GR130

#101

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

Hehe Lukacs - we'll see

Had a couple of days where I could spend a couple of hrs on it and visually I managed to make good progress. I am outsourcing the shaft tunnel so I can continue with some of the detail work (spacing, final distances etc)

So it may go "fast" now but I will have some slow periods ahead of me aswell

A mock-up of the NGV is planned so I can finalise as much as possible until I have the funds for NGV/wheel purchase.

Had a couple of days where I could spend a couple of hrs on it and visually I managed to make good progress. I am outsourcing the shaft tunnel so I can continue with some of the detail work (spacing, final distances etc)

So it may go "fast" now but I will have some slow periods ahead of me aswell

A mock-up of the NGV is planned so I can finalise as much as possible until I have the funds for NGV/wheel purchase.

#102

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

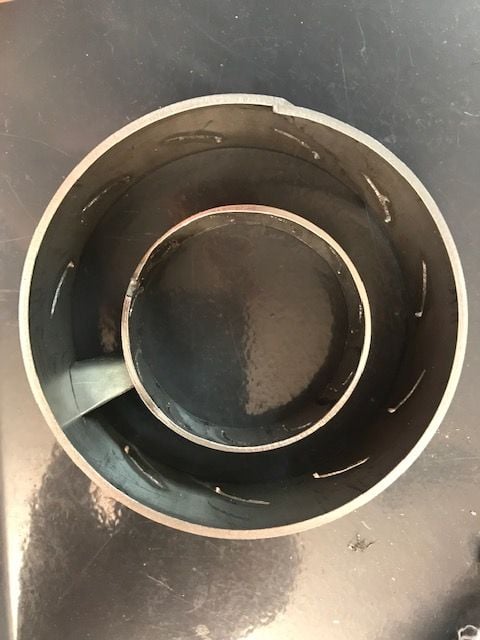

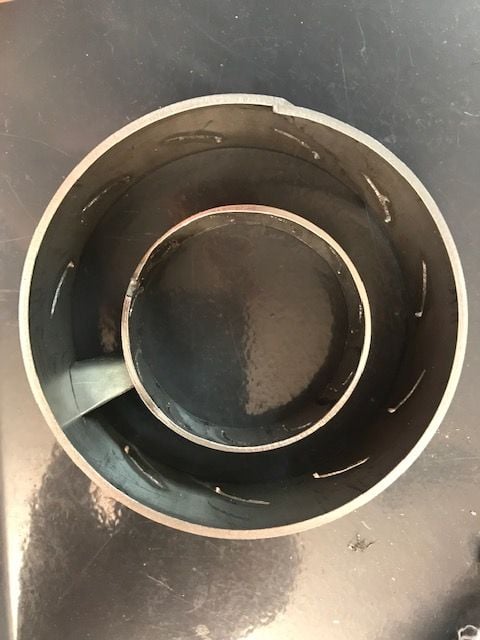

Got my hands on a older crash'n'burn Simjet3000 for €150 with the hopes that some of its components could be salvaged for my GR130. Partial tear-down show promise for the axle, bearings and turbine wheel

Need to completely disassemble the engine before I can measure the NGV.

But this look very promising!

Simjet 3000 after flame-out on base turn and post crash fire. Electronics are toast, rest seem to be light surface scuffs and sooth. A dent in the casing but I believe the internals may have survived.

SJ3000 bearings / axle / turbine whee after being extracted from the turbine. The wheel is a match for the GR130, bearings also. The vital parameters for the axle indicate good fit as well. Promising!

SJ3000 measurements in pen writing, matching parameters highlighted in yellow.

Need to completely disassemble the engine before I can measure the NGV.

But this look very promising!

Simjet 3000 after flame-out on base turn and post crash fire. Electronics are toast, rest seem to be light surface scuffs and sooth. A dent in the casing but I believe the internals may have survived.

SJ3000 bearings / axle / turbine whee after being extracted from the turbine. The wheel is a match for the GR130, bearings also. The vital parameters for the axle indicate good fit as well. Promising!

SJ3000 measurements in pen writing, matching parameters highlighted in yellow.

#103

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

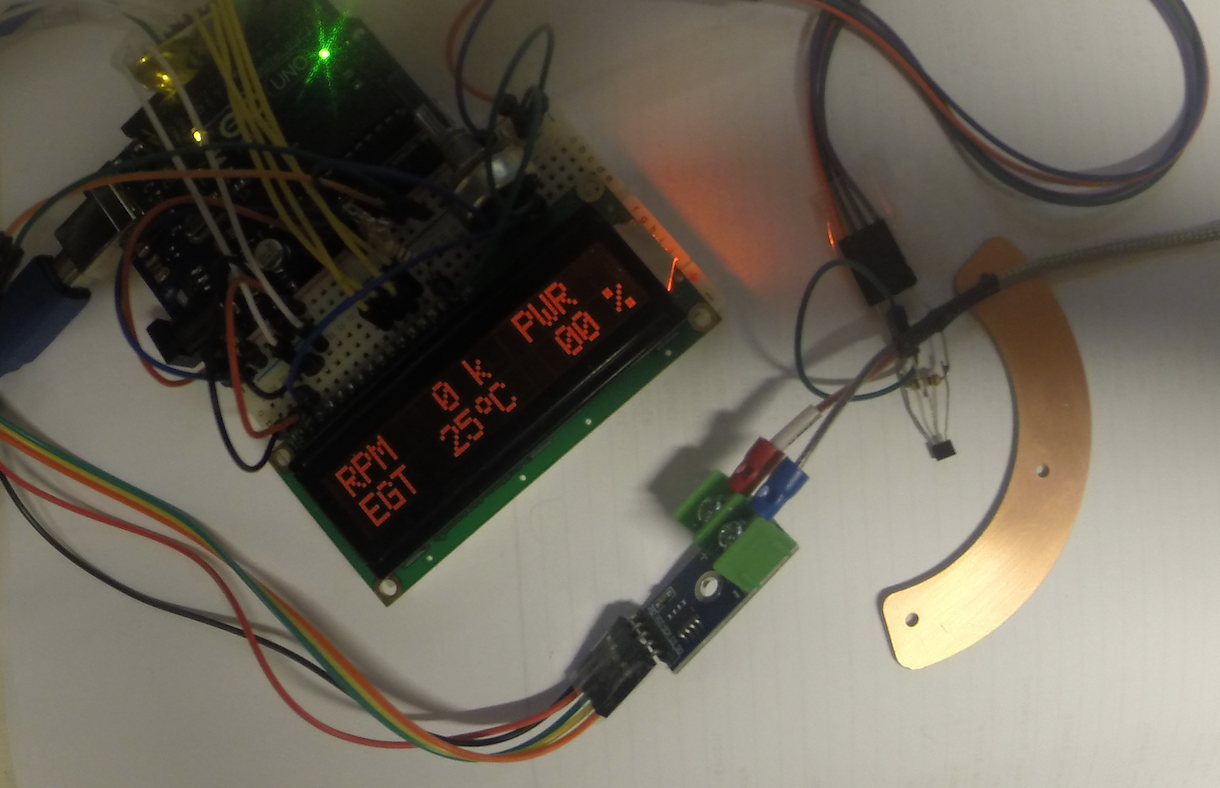

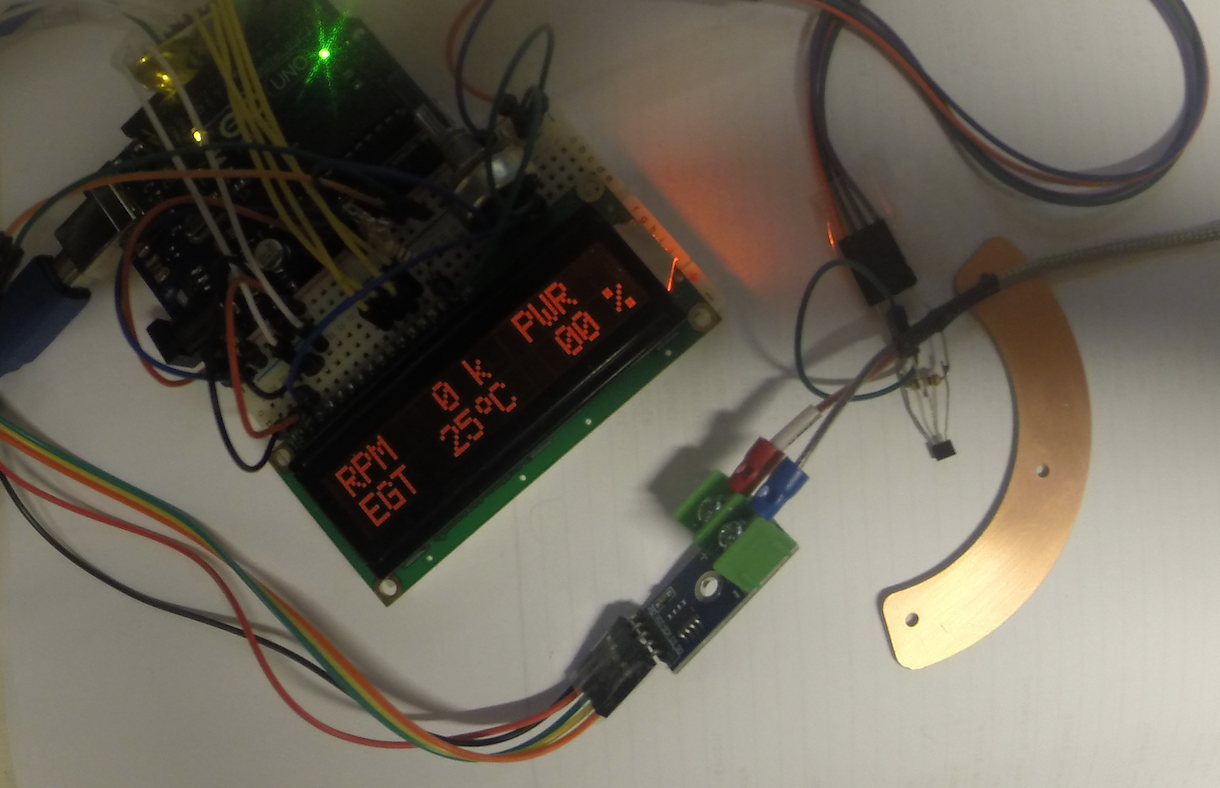

I am trying to make a ECU for ground operations and here is a short video showing initial progress.

EGT and RPM display in real-time, a Graupner Speed280 DC motor provide RPM data and a thermocouple provide temperature.

Code need to be optimized but is currently fully functional regarding its primary intention

https://www.youtube.com/watch?v=mfhCjIX6s7E

EGT and RPM display in real-time, a Graupner Speed280 DC motor provide RPM data and a thermocouple provide temperature.

Code need to be optimized but is currently fully functional regarding its primary intention

https://www.youtube.com/watch?v=mfhCjIX6s7E

#104

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

My Ground Monitor is now configured correctly, reading EGT and RPM real-time with good refresh rate

Next up is to add throttle control that will govern fuel pump voltage.

Basic read functions for the ground monitor done, EGT and RPM now being displayed/refreshed correctly.

Next up is to add throttle control that will govern fuel pump voltage.

Basic read functions for the ground monitor done, EGT and RPM now being displayed/refreshed correctly.

#106

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

No, the prototype is based on the Ardunio UNO, breadboard and individual sensorboard for the temp.sensor. The key component there is the Atmel chip (Processor), MAX6675 chip (temp) and hall sensor (RPM). Space/component wise a really condensed version can be made, and certainly lightweight (<50g)

For monitor purposes only only the sensors are needed to be installed on the turbine, with external connection to LCD for displaying the data.

This excersise isnt costwise worth it, a ready2go commercial ECU can be had for aaround $120 and up. Like building the turbine, I am in it for the challenge

For monitor purposes only only the sensors are needed to be installed on the turbine, with external connection to LCD for displaying the data.

This excersise isnt costwise worth it, a ready2go commercial ECU can be had for aaround $120 and up. Like building the turbine, I am in it for the challenge

#108

Thread Starter

#109

Thread Starter

I have also done a start controller and a logger for my ecu and I‘m building right now an extension for my ecu for the powerstage!

Here the Video of the start controller:

Regards Lukacs

Here the Video of the start controller:

Regards Lukacs

#110

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

Looks great  I want to add functionality as I go, considering I havent played with Arduinos prior to hooking up the LCD I am happy with my progress

I want to add functionality as I go, considering I havent played with Arduinos prior to hooking up the LCD I am happy with my progress

Now I need to read myself up on LCD menus and select options

Waiting for a I2C LCD display so I can free up some ports allowing me further options like solenoids and ESC for the fuel pump etc

I want to add functionality as I go, considering I havent played with Arduinos prior to hooking up the LCD I am happy with my progress

I want to add functionality as I go, considering I havent played with Arduinos prior to hooking up the LCD I am happy with my progress

Now I need to read myself up on LCD menus and select options

Waiting for a I2C LCD display so I can free up some ports allowing me further options like solenoids and ESC for the fuel pump etc

#111

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

New update - while progress have been slow, progress have been made

I needed to revise my spot welding technique and I feel the result is good, good heating of the spot and good bond.

Still manual work though..

What is done since last update is:

Make the NGV fit the rear fuel stick ring

Spot weld inner CC to front CC ring

Spot welded evaporator sticks to the rear ring

Spot welded the rear ring to the outer CC, if sequence is different one wont be able to get spot weld access for all parts.

Next on my list:

Make a spot weld arrangement for easy welding the front CC ring to the outer CC

Spot weld the CC making it complete

Adapt the diffusor so the Simjet3000 axle tunnel will fit.

The rest after that is starting to tie in all parts and make it a full system Piece of cake lol!

Piece of cake lol!

I needed to revise my spot welding technique and I feel the result is good, good heating of the spot and good bond.

Still manual work though..

What is done since last update is:

Make the NGV fit the rear fuel stick ring

Spot weld inner CC to front CC ring

Spot welded evaporator sticks to the rear ring

Spot welded the rear ring to the outer CC, if sequence is different one wont be able to get spot weld access for all parts.

Next on my list:

Make a spot weld arrangement for easy welding the front CC ring to the outer CC

Spot weld the CC making it complete

Adapt the diffusor so the Simjet3000 axle tunnel will fit.

The rest after that is starting to tie in all parts and make it a full system

#113

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, I didnt check all sticks for centricity when I welded it in place - wont change it now but will rather build a new CC should initial testing give reason for optimism

The inner CC isnt welded yet.

Work over the past week have been slim but mainly directed towards getting the canister/NGV/axle tunnel to all fit as one unit.

I need to fabricate the diffusor intake cover before I have the minimum parts required on hand.

The inner CC isnt welded yet.

Work over the past week have been slim but mainly directed towards getting the canister/NGV/axle tunnel to all fit as one unit.

I need to fabricate the diffusor intake cover before I have the minimum parts required on hand.

#114

Hi Haldor,

By any chance, have you explored the benefits (if any) of twisting the outer sticks? I believe Frank Turbines used to have twisted outer sticks. I do not know if they still make them like that.

Reuben

By any chance, have you explored the benefits (if any) of twisting the outer sticks? I believe Frank Turbines used to have twisted outer sticks. I do not know if they still make them like that.

Reuben

#115

My Feedback: (5)

Join Date: Jan 2004

Location: Algard, NORWAY

Posts: 111

Likes: 0

Received 0 Likes

on

0 Posts

I havent considered twisting them, I have seen it done during my research but keeping it simple. If I make a new CC I'll go with 12sticks vs 6 as this seem to be an upgrade aswell, especially for higher pressure engines.

#116

Thread Starter

Hey Haldor

any news?

It looks that you slowed down

I just updated my Homepage www.turbinenheli.ch

regards Lukacs

any news?

It looks that you slowed down

I just updated my Homepage www.turbinenheli.ch

regards Lukacs

Last edited by athome; 07-26-2019 at 10:59 PM.

#117

Nice site Lukacs! Also good temperatures seen on your movie. Looks like acceleration / ramp-up might be adjusted just a bit faster but still very good looking!

Rgds,

Gerald

Rgds,

Gerald

#118

Thread Starter

Hi Gerald

What a nice surprise and honor to hear from you! Thank you for your compliment, but still fighting with hot temperature on the second stage, when I connect the NGV. Right now, I'm building a new NGV with less vanes

Regards Lukacs

What a nice surprise and honor to hear from you! Thank you for your compliment, but still fighting with hot temperature on the second stage, when I connect the NGV. Right now, I'm building a new NGV with less vanes

Regards Lukacs

#120

Junior Member

Hi Guys,

I'm looking to built a jet, looked at the MW64 and the KJ66, then someone suggested the GR180

I've just purchased Kurt Schreckling's book and Thomas Kamps

Just a quick question, are all these jets more or less the same design?

This will be my first build so looking for something suitable to learn on.

Outsourcing will be my friend for anything I can't do, but I will try to do most of it.

I have a 3axis CNC with max travel of 40mm

The plan is to get a small lathe also

Anyway it's nice to meet you all, all the projects above look really neat!!!

And if you're in the neighborhood, any suggestions are warmly welcome...?!

I'm looking to built a jet, looked at the MW64 and the KJ66, then someone suggested the GR180

I've just purchased Kurt Schreckling's book and Thomas Kamps

Just a quick question, are all these jets more or less the same design?

This will be my first build so looking for something suitable to learn on.

Outsourcing will be my friend for anything I can't do, but I will try to do most of it.

I have a 3axis CNC with max travel of 40mm

The plan is to get a small lathe also

Anyway it's nice to meet you all, all the projects above look really neat!!!

And if you're in the neighborhood, any suggestions are warmly welcome...?!

#121

The basic principle of Operations is same for all jet engines available. KJ66 has been the pioneer of all from where many design were developed and successfully tested. I would suggest you to go for GR130 or GR 180. Both are well known and proven design by Gerald. I am currently making one 130 model. Welcome to the world of thrill.

#122

Junior Member

Join Date: Mar 2020

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

The basic principle of Operations is same for all jet engines available. KJ66 has been the pioneer of all from where many design were developed and successfully tested. I would suggest you to go for GR130 or GR 180. Both are well known and proven design by Gerald. I am currently making one 130 model. Welcome to the world of thrill.

Last edited by Raptor4; 03-15-2020 at 05:23 AM.

#125

Gerald's website is down for a while. I think the subscription might have expired. PM me your email.. I will send the files. @gerald I hope you approve this.