YS DZ200cdi

#330

Join Date: Feb 2007

Location: RESHON LEZIYYON, ISRAEL

Posts: 109

Likes: 0

Received 0 Likes

on

0 Posts

200 CDI

After a full overall

Which includes: piston, ring, cylinder, bearings, gaskets, rubber bands,

Maximum RPM 6500 ( prop 21.5x10.5 )

Minimum RPM 1700

I'm happy

After a full overall

Which includes: piston, ring, cylinder, bearings, gaskets, rubber bands,

Maximum RPM 6500 ( prop 21.5x10.5 )

Minimum RPM 1700

I'm happy

#331

Senior Member

#335

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

Quick update:

After about 5 hrs on the clock with the grooved throttle I found my hand starting to wander towards the needle and regulator to "fine tune" things a bit, but I've been there before so after one or two tweaks, I mentally slapped myself on the wrist and decided to go back to the potential root of the problem.

I'd just finished turning and fitting a bush for the flogged out front bearing area in my 170cdi crankcase (which turned out not to bad) and had put it all back together, so replacing the groove with an o-ring wasn't too big a deal except for the lack of meat that YS leaves in that area. Turns out I had a perfectly sized parting tool for the job and got lucky with my final diameter. Seriously the factory o-ring compression is so slight, it almost only uses the molding seam to seal but I got lucky with the final scrape of the parting tool and my fit was identical and didn't add too much drag to the rotation.

The fresh sealing of that side immediately fixed the issue I was starting to chase again, but alas the engine still isn't running as I would like. I suspect that the metering groove just isn't sealing up against the inlet hole/orifice like it should either but I can't fix that. It's usable but it's like there're only three throttle positions (idle, cruise, flat-out) and it's fussy when you decide to go from idle to cruise. I have to wait until the plane has fully slowed back down to cruise speed after a downline before throttling back up otherwise it either surges or misses during the transition until the prop loads the engine up again.

I'm also getting a fair bit oil discoloured oil up the back of the engine, firewall and landing gear area so there's another issue at hand. Almost like it's spitting back out from the carb throat. below that and around the bottom end is dry. The amount of oil seems proportionate to the amount of engine "misses" during the flight, so it's really time to put it on a test bench and watch it closely.

Got lucky with the parting tool width and final diameter.

"like a glove".....in my best Jim Carey voice.

.

In the meantime, I put my 170cdi back in the Aries 07, rebuilt with old o-rings and gaskets (new head gasket), and did two flights yesterday (same fuel, same cdi unit). While I really miss the top end grunt of the 200cdi, the 170cdi idles like a swiss watch, downline brakes, throttle transition to any position at any speed as smooth as butter and not a drop of oil in the engine bay.

After about 5 hrs on the clock with the grooved throttle I found my hand starting to wander towards the needle and regulator to "fine tune" things a bit, but I've been there before so after one or two tweaks, I mentally slapped myself on the wrist and decided to go back to the potential root of the problem.

I'd just finished turning and fitting a bush for the flogged out front bearing area in my 170cdi crankcase (which turned out not to bad) and had put it all back together, so replacing the groove with an o-ring wasn't too big a deal except for the lack of meat that YS leaves in that area. Turns out I had a perfectly sized parting tool for the job and got lucky with my final diameter. Seriously the factory o-ring compression is so slight, it almost only uses the molding seam to seal but I got lucky with the final scrape of the parting tool and my fit was identical and didn't add too much drag to the rotation.

The fresh sealing of that side immediately fixed the issue I was starting to chase again, but alas the engine still isn't running as I would like. I suspect that the metering groove just isn't sealing up against the inlet hole/orifice like it should either but I can't fix that. It's usable but it's like there're only three throttle positions (idle, cruise, flat-out) and it's fussy when you decide to go from idle to cruise. I have to wait until the plane has fully slowed back down to cruise speed after a downline before throttling back up otherwise it either surges or misses during the transition until the prop loads the engine up again.

I'm also getting a fair bit oil discoloured oil up the back of the engine, firewall and landing gear area so there's another issue at hand. Almost like it's spitting back out from the carb throat. below that and around the bottom end is dry. The amount of oil seems proportionate to the amount of engine "misses" during the flight, so it's really time to put it on a test bench and watch it closely.

Got lucky with the parting tool width and final diameter.

"like a glove".....in my best Jim Carey voice.

.

In the meantime, I put my 170cdi back in the Aries 07, rebuilt with old o-rings and gaskets (new head gasket), and did two flights yesterday (same fuel, same cdi unit). While I really miss the top end grunt of the 200cdi, the 170cdi idles like a swiss watch, downline brakes, throttle transition to any position at any speed as smooth as butter and not a drop of oil in the engine bay.

Last edited by bjr_93tz; 07-19-2021 at 04:33 PM.

#336

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

Observations on the test stand:

(1) Minor head gasket leak, fixed.

Hardly rocket science, removed the head, put in a new gasket, made sure it tightened up straight/flat/even and cranked on those head bolts more than usual.

(2) Minor intake tube leak (top) fixed.

All four the o-rings had weird cuts in the sides. Some pretty deep and some extending halfway around the o-ring. Very hard to spot without a magnifier and only then it showed up as a thin dark line that opened up with the tip of a scalpel blade. I guess they got cut from the edges of the grooves they sit in during assembly. I assemble them lubricated but they're the originals from new.

(3) valve cover leak, fixed.

I'd run the cover over some sandpaper before but clearly it still wasn't flat enough. The gasket didn't have an even impression all the way around so I got out the old bearing blue and made sure the cover was flat to the mating surface before throwing on a new gasket.

(4) pinhole in injector tubing/YS tube "C", replaced.

It still had minuscule evidence of dampness on the plug lead and injector tube, so I looked real hard at the injector tube. Found a pinhole/split with my x10 loupe. It'd only open up when pressurised with a syringe and sharply bent at that point. It was hardly pouring fuel out and wasn't letting air in but it's not how it should be. Replaced with new YS tube "C" which was noticeably stiffer and tighter than the 2yo original tubing and I had to increase the regulator 3/8th turn. The idle (~2000rpm) was much improved (as well as top end rpm stability and return to idle) after replacing this tube and I suspect the check valve action of this new tubing is working as it should.

Given my experience with my 170cdi, the valve clearance in my 200cdi is set at about 0.09mm cold and I'll sneak that up tighter if everything goes well when back in the plane. Break-in needle is also fully closed at the moment. I'm only getting about 6,650rpm on the carbon APC 21.5x10.5 PN and my backyard is about 2,400ft.

I'm in no hurry to put it back in my plane just yet, but fingers crossed....

(1) Minor head gasket leak, fixed.

Hardly rocket science, removed the head, put in a new gasket, made sure it tightened up straight/flat/even and cranked on those head bolts more than usual.

(2) Minor intake tube leak (top) fixed.

All four the o-rings had weird cuts in the sides. Some pretty deep and some extending halfway around the o-ring. Very hard to spot without a magnifier and only then it showed up as a thin dark line that opened up with the tip of a scalpel blade. I guess they got cut from the edges of the grooves they sit in during assembly. I assemble them lubricated but they're the originals from new.

(3) valve cover leak, fixed.

I'd run the cover over some sandpaper before but clearly it still wasn't flat enough. The gasket didn't have an even impression all the way around so I got out the old bearing blue and made sure the cover was flat to the mating surface before throwing on a new gasket.

(4) pinhole in injector tubing/YS tube "C", replaced.

It still had minuscule evidence of dampness on the plug lead and injector tube, so I looked real hard at the injector tube. Found a pinhole/split with my x10 loupe. It'd only open up when pressurised with a syringe and sharply bent at that point. It was hardly pouring fuel out and wasn't letting air in but it's not how it should be. Replaced with new YS tube "C" which was noticeably stiffer and tighter than the 2yo original tubing and I had to increase the regulator 3/8th turn. The idle (~2000rpm) was much improved (as well as top end rpm stability and return to idle) after replacing this tube and I suspect the check valve action of this new tubing is working as it should.

Given my experience with my 170cdi, the valve clearance in my 200cdi is set at about 0.09mm cold and I'll sneak that up tighter if everything goes well when back in the plane. Break-in needle is also fully closed at the moment. I'm only getting about 6,650rpm on the carbon APC 21.5x10.5 PN and my backyard is about 2,400ft.

I'm in no hurry to put it back in my plane just yet, but fingers crossed....

Last edited by bjr_93tz; 07-29-2021 at 10:32 PM.

#337

Observations on the test stand:

(1) Minor head gasket leak, fixed.

Hardly rocket science, removed the head, put in a new gasket, made sure it tightened up straight/flat/even and cranked on those head bolts more than usual.

(2) Minor intake tube leak (top) fixed.

All four the o-rings had weird cuts in the sides. Some pretty deep and some extending halfway around the o-ring. Very hard to spot without a magnifier and only then it showed up as a thin dark line that opened up with the tip of a scalpel blade. I guess they got cut from the edges of the grooves they sit in during assembly. I assemble them lubricated but they're the originals from new.

(3) valve cover leak, fixed.

I'd run the cover over some sandpaper before but clearly it still wasn't flat enough. The gasket didn't have an even impression all the way around so I got out the old bearing blue and made sure the cover was flat to the mating surface before throwing on a new gasket.

(4) pinhole in injector tubing/YS tube "C", replaced.

It still had minuscule evidence of dampness on the plug lead and injector tube, so I looked real hard at the injector tube. Found a pinhole/split with my x10 loupe. It'd only open up when pressurised with a syringe and sharply bent at that point. It was hardly pouring fuel out and wasn't letting air in but it's not how it should be. Replaced with new YS tube "C" which was noticeably stiffer and tighter than the 2yo original tubing and I had to increase the regulator 3/8th turn. The idle (~2000rpm) was much improved (as well as top end rpm stability and return to idle) after replacing this tube and I suspect the check valve action of this new tubing is working as it should.

Given my experience with my 170cdi, the valve clearance in my 200cdi is set at about 0.09mm cold and I'll sneak that up tighter if everything goes well when back in the plane. Break-in needle is also fully closed at the moment. I'm only getting about 6,650rpm on the carbon APC 21.5x10.5 PN and my backyard is about 2,400ft.

I'm in no hurry to put it back in my plane just yet, but fingers crossed....

(1) Minor head gasket leak, fixed.

Hardly rocket science, removed the head, put in a new gasket, made sure it tightened up straight/flat/even and cranked on those head bolts more than usual.

(2) Minor intake tube leak (top) fixed.

All four the o-rings had weird cuts in the sides. Some pretty deep and some extending halfway around the o-ring. Very hard to spot without a magnifier and only then it showed up as a thin dark line that opened up with the tip of a scalpel blade. I guess they got cut from the edges of the grooves they sit in during assembly. I assemble them lubricated but they're the originals from new.

(3) valve cover leak, fixed.

I'd run the cover over some sandpaper before but clearly it still wasn't flat enough. The gasket didn't have an even impression all the way around so I got out the old bearing blue and made sure the cover was flat to the mating surface before throwing on a new gasket.

(4) pinhole in injector tubing/YS tube "C", replaced.

It still had minuscule evidence of dampness on the plug lead and injector tube, so I looked real hard at the injector tube. Found a pinhole/split with my x10 loupe. It'd only open up when pressurised with a syringe and sharply bent at that point. It was hardly pouring fuel out and wasn't letting air in but it's not how it should be. Replaced with new YS tube "C" which was noticeably stiffer and tighter than the 2yo original tubing and I had to increase the regulator 3/8th turn. The idle (~2000rpm) was much improved (as well as top end rpm stability and return to idle) after replacing this tube and I suspect the check valve action of this new tubing is working as it should.

Given my experience with my 170cdi, the valve clearance in my 200cdi is set at about 0.09mm cold and I'll sneak that up tighter if everything goes well when back in the plane. Break-in needle is also fully closed at the moment. I'm only getting about 6,650rpm on the carbon APC 21.5x10.5 PN and my backyard is about 2,400ft.

I'm in no hurry to put it back in my plane just yet, but fingers crossed....

I always replace all O rings and gaskets when I rebuild. You have to be careful fitting the intake tube, as it can cut the O rings if not careful.

0.09 is a bit loose, they like a tight clearance. I use a .0015" feeler gauge with a tight setting, so would be around .001" (.025mm)

That RPM sounds about right for that size prop.

#338

Senior Member

WOW you got 2 years out of a tube C..........

I change mine every six months regardless .

If you google silicon tubing there's is a place in AUS that sells the same stuff for a lot less and it arrives at your front door within a couple of days.

The RPM is very good with that prop...

best regards

I change mine every six months regardless .

If you google silicon tubing there's is a place in AUS that sells the same stuff for a lot less and it arrives at your front door within a couple of days.

The RPM is very good with that prop...

best regards

#339

WOW you got 2 years out of a tube C..........

I change mine every six months regardless .

If you google silicon tubing there's is a place in AUS that sells the same stuff for a lot less and it arrives at your front door within a couple of days.

The RPM is very good with that prop...

best regards

I change mine every six months regardless .

If you google silicon tubing there's is a place in AUS that sells the same stuff for a lot less and it arrives at your front door within a couple of days.

The RPM is very good with that prop...

best regards

One of my 200cdi is 4 years old and the other is 3 1/2 years old.

Still on the original Tube C in both.

#340

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

WOW you got 2 years out of a tube C..........

I change mine every six months regardless .

If you google silicon tubing there's is a place in AUS that sells the same stuff for a lot less and it arrives at your front door within a couple of days.

The RPM is very good with that prop...

best regards

I change mine every six months regardless .

If you google silicon tubing there's is a place in AUS that sells the same stuff for a lot less and it arrives at your front door within a couple of days.

The RPM is very good with that prop...

best regards

However, dozens of happy YS users and a WC in their back pocket with it means it works good enough..

#341

Senior Member

I'm still not 100% sold on the current arrangement for the injector check valve. It's less moving parts for sure but relying on the mechanical properties of a piece of silicone tube the way it does, it just seems to add another variable compared to the original diaphragm and spring.

However, dozens of happy YS users and a WC in their back pocket with it means it works good enough..

However, dozens of happy YS users and a WC in their back pocket with it means it works good enough..

Works very well.....

#342

I'm still not 100% sold on the current arrangement for the injector check valve. It's less moving parts for sure but relying on the mechanical properties of a piece of silicone tube the way it does, it just seems to add another variable compared to the original diaphragm and spring.

However, dozens of happy YS users and a WC in their back pocket with it means it works good enough..

However, dozens of happy YS users and a WC in their back pocket with it means it works good enough..

I've never had or heard of any problems with the current injector set up. I never had any problems with the previous set up either.

It's the one part I don't even think of having trouble with. So if it ain't broke, don't fix it 😬

#343

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

Sounds like you're over thinking things Brett 🙄

I've never had or heard of any problems with the current injector set up. I never had any problems with the previous set up either.

It's the one part I don't even think of having trouble with. So if it ain't broke, don't fix it 😬

I've never had or heard of any problems with the current injector set up. I never had any problems with the previous set up either.

It's the one part I don't even think of having trouble with. So if it ain't broke, don't fix it 😬

I feel like that Aussie named Kevin, singing about his telephone

Last edited by bjr_93tz; 08-05-2021 at 04:15 PM.

#344

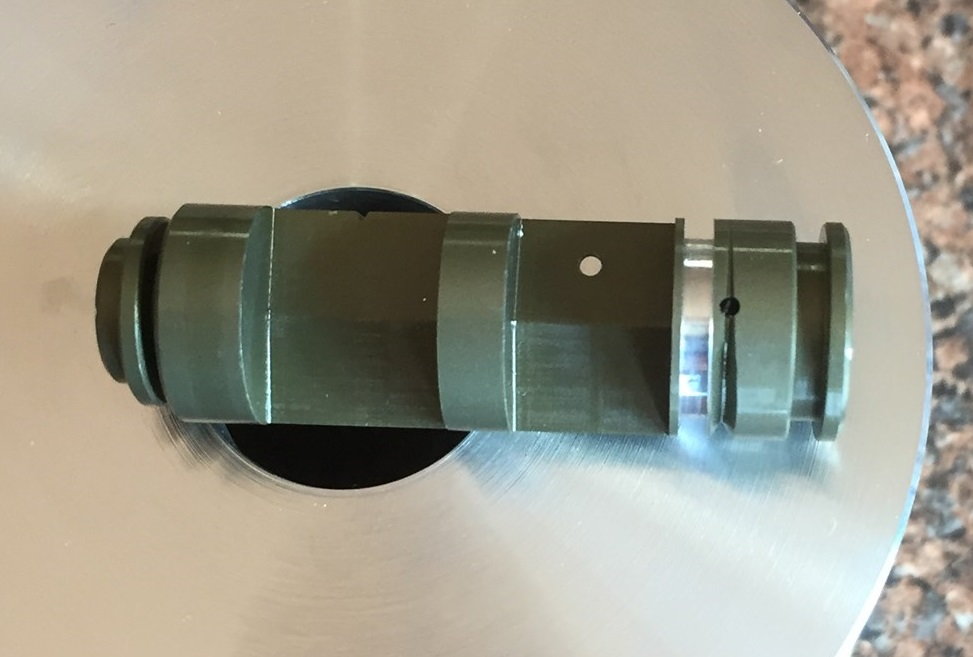

Hi,

After replacing bearings, I could not get the prop drive washer to lock on the split conical retainer, no matter how much hand torque did I apply: As soon as I released the prop nut, the prop washer came loose. I ordered and installed new cone and washer, but to no avail.

Is it safe to bench run the engine with such an issue? Will the washer lock while running?

Thanks.

After replacing bearings, I could not get the prop drive washer to lock on the split conical retainer, no matter how much hand torque did I apply: As soon as I released the prop nut, the prop washer came loose. I ordered and installed new cone and washer, but to no avail.

Is it safe to bench run the engine with such an issue? Will the washer lock while running?

Thanks.

#345

Hi,

After replacing bearings, I could not get the prop drive washer to lock on the split conical retainer, no matter how much hand torque did I apply: As soon as I released the prop nut, the prop washer came loose. I ordered and installed new cone and washer, but to no avail.

Is it safe to bench run the engine with such an issue? Will the washer lock while running?

Thanks.

After replacing bearings, I could not get the prop drive washer to lock on the split conical retainer, no matter how much hand torque did I apply: As soon as I released the prop nut, the prop washer came loose. I ordered and installed new cone and washer, but to no avail.

Is it safe to bench run the engine with such an issue? Will the washer lock while running?

Thanks.

I know it might be a stupid question as you have been flying YS for a long time, but are you sure the crankshaft is tight against the bearing and no problem with the compression ring?

The following users liked this post:

apereira (07-09-2022)

The following users liked this post:

apereira (08-04-2022)

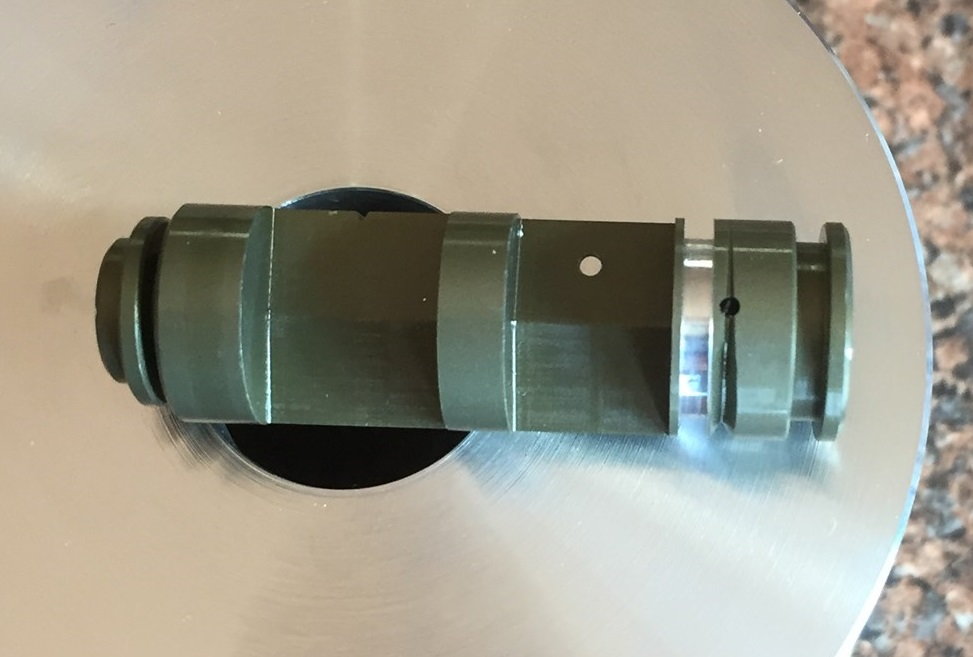

#350

Another old issue and very bothering: Even when the muffler original YS O ring slides nicely on the header at the start of the flight, after 8 minutes or so, the O ring is stuck to the header, as if it is glued to it. I tried freeing the O ring every flight, lubricating with vaseline, anti seize, polishing the header - all to no avail.

After about 8 flights the O ring starts creeping out as can be seen, loosing seal and leaking exhaust gas.

The engine performs nicely otherwise, oil is 10% Morgan Low Smoke.

Any cure?

After about 8 flights the O ring starts creeping out as can be seen, loosing seal and leaking exhaust gas.

The engine performs nicely otherwise, oil is 10% Morgan Low Smoke.

Any cure?