Servo Gears: Steel vs Titanium???

#1

Thread Starter

Join Date: Mar 2012

Location: Paducah, KY

Posts: 36

Likes: 0

Received 0 Likes

on

0 Posts

Hey all

Making the transition from glow to gas airplanes. Going to be mostly 25%, 30cc stuff. Many manyhours of research and I've decided on Savox for my servos of choice.

My main question is about steel vs titanium. I noticed the higher end Savox servos now use steel gears. In the specs the gear material is listed as "unique steel" whatever that means. I'm looking at 1268 and 1267 HV servos and they both use these "unique" steel gears.

Any input about steel vs titanium? I'm not a 3D flyer (yet) so I'm more interested in longevity and minimum wear vs brute force. Thanks.

Randy

Making the transition from glow to gas airplanes. Going to be mostly 25%, 30cc stuff. Many manyhours of research and I've decided on Savox for my servos of choice.

My main question is about steel vs titanium. I noticed the higher end Savox servos now use steel gears. In the specs the gear material is listed as "unique steel" whatever that means. I'm looking at 1268 and 1267 HV servos and they both use these "unique" steel gears.

Any input about steel vs titanium? I'm not a 3D flyer (yet) so I'm more interested in longevity and minimum wear vs brute force. Thanks.

Randy

#3

"unique" steel gears

That ain't nothin, YS makes cylinders out of "light weight" steel.

There once was a time when Titanium gears sounded like a rock crusher. Marketing convinced everyone that was the sound of quality.

That ain't nothin, YS makes cylinders out of "light weight" steel.

There once was a time when Titanium gears sounded like a rock crusher. Marketing convinced everyone that was the sound of quality.

#4

Thread Starter

Join Date: Mar 2012

Location: Paducah, KY

Posts: 36

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: BarracudaHockey

Steel gears are holding up fine in my Savox servos

Steel gears are holding up fine in my Savox servos

#5

Thread Starter

Join Date: Mar 2012

Location: Paducah, KY

Posts: 36

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: Four Stroker

"unique" steel gears

That ain't nothin, YS makes cylinders out of "light weight" steel.

There once was a time when Titanium gears sounded like a rock crusher. Marketing convinced everyone that was the sound of quality.

"unique" steel gears

That ain't nothin, YS makes cylinders out of "light weight" steel.

There once was a time when Titanium gears sounded like a rock crusher. Marketing convinced everyone that was the sound of quality.

My favorite is "metal" gear servos. Metal is a pretty broad term don't you think? Savox offers Titanium, steel and metal gears... Jeeezzz... I need a beer!

#6

Senior Member

Just a few things to consider when making your decision about steel vs Titanium servo gears.

If you will be flying on really hot days....like we have here in Texas....the Titanium gears will give you an extra margin of safety. Titanium has a melting point of 3135°F (1725°C). This melting point is approximately 400°F (220°C) above the melting point of steel. So if the air temperature was...let's say 2,800 degrees, steel gears would turn to liquid...but your Titanium gears would still be OK. Another thing to consider: Gasoline is very volatile and flammable....much more so than glow fuel. On occasion, gas powered planes crash and burn. If this ever happens with one of your planes, even if the fire destroys your plane, servos, and receiver.....your Titanium gears would survive undamaged.

Best Regards

JC

PS: Yes...I'm joking.

If you will be flying on really hot days....like we have here in Texas....the Titanium gears will give you an extra margin of safety. Titanium has a melting point of 3135°F (1725°C). This melting point is approximately 400°F (220°C) above the melting point of steel. So if the air temperature was...let's say 2,800 degrees, steel gears would turn to liquid...but your Titanium gears would still be OK. Another thing to consider: Gasoline is very volatile and flammable....much more so than glow fuel. On occasion, gas powered planes crash and burn. If this ever happens with one of your planes, even if the fire destroys your plane, servos, and receiver.....your Titanium gears would survive undamaged.

Best Regards

JC

PS: Yes...I'm joking.

#7

Thread Starter

Join Date: Mar 2012

Location: Paducah, KY

Posts: 36

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: JCINTEXAS

Just a few things to consider when making your decision about steel vs Titanium servo gears.

If you will be flying on really hot days....like we have here in Texas....the Titanium gears will give you an extra margin of safety. Titanium has a melting point of 3135°F (1725°C). This melting point is approximately 400°F (220°C) above the melting point of steel. So if the air temperature was...let's say 2,800 degrees, steel gears would turn to liquid...but your Titanium gears would still be OK. Another thing to consider: Gasoline is very volatile and flammable....much more so than glow fuel. On occasion, gas powered planes crash and burn. If this ever happens with one of your planes, even if the fire destroys your plane, servos, and receiver.....your Titanium gears would survive undamaged.

Best Regards

JC

PS: Yes...I'm joking.

Just a few things to consider when making your decision about steel vs Titanium servo gears.

If you will be flying on really hot days....like we have here in Texas....the Titanium gears will give you an extra margin of safety. Titanium has a melting point of 3135°F (1725°C). This melting point is approximately 400°F (220°C) above the melting point of steel. So if the air temperature was...let's say 2,800 degrees, steel gears would turn to liquid...but your Titanium gears would still be OK. Another thing to consider: Gasoline is very volatile and flammable....much more so than glow fuel. On occasion, gas powered planes crash and burn. If this ever happens with one of your planes, even if the fire destroys your plane, servos, and receiver.....your Titanium gears would survive undamaged.

Best Regards

JC

PS: Yes...I'm joking.

P.S. Yes... I'm joking too. Thanks for the chuckle!!

#9

Senior Member

Join Date: Apr 2010

Location: Cape Town, SOUTH AFRICA

Posts: 2,744

Likes: 0

Received 1 Like

on

1 Post

Not its not stronger. Titanium is tougher than steel, not stronger.

Toughness allows it to absorb a load (deform) and return to the same state. So for rapid changes in direction from the gearbox (like in heavy 3d flying) titanium gears can absorb the load better.

HOWEVER, the loads on the gear teeth are so small that its really of no consequence. Titanium does not not have great hardness so the gears have to be adequately lubricated. If not the titanium oxide layer will create galling which will wear the gears faster than a mouse can a chunk of cheese.

The primary reason for titanium gears is a (very) small weight reduction, bling factor and a reason for higher cost.

#11

My Feedback: (14)

Join Date: Feb 2002

Location: Noblesville,

IN

Posts: 1,503

Likes: 0

Received 0 Likes

on

0 Posts

I read on another forum, just recently, that Titanium gears are not solid Titanium, but a coating applied to steel gears to increase wear. Don't know if the truth, and I can't find the original article. But it made the comment that solid titanium would be to expensive to buy and to tool. Anyone else hear this??

#12

Servo manufacturer here. Old-ish thread addressed for serious discussion.

Actually, Ti (titanium) isn't as strong as people think 'and' it scratches easily (important because gears function by surfaces sliding against each other). Anyway, yes it's true Ti has a higher tensile strength than steel - per mass but not by volume. As a practical matter - ounce for ounce - while a piece of Ti is stronger than a piece of steel, to get the 'same' strength as steel, that piece of Ti (e.g. a gear) will be larger than than the one made of steel.

Missing this important detail when discussing the virtues of Ti gears means not grokking the simple fact that if the gears are the same size (and they're basically the exact same size whether the material is Ti or steel), then the Ti-gear is actually weaker than the steel-gear! And with respect to the few grams difference in weight between Ti and steel gear sets, it's only important in theory, not in the real world.

As background, Ti gained 'street cred' due to the SR-71 Blackbird because it captured the popular imagination - especially with aviation enthusiasts. However, there are other real world examples where cost-is-no-object . . . to include F1 racing transmissions. Guess what? Those gears are made of steel instead of Ti. Why? It's because steel is more compact for the same strength - and - it's not as brittle, which in case it's not obvious, is exactly why we prefer steel for our servo gears!

Finally, the secret sauce for ensuring the tiny gear profiles within servos - regardless of whether the underlying material is Ti or steel - lasts a long time is a surface treatment (kind of like case hardening). So not only are steel gears better than Ti because it's not as brittle, but because once you harden the wear surface of both alloys (plasma nitriding), then it no longer matters because both are hardened plenty good enough to wear for a long, long time. In fact, surface treatments are so effective we use them with aluminum-alloys for gears also (typically 7075-T6). Guess what? Surface treated aluminum gears give great service while being lighter than Ti and also last a long, long time!

However, if you want to know why your gears aren't lasting, you're looking in the wrong place. Whether the gears are made of Ti, steel, aluminum, or plastic, getting sloppy usually has more to do with case wear. This is because the pockets in which the steel gear shafts ride are pounded into an egg-shape because of the loads. And once this happens all bets are off because the gear mesh is shot! So when you buy new gears you're well advised to buy a new case as well or you're pissin' away your money!

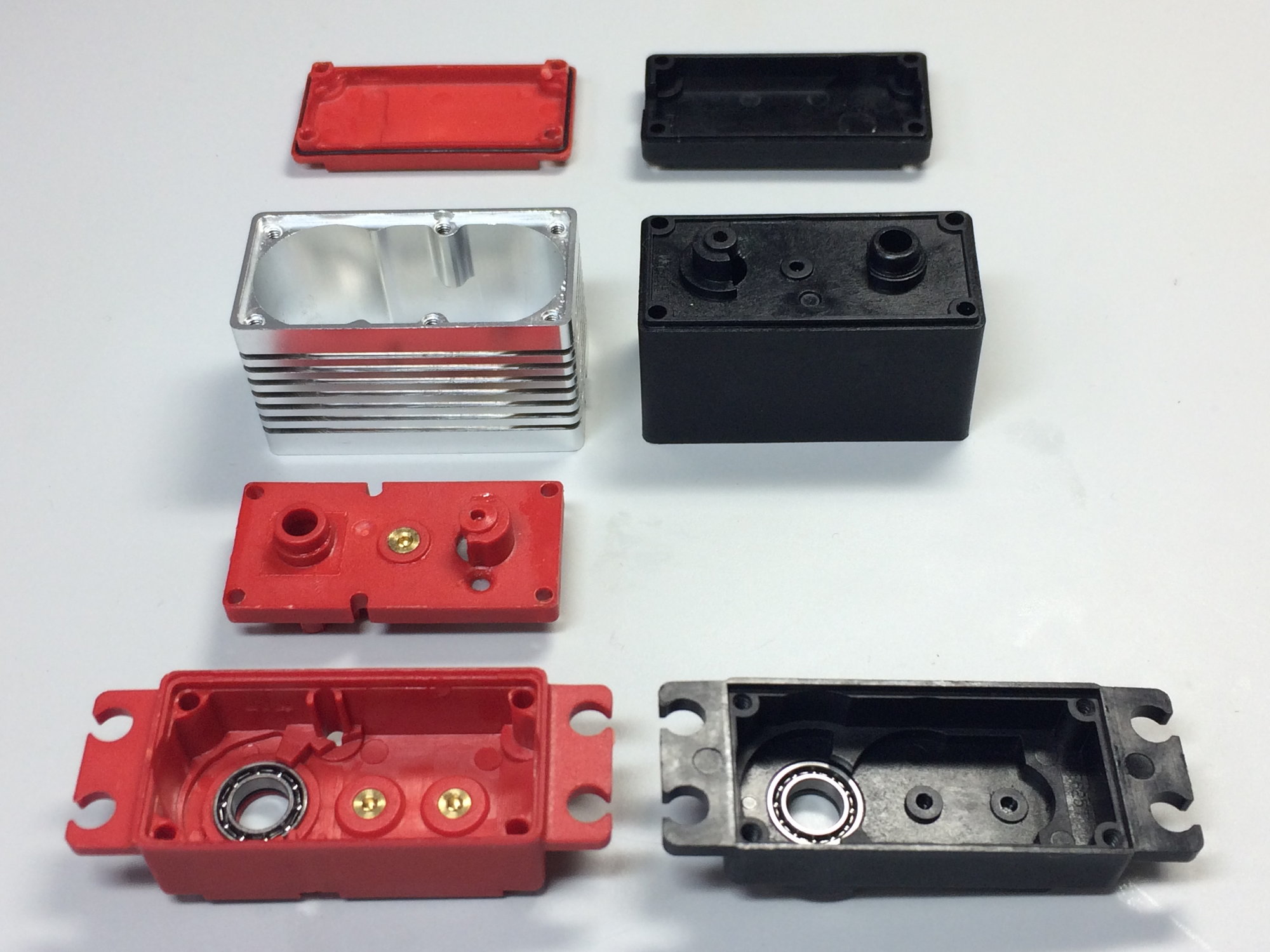

The real solution is to properly reinforce the case at the pockets to keep it from happening in the first place. But this costs money and most servos are built to a price point. Compare the popular Hitec HS-5685MH to a ProModeler DS180DLHV. Both deliver about the same torque at the same speed, and importantly, both cost about the same . . . but after eyeballing this photo, which do you think will deliver a longer service life?

Last thing; if you want to get down in the weeds regarding the pros and cons of Ti vs. steel, you're going to need a degree in Mechanical Engineering, plus a masters in Materials Engineering, and you really need to fully digest something like the Handbook Of Mechanical Alloy Design by Dekker (just to follow the conversation). My point in bringing this up isn't to insult modelers, but to observe the 'real' reason Ti gears exist within model airplane servos . . . it's because it's great for getting rubes to reach for their wallets more quickly. Or put another way, it has to do with marketing!

Actually, Ti (titanium) isn't as strong as people think 'and' it scratches easily (important because gears function by surfaces sliding against each other). Anyway, yes it's true Ti has a higher tensile strength than steel - per mass but not by volume. As a practical matter - ounce for ounce - while a piece of Ti is stronger than a piece of steel, to get the 'same' strength as steel, that piece of Ti (e.g. a gear) will be larger than than the one made of steel.

Missing this important detail when discussing the virtues of Ti gears means not grokking the simple fact that if the gears are the same size (and they're basically the exact same size whether the material is Ti or steel), then the Ti-gear is actually weaker than the steel-gear! And with respect to the few grams difference in weight between Ti and steel gear sets, it's only important in theory, not in the real world.

As background, Ti gained 'street cred' due to the SR-71 Blackbird because it captured the popular imagination - especially with aviation enthusiasts. However, there are other real world examples where cost-is-no-object . . . to include F1 racing transmissions. Guess what? Those gears are made of steel instead of Ti. Why? It's because steel is more compact for the same strength - and - it's not as brittle, which in case it's not obvious, is exactly why we prefer steel for our servo gears!

Finally, the secret sauce for ensuring the tiny gear profiles within servos - regardless of whether the underlying material is Ti or steel - lasts a long time is a surface treatment (kind of like case hardening). So not only are steel gears better than Ti because it's not as brittle, but because once you harden the wear surface of both alloys (plasma nitriding), then it no longer matters because both are hardened plenty good enough to wear for a long, long time. In fact, surface treatments are so effective we use them with aluminum-alloys for gears also (typically 7075-T6). Guess what? Surface treated aluminum gears give great service while being lighter than Ti and also last a long, long time!

However, if you want to know why your gears aren't lasting, you're looking in the wrong place. Whether the gears are made of Ti, steel, aluminum, or plastic, getting sloppy usually has more to do with case wear. This is because the pockets in which the steel gear shafts ride are pounded into an egg-shape because of the loads. And once this happens all bets are off because the gear mesh is shot! So when you buy new gears you're well advised to buy a new case as well or you're pissin' away your money!

The real solution is to properly reinforce the case at the pockets to keep it from happening in the first place. But this costs money and most servos are built to a price point. Compare the popular Hitec HS-5685MH to a ProModeler DS180DLHV. Both deliver about the same torque at the same speed, and importantly, both cost about the same . . . but after eyeballing this photo, which do you think will deliver a longer service life?

Last thing; if you want to get down in the weeds regarding the pros and cons of Ti vs. steel, you're going to need a degree in Mechanical Engineering, plus a masters in Materials Engineering, and you really need to fully digest something like the Handbook Of Mechanical Alloy Design by Dekker (just to follow the conversation). My point in bringing this up isn't to insult modelers, but to observe the 'real' reason Ti gears exist within model airplane servos . . . it's because it's great for getting rubes to reach for their wallets more quickly. Or put another way, it has to do with marketing!

Last edited by jbeech; 11-08-2018 at 08:20 AM.

#14

Used lots of heavy duty servo 25~35kg torque on my 1:5 petrol/gas monster truck for bashing and some on 1:8 for racing. Steel servo is way to go because the gearing material are denser and resist wear out, titanium is build for lightweight performance but less dense then steel and will worn out when used at same rate. On my race mountain bike and road bike steel gear last me 12 years than titanium on just 3 years. ...i learned the hard way.

#15

Since this thread has been resurrected from the dead for no other purpose other than to call us out, here is my response: Our Titanium gears have been tested in house and by 3rd party's to last as long as our steel geartrains (and in many cases, they last longer than steel). Titanium is offered in our higher performance servos as it is a lighter material that gives equal, if not better, strength and wear resistance as compared to steel. In order for us to get the weights of our SG servos to that of our TG servos, the steel is often milled or machined out of non-critical areas. On higher performance servos, steel gears would increase weights to an undesirable level (even with machining) so Titanium is substituted instead. All of our gear materials are virgin materials and are machined in our own proprietary facilities as well, so you're not getting cheap remelted materials.

TL;DR: Titanium is every bit as good as steel, and in many ways better.

We pioneered the use of it, we know its qualities the best in servo applications.

TL;DR: Titanium is every bit as good as steel, and in many ways better.

We pioneered the use of it, we know its qualities the best in servo applications.

Last edited by Xpress; 11-29-2018 at 12:07 PM.

#16

I must admit, a customer service rep arguing the merits of material science while referencing pioneering and virgins had me snorting hot coffee from my nose! Then again, perhaps in the mind of a marketing-type there really are folks flying $5000 models weighing 30 pounds who can be fooled into believing 1g of gear-weight amounts to something more important that how many angels can sit on the head of a pin (though I doubt it).

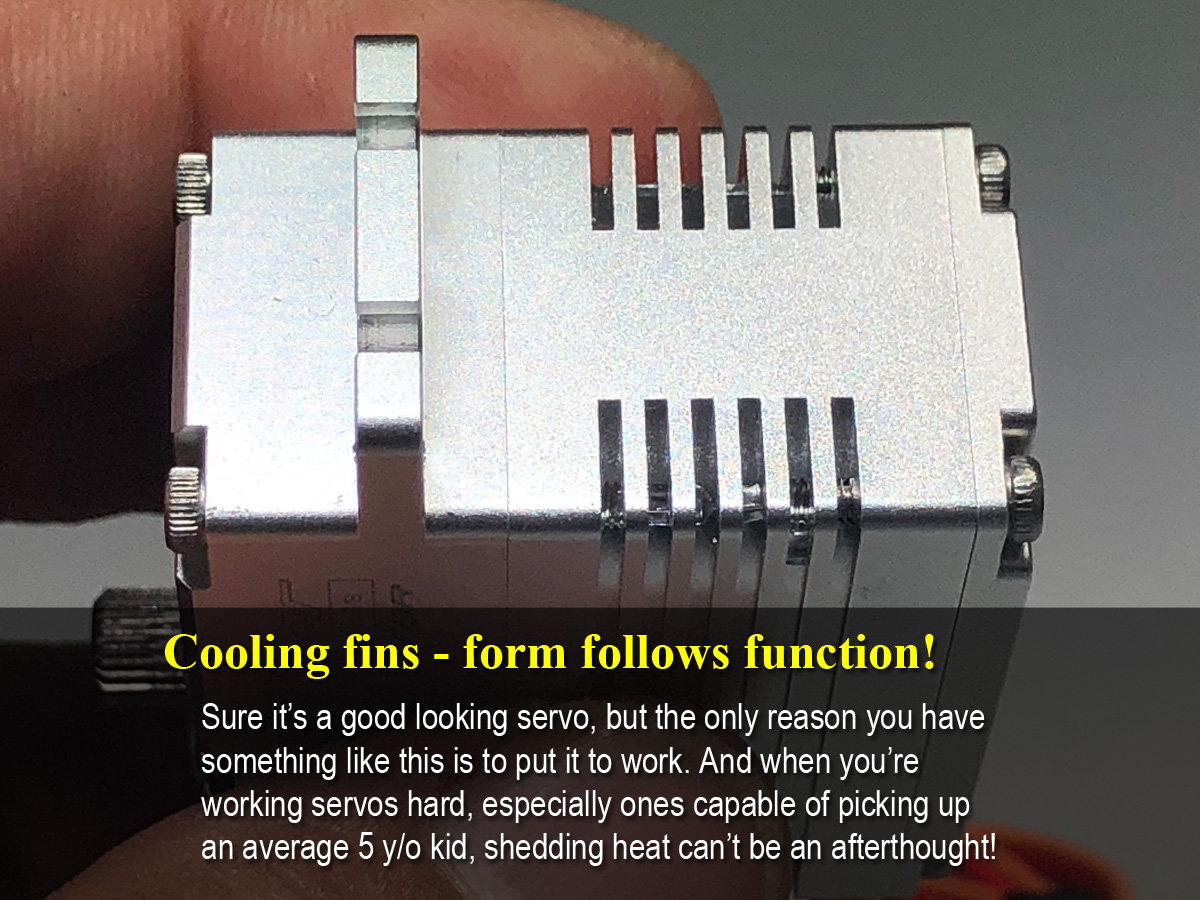

Instead, it's more likely these customers want the best - not a bunch of marketing hype and BS. And am I alone in noticing the sale rep - while pontificating on materials science - totally missed out on addressing engineering? Could it be because this is something he knows even less about? Regardless, what's rather more important for the astute modeler are details of case construction because that's the very foundation of the servo. After all, if you can't hold tolerances after a bit of heavy use (or abuse), it really doesn't matter what the gears are made of!

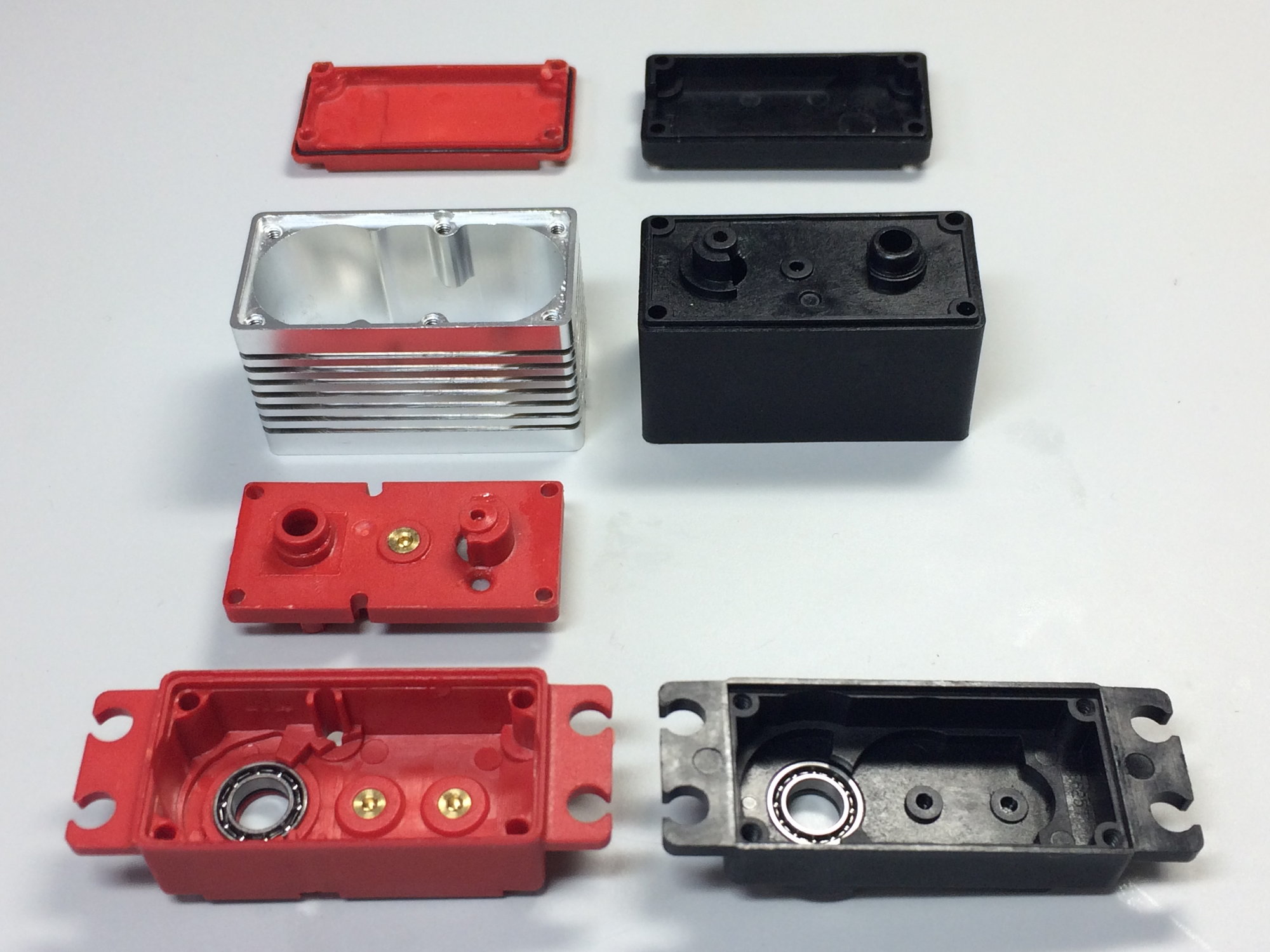

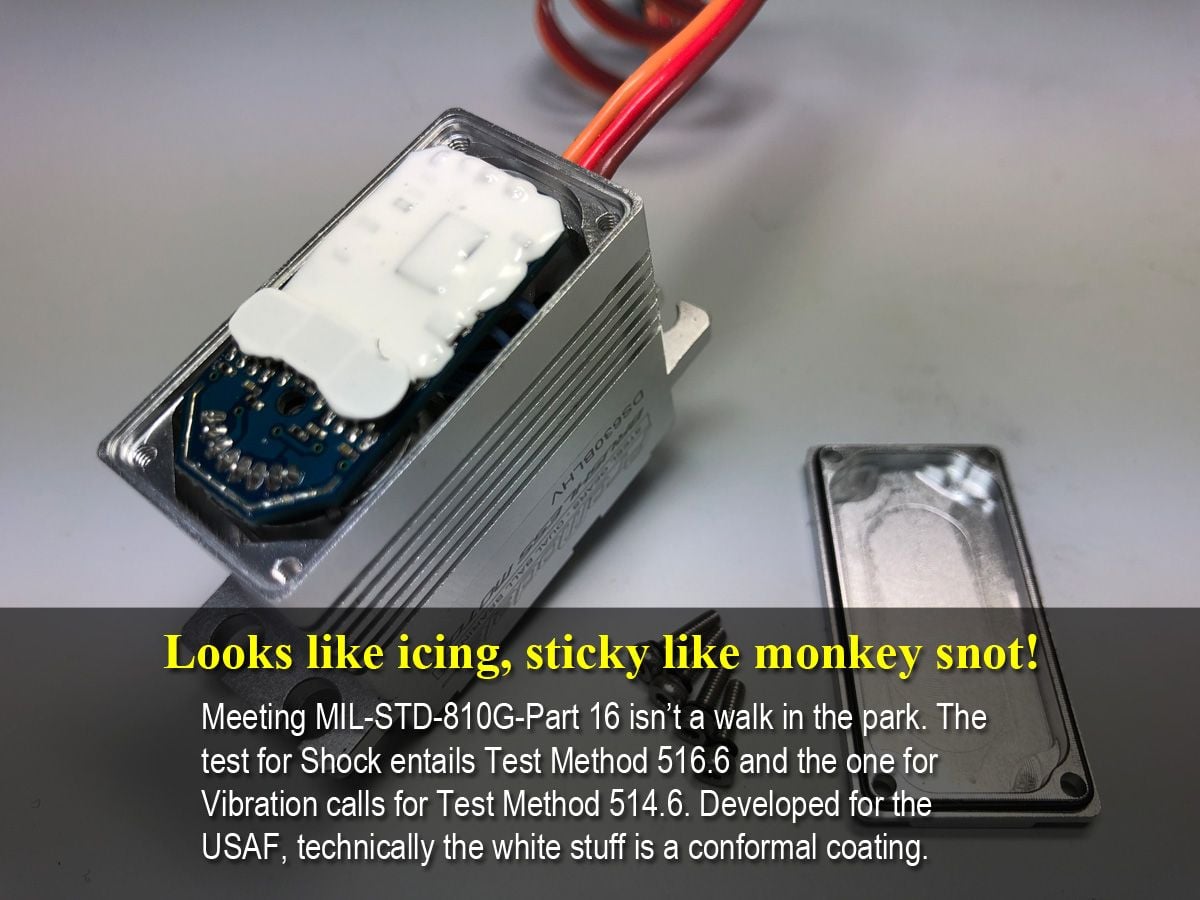

Then again, maybe like a magician waving his hand to distract you, you shouldn't wonder why he makes no mention of the little touches - like how their servos use el cheapo Phillips head screws instead of Allen head machine bolts (details that matter to modelers of a certain type). Or how ours uses more than a dozen o-rings for sealing (sourced from the same folks who supply stem-seals to Rolex). Plus ours have a conformal coating on the printed circuit board expressly to better protect the delicate electronics against high frequency vibrations.

Yes, I know these are mere technical details but spouting marketing nonsense means totally ignoring other facts. Like how modelers are fairly good jackleg engineers even if they don't have a degree! Then again, I'm not surprised because when the facts are against you, avoiding the real subject by waving your hands, or spouting abracadabra, are usually good distractions (sales tactics).

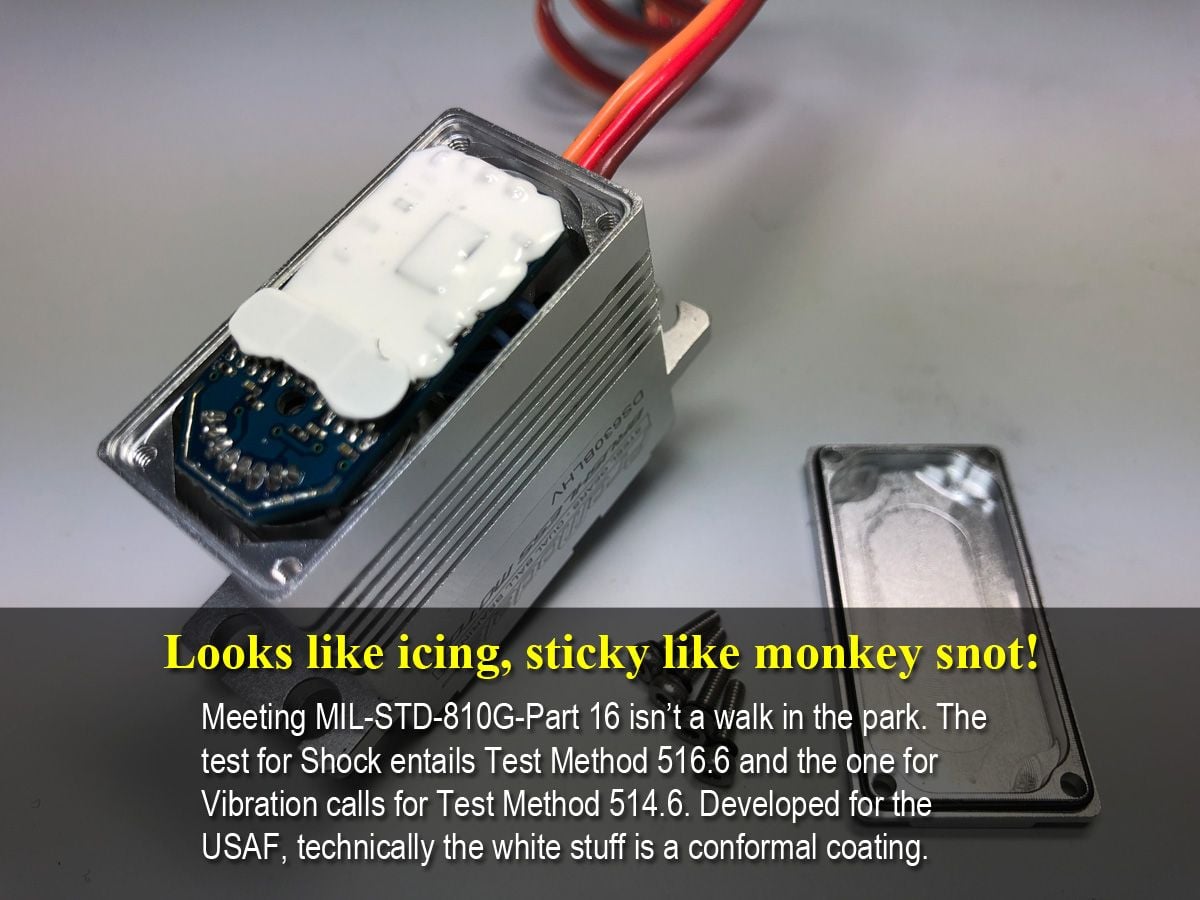

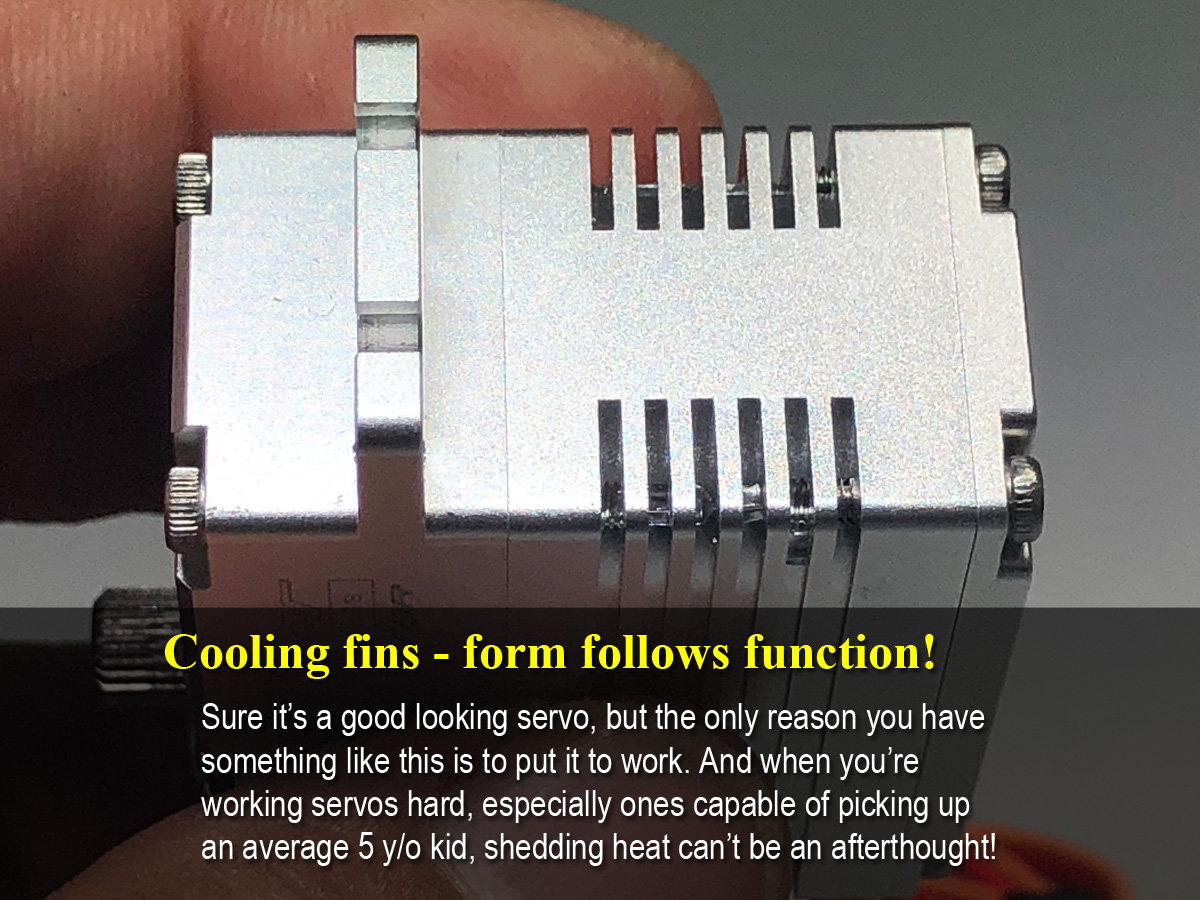

Frankly, deciding who offers the better servo is something of a no-brainer because you only need eyes. Or maybe he wants I should post side-by-side photos of our best vs. their best? In any case, I know this; even if this were poker, I wouldn't bet that fellow's hand . . . just feast your eyes on our best servo because if you think it's pretty on the outside, that's nothing to how good it is on the inside, where it really counts!

Instead, it's more likely these customers want the best - not a bunch of marketing hype and BS. And am I alone in noticing the sale rep - while pontificating on materials science - totally missed out on addressing engineering? Could it be because this is something he knows even less about? Regardless, what's rather more important for the astute modeler are details of case construction because that's the very foundation of the servo. After all, if you can't hold tolerances after a bit of heavy use (or abuse), it really doesn't matter what the gears are made of!

Then again, maybe like a magician waving his hand to distract you, you shouldn't wonder why he makes no mention of the little touches - like how their servos use el cheapo Phillips head screws instead of Allen head machine bolts (details that matter to modelers of a certain type). Or how ours uses more than a dozen o-rings for sealing (sourced from the same folks who supply stem-seals to Rolex). Plus ours have a conformal coating on the printed circuit board expressly to better protect the delicate electronics against high frequency vibrations.

Yes, I know these are mere technical details but spouting marketing nonsense means totally ignoring other facts. Like how modelers are fairly good jackleg engineers even if they don't have a degree! Then again, I'm not surprised because when the facts are against you, avoiding the real subject by waving your hands, or spouting abracadabra, are usually good distractions (sales tactics).

Frankly, deciding who offers the better servo is something of a no-brainer because you only need eyes. Or maybe he wants I should post side-by-side photos of our best vs. their best? In any case, I know this; even if this were poker, I wouldn't bet that fellow's hand . . . just feast your eyes on our best servo because if you think it's pretty on the outside, that's nothing to how good it is on the inside, where it really counts!

Last edited by jbeech; 11-29-2018 at 03:31 PM.