125% (1/4 scale) Anderson TA-152H

#329

Today was spring cleaning..

The F-14's plug was moved (to the trash can) to make room to hang up the fuse to the ceiling and the mold was stood up in a corner. This made room on my molding table for the TA fuse to get molded.

And here is the results of this weeks work. 5 sets of TA molded small parts.

The F-14's plug was moved (to the trash can) to make room to hang up the fuse to the ceiling and the mold was stood up in a corner. This made room on my molding table for the TA fuse to get molded.

And here is the results of this weeks work. 5 sets of TA molded small parts.

#334

yea i am really pressing to get all the tooling done before the end of May. Ill probably have the fuselage and tail done, but having to redesign the wing is really slowing things done. Plus in a week ive got a long week of 16hr days so there wont be any progress that week. Hopefully i can get the fuse all waxed and the parting planes built up so i can start molding it the first week of May.

#335

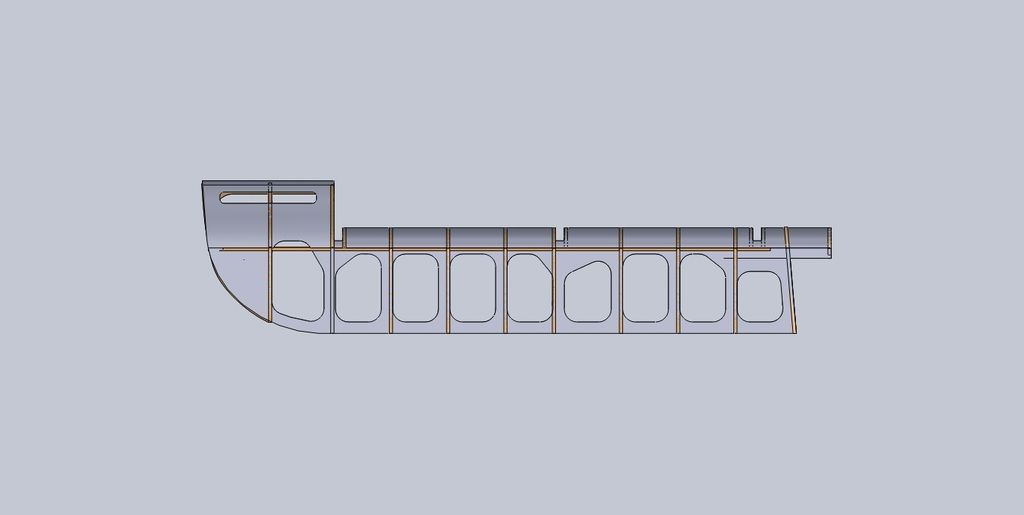

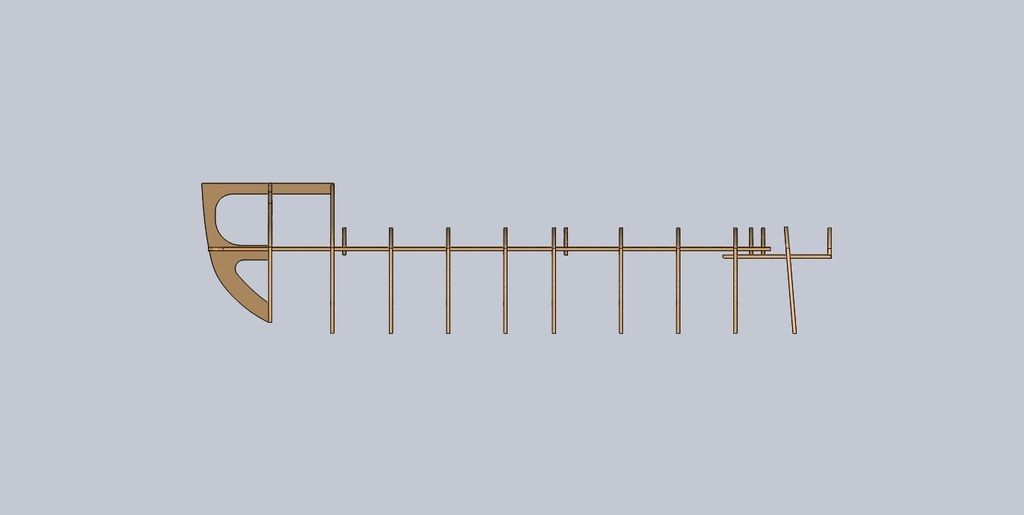

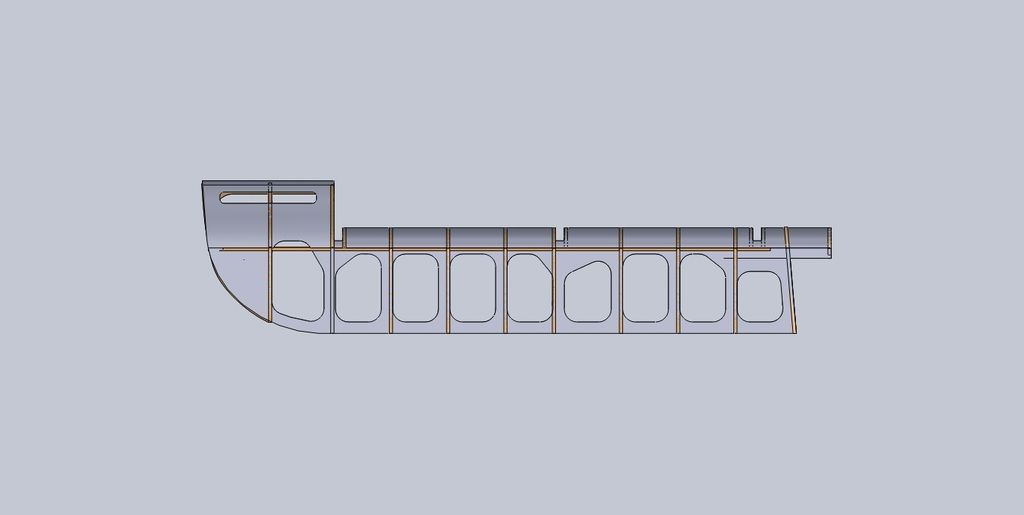

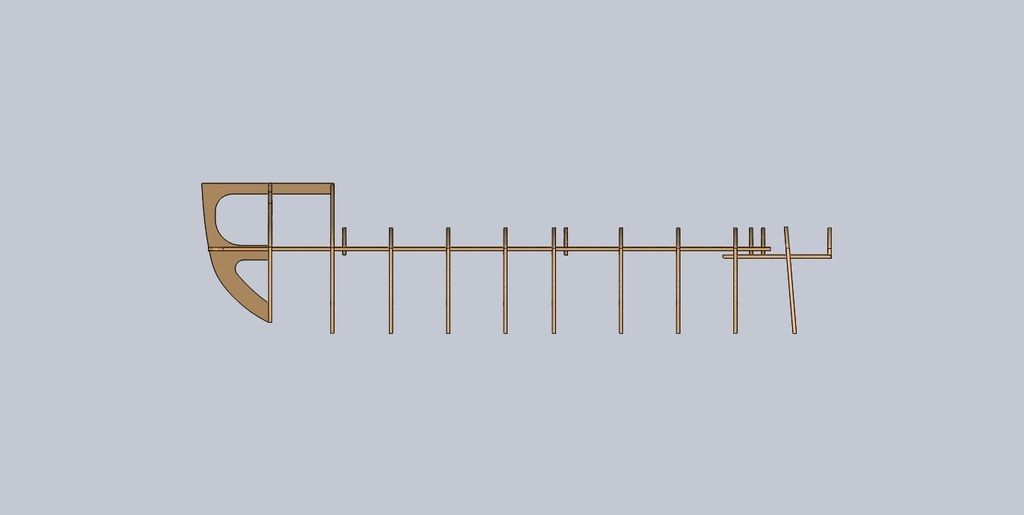

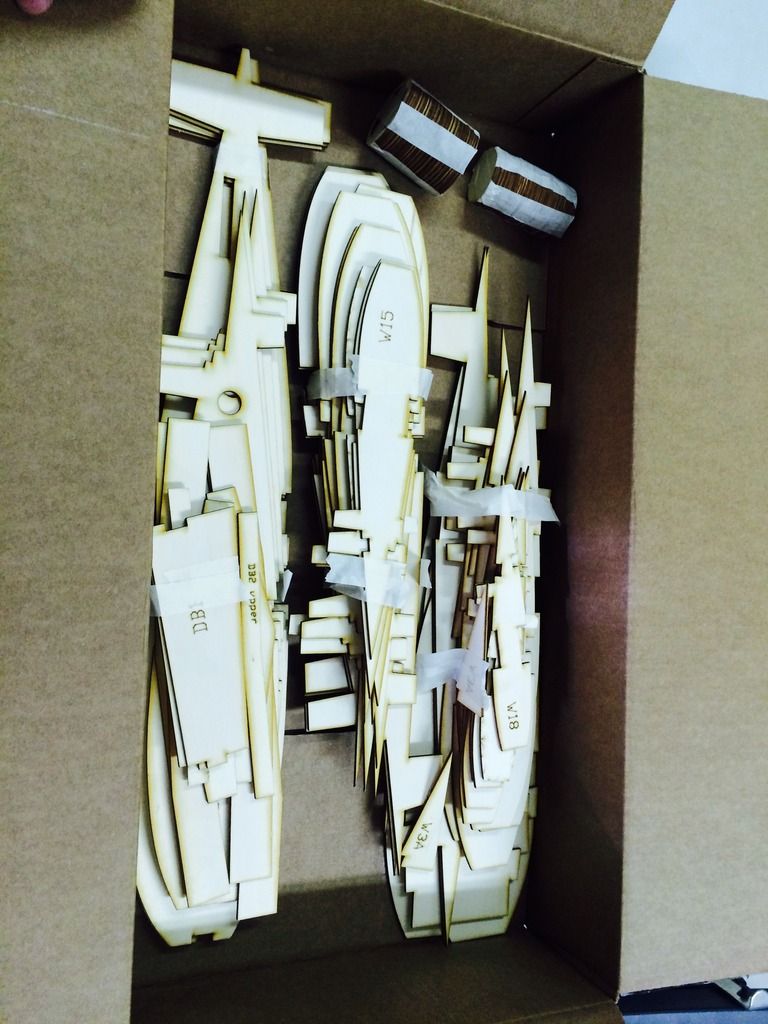

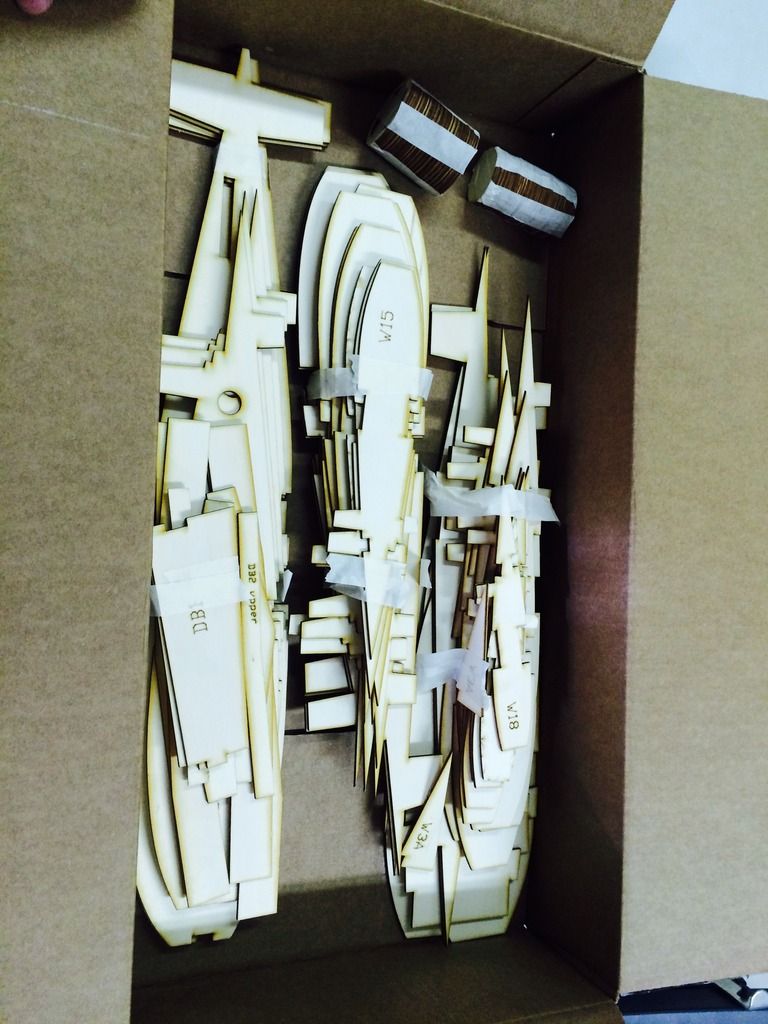

I got the wing ribs all redesigned and sent off to the laser cutter so i can get those on the way. I also got the elevator structure finalized with just a little bit of finish's to do to it and to flatten out the skin so those parts can be laser cut.

Here are a few photo's of the structure. It is all laser cut and interlocking so you can assemble the entire thing flat on a table without any glue. Weight without the skin is 1 ounce with a combination of balsa and lite ply. I'll probably end up using light ply for the majority of it for the extra ruggedness.

Here are a few photo's of the structure. It is all laser cut and interlocking so you can assemble the entire thing flat on a table without any glue. Weight without the skin is 1 ounce with a combination of balsa and lite ply. I'll probably end up using light ply for the majority of it for the extra ruggedness.

#336

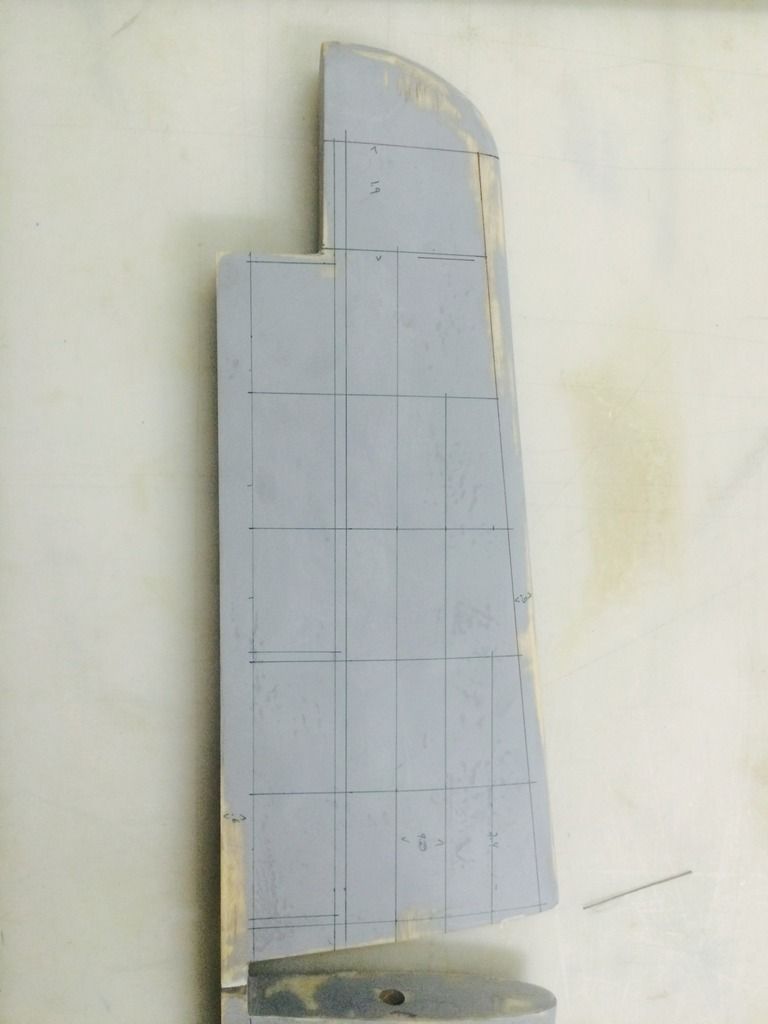

Parting planes for the stabs are done. I'll mold them in the same parting plane (which is 99% perfect from one side to the next) to save myself some time and labor.

I also did the vacuum form tool layup for the canopy.

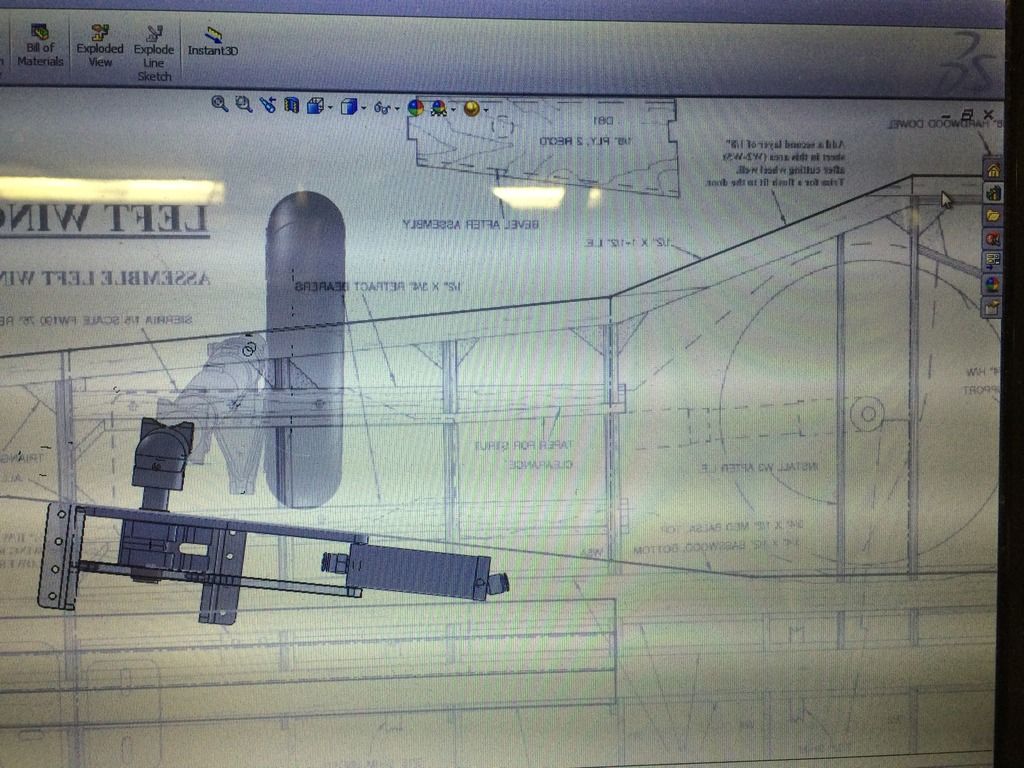

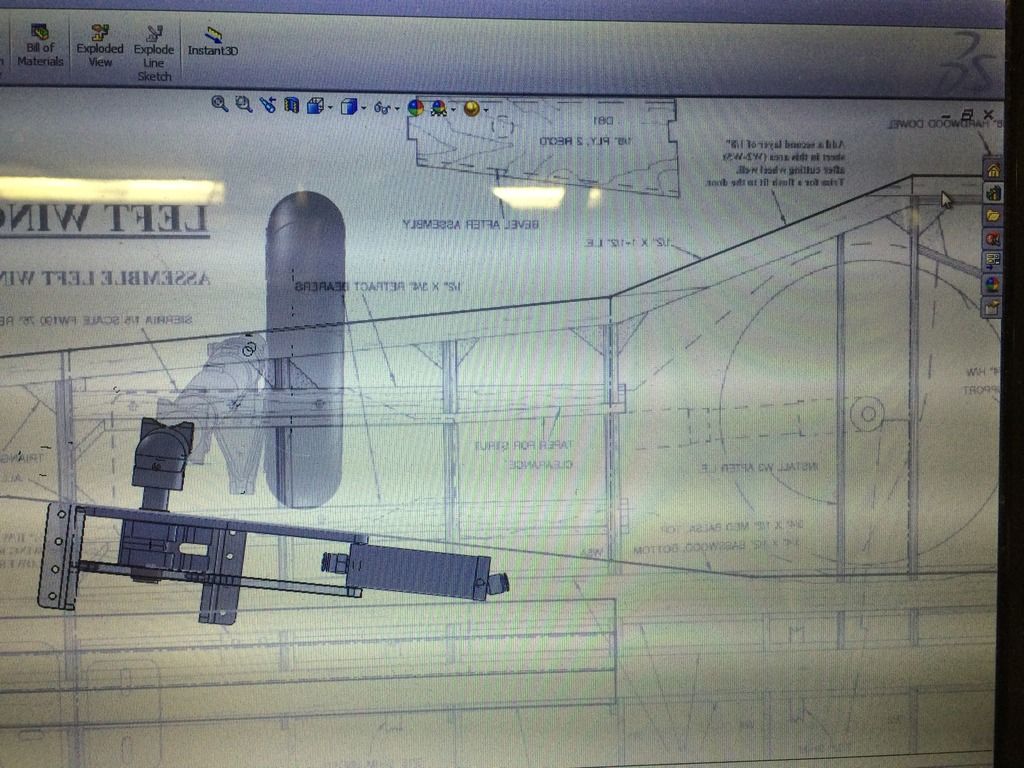

And the landing gear design is done. Here is the retract mechanism, strut and wheel overlaid over the plans with the scale spar face location. The oleo is full compressed and is right at the wing leading edge, so im happy with the final design.

I also did the vacuum form tool layup for the canopy.

And the landing gear design is done. Here is the retract mechanism, strut and wheel overlaid over the plans with the scale spar face location. The oleo is full compressed and is right at the wing leading edge, so im happy with the final design.

#337

Now that the past week is over with and while i wait on parts for the airplane at work, i have a few days to do something fun.

I pulled the vacuum form layup from the canopy frame mold. Ill add some balsa structure to the inside and then pull a few canopies.

I also have the first half of the first stab half molded. Tomorrow i hole to finish this mold and get the first half of the other done as well. Then after topgun on saturday, finish the second stab half mold.

Sunday will most probably be a parting plane day for the fuselage.

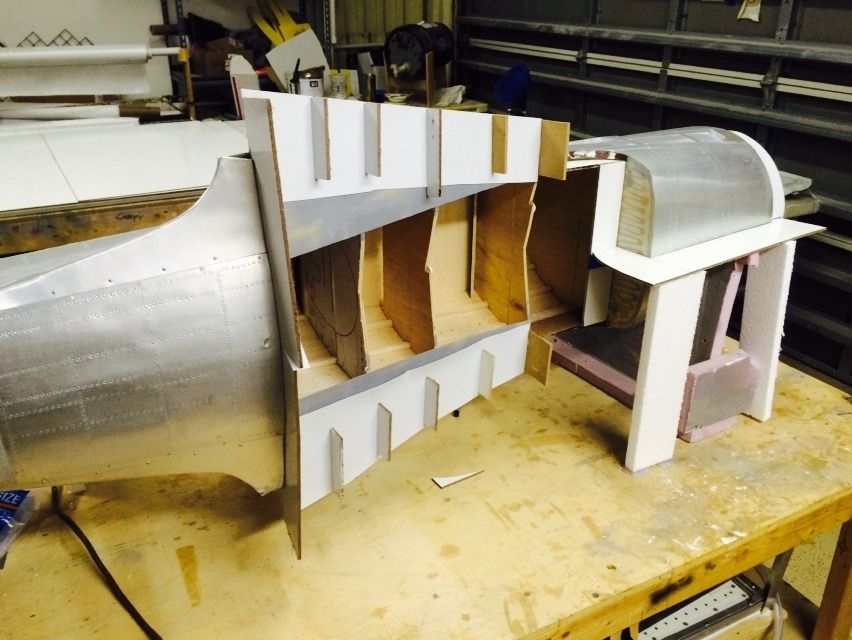

The redesigned wing laser cut ribs and parts also arrived. Since these are just for a plug, i left all of the lightening holed out of them. Once the fuse is molded and the tube sockets arrive, ill start building the new wing.

I pulled the vacuum form layup from the canopy frame mold. Ill add some balsa structure to the inside and then pull a few canopies.

I also have the first half of the first stab half molded. Tomorrow i hole to finish this mold and get the first half of the other done as well. Then after topgun on saturday, finish the second stab half mold.

Sunday will most probably be a parting plane day for the fuselage.

The redesigned wing laser cut ribs and parts also arrived. Since these are just for a plug, i left all of the lightening holed out of them. Once the fuse is molded and the tube sockets arrive, ill start building the new wing.

#340

Thomas,

When you mold it. Will you include cloth weights, number of ply's and any other materials used.

I wish to do this one day also.

Love watching your creations

Thanks

Kevin

When you mold it. Will you include cloth weights, number of ply's and any other materials used.

I wish to do this one day also.

Love watching your creations

Thanks

Kevin

#341

Yea i realized i forgot to do the one where the tail extension bolts to the forwars fuse on the real thing. Im going to do all US based fuselages as one piece (unless requested otherwise) and all international fuse's as two piece where the tail section bolts on.