Hooben M4A3E8 "Easy Eight" Review & Build Out

#27

I'll be one of your first customer if you decide to offer upgraded parts for this release. Clark already plans to offer an accurate muzzle brake but much more is needed, if only, some caps to cover those glaring phillips head screws.

#28

I plan on doing a bunch more work to improve the overall look. Right now while waiting for detailing parts to trickle in I am focusing on the mechanical aspects of the tank. I have already completed one improvement to the idler axles that I will post soon.

#29

The problem I see with making an aftermarket brake for the Hooben “Easy Eight” is the factory one is a molded part of the very flimsy plastic barrel. Also the flash LED is glued into the front of the barrel and to add to that the barrel is glued to the recoil extension “post/mount” at the rear which in turn does not allow the barrel and mantle to be separated. Given the flimsy plastic of the barrel it will make it challenging to just cut the factory brake off without a high chance of damaging the barrel and flash LED. It would be best to just make a completely new barrel and brake combinations, preferably out of metal.

I will post photos of the above shortly and it will be more clear as to the challenges posed. Nothing an experienced modeler can’t handle, but with no spare parts if one messes up?

Caps to cover the idler and sprocker screw would be nice. I did find that the screw caps from my Challenger 2 sprockets fit almost perfectly over the idler screws and look rather convincing to all but the most trained eye. These will be seen as well in the next photo up load.

#30

What is needed more are metal sprockets for the Easy Eight. The plastic used on the Easy Eight is much softer than on say Heng Long tanks. There are a number of all metal tracks already on the market that will fit the Easy Eight. Regardless if the track is Hooben or other metal track the sprockets are not durable enough to handle long term use of metal tracks. Already mine are showings a fair amount wear from just the factory plastic track. Given I have been driving this tank much harder than most would.

#31

I'm right now looking to squirrel away some replacement tracks. Problem is I'm not a fan of the rubber cheveron tracks being made in metal, and for the build I have in mind the T66 links would not work either. Ideally would be a set of tracks from tamiya, or the same pattern as the tamiya ones just in metal. Been looking around and so far I've been coming up dry.

#32

Sprockets are supposed to be forthcoming with the track. I have a set of IMPACT track laying around & they'd shred the plastic sprockets if I tried doing a test run. Already tried Mato's sprockets & they won't fit. I live less than an hour from Feng's workshop so as soon as they become available, I'll run up & pick up a set.

Armorguy, I'll check out your 1/16 parts section. I have an IBS Atlantic sail for my Gato that I got from your father years ago so happy to get from you.

Armorguy, I'll check out your 1/16 parts section. I have an IBS Atlantic sail for my Gato that I got from your father years ago so happy to get from you.

#33

Sprockets are supposed to be forthcoming with the track. I have a set of IMPACT track laying around & they'd shred the plastic sprockets if I tried doing a test run. Already tried Mato's sprockets & they won't fit. I live less than an hour from Feng's workshop so as soon as they become available, I'll run up & pick up a set.

Armorguy, I'll check out your 1/16 parts section. I have an IBS Atlantic sail for my Gato that I got from your father years ago so happy to get from you.

Armorguy, I'll check out your 1/16 parts section. I have an IBS Atlantic sail for my Gato that I got from your father years ago so happy to get from you.

On another note the Hooben plastic track now used on their “Easy Eight” is proving to be superior to the Heng Long M26 Pershing tracks (supplies with the first batch of Easy Eights). I swapped a set of Heng Long M26 tracks on to the Hooben yesterday and ran them. The Hooben tracks look to be all around better performing.

#34

After about 4 hours of running over the last few days it has become clear that the plastic idler wheel rolling on a plastic idler axle shaft is wearing fast. Also three of the return rollers have become very stiff and do not turn while running the tank. The issue is not dirt getting in and causing wear or sticking it is the fine "white colored" plastic dust from the parts rubbing against each other and wearing down. This does happen on other brands just not as quickly and given the much lower speeds I am driving the Hooben at is a bit disappointing. On a positive note the fitment of all the Hooben "wheels to axles" are much tighter to begin with than the other Chinese brands. Combining tighter fitting parts with what I believe is "softer" plastic is the underline problem.

I decided to focus my attention on the idler axles as they posses the most immediate issue. The simplest solutions I have found are often the best and there were two to choose from. So for sake of experimentation with this relatively new tank I am trying both, one on either side and comparing the results as run time increases.

The first is to simply, add a fine grease and "grease seal". Yes, this will attract dust to the exposed grease and that is the point. The dust actually helps seal gaps and keep the exposed grease in places. It will need to be cleaned and re-greased from time to time but that is a simple matter and this method has worked well for me on a few tanks, some I still utilize this on.

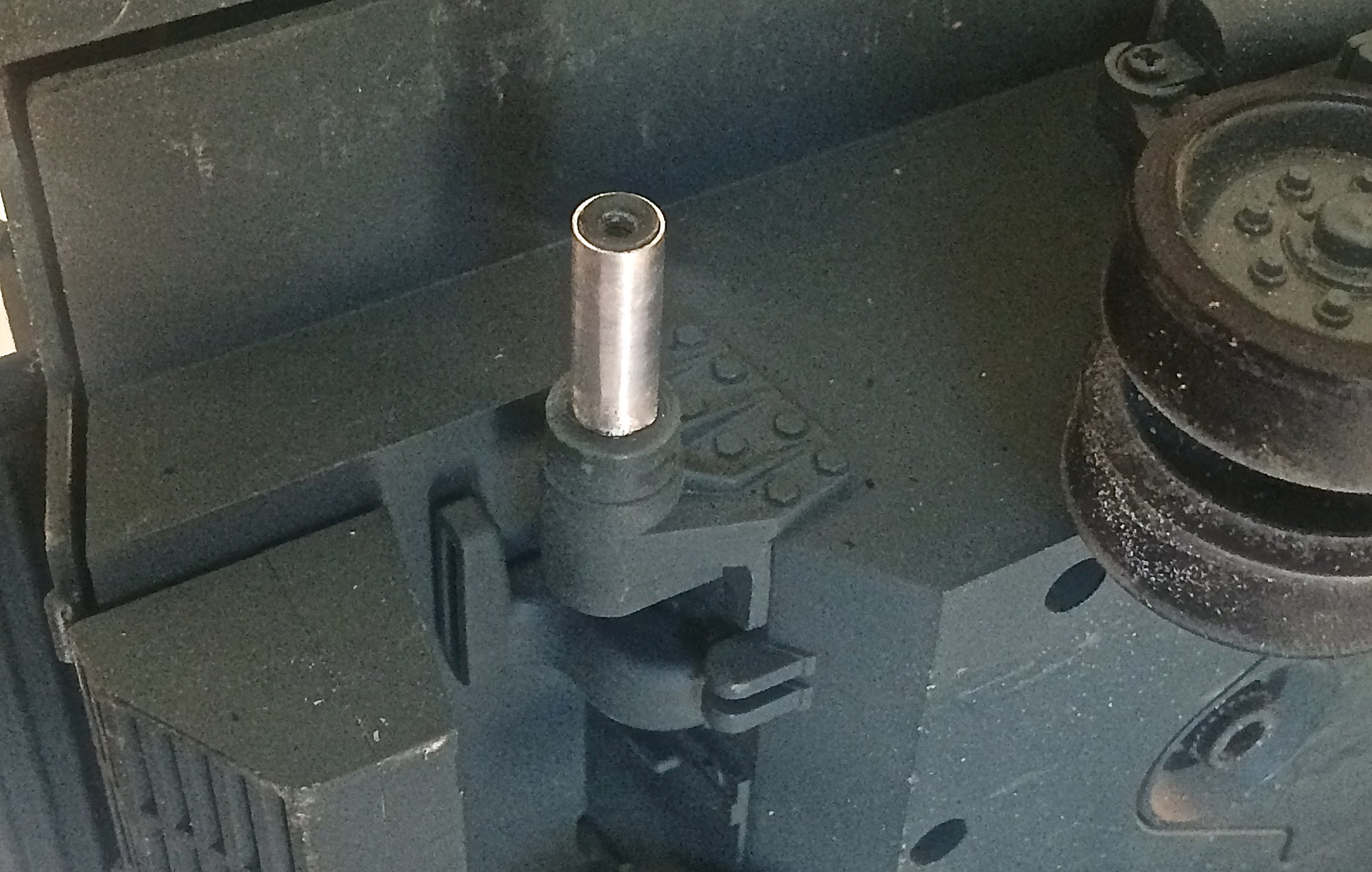

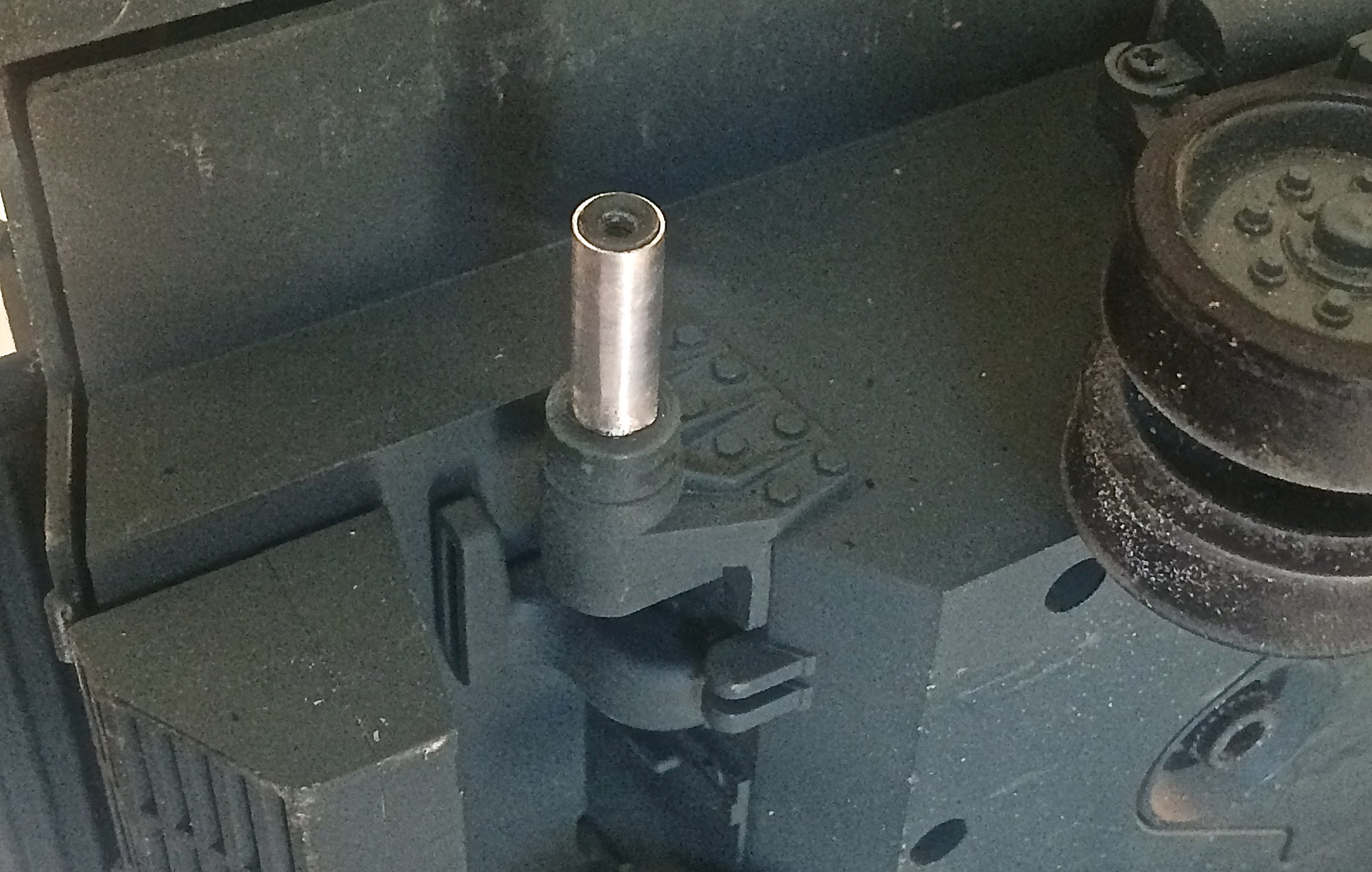

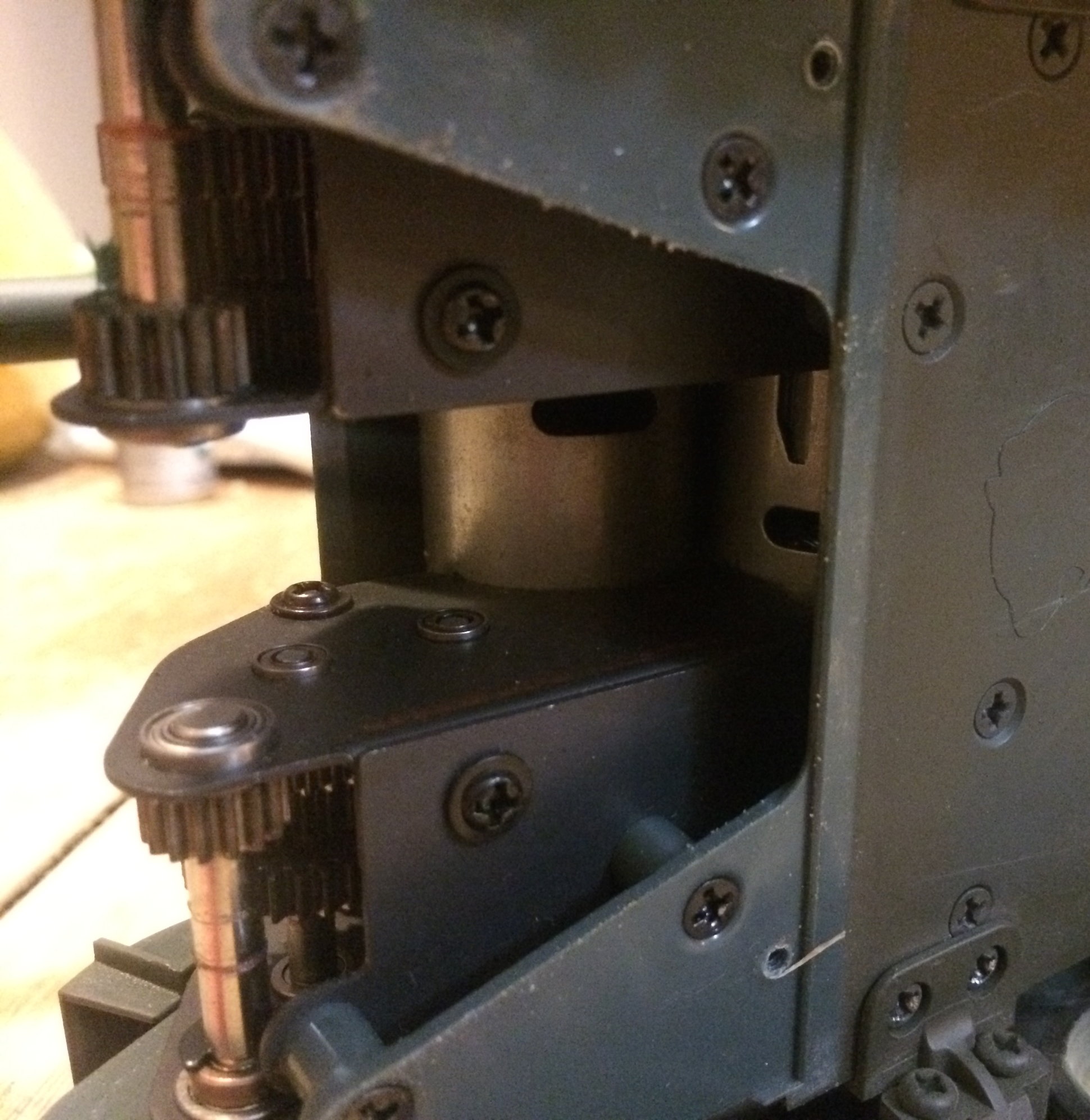

The second simple solutions was to sleeve the idler axle with metal. In this case ~ 6mm aluminum tube worked out almost perfect (see photo). I had to do a little fitting but that took only 5 mins. Yes the idler wheel will still wear (?) but at a much slower rate. There is still enough material on the idler wheel to add a bushing to it that would fit over the metal sleeve. If I see signs of rapid wear continuing I will take this next step.

Now onto the barrel and muzzle brake. I just cannot stand the look of the factory Hooben "East Eight" muzzel brake it looks too 1945 era German and not at all U.S. Fortunately there was enough material on the brake for me to reprofile it into something more U.S. looking for the era. The soft plastic used made this surprisingly easy and to my eye the brake looks much better (see photo).

I also looked for ways to address in the short term the lack of screw covers especially for the idler wheels and drive sprockets. Digging through my parts bin revealed a reasonable solution that fit, looked the era and could be made at a later date in the build to look even better. It seems that the sprocket screw caps from my Heng Long Challenger 2 were the solution (see photo).

For those of you that PM'd me about the "bogie" suspension compression range (see photos).

Lastly I did start some painting (ModelMaster GD 1787) on the lower hull sides, suspension and muzzle brake. This was to advance the dirt and grim weathering and to cover the sanding makers of the muzzle. You can see the color difference of the Hooben factory green vs ModelMaster green(see photos). And YES the tracks are on "backwards". I was going to leave them with the chevrons pointing forward for the modeling aspect, but they just work so much better with them reversed. It is almost night and day in performance.

As always your questions and constructive input are welcome.

Metal sleeve added to idler shaft.

Reprofiled muzzle brake.

Reprofiled muzzle brake. Also notice the difference in the factory green paint (upper hull & turret) compared to the ModelMaster green.

Idler wheel screw cap close up.

No compression.

Full compression.

Clear signs they are working. Notice the amount of wear just from plastic on plastic rubbing.

I decided to focus my attention on the idler axles as they posses the most immediate issue. The simplest solutions I have found are often the best and there were two to choose from. So for sake of experimentation with this relatively new tank I am trying both, one on either side and comparing the results as run time increases.

The first is to simply, add a fine grease and "grease seal". Yes, this will attract dust to the exposed grease and that is the point. The dust actually helps seal gaps and keep the exposed grease in places. It will need to be cleaned and re-greased from time to time but that is a simple matter and this method has worked well for me on a few tanks, some I still utilize this on.

The second simple solutions was to sleeve the idler axle with metal. In this case ~ 6mm aluminum tube worked out almost perfect (see photo). I had to do a little fitting but that took only 5 mins. Yes the idler wheel will still wear (?) but at a much slower rate. There is still enough material on the idler wheel to add a bushing to it that would fit over the metal sleeve. If I see signs of rapid wear continuing I will take this next step.

Now onto the barrel and muzzle brake. I just cannot stand the look of the factory Hooben "East Eight" muzzel brake it looks too 1945 era German and not at all U.S. Fortunately there was enough material on the brake for me to reprofile it into something more U.S. looking for the era. The soft plastic used made this surprisingly easy and to my eye the brake looks much better (see photo).

I also looked for ways to address in the short term the lack of screw covers especially for the idler wheels and drive sprockets. Digging through my parts bin revealed a reasonable solution that fit, looked the era and could be made at a later date in the build to look even better. It seems that the sprocket screw caps from my Heng Long Challenger 2 were the solution (see photo).

For those of you that PM'd me about the "bogie" suspension compression range (see photos).

Lastly I did start some painting (ModelMaster GD 1787) on the lower hull sides, suspension and muzzle brake. This was to advance the dirt and grim weathering and to cover the sanding makers of the muzzle. You can see the color difference of the Hooben factory green vs ModelMaster green(see photos). And YES the tracks are on "backwards". I was going to leave them with the chevrons pointing forward for the modeling aspect, but they just work so much better with them reversed. It is almost night and day in performance.

As always your questions and constructive input are welcome.

Metal sleeve added to idler shaft.

Reprofiled muzzle brake.

Reprofiled muzzle brake. Also notice the difference in the factory green paint (upper hull & turret) compared to the ModelMaster green.

Idler wheel screw cap close up.

No compression.

Full compression.

Clear signs they are working. Notice the amount of wear just from plastic on plastic rubbing.

Last edited by Fsttanks; 01-27-2019 at 11:45 AM.

#35

Some hard turns in light dirt to test track retention. No track loss occurred. Turns were done both forward and reverse. To date the Hooben "Easy Eight" has not thrown a track. Photos are highlight captured screen shots.

#37

I have one of Nick A's M4A1E8 kits that I'm finally getting around to building on a Mato lower. I hadn't looked at the parts bags for some time & just discovered Nick was kind enough to include 2 muzzle brakes so now I can correct the Hooben.

#38

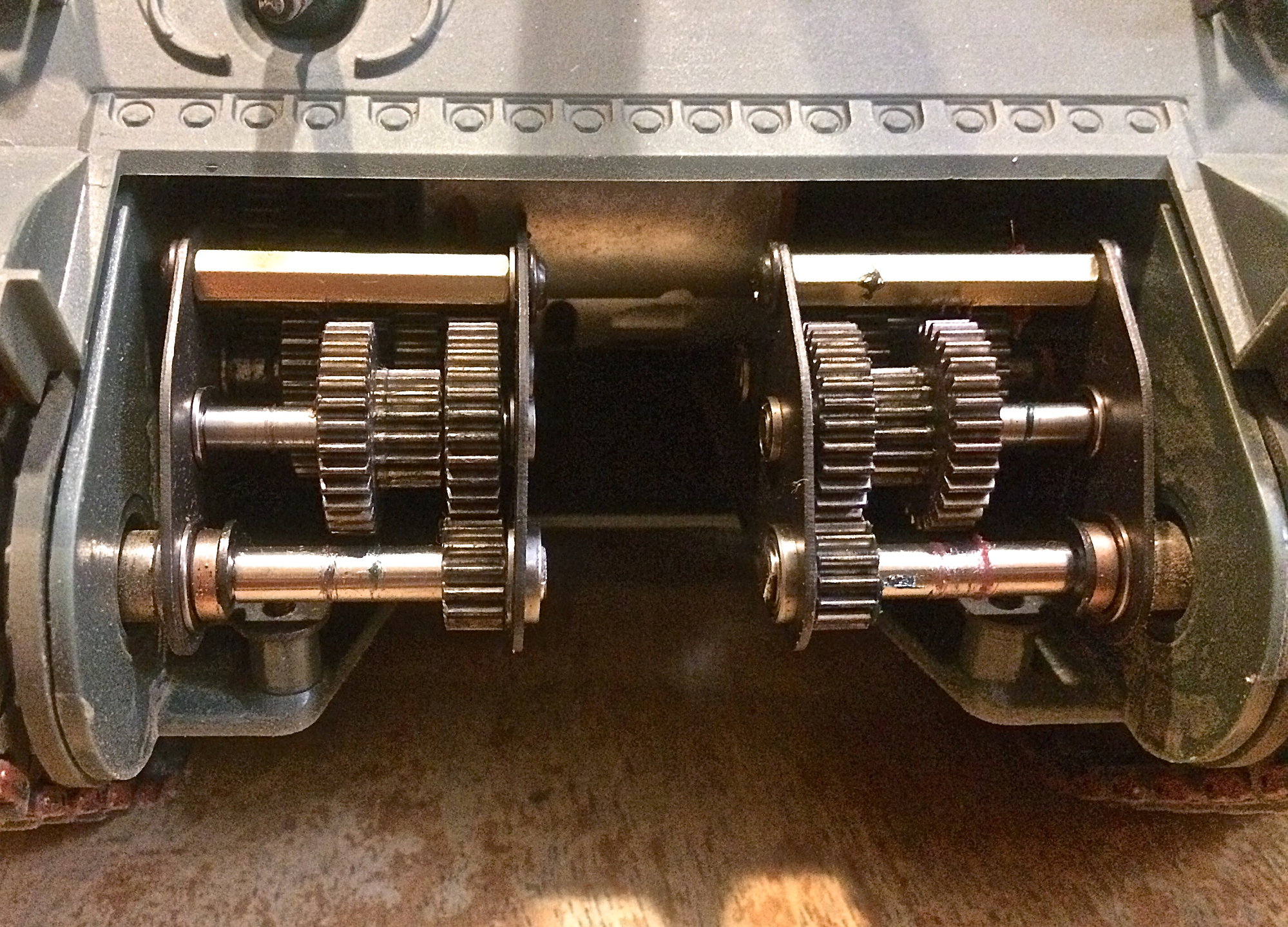

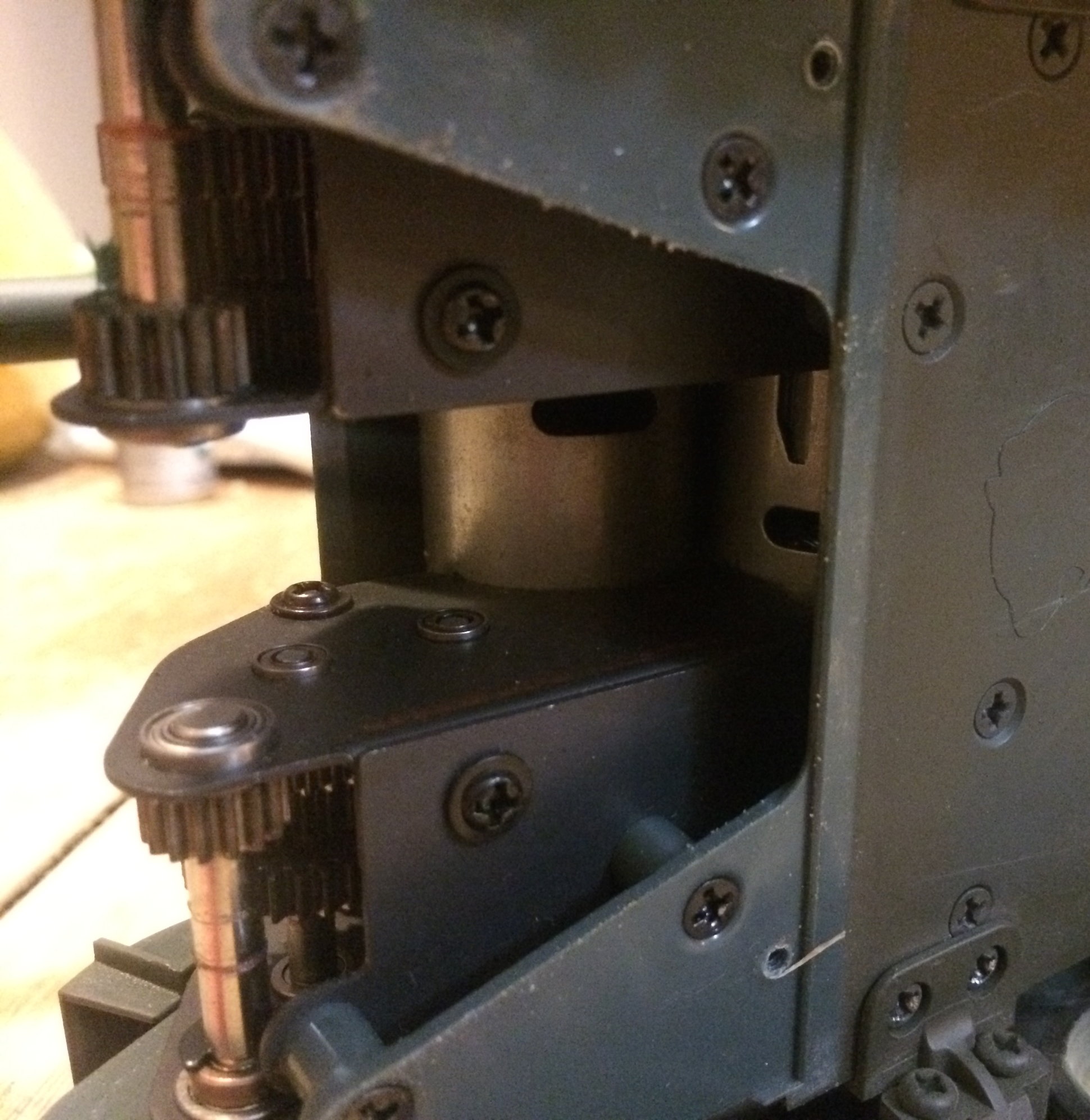

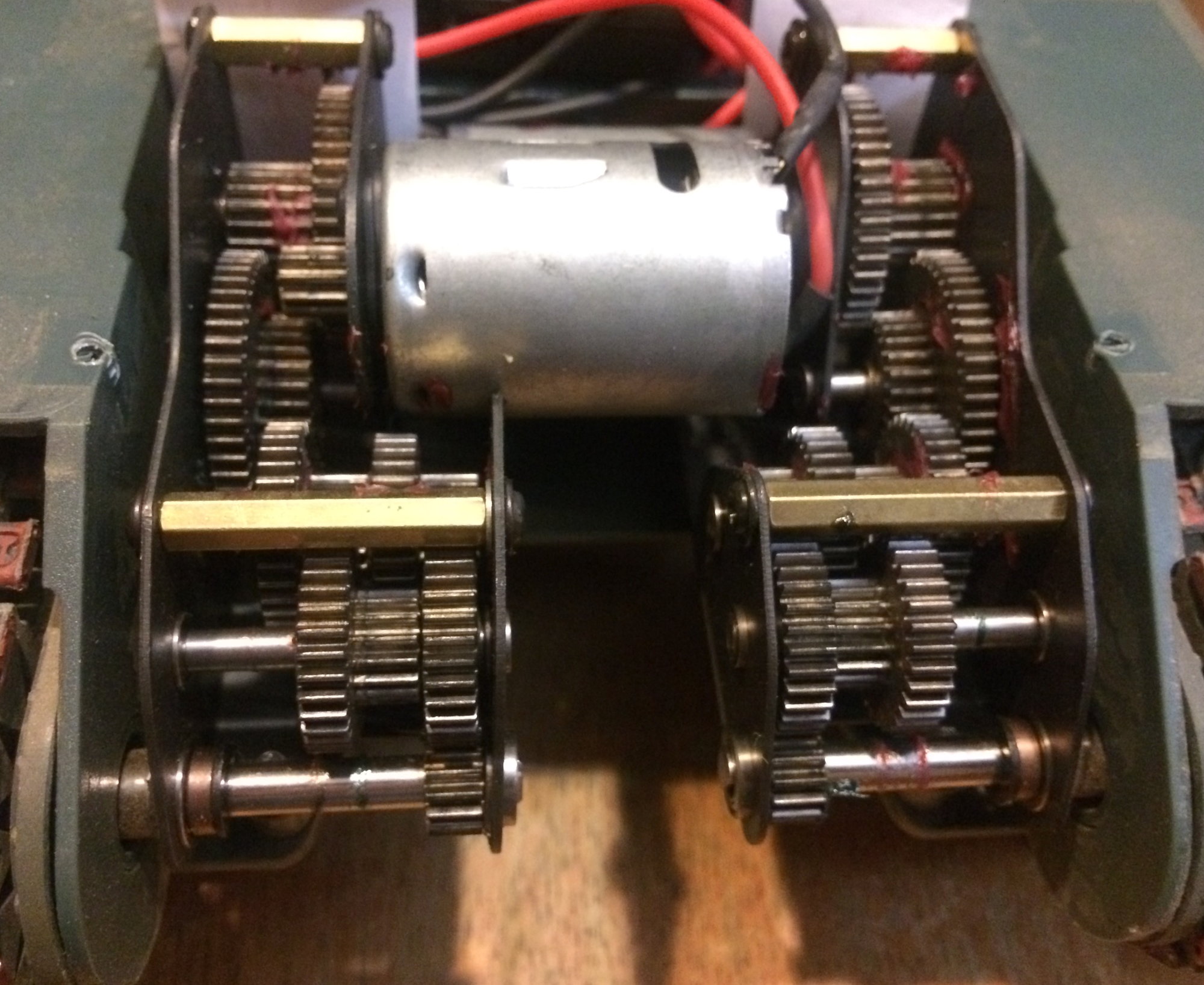

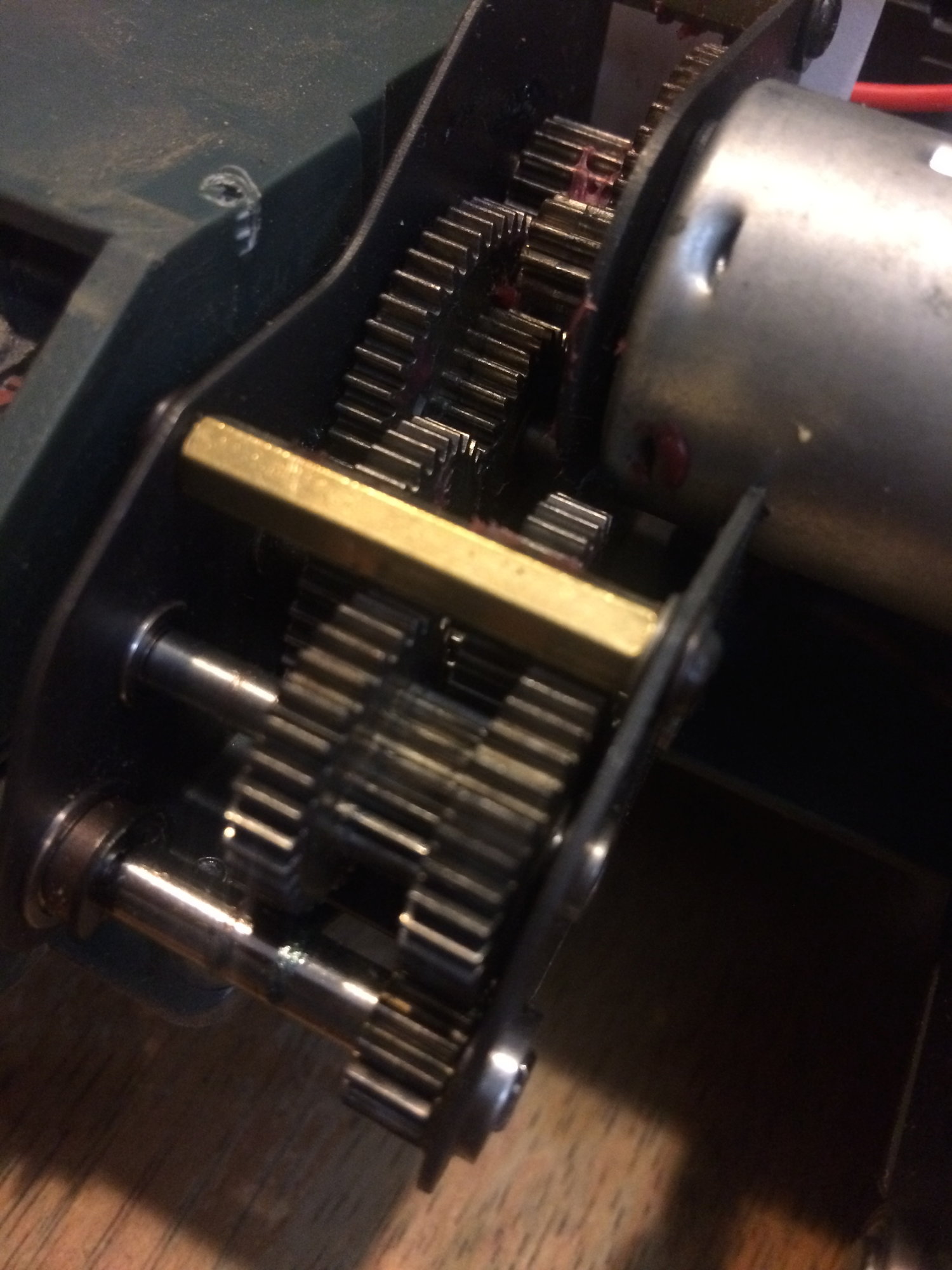

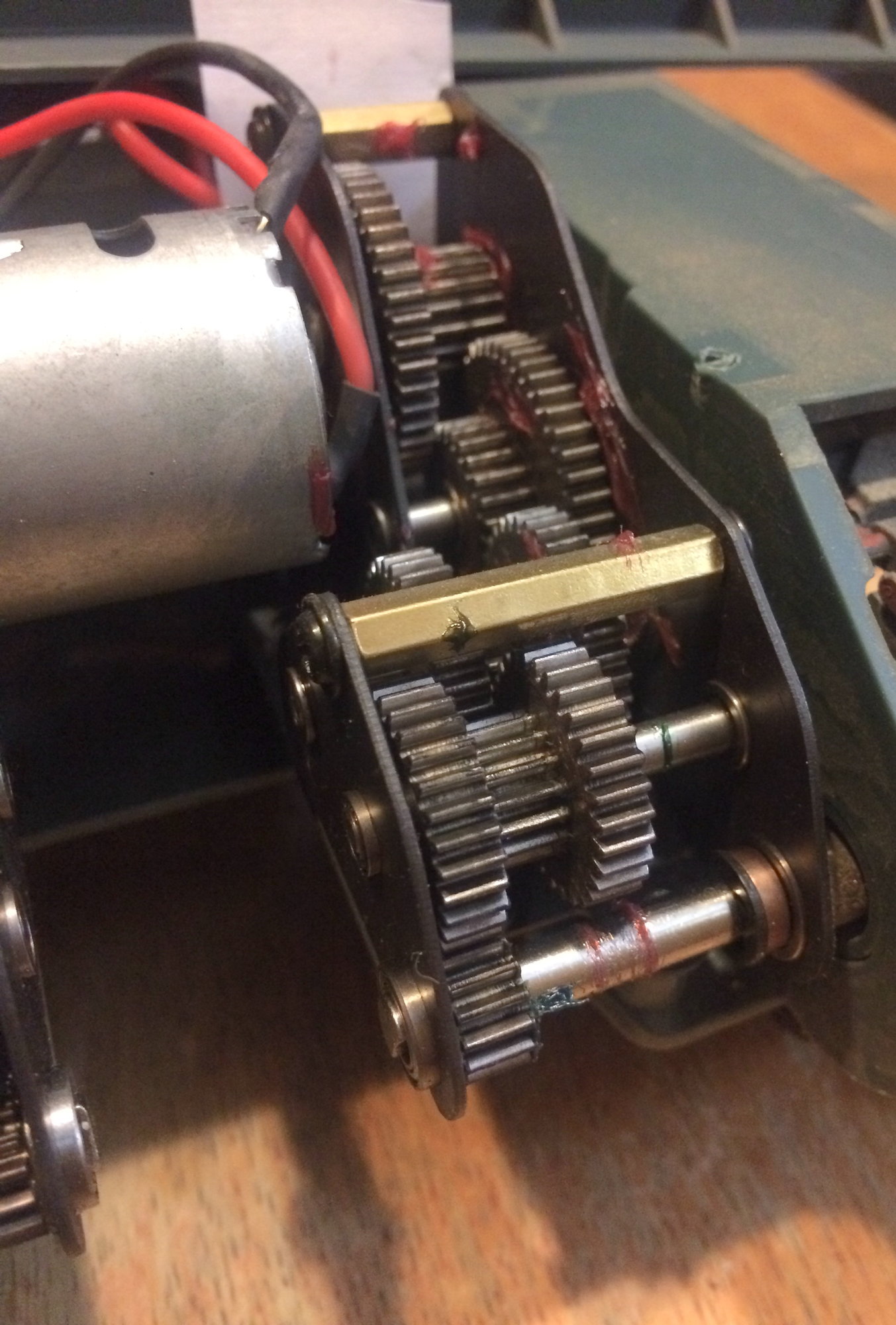

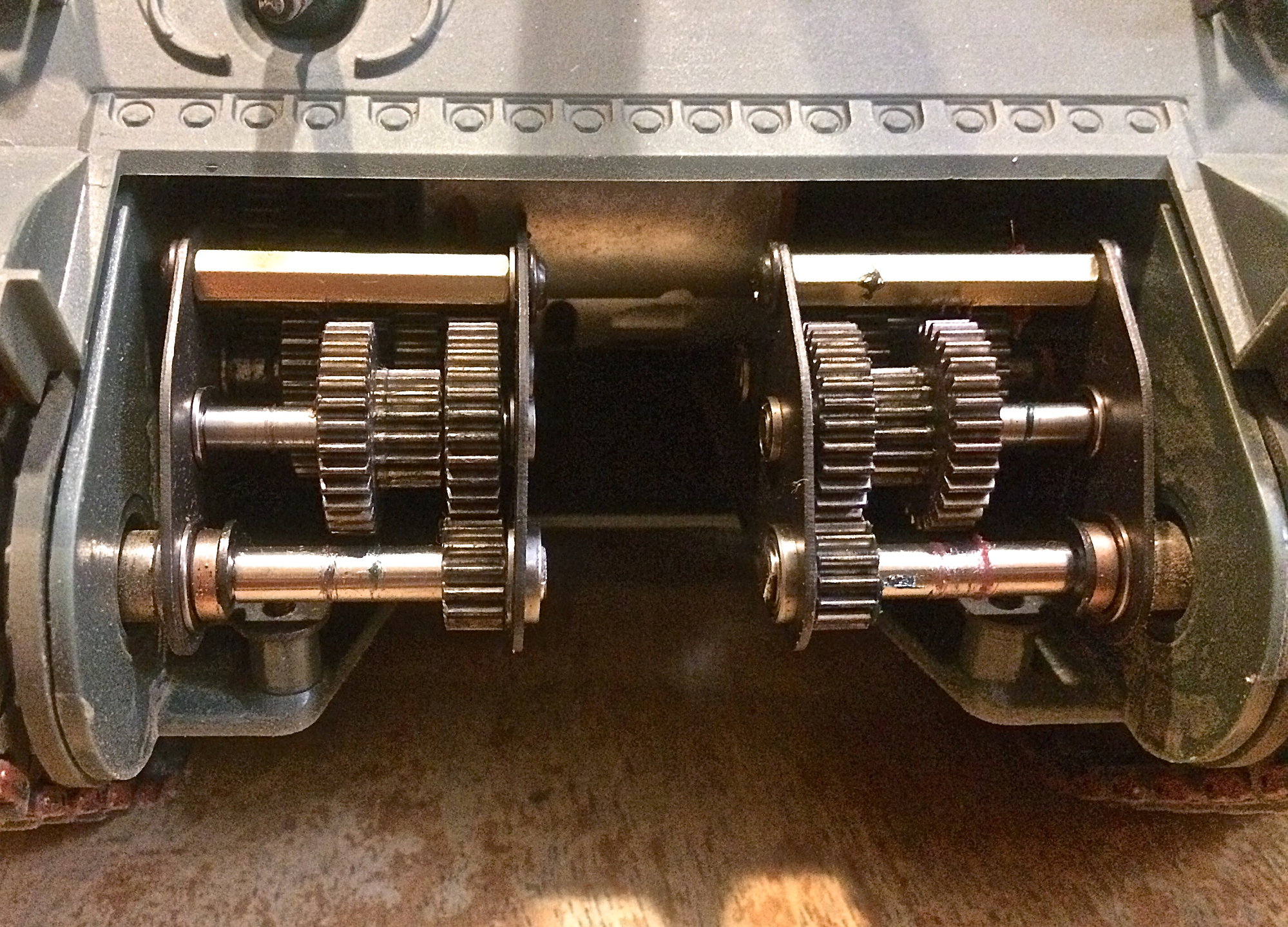

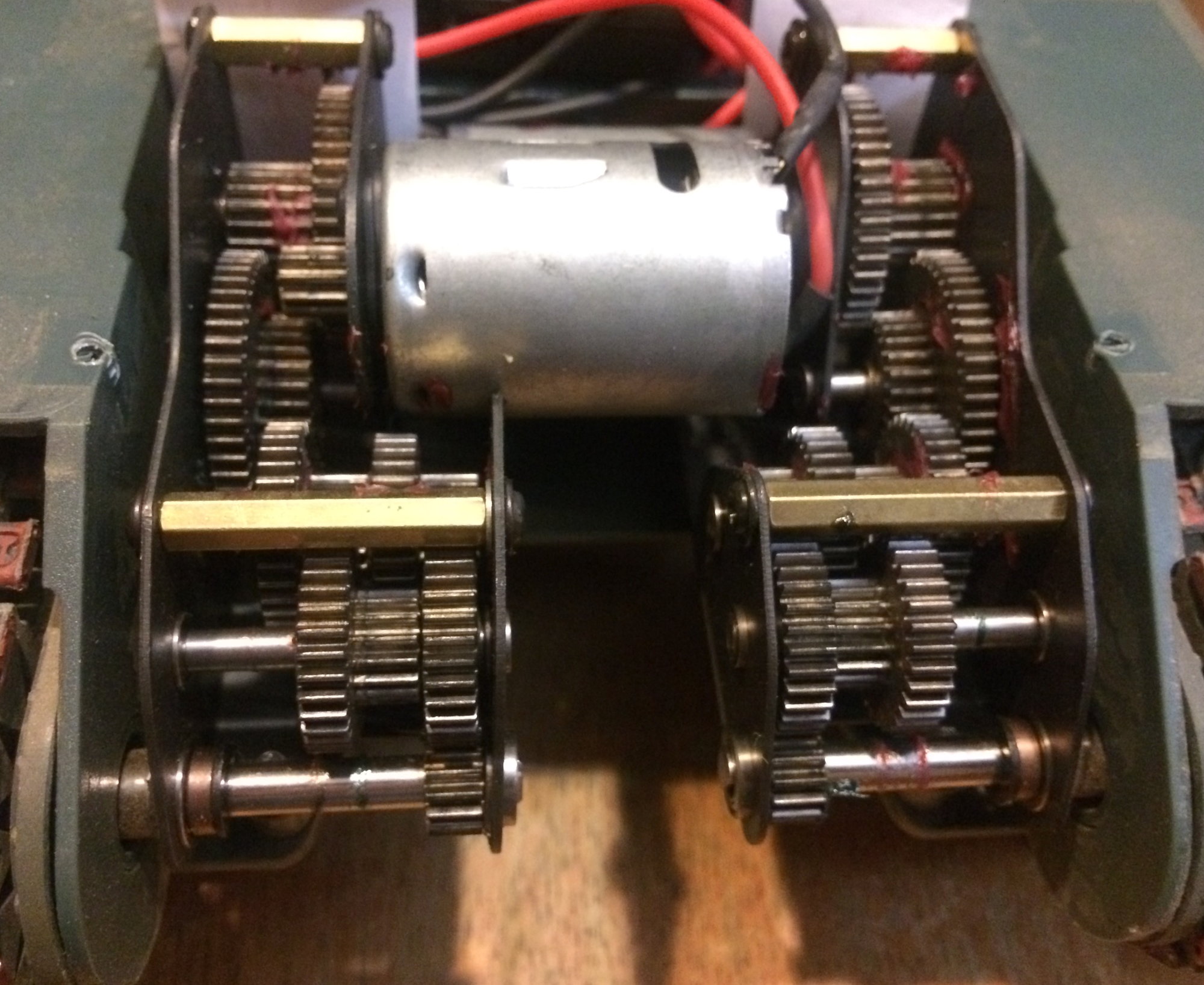

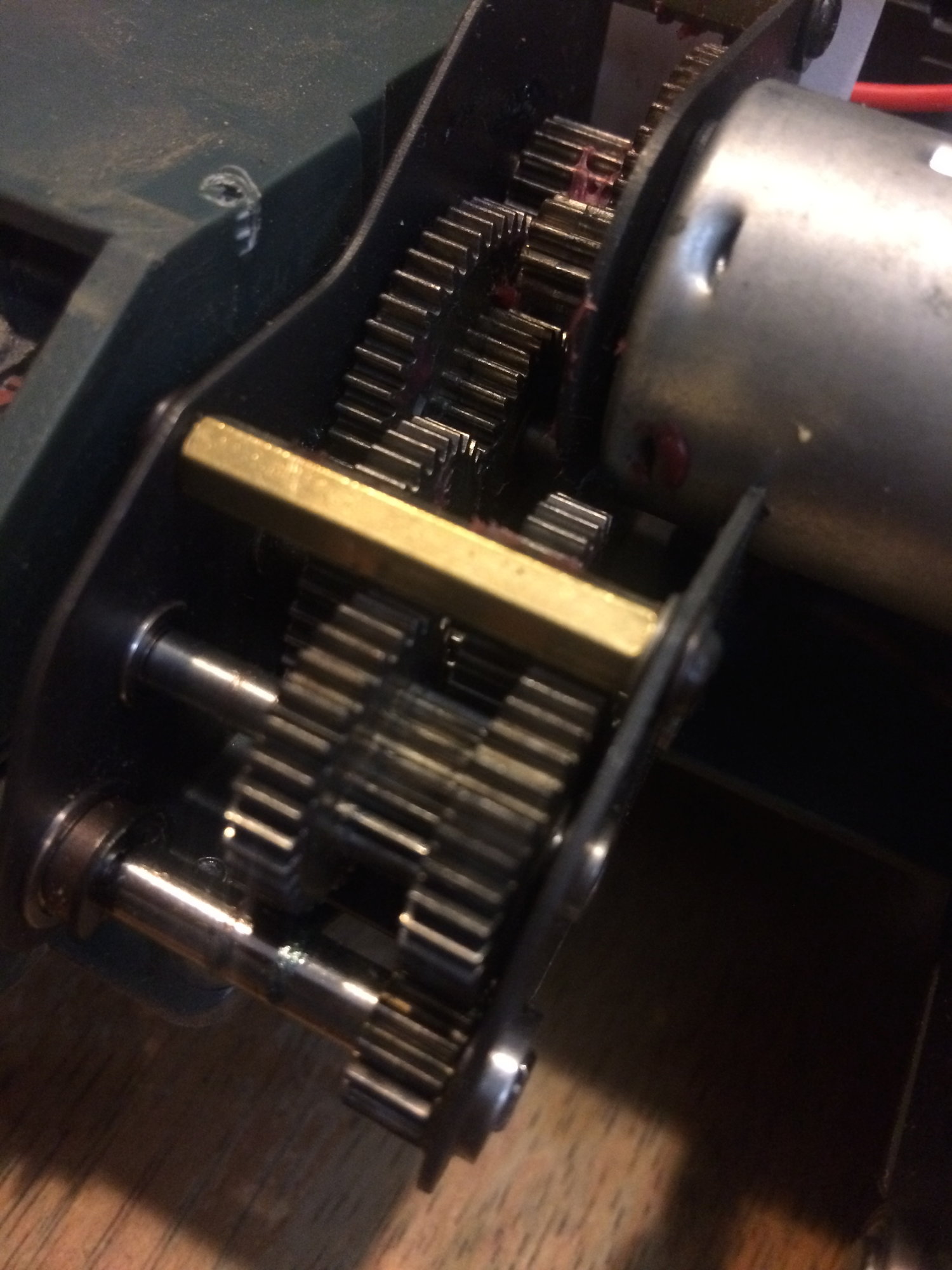

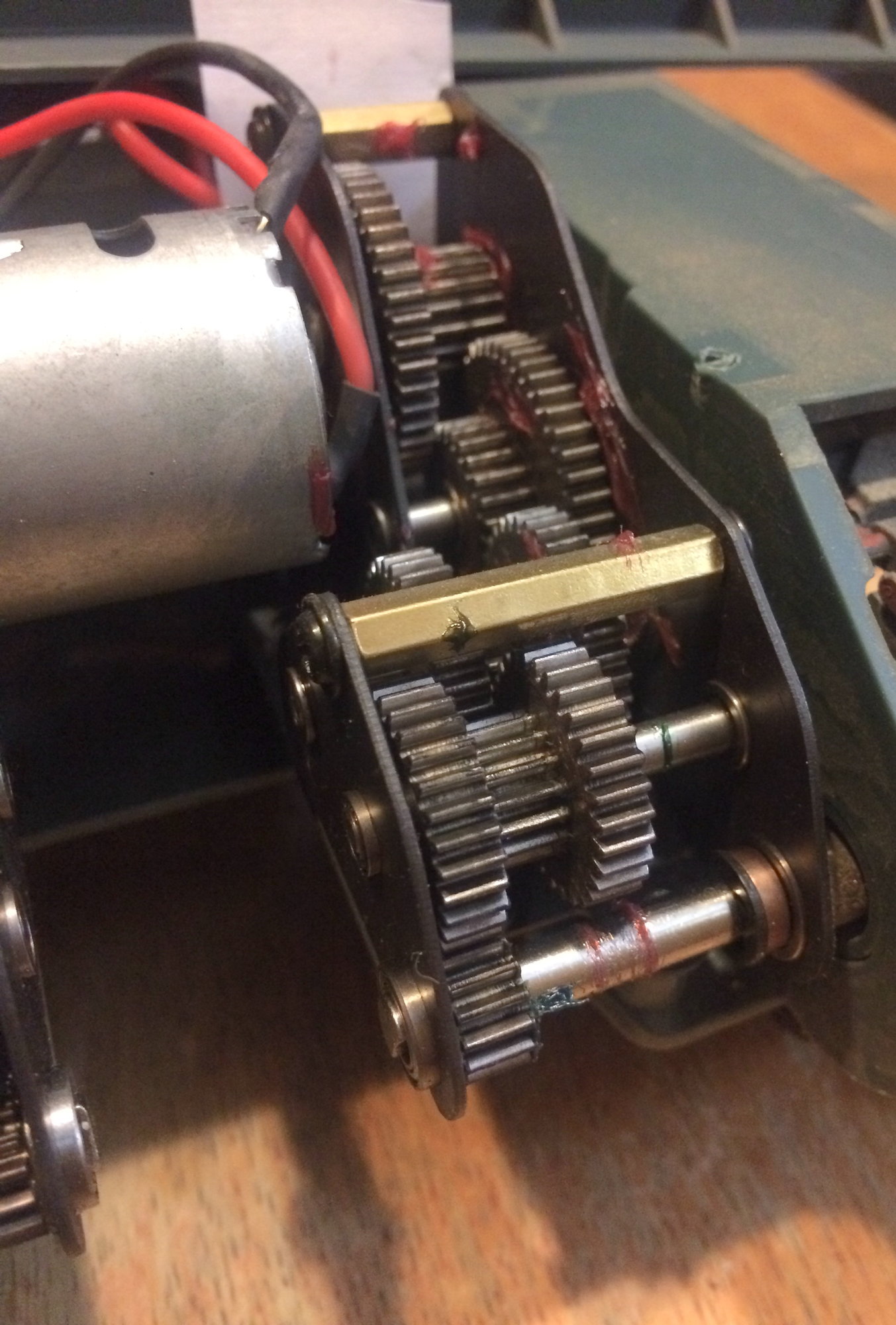

A quick look at the gearboxes since I had the hull pulled off to inspect/clean them after a lengthy couple of days of hard running and kicking up dirt and dust. Surprisingly there was VERY little dust or dirt intrusion that entered through the hull seems or drive shaft hull pass through whole. Given the amount of dust and dirt I was working hard at kicking up into the tracks and sprocket the inner hull and gear box should have been covered heavily in dust.

The red grease is something I started added during the taking of these photos and not factory. In fact the gearboxes did not have much factory lubricant on the gears. The gearboxes were decent running before, but now properly greased they run butter smooth and super quite.

Bottom view.

Right gearbox.

Left gearbox.

The red grease is something I started added during the taking of these photos and not factory. In fact the gearboxes did not have much factory lubricant on the gears. The gearboxes were decent running before, but now properly greased they run butter smooth and super quite.

Bottom view.

Right gearbox.

Left gearbox.

#40

Side note: I am actually more concerned that the tracks or sprockets will fail long before there are any issues with the gearboxes. The Gearboxes in my opinion are overbuilt for this tank and a simpler 3:1 or 4:1 design would have been just as good and possibly brought the retail price down a bit. Plus it would have made for easier customization.

Sorry that was a rather long winded responce to a simple question.

Last edited by Fsttanks; 01-30-2019 at 11:22 AM.

#42

This has all been great reporting on shaking down this new sherman model. The insides really seem to be a design all their own rather than follow the HL and Tiagen standard design.

We’ v e seen this tank perform and where is wearing fast.

I cannot wait to get my hands on this as John and I will tear into it and see what parts from other brands will fit for mixing and bashing and replacing amd upgrading. I have lots of brands of track and sprockets to see what we can come up with and what will work. Im also excited a about the track as until now that large rubber chevron was only available from impact and was costly. We may give the track a try on a tamiya and see it it fits hoping it will become available after market on the parts side. Were looking to do the sherman expirememt this weekend if wverything works out.

We’ v e seen this tank perform and where is wearing fast.

I cannot wait to get my hands on this as John and I will tear into it and see what parts from other brands will fit for mixing and bashing and replacing amd upgrading. I have lots of brands of track and sprockets to see what we can come up with and what will work. Im also excited a about the track as until now that large rubber chevron was only available from impact and was costly. We may give the track a try on a tamiya and see it it fits hoping it will become available after market on the parts side. Were looking to do the sherman expirememt this weekend if wverything works out.

#43

Started sand performance testing today. The sand used was typical child play sand one can purchase at any home improvement store. This sand is just course enough to find any weaknesses or issues in the suspension, road wheels, sprockets and tracks. As you can see in the the photos I did not spare the Hooben "Easy Eight" and packed the tracks and suspension components with sand as I repeated sharp turn after sharp turn both forward and reverse. I did this for about 20 minutes. During that time I experienced no track lose and the Hooben "Easy Eight" did not skip a beat in clearing the sand as I drove it out of each turn.

Also did some off camber driving to find the "roll over" point. I had an few issues earlier in the day on a obstacle that has never been a problem for my other tanks including the "Easy Eights" contemporary the M26 Pershing. The photo shown below is a simple mound with 40 degree side slops. Though the Hooben can handle driving along these off camber slops its clear it is nearing the limits of safe performance. It is a Sherman after all and well know for having a high CG coupled with a narrow hull/track width.

Photos below are screen shots from sand and off camber drive testing (YES the tracks are on backwards).

Hooben M4A3E8 Sherman, about to turn onto side slope.

On side slope test mound.

Sand testing.

Sand testing.

Sand testing.

Sand testing.

Sand testing.

Also did some off camber driving to find the "roll over" point. I had an few issues earlier in the day on a obstacle that has never been a problem for my other tanks including the "Easy Eights" contemporary the M26 Pershing. The photo shown below is a simple mound with 40 degree side slops. Though the Hooben can handle driving along these off camber slops its clear it is nearing the limits of safe performance. It is a Sherman after all and well know for having a high CG coupled with a narrow hull/track width.

Photos below are screen shots from sand and off camber drive testing (YES the tracks are on backwards).

Hooben M4A3E8 Sherman, about to turn onto side slope.

On side slope test mound.

Sand testing.

Sand testing.

Sand testing.

Sand testing.

Sand testing.

Last edited by Fsttanks; 01-30-2019 at 11:36 PM.

#44

Time for some MUDDING!!!!

Ran the Hooben "Easy Eight" though one of my test course mud holes that is filled with 2 inch deep silty mud and a thin layer of water. I did not run the "Easy Eight" through my deeper mud because of the low ground clearance under the hull, it would have just gotten "bottomed out" and stuck.

Overall the Hooben "Easy Eight" did rather well. I had no track lose and the tank cleared the silty mud easily. I did get stuck once as the silt became more churned up and softer, though the tank was able to free itself with a little left-right-back-forth toggling of the control stick. A couple of small issues came up as the testing progressed, one was the rear exhaust grill dragging through the now churned up softer mud began to act more like an anchor. The second was the silt particles getting into the rear open slot on the fake shocks. This caused the suspension to lock up, but did do stop the tank or cause any other issues.

I had a REALLY fun time with this phase of testing and wanted to keep going!! But 35 min. of mud play and a locked up suspension was pushing it knowing there is still more testing that needs to follow.

I will be letting the mud dry on the tank then running it to see how "Easy Eight" components can self clear. After which I will be doing a suspension breakdown cleaning before moving on with further testing.

Below are some of the screen shots highlights from the "MUDDING" fun.

Ran the Hooben "Easy Eight" though one of my test course mud holes that is filled with 2 inch deep silty mud and a thin layer of water. I did not run the "Easy Eight" through my deeper mud because of the low ground clearance under the hull, it would have just gotten "bottomed out" and stuck.

Overall the Hooben "Easy Eight" did rather well. I had no track lose and the tank cleared the silty mud easily. I did get stuck once as the silt became more churned up and softer, though the tank was able to free itself with a little left-right-back-forth toggling of the control stick. A couple of small issues came up as the testing progressed, one was the rear exhaust grill dragging through the now churned up softer mud began to act more like an anchor. The second was the silt particles getting into the rear open slot on the fake shocks. This caused the suspension to lock up, but did do stop the tank or cause any other issues.

I had a REALLY fun time with this phase of testing and wanted to keep going!! But 35 min. of mud play and a locked up suspension was pushing it knowing there is still more testing that needs to follow.

I will be letting the mud dry on the tank then running it to see how "Easy Eight" components can self clear. After which I will be doing a suspension breakdown cleaning before moving on with further testing.

Below are some of the screen shots highlights from the "MUDDING" fun.

Last edited by Fsttanks; 02-01-2019 at 11:48 AM.

The following users liked this post:

BlitzPig (04-05-2020)

#45

Wow, the easy way to weather your tracks!!!

#46

Looks to me like a pretty good tank. Only thing that worries me is the plastic drive components but it's possible Tamiya suspension and idler brackets will fit. That and some hull reinforcement might be all that's needed to bring this thing up to killer battle status.

#47

The tamiya idler has the same problem as the hooben. It is a plastic wheel over a metal arm, so it wears... Thanks god Daryl installed bearings for me.

#48

Rad, the mount on the Tamiya idler is metal and I agree, Tammy could have done better with that idler. On the other hand, one of my two fighting Shermans is from 2003 and still going strong with the original idler. The Hooben idler shaft is plastic, it's photoed earlier in this post.

#49

My EZ8 is built on a 2000 dmd Sherman with white gear tranys. The ilder has no problem at all. And I ran the **** out of it. The old bogies however are shot. The old wheels rolling on the cast axles have the hubs wearing upward into the wheels. The tank squeaks really bad now. I have a set of modern bogies to install and rebuild Katy Cat that are left from the hull I cut up to make my M50. More or less, saying the Tamiya idler is not an issue. in a relative time frame of wear.

#50

We will be looking into the Tamiya cross over parts (?) shortly. As for hull reinforcement there is no need as the hull has been taking a beating with no issues and is rock solid when screwed down. I even have an additional 2lbs of weight added to the tank just to make it heavier and hull has handled it like it was not even there.