Starting a DNU (first kit build for me)

#1

Senior Member

Thread Starter

My Feedback: (1)

Join Date: Jul 2008

Location: Fort Lauderdale, FL

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

Hey guys. I just got a DNU kit and this will be my first build. I'm thinking about doing dual servos (9g) for the ailerons. The reason would be to simply the setup by avioding the torque rod setup as origionally designed. What do you all think?

Also I'm sure I'll have more questions as the build gets going so bear with a beginner builder.

Thanks to all,

Also I'm sure I'll have more questions as the build gets going so bear with a beginner builder.

Thanks to all,

#3

The torque rod set up is pretty easy. There's various ways of doing it, but the way I like is to do away with the tubes and set the rods in epoxy. Makes for an absolutely slop-free set up. If you do enough searching on here, you will find info on how to do it.

#4

Senior Member

My Feedback: (1)

Join Date: Jan 2002

Location: Shakopee,

MN

Posts: 338

Likes: 0

Received 0 Likes

on

0 Posts

I just completed that very operation about 30 minutes ago on my SureShark. It is so easy to do and there is no slop at all in the linkage. I think on a model of this size I like to use the torque method. On larger models, I prefer two servos, one for each aileron.

#7

My Feedback: (10)

On 1/2a models I am waaaayyyy in favor of using one servo for ailerons. Torque rods are super easy to pot in epoxy, never mind using a tube. If you need a pic lemme know. However I highly recomend using one servo for ailerons on a model of this size just to cut the weight and keep things simple.

#8

Vicman is right. The DNU is a small simple model. One servo is much easier than 2. It keeps the weight down, and it keeps the weight inboard, not out in the wings where it slows roll rate, and also keeps it rolling when you want it to stop (angular momentum). It also means 2 wires to plug in, or the added weight (and volume) of a Y-harness.

With the epoxy method, the grooves you cut in the TE don't even have to be straight or consistent width/depth. As long as the rod sits in it, the epoxy will fill up the rest. I would use epoxy/microballoons rather than straight epoxy since its lighter and not so runny. Remember to grease the rods so the epoxy doesn't stick to them. Believe me, once you've done it, you will wonder why you even considered 2 servos.

The extra power of a second servo is wasted on a model of this size. It will only drain your battery faster. And for a model like this, you will be wanting a pretty small battery pack.

What engine do you plan on putting in it?

With the epoxy method, the grooves you cut in the TE don't even have to be straight or consistent width/depth. As long as the rod sits in it, the epoxy will fill up the rest. I would use epoxy/microballoons rather than straight epoxy since its lighter and not so runny. Remember to grease the rods so the epoxy doesn't stick to them. Believe me, once you've done it, you will wonder why you even considered 2 servos.

The extra power of a second servo is wasted on a model of this size. It will only drain your battery faster. And for a model like this, you will be wanting a pretty small battery pack.

What engine do you plan on putting in it?

#9

Senior Member

Join Date: Jan 2003

Location: Omaha,

NE

Posts: 283

Likes: 0

Received 0 Likes

on

0 Posts

Actually having cut foam wings for a very long time for CL combat models I dont think there is an easier way to get a straight light wing. Do a google search on foam wing cutting and there are lots of videos and websites with good advice on cutting foam. My son sells a video as a direct download on how to hand cut wings that a friend and I taped a few years ago. Bob

#10

ORIGINAL: icerinkdad

Actually having cut foam wings for a very long time for CL combat models I dont think there is an easier way to get a straight light wing. Do a google search on foam wing cutting and there are lots of videos and websites with good advice on cutting foam. My son sells a video as a direct download on how to hand cut wings that a friend and I taped a few years ago. Bob

Actually having cut foam wings for a very long time for CL combat models I dont think there is an easier way to get a straight light wing. Do a google search on foam wing cutting and there are lots of videos and websites with good advice on cutting foam. My son sells a video as a direct download on how to hand cut wings that a friend and I taped a few years ago. Bob

I built a CNC foam cutter and now foam wings are super easy.

#11

Senior Member

Join Date: Jan 2003

Location: Omaha,

NE

Posts: 283

Likes: 0

Received 0 Likes

on

0 Posts

I am glad you got your cnc machine to work... actually I take a great deal of pride in being able to find ways to do this hobby on a budget and have to tell you that the total investment to hand cut wings better than any can make from wood is under $100. Heck if you already have an auto battery charger its under $50.

Just some easy skills to learn and a few tools. If you want to know more about the video its at www.foamwingcutting.com as well as youtube

Bob

Bob

Just some easy skills to learn and a few tools. If you want to know more about the video its at www.foamwingcutting.com as well as youtube

Bob

Bob

#14

Senior Member

My Feedback: (3)

It cost me $7 to get set up to hot wire foam.

Well, I did have to replace the 120v light dimmer switch once after 15 years or so...plus there is the cost of the .020" stainless wire, so add another $2 for that.

When I'm done cutting foam, I hang my "foam cutting system" back up on a nail on the wall.

Well, I did have to replace the 120v light dimmer switch once after 15 years or so...plus there is the cost of the .020" stainless wire, so add another $2 for that.

When I'm done cutting foam, I hang my "foam cutting system" back up on a nail on the wall.

#15

Senior Member

Join Date: Jan 2003

Location: Omaha,

NE

Posts: 283

Likes: 0

Received 0 Likes

on

0 Posts

Gee mine is almost as expensive... bow is a dowel rod bent and wire is .012 or .015 control line 7 strand wire pulled out of the trash when someone here crashed a plane and decided to throw away the lines with the broken plane... power source is the output side on a 10 amp car battery charger I got from Sears 30 years ago.

Bob

Oh and btw I use either polyurathane glue for sheeting foam wings or epoxy. I prefer the poly glue but you have to remember to use wax paper as a "mold release agent" or you may glue the wings back into the shells as the poly glue foams and finds every little pore in the balsa wood. It does sand easy though....

Bob

Oh and btw I use either polyurathane glue for sheeting foam wings or epoxy. I prefer the poly glue but you have to remember to use wax paper as a "mold release agent" or you may glue the wings back into the shells as the poly glue foams and finds every little pore in the balsa wood. It does sand easy though....

#16

Senior Member

Thread Starter

My Feedback: (1)

Join Date: Jul 2008

Location: Fort Lauderdale, FL

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

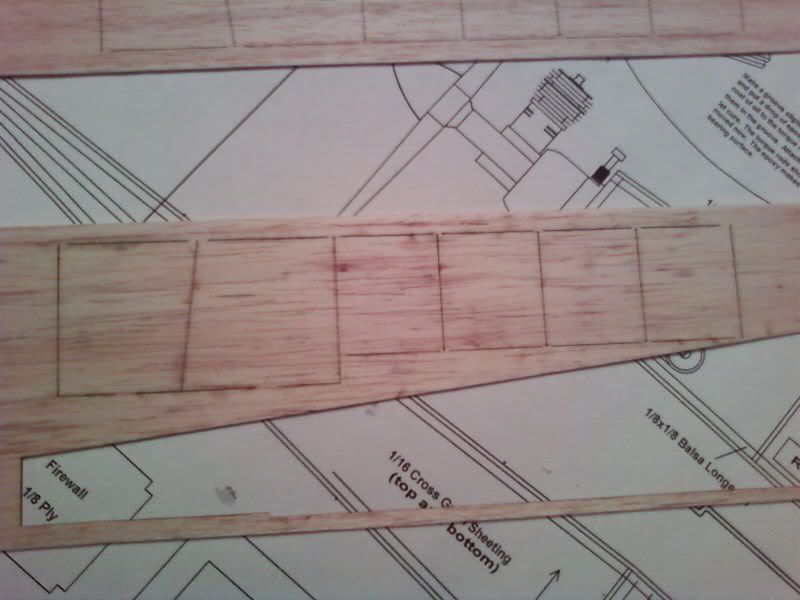

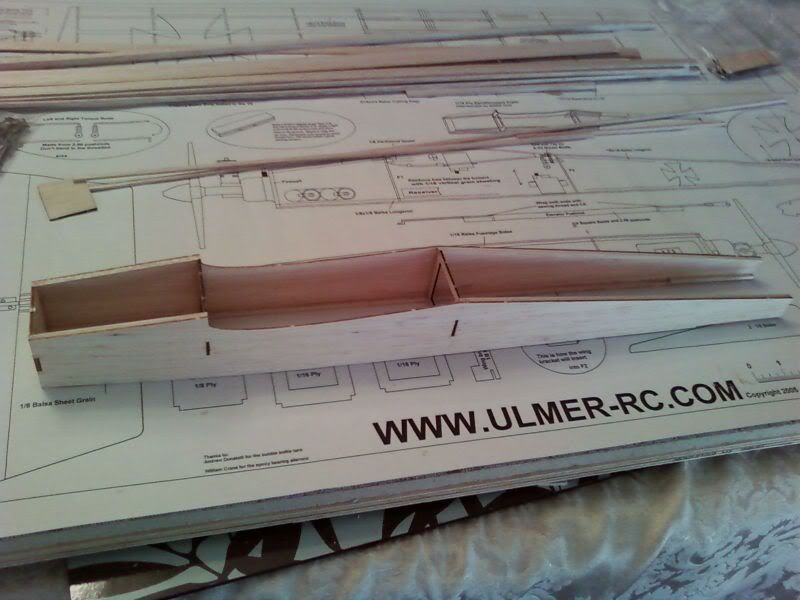

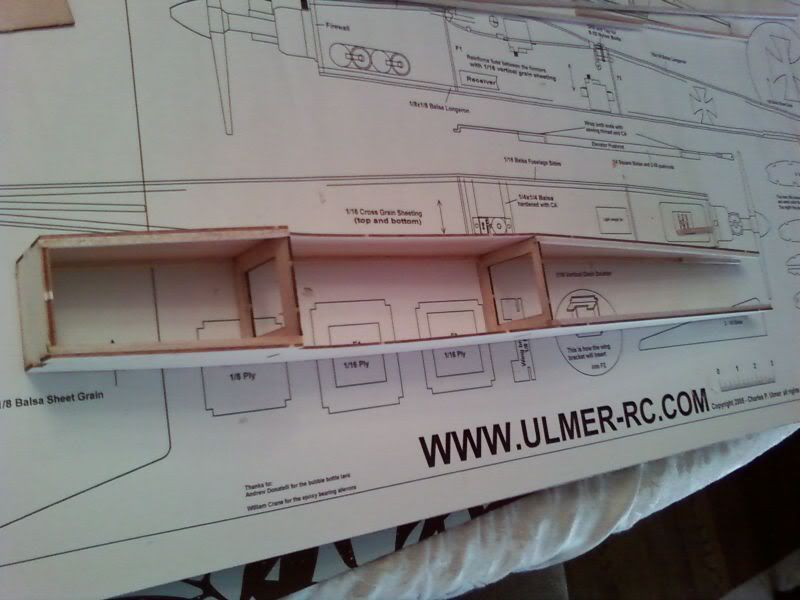

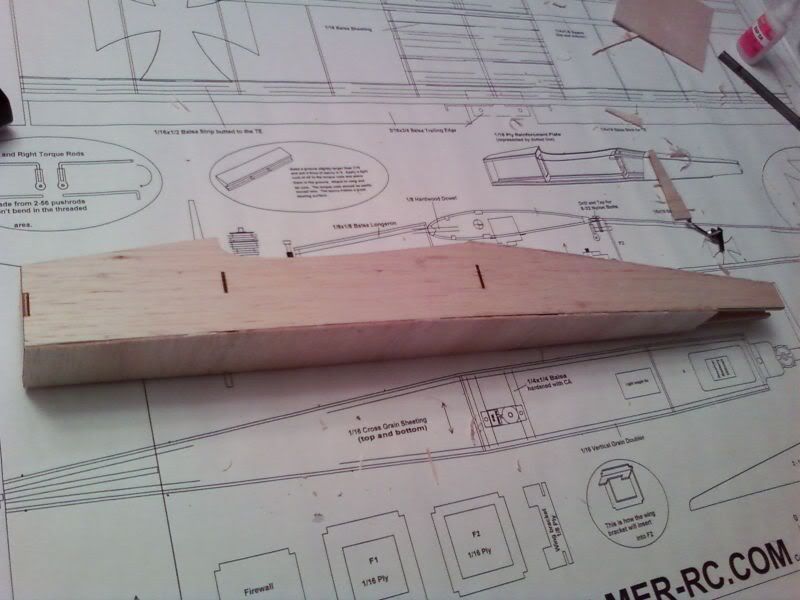

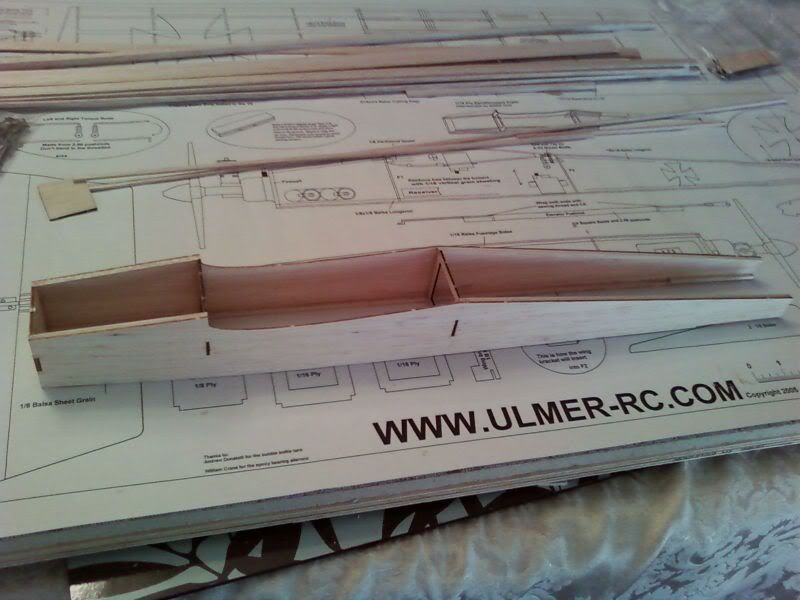

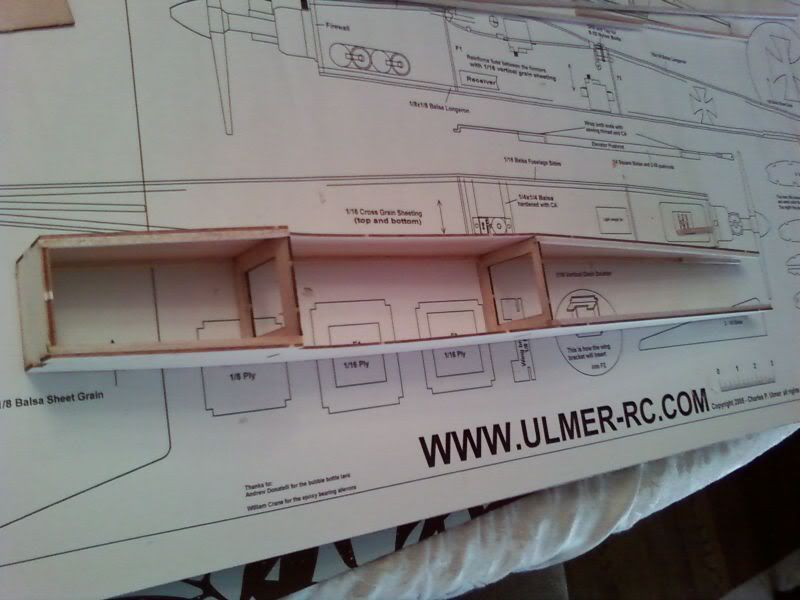

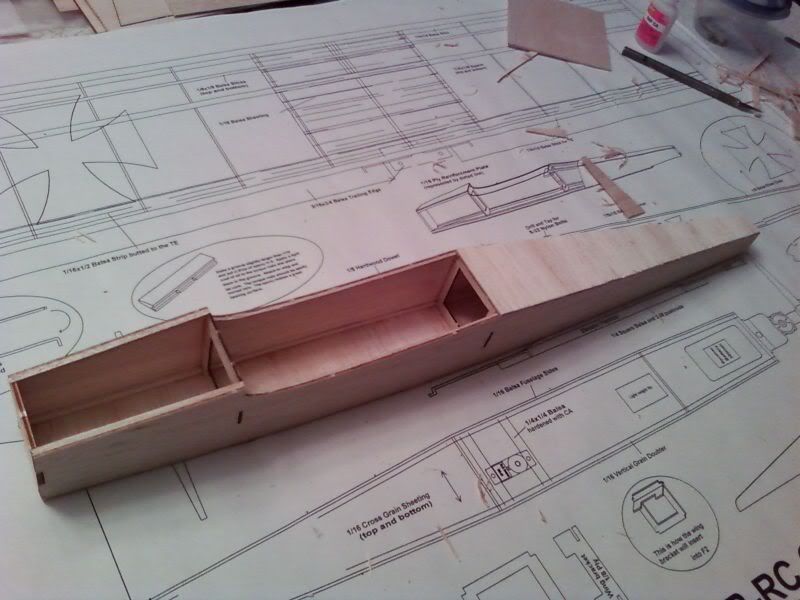

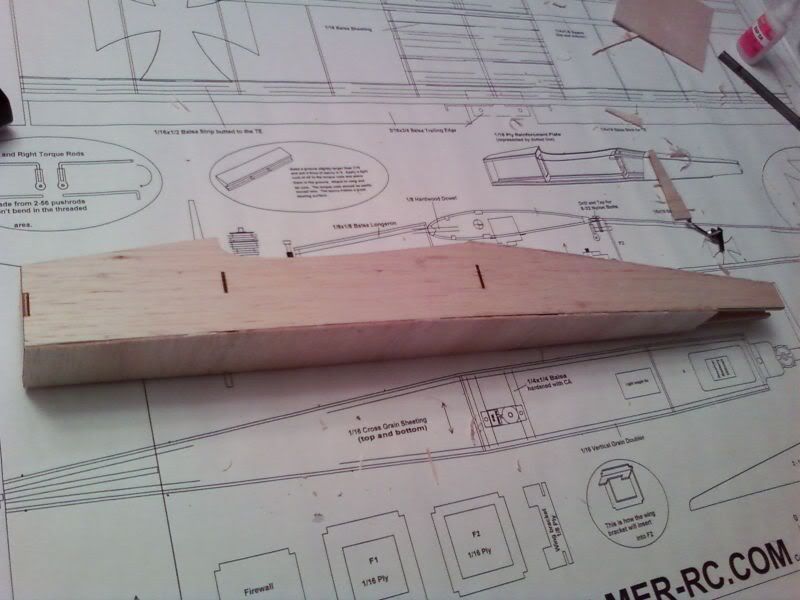

Alright guys, I've got most of the fuse done. I've already made some mistakes. Take a look at the chunks out of the sheeting on the top. I was trying to cut it nice, but the wood just seemed to crush there. Should I fill these voids or can I just cover over it? Do I assemble the empennage before or after covering? Is there a brand of covering that is better(lighter) for smaller airplanes? Thanks alot guys.

#18

My Feedback: (1)

The long parts are for the Strongback (Vertical) Spar. The wing ribs may not be notched to match. You can choose to notch the ribs or cut the spar into pieces and fit them between the ribs.

The 1/16th sheet pieces are the front fuselage doublers. Put all the parts on the plan and you will see. The grain goes opposite way to the fuselage sides and fit between the 1/8th stringers

The 1/16th sheet pieces are the front fuselage doublers. Put all the parts on the plan and you will see. The grain goes opposite way to the fuselage sides and fit between the 1/8th stringers

#19

Senior Member

Thread Starter

My Feedback: (1)

Join Date: Jul 2008

Location: Fort Lauderdale, FL

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

Ahhh. I see what you mean with the reinforcing sheeting. I'm making this alot harder on myself than need be. I had cut sheeting for the reinforcing already.

I'm still not clear on exactly how the wing pieces go. I don't believe the ribs are knotched for them. If I cut them do I put them between the ribs and between the top and bottom 1/4 x 1/8 spars?

Thanks so much,

C

I'm still not clear on exactly how the wing pieces go. I don't believe the ribs are knotched for them. If I cut them do I put them between the ribs and between the top and bottom 1/4 x 1/8 spars?

Thanks so much,

C

#21

Senior Member

Join Date: Jun 2009

Location: little river, SC

Posts: 133

Likes: 0

Received 0 Likes

on

0 Posts

Hey BipeFlyer: If I send you the templates, will you cut and ship wing cores? Just curious, as I designed a sport pattern ship a long time ago, and still have the templates. That thing was a monster, and I'd like to build another, but don't want to go to the trouble of building a foam cutter, and my shop space is too limited for it anyway. I have formica rib (sectionals) templates and a planform layout that translates to CNC from a Post-it note, so it's an easy core to cut; I just don't know anyone that'll do it around here.

#22

I would need cut files for the foam cutter - I can't cut from templates. The biggest problem would be shipping, which is why I quit making short kits. The wings get charged as an oversize/underweight item and when shipping to the states it gets pretty expensive.

#23

Senior Member

My Feedback: (1)

ORIGINAL: combatpigg

It cost me $7 to get set up to hot wire foam.

Well, I did have to replace the 120v light dimmer switch once after 15 years or so...plus there is the cost of the .020'' stainless wire, so add another $2 for that.

When I'm done cutting foam, I hang my ''foam cutting system'' back up on a nail on the wall.

It cost me $7 to get set up to hot wire foam.

Well, I did have to replace the 120v light dimmer switch once after 15 years or so...plus there is the cost of the .020'' stainless wire, so add another $2 for that.

When I'm done cutting foam, I hang my ''foam cutting system'' back up on a nail on the wall.

and I can vouch for Bipe on the postage...I sent AJ some stuff years ago and IIRC it was like $16 postage to get across the border to Canada,and I think the price depended on what you listed it as,,not positive on that but the lady told me it was best to label it as a toy....Rog

#24

Senior Member

Thread Starter

My Feedback: (1)

Join Date: Jul 2008

Location: Fort Lauderdale, FL

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

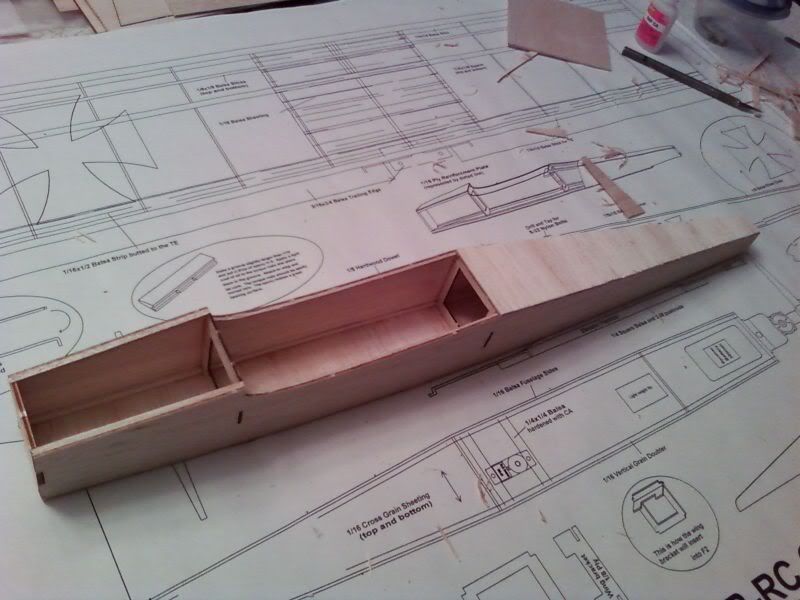

Well, here she is in all her glory. Total weight at 11 3/8 oz. I think I'm going to name her "The Nag" after the way my wife (the neat freak) was while the project was going.