Originally Posted by

FlyerInOKC

Could you tell where the slop was occurring?

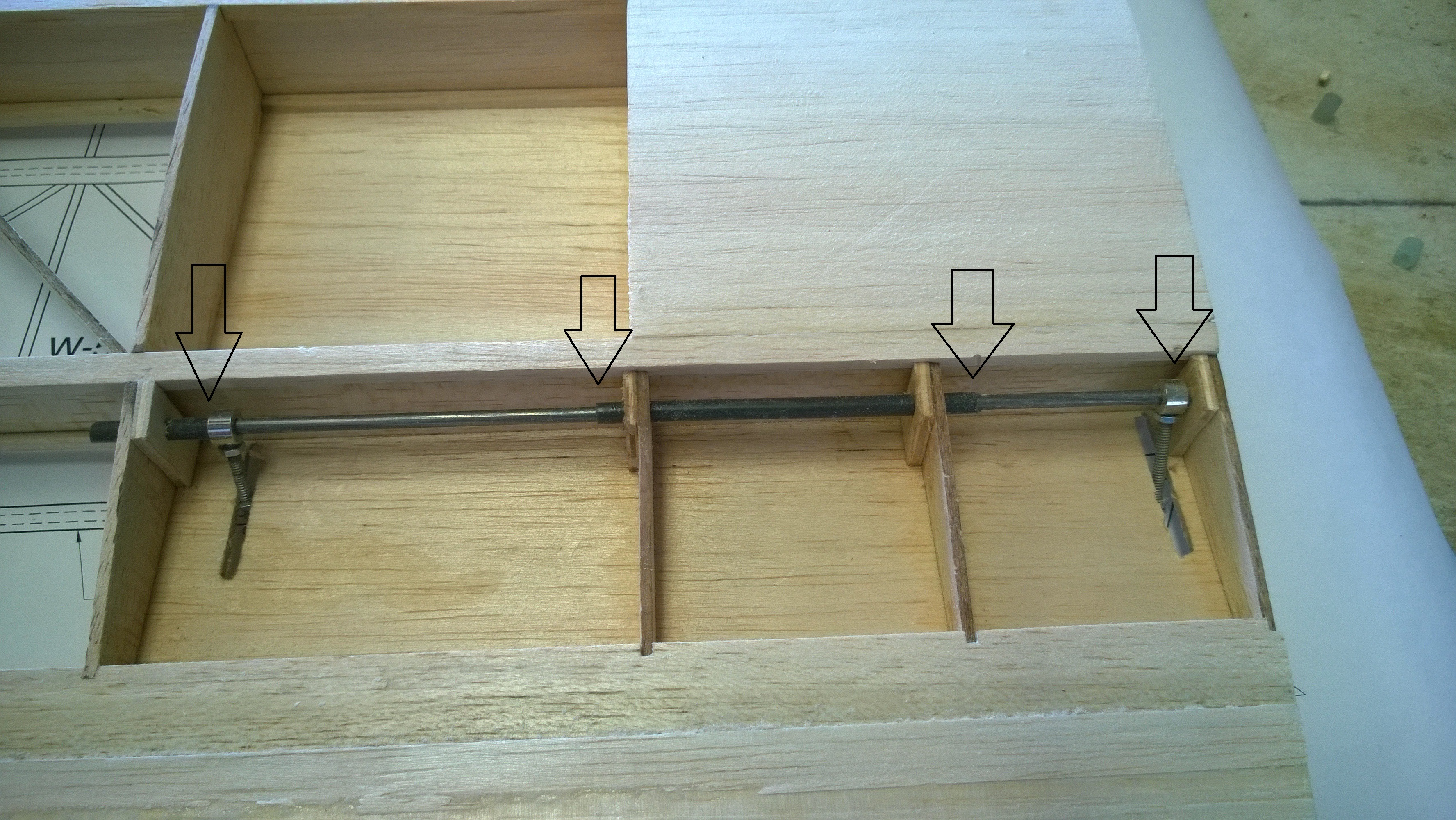

I could see the "slop" at the bearing surface of the horizontal rod that connected the two 4-40 size horns that came out of the collars. lets see if I can do a better job of explaining. In the pictures you see a 4-40 screw in each of the collars at either end of the horizontal rod. After I attached linkage to those 4-40 screws which were about an 1-1/4 long, the leverage created at the collar was enough to make the horizontal rod jamb against the side of the nylon tubing I used as the bearing surface. It was a good fit but not really snug enough because it moved laterally. Which allowed about a half inch of free movement at the end of the lever where the linkage to the aileron was attached. The slop was enough that I could move the ailerons almost 50% of their travel before the servo would move. Some "give" in the linkage was expected but this was way too much and I need that linkage to be solid in order to trust adjustments when I fly this thing the first time. Adding to the problem is the lever on the aileron is real short.

Long story short there were just too many opportunities for slop in the system and it had to go. I thought about ny-rod but there is actually a lot of slop in that as well and I would have had to plumb it through an already sheeted wing with a very tight curve.. My only choice was to go ahead and move the servos out under the wing which gave me a straight shot with simple linkage hookups. I'll do some pics tomorrow and show how I have the linkage setup.