I bought a SIG Rascal 110 ARF last summer as soon as they came in. About a week ago, I bought the servos & various things to get her together. Everything in the picture below except for the "woodpecker", 15 X 5 XOAR propellers & black nylon 1/4-20 wing bolts is for the Rascal.

The goal it to build it as light as reasonably possible & power it W/a hopped up high compression Saito FA-180 burning glow fuel W/CDI. The engine should be capable of 8400+ RPM (static) W/an 18X8 prop so if I can keep the weight near 12#, it should have impressive vertical performance.

The 1st thing I did was pull the Ultracote from the bottom of the fuselage. I want to make a hatch just behind the firewall to access the CDI module. I may or may not install a 2nd hatch aft of the CG if I need to shift weight W/battery packs. I'm hoping to avoid that.

Another change I am making is to mount the elevator servo under the wing. I am using a Hitec HS-645MG for the elevator & rudder & wanted to avoid the weight in the tail.

I peeled back the Ultracote on the starboard side under the horizontal stabilizer. I then filed an oblong slot at the top of the factory servo mount hole to allow the installation of the outer tube for the Sullivan high stress nylon pushrod W/4-40 ends.

After gluing the tube in the hole W/CA & adding some balsa fill under it, I mixed up some micro-balloons & epoxy to fill around & anchor the tube.

I made anchor blocks out of 1/4" balsa & glued them to locate the tube behind one of the fuselage stringers for aesthetic purposes.

By routing the tube to the opposite side of the fuselage, there is a very gentle curvature to the tube & the pushrod operates freely.

After letting the epoxy/micro-balloons set up overnight, I sanded the tube flush W/the fuselage.

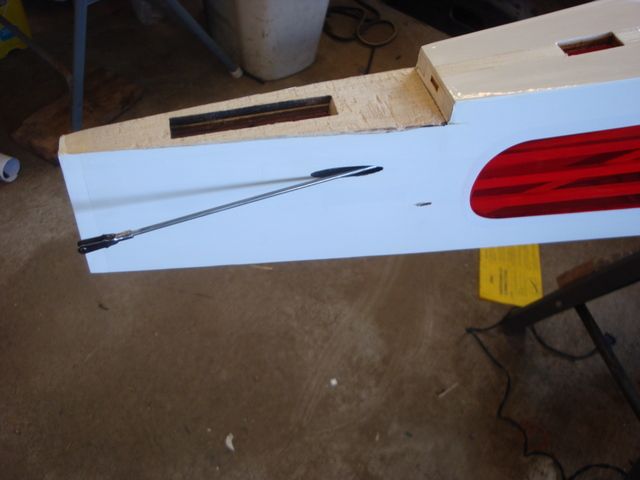

Here is the final result after re-attaching the Ultracote.

The large diameter semi-ridged nylon portion of the pushrod seen here is hidden a few inches inside the tube when attached to the elevator.

Next step is to mount the engine so I can plan out the hatch & location of the ignition module. I may also have to make modifications to the firewall to allow the muffler to point down & centered.