Originally Posted by

Pull Up Now!

Gus (Mtnflyr), thanks for the great photos, and the plumbing diagram. Interesting divergence of thought on how to plumb the tanks! Have any of the folks in the parallel school of thought had any issues with uneven fuel usage between the two tanks? If parallel, it seems like it would be best to locate the Y connector between the two as close the the tanks as possible to minimize any differences in flow rate. Also, the Greg Moore review didn't offer any info on tank plumbing. I know Joe Grice, he lives near here. I'll shoot him an email about plumbing just for kicks. Lots of people recommend Hysol 9462, which just seems like structural epoxy. How do you say JB Weld???

Anyway, seriously the cost is TEN TIMES what 30 minute epoxy is. Add microbaloons for viscosity if needed. The Greg Moore article says that goop is ok, too. Or even plain old silicone caulk.

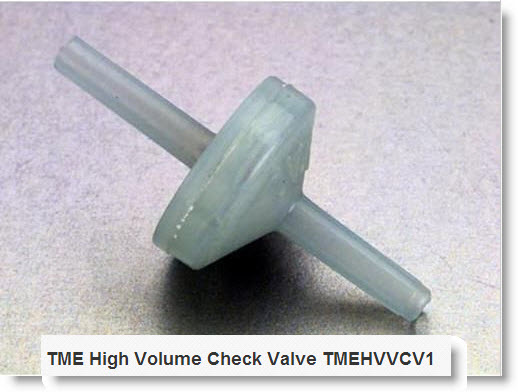

For the vent, on gasoline engines I've always terminated the vent line with one of these TME check valves. They completely prevent leaks inside the plane, and take no pressure at all to draw fuel through because they contain a flapper reed valve. It's not the ball-and-spring affair where the fuel draw has to overcome the spring tension. Does anyone see any issue with using these for turbines, to terminate the vent(s)?

Who sells these check velves. I,m too lazy to look it up.