3D Printed 1/16th FV101 Scorpion

#51

#52

Join Date: Sep 2015

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Well done! i have seen different DIY 3D printers but so far the parts quality and definition was not so good and smooth up to today's modelling standard. is your printer high definition? Could you post a couple of pics with close-up of upper hull / turret ?

... beside that, please make a little effort more for Scimitar version too ))

))

... beside that, please make a little effort more for Scimitar version too

))

))

#53

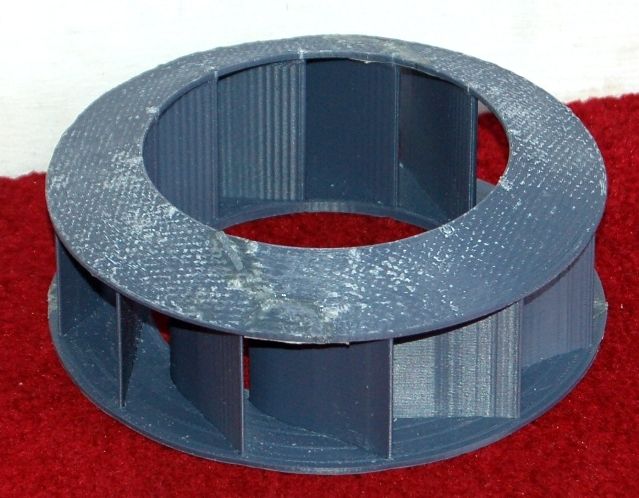

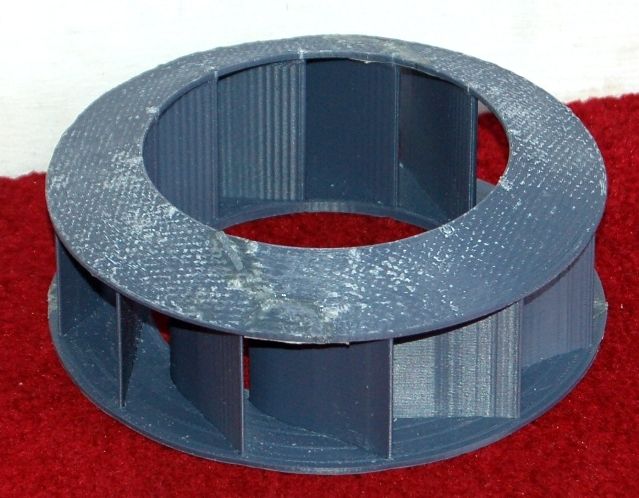

This is a before and after ABS lift fan I printed for another member of this forum.

In the first pic you can see the mess left from the support material (I printed it upside down) and in the second pic you see the top after acetone and sanding-

Printed at 0.2mm layers.

In the first pic you can see the mess left from the support material (I printed it upside down) and in the second pic you see the top after acetone and sanding-

Printed at 0.2mm layers.

#54

Join Date: Sep 2015

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

That's impressive indeed, but consider that we are talking about a tank model with lot of details on it.

Acetone treatment is impressive on ABS but it would melt if PVC stirene is used, I think (?)

Acetone treatment is impressive on ABS but it would melt if PVC stirene is used, I think (?)

#55

You use the acetone before adding the detail. The large parts (hull, wheels, etc) would be printed at high speed and low res and the detailed parts (lights, tools etc) are printed at slower speeds and better resolution. Then the large parts can be smoothed with an acetone bath then sanded and with the detailed parts you'd use a brush to apply the acetone then file it smooth).

Or you could get detailed parts done online via Shapeways or some such company.

Or you could get detailed parts done online via Shapeways or some such company.

#56

Join Date: Sep 2015

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

I mean with reference to this Scorpion tank hull, there is a lot of crisp details so cannot be so easily sanded like your vent

i would like to give a try to this new tecnique of 3D printing applied to modelling

i would like to give a try to this new tecnique of 3D printing applied to modelling

#57

Hi Ryan,

I just looked through your thread and its amazing the work you've done on building your Scorpion!!! A good friend of mine wants to build a 3D tank from start to finish like what you've done, but he's not sure how well the tracks will come out on his printer. I told him to check out your thread for some inspiration. I know he can do it.

I started a thread here for the Leopard I won from you on E-bay. Check it out when you have the time.

I just looked through your thread and its amazing the work you've done on building your Scorpion!!! A good friend of mine wants to build a 3D tank from start to finish like what you've done, but he's not sure how well the tracks will come out on his printer. I told him to check out your thread for some inspiration. I know he can do it.

I started a thread here for the Leopard I won from you on E-bay. Check it out when you have the time.

#58

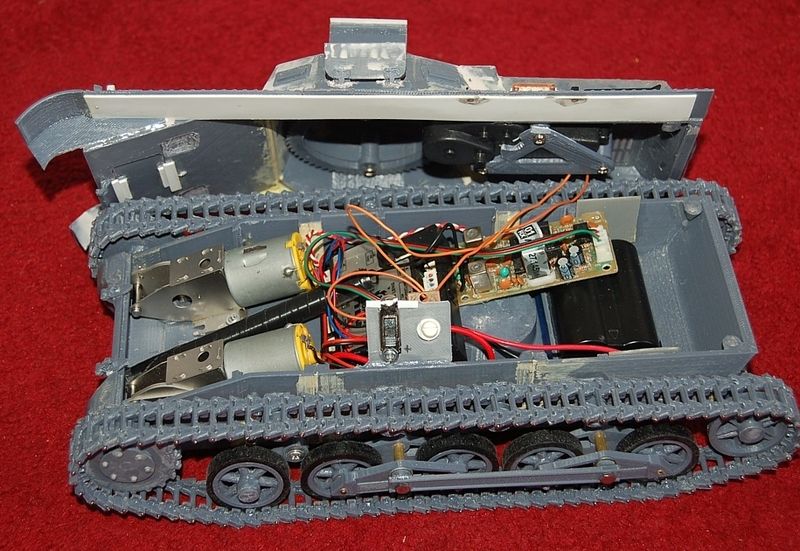

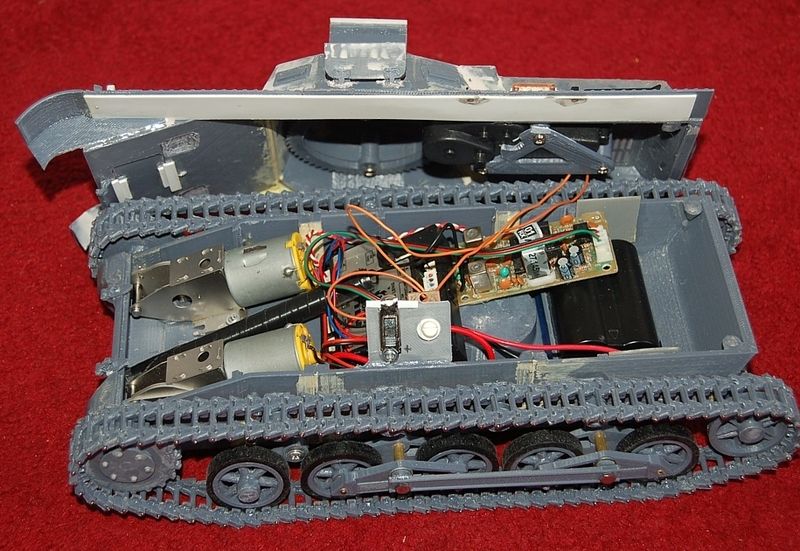

Tracks can be done. I made some for my PZ I. I've only run them for about 1 hour on carpet and concrete but they don't show any signs of breaking yet.

I also printed out some 1/16 Bren carrier tracks for someone else.

I also printed out some 1/16 Bren carrier tracks for someone else.

Last edited by Wozwasnt; 10-14-2015 at 03:34 PM.

#60

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

I've been busy building my own 12" 3d printer all summer, I have not done anything new with the Scorpion yet. I plan to start actually making and selling them next spring time. Over the winter I will be busy with my snow blowers, you should check them out here! http://s1.zetaboards.com/RCsnowcats/topic/5749076/25/

The snow blowers fit onto the Kyosho Blizzard SR kits are for sale on my site: http://spykerworkshop.webs.com/order

https://www.youtube.com/watch?v=IPxKA31NYyY

The snow blowers fit onto the Kyosho Blizzard SR kits are for sale on my site: http://spykerworkshop.webs.com/order

https://www.youtube.com/watch?v=IPxKA31NYyY

Last edited by TheGreatestMoo; 11-10-2015 at 07:34 PM.

#61

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

I have not done much new on this tank, I have been too busy with my 3d printed snow blowers. I just made a new video of the Scorpion cruising around the snow.

https://m.youtube.com/watch?v=zTRgPPElfNs&feature=youtu.be

https://m.youtube.com/watch?v=zTRgPPElfNs&feature=youtu.be

#62

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

I've recently gotten back to getting this Scorpion ready to sell! With the snow melting everywhere I think my snow blowers are done for the year sadly!

Over the summer I made my own 12x12" 3d printers, I can fit a vast amount of parts in each print now. I re-designed nearly the whole Scorpion over the past week, mainly separating parts for easier printing. The whole tank uses very little support material now. I also have smooth PEI beds in my printers. The bottom surfaces look like cast ABS, so I took advantage of that when re-designing it now. The old tank you see in this thread was printed on blue painters tape and Elmers glue so it was not very good.

The main hull has been totally changed, its printed in half, and all the detailed parts will be glued on. It uses the bearings/bushings to align the parts as you glue them on, really easy to do.

I totally re-worked the suspension arm design. It now uses nylon spacers that are inserted into the suspension arm, and those go into the bronze bushings in the hull. The arms used to have a printed shaft which I had several crack on my tank.

The interior of the turret layout has changed to be very easy to do maintiance on everything. The servos for recoil and elevation have a cradle now that only takes 1 screw to remove the servo. Also arms with clips on the end that hold the whole gun mount in, so its easy to remove to get at everything. The top of the turret also has a simple snap clip that keeps it in place, very easy to open up.

The whole tank uses a mixture of metric and imperial screws, I know a lot of people won't like that but I love sheet metal screws into plastic. It uses all metric hardware like bearings, rods etc. but all the screws are imperial. So if you really can't stand that you can always just replace the screws, but nothing works better then sheet metal screws for plastic threads!

I have not decided weather or not I will be selling the STL files. I sold my snow blower files but I think they already got passed around... What are your opinions on this? Its a really difficult thing because STL files can't be protected AT ALL. There is a service out there called "Pinshape" that forces you to stream the STL files and run your printer through a web browser, but I think its pretty limited on what printers it works with.

I'm printing myself out 2 new tanks, one will have all the early stuff, and the other late. Different wheels/sprockets/storage boxes/front lights. I need to make an instruction manual for the whole tank still but then it is just about ready to begin selling! Who is all interested in this still? I don't have a price quite yet. It will be sold in un-assembled kit form.

Check out this instruction manual I made for my snow blowers, I will be doing a very similar manual for this Scorpion! http://spykerworkshop.webs.com/Snow%20Blower%20Manual%20v2.0.pdf

Attached some images of the new parts being printed out.

Over the summer I made my own 12x12" 3d printers, I can fit a vast amount of parts in each print now. I re-designed nearly the whole Scorpion over the past week, mainly separating parts for easier printing. The whole tank uses very little support material now. I also have smooth PEI beds in my printers. The bottom surfaces look like cast ABS, so I took advantage of that when re-designing it now. The old tank you see in this thread was printed on blue painters tape and Elmers glue so it was not very good.

The main hull has been totally changed, its printed in half, and all the detailed parts will be glued on. It uses the bearings/bushings to align the parts as you glue them on, really easy to do.

I totally re-worked the suspension arm design. It now uses nylon spacers that are inserted into the suspension arm, and those go into the bronze bushings in the hull. The arms used to have a printed shaft which I had several crack on my tank.

The interior of the turret layout has changed to be very easy to do maintiance on everything. The servos for recoil and elevation have a cradle now that only takes 1 screw to remove the servo. Also arms with clips on the end that hold the whole gun mount in, so its easy to remove to get at everything. The top of the turret also has a simple snap clip that keeps it in place, very easy to open up.

The whole tank uses a mixture of metric and imperial screws, I know a lot of people won't like that but I love sheet metal screws into plastic. It uses all metric hardware like bearings, rods etc. but all the screws are imperial. So if you really can't stand that you can always just replace the screws, but nothing works better then sheet metal screws for plastic threads!

I have not decided weather or not I will be selling the STL files. I sold my snow blower files but I think they already got passed around... What are your opinions on this? Its a really difficult thing because STL files can't be protected AT ALL. There is a service out there called "Pinshape" that forces you to stream the STL files and run your printer through a web browser, but I think its pretty limited on what printers it works with.

I'm printing myself out 2 new tanks, one will have all the early stuff, and the other late. Different wheels/sprockets/storage boxes/front lights. I need to make an instruction manual for the whole tank still but then it is just about ready to begin selling! Who is all interested in this still? I don't have a price quite yet. It will be sold in un-assembled kit form.

Check out this instruction manual I made for my snow blowers, I will be doing a very similar manual for this Scorpion! http://spykerworkshop.webs.com/Snow%20Blower%20Manual%20v2.0.pdf

Attached some images of the new parts being printed out.

#65

^ This.

As somebody who has posted building plans here, and then later found that another individual on another forum had basically taken screen shots of the important bits and reposted them as his own work, I can whole heartedly say you should keep control of what you have made. Its not like I lost any money thru his theft, but it would have been nice to be credited for my work...

Back on topic - I'd love a family of CVR(t)'s, but I don't have the cash to buy my own printer. A kit printed to order would work for me.

As somebody who has posted building plans here, and then later found that another individual on another forum had basically taken screen shots of the important bits and reposted them as his own work, I can whole heartedly say you should keep control of what you have made. Its not like I lost any money thru his theft, but it would have been nice to be credited for my work...

Back on topic - I'd love a family of CVR(t)'s, but I don't have the cash to buy my own printer. A kit printed to order would work for me.

#66

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for all the input. I think I will avoid selling the STL files at least for now. I might try that Pinshape site since it does actually have some protection.

I still need to make a very elaborate and fancy instruction manual, There are so many pieces to this kit. I don't think I will offer the kit in a ready to run form. Mainly because I'm not really a good painter... lol I will be using just Krylon paint for my next 2 tanks. The filament brand I use also has no military colors to just print it colored. Some paint on my current one peeled off just because I never primed it. Its all just normal ABS plastic.

I also don't want to source out all the electronics to sell with a ready to run kit, like a main controller board and radio etc... I will probably offer a simple electronics package for the tank though with the motors, servos and lights.

The tank is actually designed with mounting holes for the Clark TK22 board (probably fits the new TK24 not sure though)

Attached some images of the current parts in the printers. Both those prints are about 10 hours each. I use the tiny 0.4mm nozzle for most of the parts, 0.2mm layers. The internal skeleton structure and the main lower hull is printed with a 0.6mm nozzle, 0.3mm layers. I think the whole tank is approximately 60-70 hours of print time. The kit could be on the expensive side, but I'm trying my best to keep the cost down. Just like my snow blowers I sell, the kit will come pre-drilled and support material all cleaned up. Still will need some sanding depending how smooth you want everything. The layer lines are visible, especially with paint but for me it is not noticable enough. I will be painting the raw prints on my next 2 tanks to show exactly what they look like off the printers. Easy to sand ABS though.

Image of a part of the internal skeleton spray painted with Krylon paint, and a massive bucket of a lot of the new tank parts!

*Kind of late in my project here to even ask this... but is it even fine for me to sell something like this? Do military vehicles have copyrights on them that could bring up legal issues for me selling this model Scorpion?

I still need to make a very elaborate and fancy instruction manual, There are so many pieces to this kit. I don't think I will offer the kit in a ready to run form. Mainly because I'm not really a good painter... lol I will be using just Krylon paint for my next 2 tanks. The filament brand I use also has no military colors to just print it colored. Some paint on my current one peeled off just because I never primed it. Its all just normal ABS plastic.

I also don't want to source out all the electronics to sell with a ready to run kit, like a main controller board and radio etc... I will probably offer a simple electronics package for the tank though with the motors, servos and lights.

The tank is actually designed with mounting holes for the Clark TK22 board (probably fits the new TK24 not sure though)

Attached some images of the current parts in the printers. Both those prints are about 10 hours each. I use the tiny 0.4mm nozzle for most of the parts, 0.2mm layers. The internal skeleton structure and the main lower hull is printed with a 0.6mm nozzle, 0.3mm layers. I think the whole tank is approximately 60-70 hours of print time. The kit could be on the expensive side, but I'm trying my best to keep the cost down. Just like my snow blowers I sell, the kit will come pre-drilled and support material all cleaned up. Still will need some sanding depending how smooth you want everything. The layer lines are visible, especially with paint but for me it is not noticable enough. I will be painting the raw prints on my next 2 tanks to show exactly what they look like off the printers. Easy to sand ABS though.

Image of a part of the internal skeleton spray painted with Krylon paint, and a massive bucket of a lot of the new tank parts!

*Kind of late in my project here to even ask this... but is it even fine for me to sell something like this? Do military vehicles have copyrights on them that could bring up legal issues for me selling this model Scorpion?

Last edited by TheGreatestMoo; 02-20-2016 at 10:15 PM.

#67

Senior Member

Join Date: Dec 2012

Location: littlestown, PA

Posts: 758

Likes: 0

Received 0 Likes

on

0 Posts

You will be fine selling the model since it is just that. Names and such can be IP so those references can get you in trouble but in this case you aren't saying it's produced by the GM corp for example. Also you didn't use any actual plans for the real deal so a Non Disclosure Agreement wasn't broken.

Sell the files is tricky but you could do it with a ULA agreement that prohibites the sharing. Then you would have to enforce it which is always the problem. If you sell the file or share the file to good company they will always have an NDA to protect you.

Side note.... How large is that build plate?

Sell the files is tricky but you could do it with a ULA agreement that prohibites the sharing. Then you would have to enforce it which is always the problem. If you sell the file or share the file to good company they will always have an NDA to protect you.

Side note.... How large is that build plate?

#68

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

My printers are 12x12x12". I designed the printers too, check out the vid of them here: https://www.youtube.com/watch?v=5B25n4NaEo8

Attached are pics of nearly the entire lot of tank parts (minus some storage boxes)

Attached are pics of nearly the entire lot of tank parts (minus some storage boxes)

#69

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

I've been painting and assembling the newest tank. Finding every last thing to tweak and fix for the final version. I still need to do a black wash and paint the detail parts but everything looks great!

The new suspension design works so well. It uses bronze bushings pressed into the hull (physical stop inside the hull to keep them all in line) and the suspension arm is press fitted with a nylon spacer. Then a piano wire is bent into the suspension arm, cap glued on, and the spring has a hook bent into the other end screwed into the hull. The spring wire itself takes the whole load of the tank. My first tank I made I ran it a lot since last year and I only ever broke 1 suspension arm at the joint, but now the nylon spacer is used. Very strong and reliable suspension setup now!

The whole tank uses 38 ball bearings also! All wheels, gun elevation, sprockets have 2 stages of bearings (some the Tamiya science kit gears don't use bearings) Even the idler tension system has bearings fitted.

Most of the large storage boxes will open up to be able to keep spare parts stored. All kits will come with a large amount of spare parts.

The actual tanks wheels have a very slight curve in the rims, but it does not print very well, since its basically cake layers on 3d printed parts, you can easily see the steps. I'm thinking of just making the wheels flat but it does not look as good. I can't find any way around that to make it nice and smooth. Any ideas? See this image here: http://content.screencast.com/users/moo10032/folders/Jing/media/7cbfda7c-f1f6-459e-9372-ffbfe596bb92/2016-02-23_1450.png

The new suspension design works so well. It uses bronze bushings pressed into the hull (physical stop inside the hull to keep them all in line) and the suspension arm is press fitted with a nylon spacer. Then a piano wire is bent into the suspension arm, cap glued on, and the spring has a hook bent into the other end screwed into the hull. The spring wire itself takes the whole load of the tank. My first tank I made I ran it a lot since last year and I only ever broke 1 suspension arm at the joint, but now the nylon spacer is used. Very strong and reliable suspension setup now!

The whole tank uses 38 ball bearings also! All wheels, gun elevation, sprockets have 2 stages of bearings (some the Tamiya science kit gears don't use bearings) Even the idler tension system has bearings fitted.

Most of the large storage boxes will open up to be able to keep spare parts stored. All kits will come with a large amount of spare parts.

The actual tanks wheels have a very slight curve in the rims, but it does not print very well, since its basically cake layers on 3d printed parts, you can easily see the steps. I'm thinking of just making the wheels flat but it does not look as good. I can't find any way around that to make it nice and smooth. Any ideas? See this image here: http://content.screencast.com/users/moo10032/folders/Jing/media/7cbfda7c-f1f6-459e-9372-ffbfe596bb92/2016-02-23_1450.png

Last edited by TheGreatestMoo; 02-23-2016 at 01:00 PM.

#70

Join Date: Nov 2010

Location: HamiltonWaikato, NEW ZEALAND

Posts: 937

Likes: 0

Received 78 Likes

on

55 Posts

Hi Moo

Looking good. Re the wheel printing problem, have a word with Woz, he's just done some M113 Road wheels which feature a similar curve

I'm still interested in the Scorpion, but the low NZ Dollar at the mo is a concern. Be interested to hear the price you come up with.

Also, I'd want to have the NZ version - without the LID (Light Intensifier Device) and those extra side boxes on the turret stowage box.

Mal

Looking good. Re the wheel printing problem, have a word with Woz, he's just done some M113 Road wheels which feature a similar curve

I'm still interested in the Scorpion, but the low NZ Dollar at the mo is a concern. Be interested to hear the price you come up with.

Also, I'd want to have the NZ version - without the LID (Light Intensifier Device) and those extra side boxes on the turret stowage box.

Mal

#71

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

I will be doing several variations of parts. Not all the parts shown on that NZ version though. I will be doing 2 different sprockets, 3 different idler wheels, 2 different headlights (the ones with covers on top, and the smaller ones hanging below) The storage boxes on the left side of the tank will have 2 choices, and a water can. The turret will have 2 different rear boxes, and 2 different side boxes, 2 different smoke grenades (4 or 3 grenade ones). I will post images of the CAD once I finish the other storage boxes.

All the parts will come in the kit so you can mix and match how ever you want.

The pics from Woz look cast or injection molded?

All the parts will come in the kit so you can mix and match how ever you want.

The pics from Woz look cast or injection molded?

#72

Join Date: Nov 2010

Location: HamiltonWaikato, NEW ZEALAND

Posts: 937

Likes: 0

Received 78 Likes

on

55 Posts

Hi Moo

The options are cool, but probably pushes up the price?

The M113 spare wheels - http://www.shapeways.com/product/TMC...i=shareProduct - definitely 3D printed. Pics are of the shipment from Shapeways, I rec'd last Friday.

Mal

The options are cool, but probably pushes up the price?

The M113 spare wheels - http://www.shapeways.com/product/TMC...i=shareProduct - definitely 3D printed. Pics are of the shipment from Shapeways, I rec'd last Friday.

Mal

#73

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

Shapeways is ridiculously overpriced for printing, I uploaded some tank parts to there, it came up to like 225$ for all the tracks, like 120$ for just the lower hull of the tank, I can't even imagine the cost of the whole thing from them rofl! I'm sure the quality is very nice, but my printed parts will be no where near the quality of something from them. My printers are FDM, Shapeways uses the crazy expensive powder printers. My printers can only go down to 0.2mm layers, I may have to end up doing flat wheels. I really want to avoid making molds and casting parts, I did not have a good experience with doing that in the past, bubbles etc. also I no longer have a CNC machine. Even if I uploaded just the detail wheel part for people as a option to buy from Shapeways it would be like 60$ or something.

Basically this kit is not for the extreme scale modelers... It looks great, but it would take a lot of sanding and filling to get everything perfectly model quality smooth. My focus on this whole project is the mechanical and functionality of the whole tank. Everything is built the last on this thing.

All the option parts only add a few hours of print time, so it won't effect the cost hardly. I think its the easiest way to sell it, with everything you need in one package. Some of these storage boxes could work on other tanks too they are really cool with removable tops to actually store stuff inside. The lids press on, they are not hinged.

Basically this kit is not for the extreme scale modelers... It looks great, but it would take a lot of sanding and filling to get everything perfectly model quality smooth. My focus on this whole project is the mechanical and functionality of the whole tank. Everything is built the last on this thing.

All the option parts only add a few hours of print time, so it won't effect the cost hardly. I think its the easiest way to sell it, with everything you need in one package. Some of these storage boxes could work on other tanks too they are really cool with removable tops to actually store stuff inside. The lids press on, they are not hinged.

Last edited by TheGreatestMoo; 02-23-2016 at 03:16 PM.

#74

Join Date: Nov 2010

Location: HamiltonWaikato, NEW ZEALAND

Posts: 937

Likes: 0

Received 78 Likes

on

55 Posts

Hi Moo

Shapeways is ok for 1 offs, but buying multiples tends to hurt, so I know where you're coming from. If you follow the Armorama posts on 3D printing, there have been complaints about the quality they achieve - but that's mostly 1/35th scale.

Really like the durability aspect.

Re the options - ok. Have had some thoughts on getting British pressed steel type ammo boxes made, though the hinges are a concern, but the press on lid idea would fix that.

Mal

Shapeways is ok for 1 offs, but buying multiples tends to hurt, so I know where you're coming from. If you follow the Armorama posts on 3D printing, there have been complaints about the quality they achieve - but that's mostly 1/35th scale.

Really like the durability aspect.

Re the options - ok. Have had some thoughts on getting British pressed steel type ammo boxes made, though the hinges are a concern, but the press on lid idea would fix that.

Mal