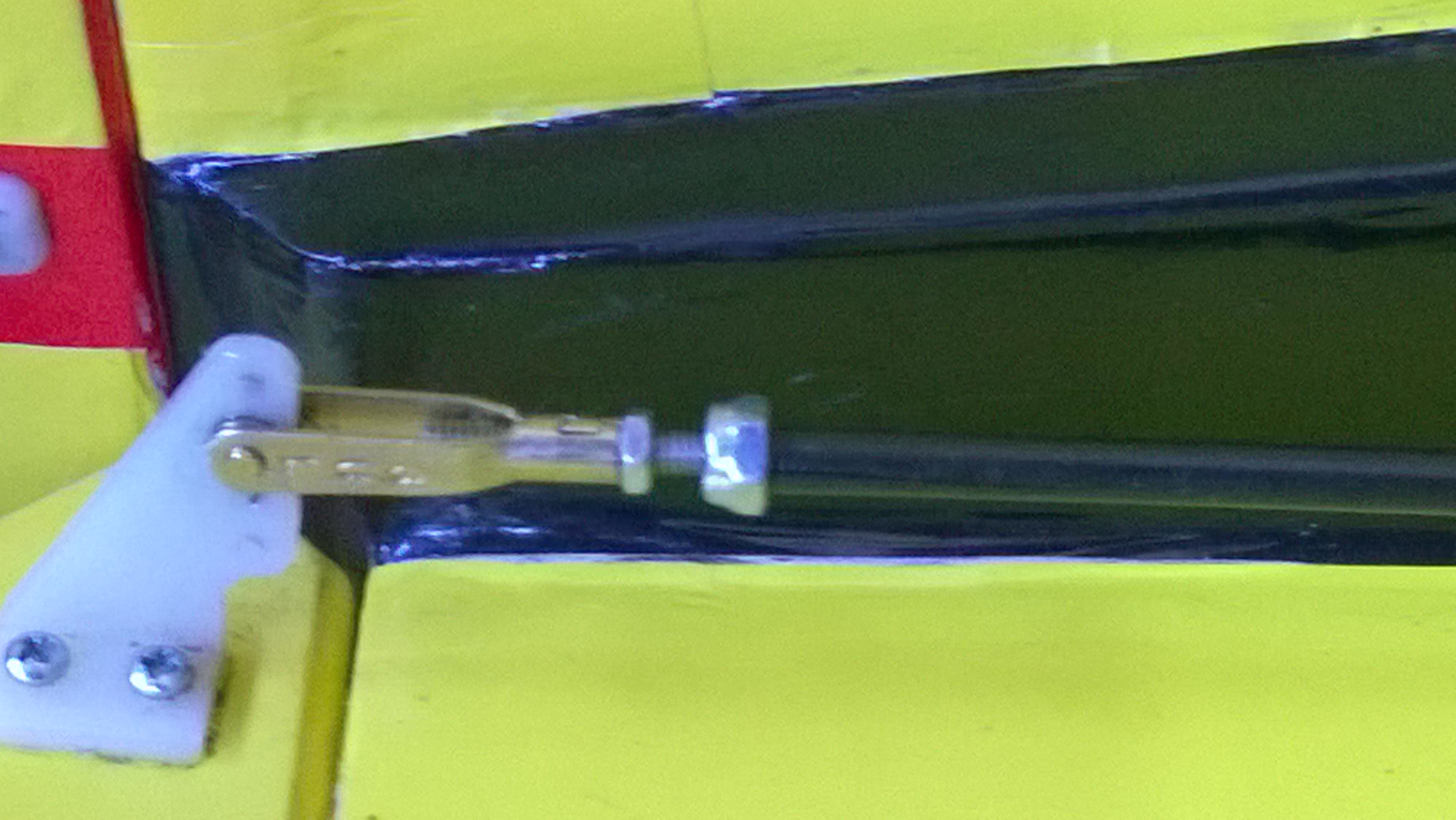

I'm sorry, I just can't resist. Even though this is a more expensive setup I have to tell you guys it has the least flex of any I have used. The application is limited though because it is so rigid. The picture is my homebuilt Sport P38 where the elevator pushrod is on the outside of the fuse. The servo is housed in the radiator bubble about 8 to 10 inches away from the elevator on the side of the boom. Any other setup I tried had too much flex or needed a support or just plain ugly.

So this is what your looking at......A black carbon fiber tube with a threaded rod through the tube made up at each end with a nut and a washer. Just tighten up the nuts against the end of the tubing and the whole assembly is very lightweight and does not flex hardly at all. Best of all the threaded rod is available at both ends and I can use any attaching system I want that threads on. The other end of this one has a ball link on the servo arm, this end is set up for easy adjustment. Best of all very very very little play in the system.

I scavenged the carbon fiber out of an ARF that crashed and I know carbon fiber is spendy which is why I cautioned it was a more expensive setup. But so far I've used it whenever I could and I love the threaded ends without having to worry about a soldered end coming loose. If it has a downfall it is that the threaded rod that sticks out has to be short as it does not stand up well to compression, but if it is a straight shot from servo to horn it is a great contraption.