carbon fibre added ) for my shiney new Moki 250 !

For me carbon fibre is the very best Material for high stress applications, such as wing structure just as it is now with Airbus and Boeing and many other fullsize manufacturers who know its properties.

Whatever you decide, good luck with your large model project

Anyway back to the workshop getting ready for the new season and to start work on my Vailly Tempest ( which will have much carbon fibre added ) for my shiney new Moki 250 !

#31

My Feedback: (18)

I have used them for multiple models to replace aluminum with carbon. They are the old Ohio RC guys. You just give them your specs and they have sizes on-hand, or they can make them custom. I've used them for both aerobatic airplanes and jets. I think if you size the tube properly you should be ok, although I have seen rods used a lot on scale jets. My rebel and shockwave have carbon tubes(don't remember if they're lined), these models are typically flown harder but have a lower wing loading than scale jets. good luck!

#32

My Feedback: (27)

Join Date: Mar 2009

Location: St Francois,

QC, CANADA

Posts: 135

Received 0 Likes

on

0 Posts

There are a lot of places that sell them, but you do also need matching sleeves for the wing.

Jtec sells them with matching sleeves (www.jtecrc.com)

CST also sells them with matching sleeves (Carbon Fiber Tubes with Fiberglass Sleeves Page 1 of 1)

The question is, how big, with what wall thickness, and what type of extrusion/materials do you need for your application? I don't know. David knows a lot of stuff, maybe he can tell you...

Bob

Jtec sells them with matching sleeves (www.jtecrc.com)

CST also sells them with matching sleeves (Carbon Fiber Tubes with Fiberglass Sleeves Page 1 of 1)

The question is, how big, with what wall thickness, and what type of extrusion/materials do you need for your application? I don't know. David knows a lot of stuff, maybe he can tell you...

Bob

#33

My Feedback: (29)

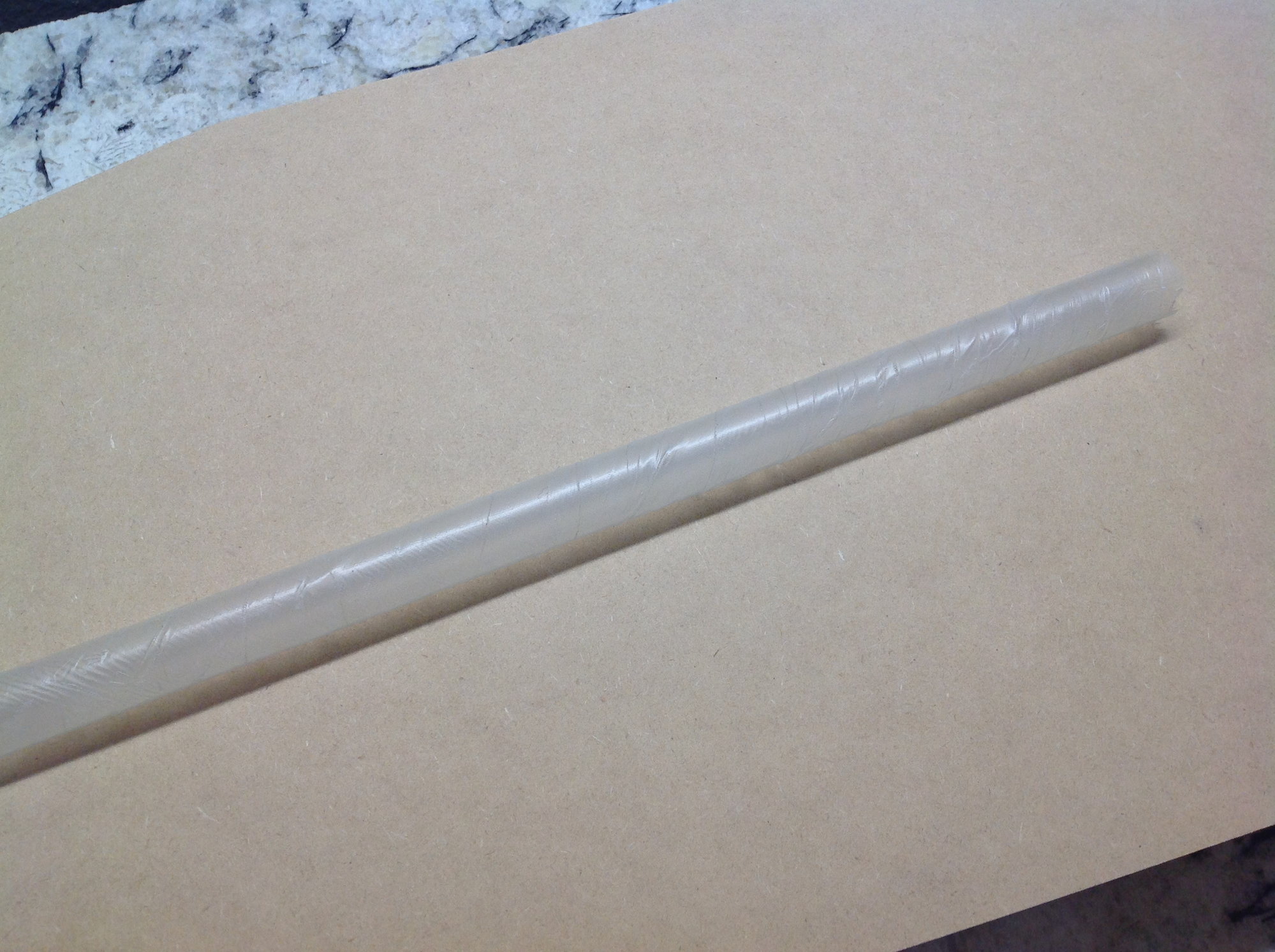

Sleeve made from described method.

Plain weave CF tube chosen for the Divergent project.

The pultruded tubes would be the worst option as it only has fibers running in a single direction. Most wing tubes I have seen look to be made out of a CF woven sleeve that has been placed onto a mandrel. Several layers are applied and then cured, machined and have a gloss coat applied. These are the types I choose to use on my 2M pattern Biplane design. The tube dimensions are 18mm OD and 16mm ID so wall thickness is 1mm. The strongest CF tube you can get would be one that is wound. During the winding process the fiber orientation is alternated in multiple patterns usually something like 90, 60 and 20 degree angles. I have not personally searched for wound tubes so I can't comment on availability but if I were I would check into Kite boarding suppliers. I agree that the difficult aspect is determining the size. I would think that holds true for both materials however if I were building a jet and wanted to replace aluminum with CF I would just go with the same OD and increase the wall thickness by a minimum of 20% and select a tube made from woven fabric. Sleeves are actually quite easy, simply take your actual tube, wrap it with two layers of 1mil painters plastic and then wrap with fiberglass cloth that has been wetted out with resin. After the glass/epoxy has cured just slide off the tube. The plastic film barrier will provide an almost perfect slip fit between the tube and sleeve. This would also work on tapered tubes.

#34

You guys are outstanding with your technical and practical knowledge. Really enjoying the reading. However, I have not heard anyone discuss using an aluminum tube and a carbon fiber sleeve. I have rec'd the aluminum tube and sleeve and also the CF tube and sleeve. Would the CF sleeve be a useful substitute for the cardboard or phenolic sleeve that came with the CF tube? Now let me sit back and continue to enjoy my learning. Chic

#35

My Feedback: (29)

I have yet to see a CF sleeve however I would not use a CF sleeve with an aluminum tube unless the tube has been hard anodized. CF is a very poor bearing surface and will wear away very quickly, bare aluminum under certain harmonics would wear the CF rapidly. I have a hunch your sleeve is just black fiberglass which would be fine. Even bare aluminum in a cardboard or phenolic sleeve will come out " dirty " meaning that the aluminum is being worn down and the particles are becoming somewhat lapping compound. Of course with jets there is less vibration so to some degree the effect is less. So far the best combination that I have used is a CF tube that has been waxed inside a fiberglass sleeve.