1/7th F-14D Scratch build thread *building started*

#1457

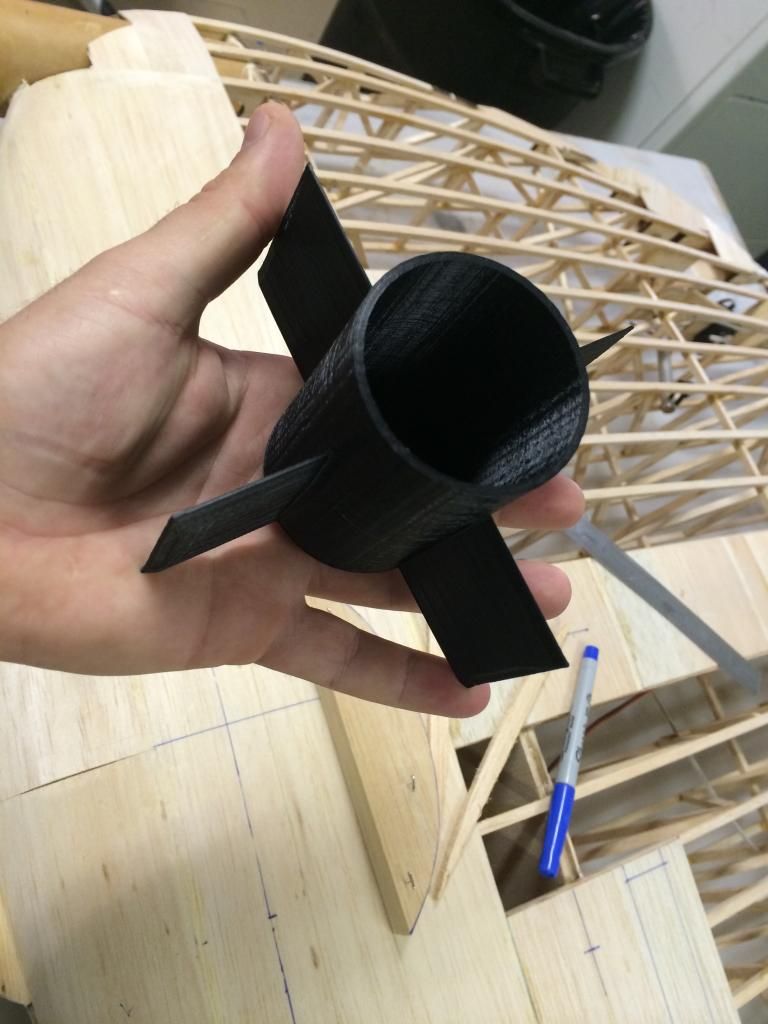

Unfortunately, a certain pair of pancakes have been keeping me busy, so not much work to report on the F14. I have however been playing around with the 3D printer and printed out the mold for the nose wheel tire. I also printed out a cavity plug that i hope will assist in lightening these tires up a good bit. If it works well on this, ive got to so a set of tires for my buddies YA F-18..

#1464

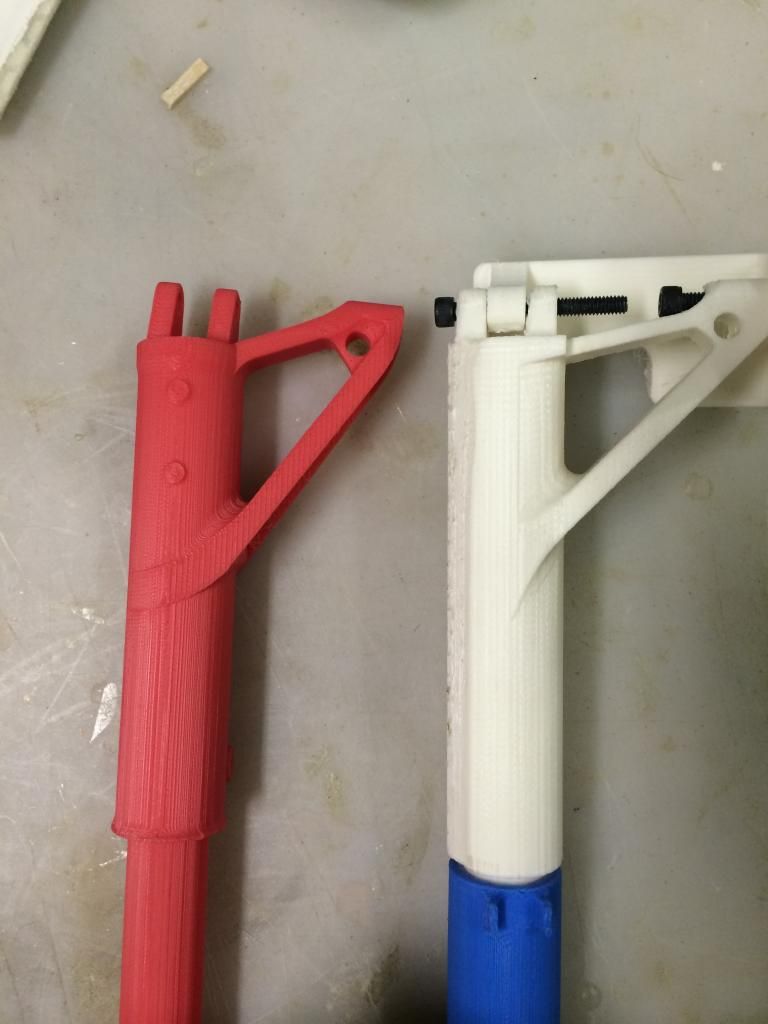

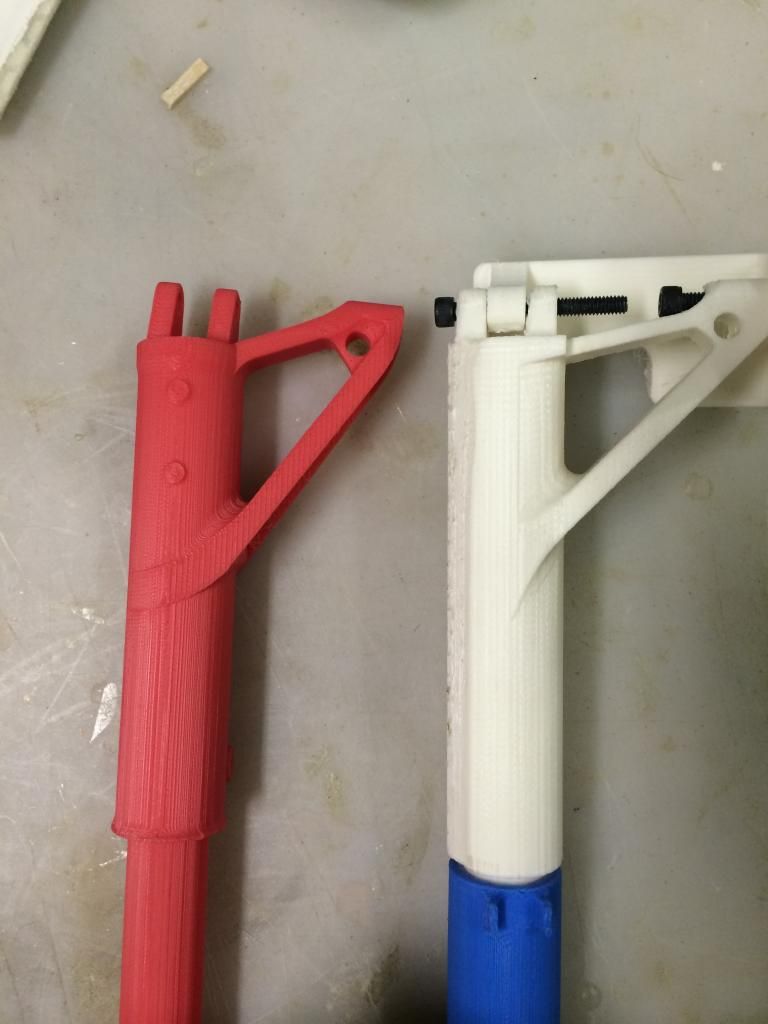

After playing around with the mockup i did and looking back through some documentation, i realized i completed screwed up the majority of the geometry and the upper main gear strut. So i spent about 12 hours reworking the strut in CAD and printed a new upper strut. This one is mile stones better than the last as far as scale accuracy and the geometry is perfect as it will suck into the wheel well perfectly. I need to rework the mount design to work with the new geometry and add some details to the rest of the gear and the main landing gear design will finally be done.

The newest strut is in red.

The newest strut is in red.

#1465

My Feedback: (33)

Join Date: Feb 2002

Location: Chicago, IL

Posts: 469

Likes: 0

Received 0 Likes

on

0 Posts

Thomas, did you buy the E3D v6 hot end extruder assembly in the US and how many different nozzles tips are currently using?

BTW, Nice job Though time consuming(photos videos, posting), we appreciate your efforts!

BTW, Nice job Though time consuming(photos videos, posting), we appreciate your efforts!

Last edited by myersflyers; 09-17-2014 at 12:36 AM.

#1468

The downside to my cockpit is you will probably lose every bit of room under the canopy area to fit the cockpit as it is full depth. If you'd like, i can attach a pdf of my panels that you can print to see how they fit. I know they will be to large, but you can trim them to size to fit and then i can scale them to fit the dimension.

Or if someone just had a F14 they wanted built, i could just do a build for them and the cockpit for a good price

#1470

Member

Join Date: Sep 2005

Location: Perth, AUSTRALIA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Thomas

Your work is just so AMAZING..... WOW....

One of our friends just bought the F-14 from skymaster, it is a great looking plane.

Can't wait to see yours on its wheels..

Good job mate, keep it up.

Cheers

Moa

Your work is just so AMAZING..... WOW....

One of our friends just bought the F-14 from skymaster, it is a great looking plane.

Can't wait to see yours on its wheels..

Good job mate, keep it up.

Cheers

Moa

#1471

Thanks Moa!

Ill probably have this thing sitting on a set of 3D printed landing gear before I even send the files to the machinist. My landing gear design is somewhat complicated (30+ parts) but will result in a bullet proof gear that shouldnt wear out. Unfortunately, it'll be $$$$$

Ill probably have this thing sitting on a set of 3D printed landing gear before I even send the files to the machinist. My landing gear design is somewhat complicated (30+ parts) but will result in a bullet proof gear that shouldnt wear out. Unfortunately, it'll be $$$$$

#1474

Nope, I don't want to have to switch from one thing to the other because it is nice to be able to have two machines running at once. The other problem is most of my prints are 2+ hours long (cockpit panels are 9-18hrs!), I don't want to hog up my cnc router that much...

And like they say "jack of all trades, master at none". Each machine has its dedicated purpose which makes it easier to fine tune each one for that purpose