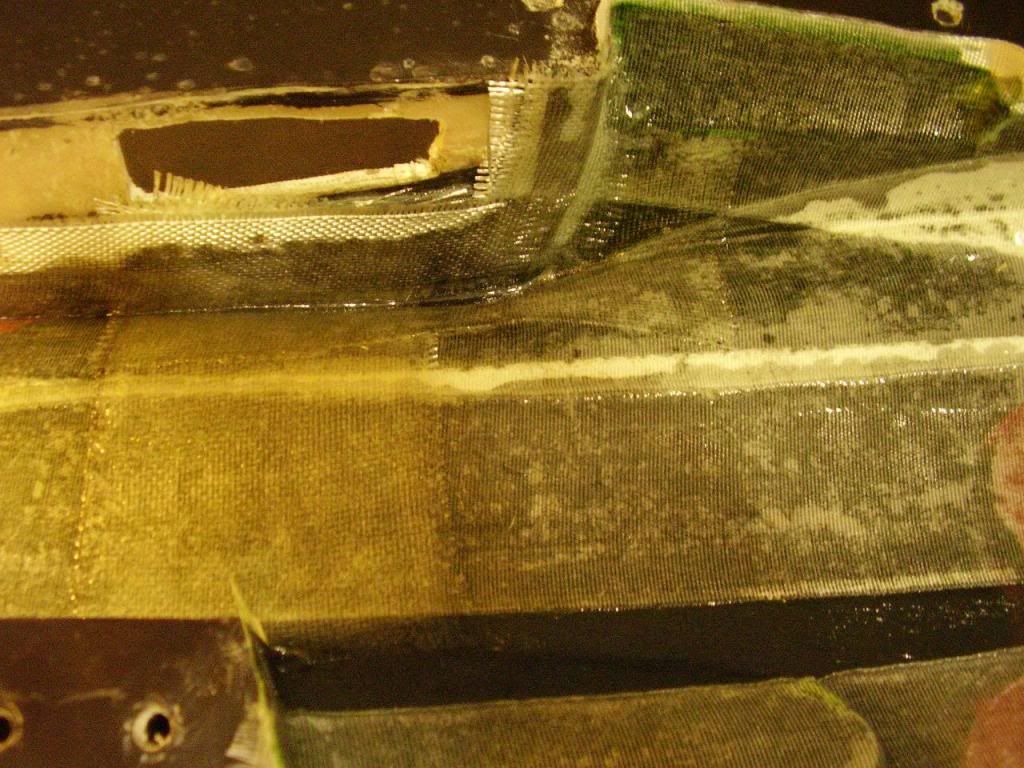

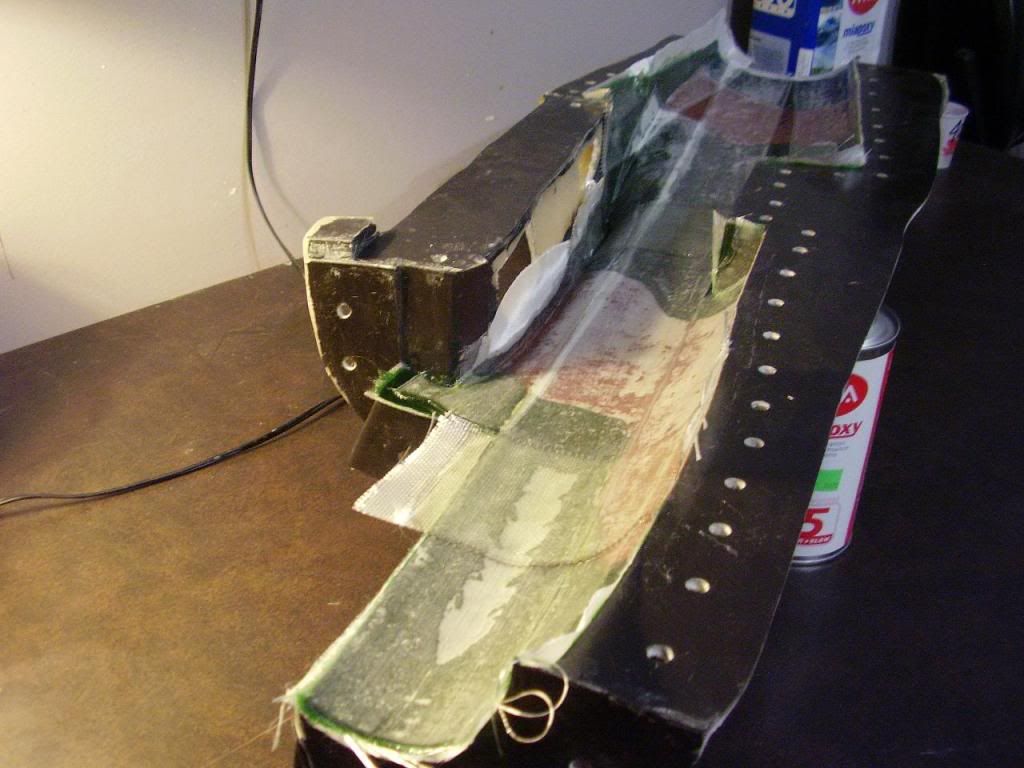

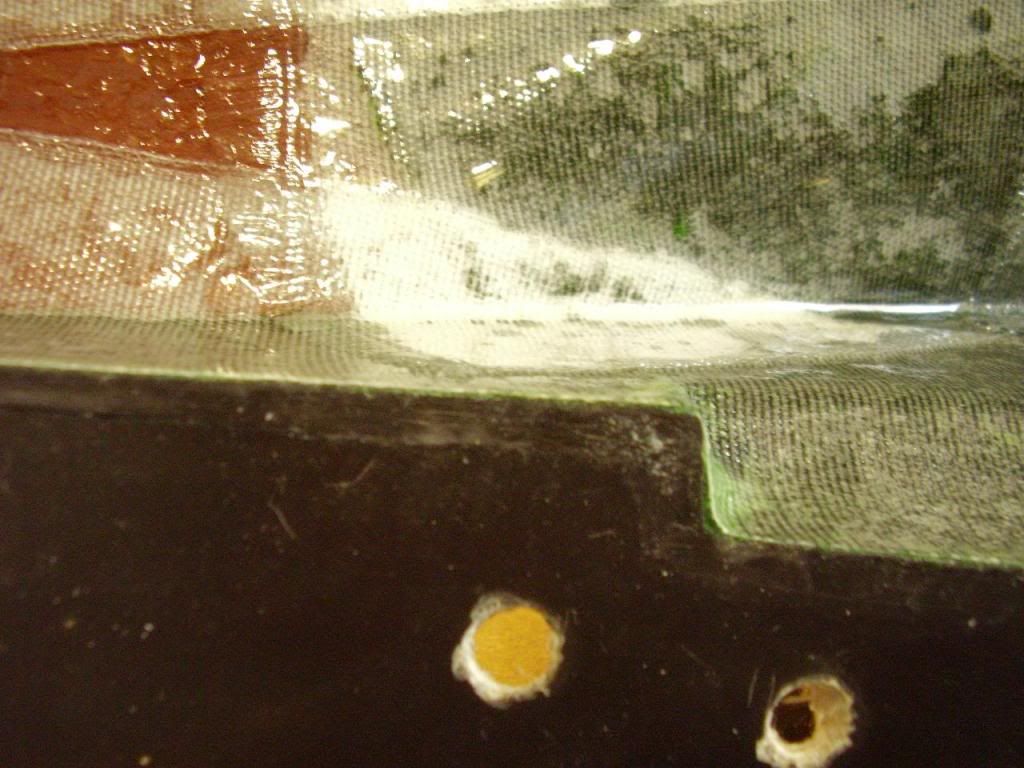

OK time to do a 'splainin' - what am I doing!?There are a few things going on here at once but I'll do my best to take some time and explain my approach. I could lay down 2 layers of 6 Oz cloth, peel ply, blotter, bag it, and be done with it. Does that sound like me?? HECK NO!!No, I want to capture that late 20th century, industrially manufactured, moulded-in, toy-like, monotonal opaque plastic look that people are drawn to and they don't know why.The other thing I'm trying to do is make an airframe with a factor of safety of 1.1 - what's that mean? - that means just strong enough and that's it.The main intent here is to saddle the firewall to the wing. In the following photos you can see where I've added 2 layers of a heavy 9 Oz cloth where the firewall and also the wing mounting blocks at the rear of the cockpit will be installed. Essentially they are 4" wide composite integral bulkheads. They are directly connected again by 9 Oz cloth through the chin plate in the firewall subassembly and also 2 layers of heavy cloth in the aft portion of the wing saddle.Another concern are tail loads. Pitch loads are handled pretty well by the inherent "egg" cross section of the rear fuselage, but this capacity will be greatly enhanced when the port and starboard subassemblies are joined using 1" stips of 9 Oz cloth.Yaw loading is transferred down the sides of the fuselage wall through and into the reinforced wing saddle by the 6 Oz tape that I've also overlapped along the centerline to form an integral longeron for additional beam strength.If you look closely you will notice that there are areas where the fuselage will be only the thickness of the saturated cssv that forms the camouflage surface. Will this be enough?? Honestly, I don't know. That's why I tried it in a couple of small areas that are supported peripherally. I can say this much - I expect it to be as puncture resistant and as strong in tension as any iron on film.I've also improved the flow through the integral exhaust manifolds.