GR130

#76

Thread Starter

I went yesterday to Dieter Albisser, and he balanced my turbine...

So I'm ready for a new trestle to mount my stand and then Accelerate to 123K

Regards Lukacs

So I'm ready for a new trestle to mount my stand and then Accelerate to 123K

Regards Lukacs

#79

Join Date: Mar 2004

Location: ferrara, ITALY

Posts: 1,567

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: athome

Hi Chrigui

It's an original Schenck! No Chinese rubish

Just a few Milligramm...don't know exactly how much...

regards Lukacs

Hi Chrigui

It's an original Schenck! No Chinese rubish

Just a few Milligramm...don't know exactly how much...

regards Lukacs

many thx .... chinese people are teacher to copy all things....their machine is exactly the same

#81

There is not very much action on the GTBA forum, but I think it is worth the price just to acsess all the archived information.

Lars, member #851

Lars, member #851

ORIGINAL: athome

Hi all

Are you member of the GTBA. Would you recommend it?

Regards Lukacs

Hi all

Are you member of the GTBA. Would you recommend it?

Regards Lukacs

#82

Same for me, been member for a while but forum is used by only a few people. There's load's of information though from the past which can be very helpful.

Best regards,

Gerald

Best regards,

Gerald

#83

Junior Member

Join Date: Feb 2014

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

Hello!

I am new in this forum. I wrote several posts about turbine nuilding in the german forum but there ist not so much going on there right now. I found out that on rcgroups there is so much knowledge so i like to take part.

Like Lukacs i come from switzerland and i am building my first turbine (UT-160)

This is my first post here but I read and learned a lot on rcuniverse.

I am new in this forum. I wrote several posts about turbine nuilding in the german forum but there ist not so much going on there right now. I found out that on rcgroups there is so much knowledge so i like to take part.

Like Lukacs i come from switzerland and i am building my first turbine (UT-160)

This is my first post here but I read and learned a lot on rcuniverse.

Last edited by surfdom; 02-17-2014 at 12:19 AM.

#85

Thread Starter

Hi guys

The project is not dead! Just combined for the first time the gasgenrator with the 2nd stage! Amazing.

Still some problems to fix, but happy so far!

Here a video (sorry it's in german)

regards Lukacs

The project is not dead! Just combined for the first time the gasgenrator with the 2nd stage! Amazing.

Still some problems to fix, but happy so far!

Here a video (sorry it's in german)

#86

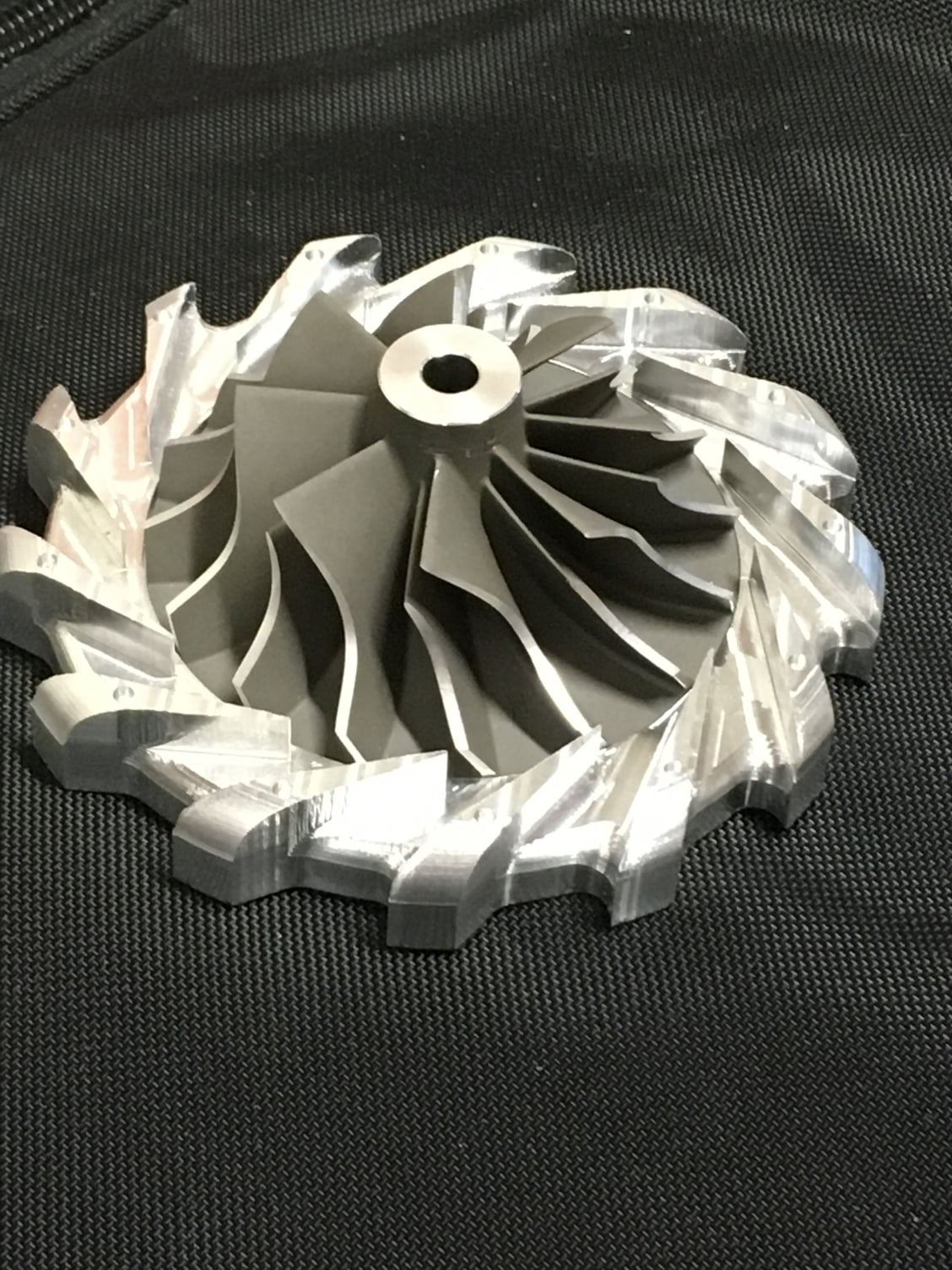

I have jetcat p120 compressor wheel which is i m planning to use in making GR130.. My concern is, the outee dia of comp wheel is 68mm insteed of 70mm as in Gerald switzer wheel. Now m wondering how the diffuser angle will change here. Cause if u still go with the same plan.. The gap between comp wheel and diffuser inlet vane woukd increase to 4mm..in gr130 it is 2mm.. This may change the flow dynamics. Need your suggestions guys because the wheel gerald use is no longer available here.

#87

Thread Starter

You can just try it with same angle! It would be it less effective. And therefore you may not have so much pressure, But it will help prevent surging!

Regards Lukacs

Regards Lukacs

#88

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

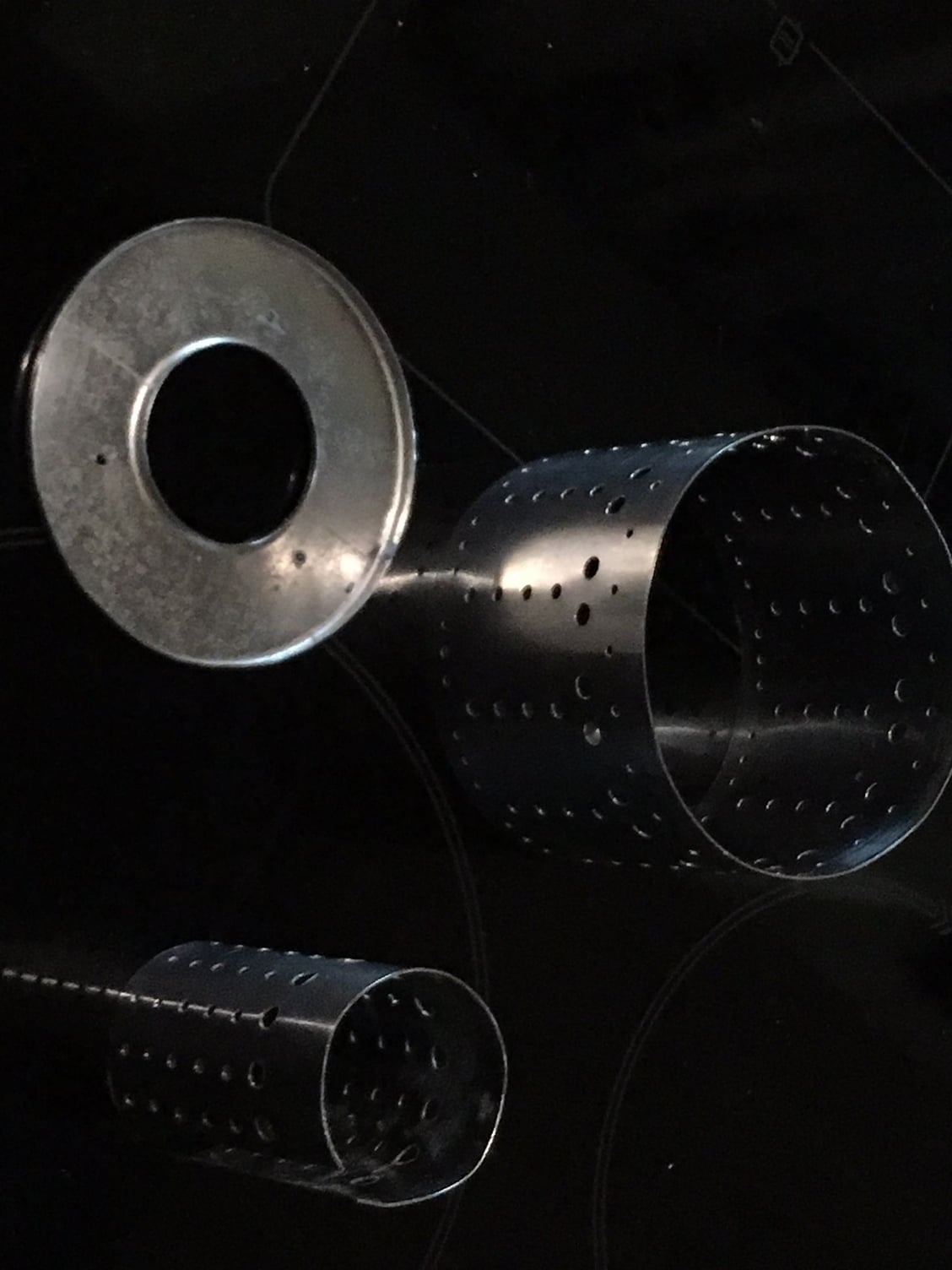

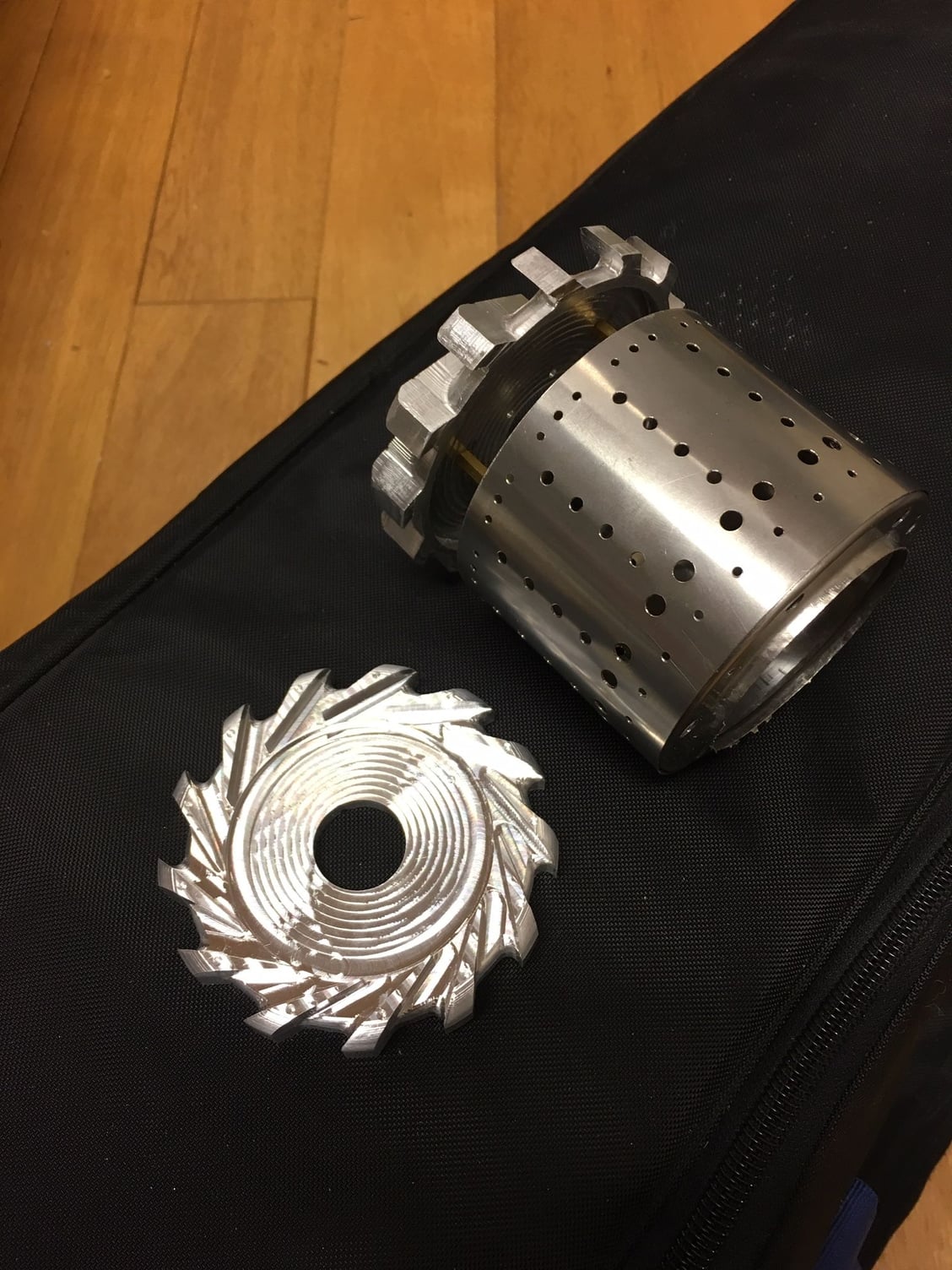

Rings for clamping the rear housing to NGV.

Joining this thread as I am in the progress of making the parts for my own GR130. Actually have been for a while but its a steep learning curve, not only the engine but tools and everything.

Have a CNC at home so this have been used for making the combustion chamber parts and the rear clamping rings. Have made a diffusor earlier but it isn't true so I will need to make it again.

Dont have a lathe though which would be ideal for the turning of the front parts, in combination with CNC to make bolt holes etc. But might outsource some of this part, the fun part i making it yourself

I will need to outsource for sure the tunnel, shaft and get my hands on premade NGV/turbine wheel, dont think I have the skills or tolerances to mfgr them myself...

I will need to outsource for sure the tunnel, shaft and get my hands on premade NGV/turbine wheel, dont think I have the skills or tolerances to mfgr them myself...The Garrett part I purchased for is which I hope will work:

TO4B 8 blade

409179-0018

Why the GR130 and not the GR180?

Should I ever get it to work I can keep the plane to a manageable size

Stainless steel plate, 0.5mm CNC´d with a 2mm Tungsten Carbide bit. A lot cleaner and more precise than I could have done by hand!

Diffusor mk1, with errors. Learning experience.

#89

Thread Starter

Hey cool. Keep posting. We all have to learn. I always built 2 or 3 parts of the same stage and finaly only one was usable :-)

If you need a spare compressor which works, I bought a few when they where available! so drop me a line

Regards Lukacs

If you need a spare compressor which works, I bought a few when they where available! so drop me a line

Regards Lukacs

#90

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

Hi Lukacs and thanks for the reply

Good work on your GR130, I have browsed everything I could find regarding the GR130/G180 for details and relevant information for my build.

At the moment progress is slow and restricted to the CC, the inner & outer rings are spot welded and next job is to turn the flanges for the front/rear CC rings. Evaporator tubes need to be sourced too.

Brass tubing is on hand.

My main obstacle at the moment is lack of a lathe and €600 to spend on NGV, shaft, tunnel and turbine wheel (Dieter Albisser likely scenario when its time).

You wouldnt have a spare shaft, tunnel would you? Dont have to pass QC but need to be dimensionally true so I can basically complete assembly while I build up funds for the pricey parts

Good work on your GR130, I have browsed everything I could find regarding the GR130/G180 for details and relevant information for my build.

At the moment progress is slow and restricted to the CC, the inner & outer rings are spot welded and next job is to turn the flanges for the front/rear CC rings. Evaporator tubes need to be sourced too.

Brass tubing is on hand.

My main obstacle at the moment is lack of a lathe and €600 to spend on NGV, shaft, tunnel and turbine wheel (Dieter Albisser likely scenario when its time).

You wouldnt have a spare shaft, tunnel would you? Dont have to pass QC but need to be dimensionally true so I can basically complete assembly while I build up funds for the pricey parts

Last edited by Haldor; 11-30-2018 at 04:58 AM.

#91

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

Minor update.

After waiting for a new tungsten carbide end mill I was finally able to cut out the front/rear CC walls.

Turned the front wall flanges down by hand using two stacked layers of 19mm MDF rings with the steel plate sandwiched in-between. The MDF rings were CNC´d to correct dimension and I used blue masking tape / CA to bond the steel plate centred between the two.

Using a hammer and going slowly/light I was able to achieve a nice flange Repeated for the inside but since the hole is only about 42mm wide there isn't much room for hammering

Repeated for the inside but since the hole is only about 42mm wide there isn't much room for hammering

So I used a round bar as a rolling pin and slowly the right opening diameter was achieved.

This is my first attempt at metalworking so quite pleased with the outcome

As I dont have a NGV on hand I will CNC a disk blank I can use as guide when spot welding the inner CC tube exit side to exact diameter.

...slow and steady...

After waiting for a new tungsten carbide end mill I was finally able to cut out the front/rear CC walls.

Turned the front wall flanges down by hand using two stacked layers of 19mm MDF rings with the steel plate sandwiched in-between. The MDF rings were CNC´d to correct dimension and I used blue masking tape / CA to bond the steel plate centred between the two.

Using a hammer and going slowly/light I was able to achieve a nice flange

Repeated for the inside but since the hole is only about 42mm wide there isn't much room for hammering

Repeated for the inside but since the hole is only about 42mm wide there isn't much room for hammering

So I used a round bar as a rolling pin and slowly the right opening diameter was achieved.

This is my first attempt at metalworking so quite pleased with the outcome

As I dont have a NGV on hand I will CNC a disk blank I can use as guide when spot welding the inner CC tube exit side to exact diameter.

...slow and steady...

#92

Thread Starter

Looks promising! I think yo have to buy a lathe before you continue. It’s essentiell. Also I think the budget is more than optimistic. If money is your argument for building a DIY Turbine than it’s better to buy a used one!

just my two cents

regards Lukacs

just my two cents

regards Lukacs

#93

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

No-no, the number mentioned isn't for the whole build, it will be somewhere around that for NGV/exhaust wheel/shaft/tunnel alone once I get to that stage.

Bearings aren't cheap either, I am well aware of that. ECU of some sort will be required too, may use an Arduino to host one.. but that is a different project ha!

My objective is to build the motor and hopefully be able to run it, not to save cash If that was the case a 2nd hand unit is the way to go for sure

If that was the case a 2nd hand unit is the way to go for sure

I have a wife that is starting up her business so spending money for the time being is limited, thats all.

Bearings aren't cheap either, I am well aware of that. ECU of some sort will be required too, may use an Arduino to host one.. but that is a different project ha!

My objective is to build the motor and hopefully be able to run it, not to save cash

If that was the case a 2nd hand unit is the way to go for sure

If that was the case a 2nd hand unit is the way to go for sure

I have a wife that is starting up her business so spending money for the time being is limited, thats all.

#94

Thread Starter

Just found your other postings on other forums like: https://discuss.inventables.com/t/ha...og-diary/51869

and https://www.rcgroups.com/forums/show...n-GR130-design

Cool! *thumbup*

regards Lukacs

and https://www.rcgroups.com/forums/show...n-GR130-design

Cool! *thumbup*

regards Lukacs

#95

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Lukacs - it will be needed

I knew from the beginning that the GR130 is a experimental design, upgraded/modernized version of the KJ66.

Gerard quickly moved up to the GR180/220 which suited his purposed better

I dont need that power, it isn't required nor the goal - turbines are simply sexy (dont mind the smell either...!) and I always wanted one since JPX did their propane version in the mid 90´s IIRC.

Adding to that I am a DIY kinda guy and I am not fearful of the deep end of the pool... I am not without fear, but I take it slow.

I am not without fear, but I take it slow.

For my GR130 build I have been "forced" to made some modifications as the housing canister is ID105mm only, not 107.3

Another factor is the compressor which is marginally different than the "original". So minor changes to the drawings have been made.

Since my intent isn't to get maximum power with minimum effort I am not worried, I enjoy the challenge and learn a TON while working on this

At the moment the bulk of my efforts have been made towards the CC and my next move must be to source some evaporator sticks. These need to be complete and welded to the stick ring prior to closing of the complete CC.

Parallell to that I will make an attempt to CNC a new diffusor and diffusor cover with the correct OD.

The inlet bell/compressor cover will follow at a later date since I have many steps to complete before those are required.

Will update with more pictures soon

I knew from the beginning that the GR130 is a experimental design, upgraded/modernized version of the KJ66.

Gerard quickly moved up to the GR180/220 which suited his purposed better

I dont need that power, it isn't required nor the goal - turbines are simply sexy (dont mind the smell either...!) and I always wanted one since JPX did their propane version in the mid 90´s IIRC.

Adding to that I am a DIY kinda guy and I am not fearful of the deep end of the pool...

I am not without fear, but I take it slow.

I am not without fear, but I take it slow.For my GR130 build I have been "forced" to made some modifications as the housing canister is ID105mm only, not 107.3

Another factor is the compressor which is marginally different than the "original". So minor changes to the drawings have been made.

Since my intent isn't to get maximum power with minimum effort I am not worried, I enjoy the challenge and learn a TON while working on this

At the moment the bulk of my efforts have been made towards the CC and my next move must be to source some evaporator sticks. These need to be complete and welded to the stick ring prior to closing of the complete CC.

Parallell to that I will make an attempt to CNC a new diffusor and diffusor cover with the correct OD.

The inlet bell/compressor cover will follow at a later date since I have many steps to complete before those are required.

Will update with more pictures soon

#96

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

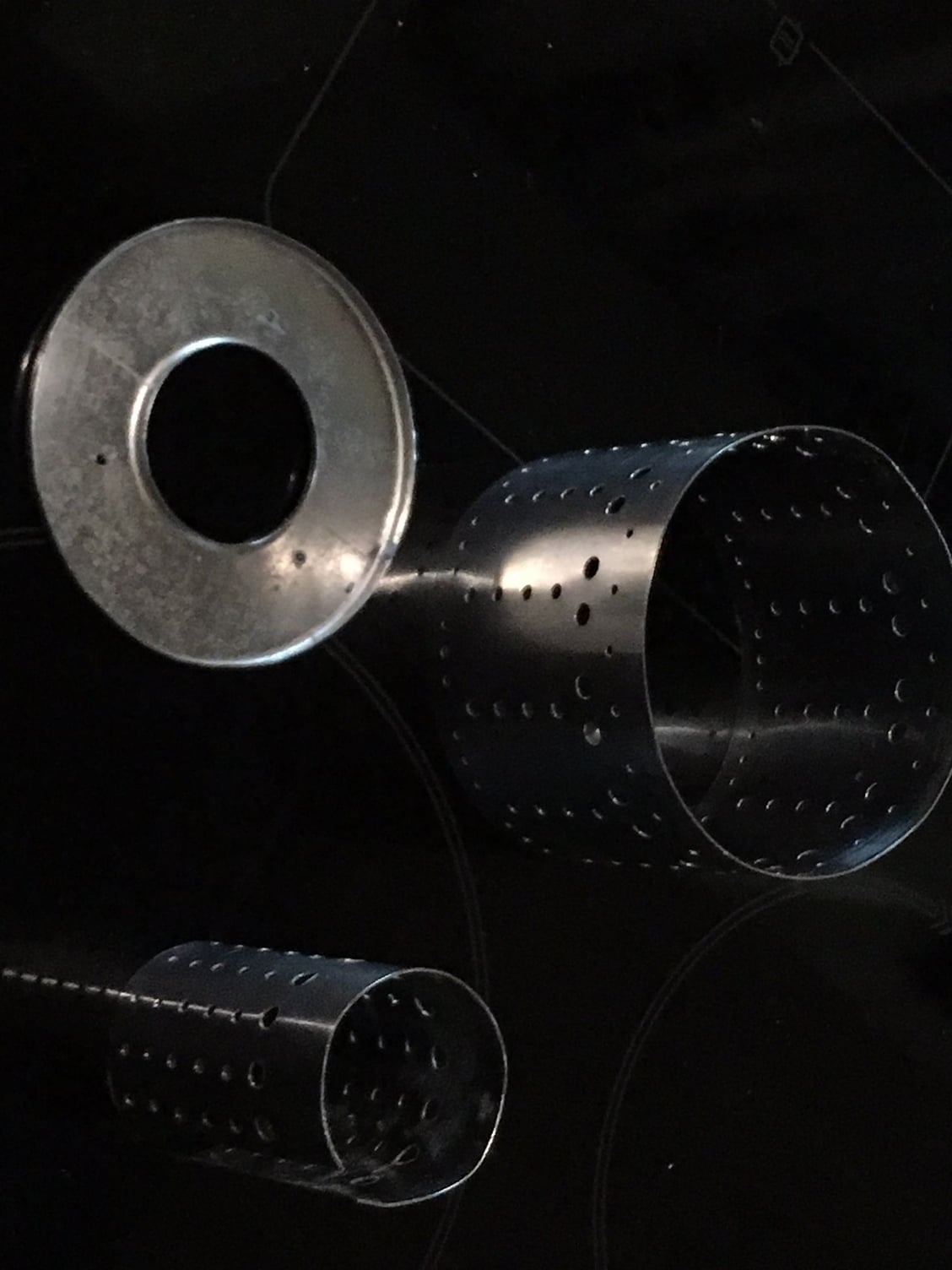

New diffusor done except for the rear side which I will machine out later.

Came out half decent, hopefully a viable part. Was plagued with CNC gremlins and had several interrupts

Diffusor mk.2

Trial fitting and builder satisfaction, trial fitting of the mk1 diffusor and CC.

Came out half decent, hopefully a viable part. Was plagued with CNC gremlins and had several interrupts

Diffusor mk.2

Trial fitting and builder satisfaction, trial fitting of the mk1 diffusor and CC.

#98

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

Minor update on my engine, diffusor and diffusor cover done and tapped for M3 screws.

Fit seem very good and the housing is real tight hugging the diff.cover

Starting to look like an engine, still lacking the shaft & shaft tunnel though

Inlet bell is next

Fit seem very good and the housing is real tight hugging the diff.cover

Starting to look like an engine, still lacking the shaft & shaft tunnel though

Inlet bell is next

Last edited by Haldor; 12-14-2018 at 02:33 PM.

#99

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

Wife is out of town (kids are not) so I didn't get to spend a lot of time with the CNC today so opted to begin some of the more tedious tasks like opening the rear end of the canister and starting the fuel delivery system.

First the brass 6mm and 3mm rods were annealed and formed quite nicely to a decent shape. I will braze these during work hours the coming week hopefully. I also found a cup from an old thermos bottle with OD70mm which neck down to 48mm, perfect exhaust cone

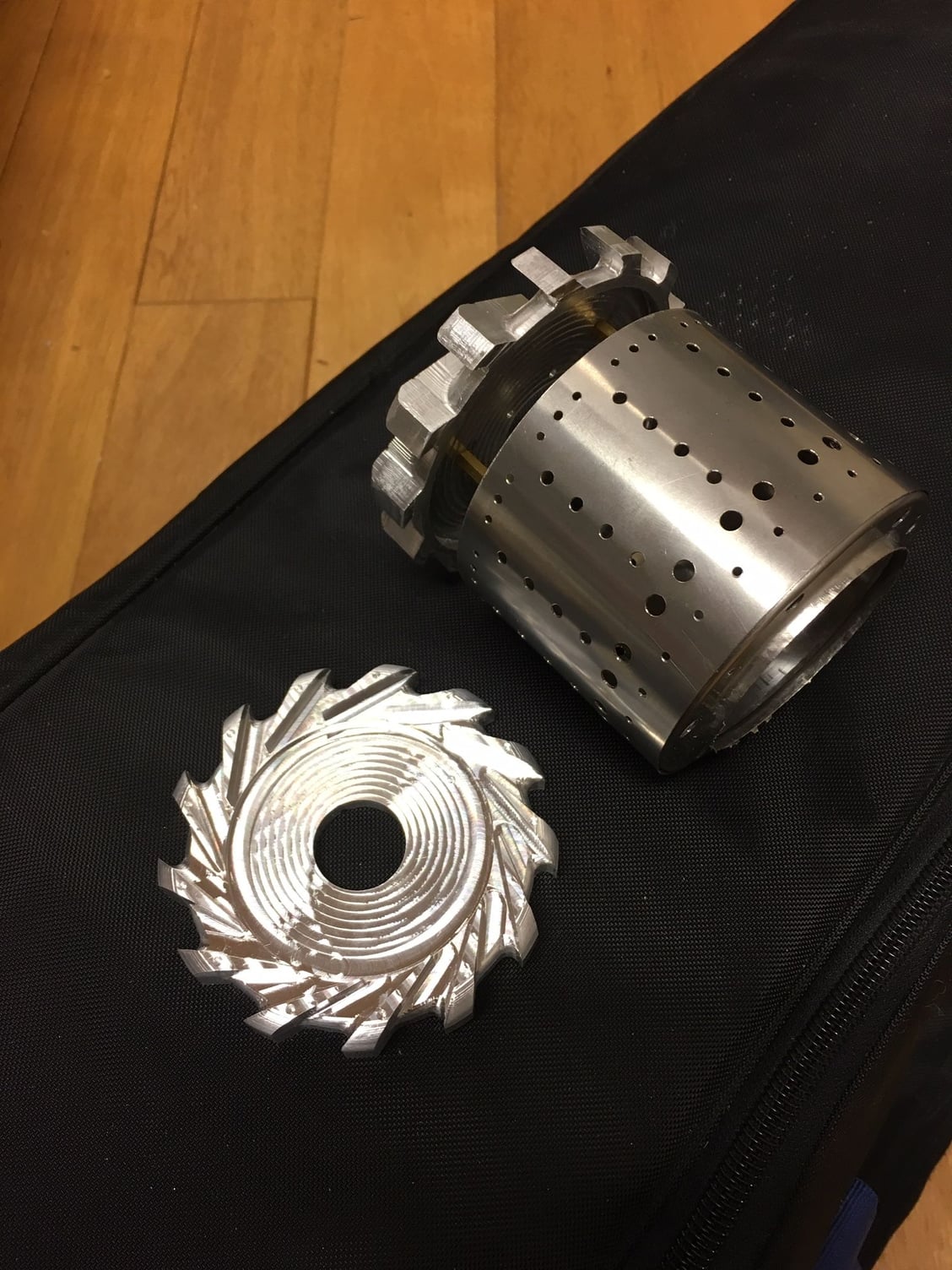

Sight for sore eyes, at least to me!

Rear end opened up and brass tubing for the fuel system shaped up.

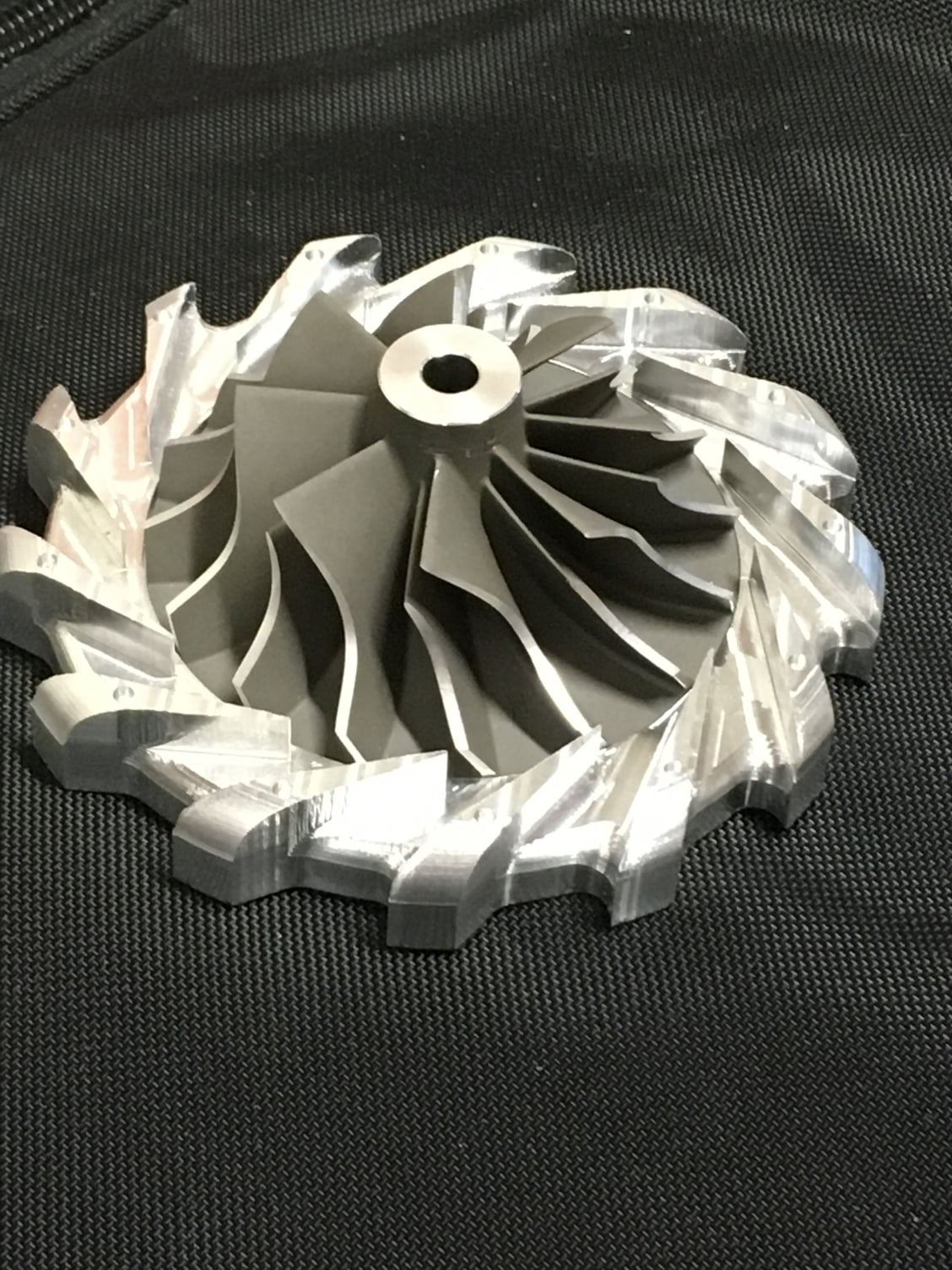

Component overview

First the brass 6mm and 3mm rods were annealed and formed quite nicely to a decent shape. I will braze these during work hours the coming week hopefully. I also found a cup from an old thermos bottle with OD70mm which neck down to 48mm, perfect exhaust cone

Sight for sore eyes, at least to me!

Rear end opened up and brass tubing for the fuel system shaped up.

Component overview