Assembler~Builder $

#51

You also made a similar rediculous argument about "decelerons" even intimating that they provided roll input. Again, after citing the manual written by the designer/manufacturer that they do not function that way and are in fact called "speed brakes," you justify the misrepresentation by saying you reference things "outside of NATOPS?"

In scale competition the documentation provided by the competitor is the "only" resource utilized by the static judge...nothing more. A static judges' personal recollections/knowledge of the subject being judged are not permitted to be the point of comparison of models in competition. Subjective judging is not permitted in R/C scale contests...FAI, USSMA, AMA, nor Top Gun protocols.

#52

I'm baffled why he's clinging to nomenclature and misunderstanding of the aircraft despite ample primary source document (NATOPS) proof to the contrary. I think it comes down to effort to capture scale builders. For example, he knows the model's flaps aren't accurate (split vs. semi-Fowler), but if he can find documentation somewhere saying they're split, even if he knows it's wrong, then he can tell customers can submit that incorrect info for scale documentation.

#53

My Feedback: (23)

I dont see where Ed said they were ever “split” flaps, he said there was a truss that was the hinge. In this instance, his choice of “truss” is referring to the flap track the flap rolls on.

his cross section of the wing is cleary showing the black area as the original wing outline, while the blue is showing the outline with a simplified, bottom hinged, non-fowler flap. It doesnt even look like a split flap, so im not sure how someone would portray that diagram as one.

as for the semantics of what something is called…. Its not like this thing is an ARF and your stuck with whatever you get.

Its a KIT and any builder can detail it out however they need, irregardless of whatever the name the manufacturer may refer to each control surface as.

his cross section of the wing is cleary showing the black area as the original wing outline, while the blue is showing the outline with a simplified, bottom hinged, non-fowler flap. It doesnt even look like a split flap, so im not sure how someone would portray that diagram as one.

as for the semantics of what something is called…. Its not like this thing is an ARF and your stuck with whatever you get.

Its a KIT and any builder can detail it out however they need, irregardless of whatever the name the manufacturer may refer to each control surface as.

#55

I want to thank everyone for their posts~contributions to discussion of our A6 project.

If anyone takes issue with this thread. The solution is to simply delete it from your subscriptions. Life exists outside of NATOPS who in all cases prefers to name mechanical function and devices their own. These devices and functions exist outside of any one manufacturer and NATOPS under multiple names/titles. One man's lemon is another man's limon... or is it? Order lemon with your tea in a hispanic country and it usually will arrive at your table with a lime (limon).

I made the point why we did not feel "comfortable" with the use of a "suspended" flap track...considering the material it would be made of. Our concern was simple...there were too many opportunities for someone to "not" assemble the flap track correctly.

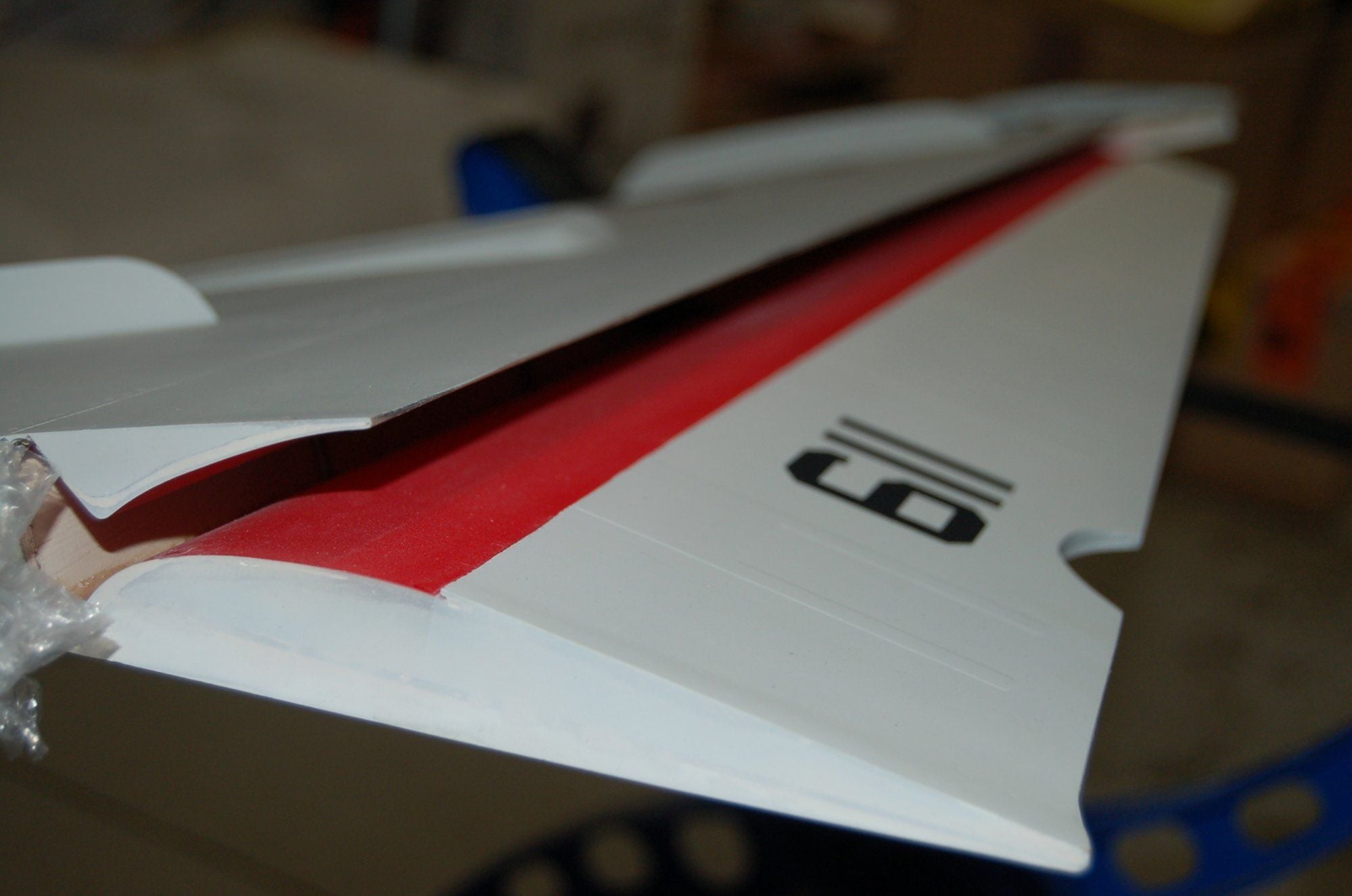

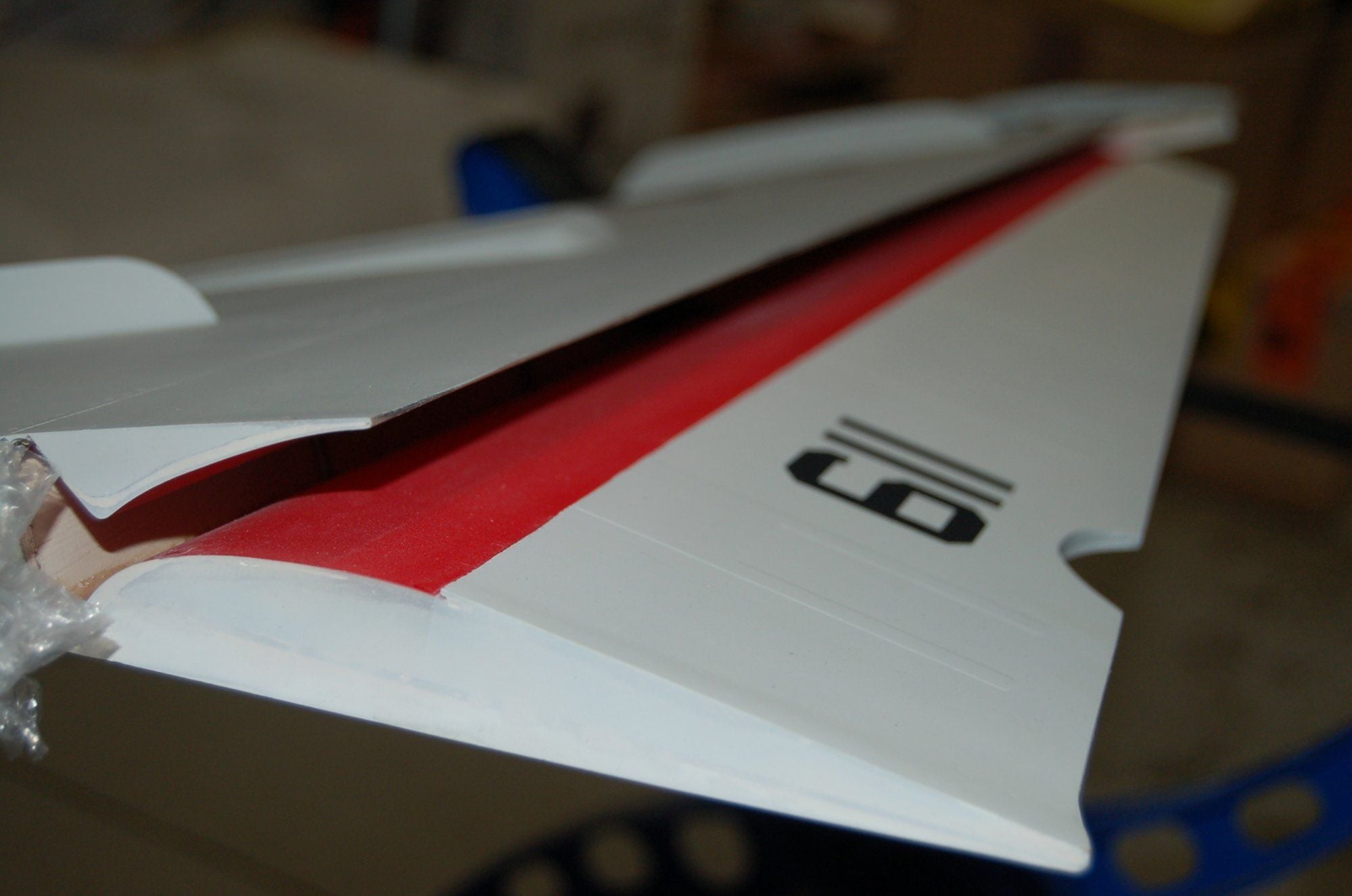

The bottom hinged flap provides function with the greatest degree of proper form as can be achieved without compromising operation. The % of rearward travel on the 1:1 A6 is low enough to permit a top down view of the fully extended flap no different than occurs when the flap is bottom hinged when the spoiler/spoileron/flaperon is in the unopened position. There are plenty of R/C A6 examples out there...all are bottom hinged for the same reason...

Scale competition does not downgrade scores on what a judge's personal knowledge of the subject may be. Contests are not conducted under the premise of subjectivity. Literally, what the judge sees and what the competitor discloses in their doc binder. When compared, a % of matching the "documentation" determines the score value awarded the model. These are models, not replicas. Events at the highest level of competition are awarded scores based on what the judge can see...not what is not seen. All r/c scale competition is based on this premise.

The scale competitors nemisis is the competitor, themselves. The degree of building skill to duplicate competitor's documentation is limited most often by their failing to recognize what they overlooked or misinterpreted that causes their contest entry to not match their documentation. For the most part there are no, nor have there ever been 100% matches due to the fact there are always more than one judge scoring the same model. Contest winners are the competitors with the least number faults/overlooked or misinterpreted model attributes.

If anyone takes issue with this thread. The solution is to simply delete it from your subscriptions. Life exists outside of NATOPS who in all cases prefers to name mechanical function and devices their own. These devices and functions exist outside of any one manufacturer and NATOPS under multiple names/titles. One man's lemon is another man's limon... or is it? Order lemon with your tea in a hispanic country and it usually will arrive at your table with a lime (limon).

I made the point why we did not feel "comfortable" with the use of a "suspended" flap track...considering the material it would be made of. Our concern was simple...there were too many opportunities for someone to "not" assemble the flap track correctly.

The bottom hinged flap provides function with the greatest degree of proper form as can be achieved without compromising operation. The % of rearward travel on the 1:1 A6 is low enough to permit a top down view of the fully extended flap no different than occurs when the flap is bottom hinged when the spoiler/spoileron/flaperon is in the unopened position. There are plenty of R/C A6 examples out there...all are bottom hinged for the same reason...

.

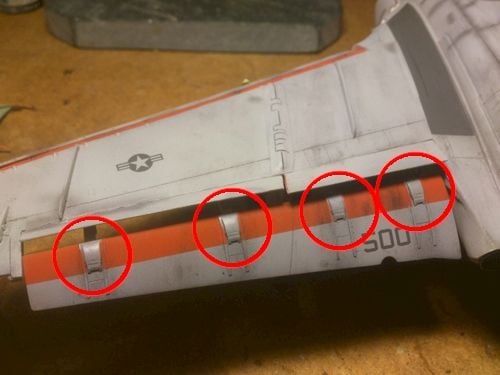

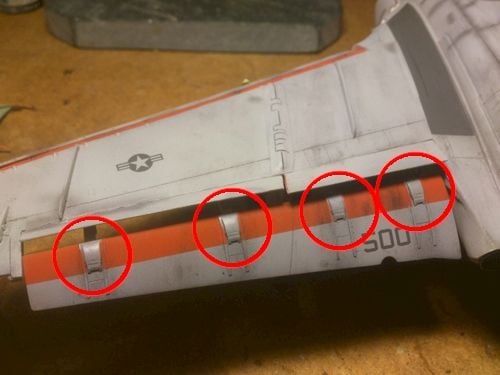

The above A6 model does not have a faux flap track... which I show in our YouTube wing video:

.

A typical misunderstanding by those who do not compete in r/c or c/l scale competition is:Scale competition does not downgrade scores on what a judge's personal knowledge of the subject may be. Contests are not conducted under the premise of subjectivity. Literally, what the judge sees and what the competitor discloses in their doc binder. When compared, a % of matching the "documentation" determines the score value awarded the model. These are models, not replicas. Events at the highest level of competition are awarded scores based on what the judge can see...not what is not seen. All r/c scale competition is based on this premise.

The scale competitors nemisis is the competitor, themselves. The degree of building skill to duplicate competitor's documentation is limited most often by their failing to recognize what they overlooked or misinterpreted that causes their contest entry to not match their documentation. For the most part there are no, nor have there ever been 100% matches due to the fact there are always more than one judge scoring the same model. Contest winners are the competitors with the least number faults/overlooked or misinterpreted model attributes.

Last edited by Flite-Metal; 10-06-2021 at 07:10 AM.

#57

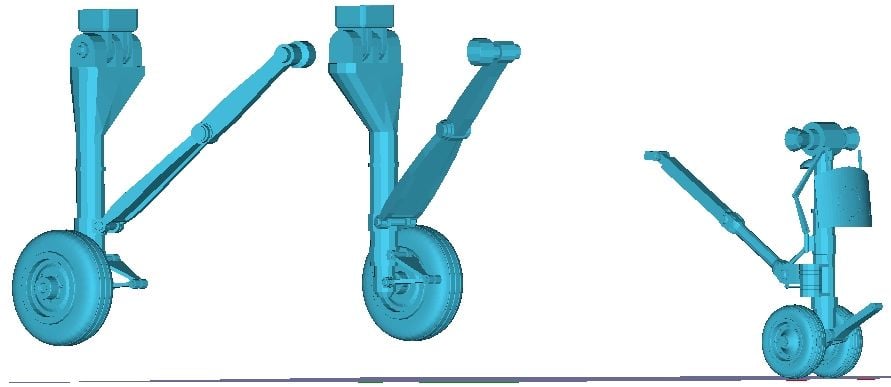

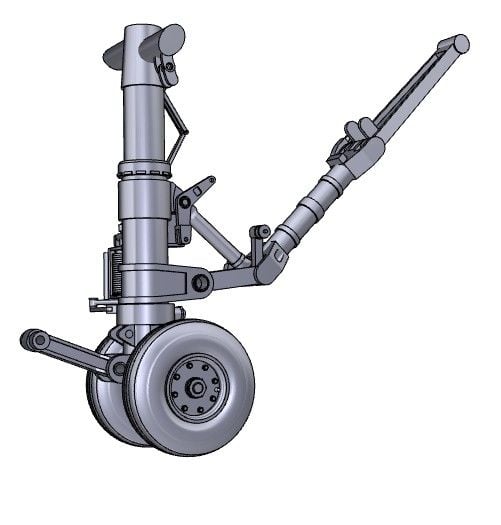

The standard strut is 10". The modified strut is a more scale 14" pivot to axle. Glued to this strut are molded scale parts. The mains are 90% obscured by a massive two piece gear door. Electro-magnetic brakes provide proportional braking. Below are a few pixs of the CAD strut sheath. The original "Flight Of The Intruder" movie gear weighed 14+#.

Last edited by Flite-Metal; 10-06-2021 at 11:13 PM.

#58

My Feedback: (2)

Ed,

Do you have any REAL gear parts (actual hardware) to show us to answer Matt's question?

Your CAD drawings don't even show the integration of the proposed Robart retract unit into these struts.

What you have shown does not represent a CAD model of an actual install-able gear design.

Paul

Do you have any REAL gear parts (actual hardware) to show us to answer Matt's question?

Your CAD drawings don't even show the integration of the proposed Robart retract unit into these struts.

What you have shown does not represent a CAD model of an actual install-able gear design.

Paul

#59

Paul,

Thank you for asking.

Our chosen gear is the 150HD10E lengthened to 14" with a resin sheath molded with Robart's strut OD.

CAD strut is broken down to individual parts contributing to a more scale appearance than the Robart

strut on its own. Molded parts are attached to Robart strut.

Paul if you are asking because you are considering creation of a scale gear...go for it. We chose an off-

the-shelf gear to provide customers with an availability of reasonably priced spare parts. I encourage

you to design, mill, and sell a 100% scale gear. We are not.

Sam is yet to print the sheath parts. When it is printed images will appear on the MAC6 website. There

have been greater priorities than printing this on our Creality.

Thank you for asking.

Our chosen gear is the 150HD10E lengthened to 14" with a resin sheath molded with Robart's strut OD.

CAD strut is broken down to individual parts contributing to a more scale appearance than the Robart

strut on its own. Molded parts are attached to Robart strut.

Paul if you are asking because you are considering creation of a scale gear...go for it. We chose an off-

the-shelf gear to provide customers with an availability of reasonably priced spare parts. I encourage

you to design, mill, and sell a 100% scale gear. We are not.

Sam is yet to print the sheath parts. When it is printed images will appear on the MAC6 website. There

have been greater priorities than printing this on our Creality.

Last edited by Flite-Metal; 10-06-2021 at 11:15 PM.

#60

Hi,

I've built 4 Yellow Aircraft F/A-18 kits for customers. Two for twin turbine and two for single. One was built to primer and the other three painted. The build fee alone was $6k to primer with basic installation. That was when I was a man of leisure.

I've built 4 Yellow Aircraft F/A-18 kits for customers. Two for twin turbine and two for single. One was built to primer and the other three painted. The build fee alone was $6k to primer with basic installation. That was when I was a man of leisure.

The following users liked this post:

patf (10-08-2021)

#61

Shaun,

Thank you for your input. It has been said the 6's would be similar to the build-out of the Yellow F-18. This of course is only a baseline. Actual pricing can only be calculated as a result of builder negotiating with their customer. The ŕ la carte aspect makes it easier for both builder and their customer to define what is required along a given timeline effected by the builders backlog. That brings us to an anticipated timeline to build~assemble the Yellow F-18.

Thank you for your input. It has been said the 6's would be similar to the build-out of the Yellow F-18. This of course is only a baseline. Actual pricing can only be calculated as a result of builder negotiating with their customer. The ŕ la carte aspect makes it easier for both builder and their customer to define what is required along a given timeline effected by the builders backlog. That brings us to an anticipated timeline to build~assemble the Yellow F-18.

Last edited by Flite-Metal; 10-08-2021 at 10:43 AM.

#62

My Feedback: (34)

Get a fuse, wing, and landings gear ready to go, price it with understanding its a builders kit, and see how many you can sell. I would be in if price is good due to building time and materials.

Its like BVM, I have been looking at an F86 kit, the BVM builder kit (tiny takes 80n motor) cost almost the same as ARF Skymaster new Huge F86

Its like BVM, I have been looking at an F86 kit, the BVM builder kit (tiny takes 80n motor) cost almost the same as ARF Skymaster new Huge F86

#63

My Feedback: (2)

Why not offer the empty shell fuselage moldings 'as-is' today for true scratch-builders to use on their own terms.

Let then develop their own solution to internal structure, wings and landing gear. It's not an impossible task.

I know someone who would be interested in an empty shell now to do their own thing with........

Paul

Let then develop their own solution to internal structure, wings and landing gear. It's not an impossible task.

I know someone who would be interested in an empty shell now to do their own thing with........

Paul

The following users liked this post:

mikes68charger (10-08-2021)

#64

My Feedback: (4)

Paul's suggestion may be a great option to crowd source more solutions. many of the modeling community have access to means, software, and talent that continues to blow me away. If a library was established for sharing of those files and information, this could really accelerate development without additional effort on your part

#65

Patrick,

Thank you for your post. The 6's will be released with all formers in the layup...unless requests for a turbine option are received which will alter the mounting cradle to accomodate new dims.

Thank you for your post. The 6's will be released with all formers in the layup...unless requests for a turbine option are received which will alter the mounting cradle to accomodate new dims.

#66

This whole concept was designed around EDF as the primary expected power source? I get having the option for either, but - and maybe it's just me - I think the demand for something of this size will be about 10:1 in favor of turbine power. I might be wrong, it's happened before.

The following users liked this post:

Ron S (10-08-2021)

#67

My Feedback: (1)

I fly EDF myself, but if the plan is to actually sell airplanes I really do not get the insistance of this being a EDF powered project. I think 10:1 to favor it being a turbine powered plane is being nice, I think it's more like 100:1 based on how often I see someone else besides myself flying large EDF's when I travel to meetings.

This is a large model, and will end up costing $$$ to get flying and the crowd with the pockets to do so fly turbines. EDF's are rare like hens teeth in this segment of the hobby.

This is a large model, and will end up costing $$$ to get flying and the crowd with the pockets to do so fly turbines. EDF's are rare like hens teeth in this segment of the hobby.

Last edited by Pondus; 10-08-2021 at 02:42 PM.

#68

This whole concept was designed around EDF as the primary expected power source? I get having the option for either, but - and maybe it's just me - I think the demand for something of this size will be about 10:1 in favor of turbine power. I might be wrong, it's happened before.

Last edited by Flite-Metal; 10-09-2021 at 03:50 AM.

#69

My Feedback: (2)

Our chosen gear is the 150HD10E lengthened to 14" with a resin sheath molded with Robart's strut OD.

Also, these gear retract forward against the airflow, so adding in all the above, there is a high probability that the retracts will not have sufficient authority to retract and will amp-out.

Robart retracts tend to be favored by the warbird community, and most of those don't use brakes and also retract to the rear, then being assisted by the airflow.

Building a full gear assembly with strut/ wheel/ brake and testing it to see what margin you have would be worthwhile.

Paul

#71

My Feedback: (2)

Why would Robart have spec'd the upgraded 150HD10E if it would not work?

Did you provide Robart with the design requirements for a 1/5.5 scale A-6 main gear with a 14" strut with scale covers and a 6.5" diameter wheel/ brake retracting forward at 60-70mph for them to take into account when they designed the 150DHE10E?

With the gear twisting as it retracts forward, at about half-retraction (~45deg) you will get a lot of drag from the rotated gear at the same time you encounter the least mechanical advantage from the retract unit, compounding the issue.

Like I said before...if you want to design a scale gear for the MAC6's go for it.

At least the gear is at the same maturity level as the rest of the project.

Paul

#72

Paul,

Thank you for your contribution to this discussion of Assembler/Builder service charges. With respect to the subject of landing gear, Sam and I relied on Robart's vast experience to recommend a specific gear to meet our requirement. I encourage you to create a scale retract, wheel, and brake. Your previous work has been good.

Thank you for your contribution to this discussion of Assembler/Builder service charges. With respect to the subject of landing gear, Sam and I relied on Robart's vast experience to recommend a specific gear to meet our requirement. I encourage you to create a scale retract, wheel, and brake. Your previous work has been good.

#73

My Feedback: (2)

Talking about landing gear, I have gotten many questions regarding if RS Model Products will be making chocks available for this kit.

So the answer is a resounding yes! To commemorate the rollout of this kit, A-6 Intruder chocks will be available for this model (and others!).

Please PM me for more info.

Commemorative A-6 Intruder Chocks!

So the answer is a resounding yes! To commemorate the rollout of this kit, A-6 Intruder chocks will be available for this model (and others!).

Please PM me for more info.

Commemorative A-6 Intruder Chocks!

#74

Stephen would probably prefer..."Flight Of The Intruder" ...

Last edited by Flite-Metal; 10-09-2021 at 09:49 AM.

#75

Paul,

I didn't think you'd be interested in creating gear for customers or I would have asked. Sounds like you are interested. .(dae, .stl, .skp)

Last edited by Flite-Metal; 10-09-2021 at 12:09 PM.

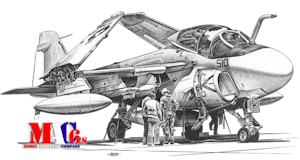

These jets are four models of Grumman A6 Intruders...not, nor intended to be, 1:5.5 replicas.

These jets are four models of Grumman A6 Intruders...not, nor intended to be, 1:5.5 replicas.