If you do IR battle or use your tank a lot and if you run it outside you will need to take a much more serious approach to PM (Preventative Maintenance) than the tanker who runs indoors and just a few times a month for fun. Being "anal" about PM myself and having been a mechanic for 35+ years let me ask a simple question...Would you run a manual transmission or rear-end/differential in your car/truck without oil...NO.

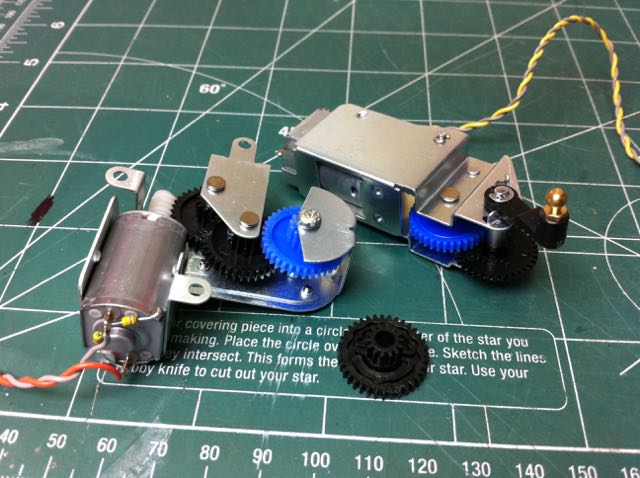

TUs: The shafts, bushings/bearings need a easy flowing light machine oil (Never WD40) and the faces of the gears (which see much less friction and heat) need grease. Oil will be flung off gear teeth quickly with centrifugal force. Both oil and grease are needed. Drip the machine oil (needle oiler is best & spray is OK) in by tilting the tank sideways. Then work the oil in by hand rotation of the TU. DO NOT DRIVE THE MOTORS...aerosol fumes may cause a fire! Then grease the gear teeth. Hand rotate again. Remove any excess. I use white lithium grease spray with 4 inch tube tip. The lith turns dark brown when it gets dirty and the light color makes is easy to see/check for coverage.

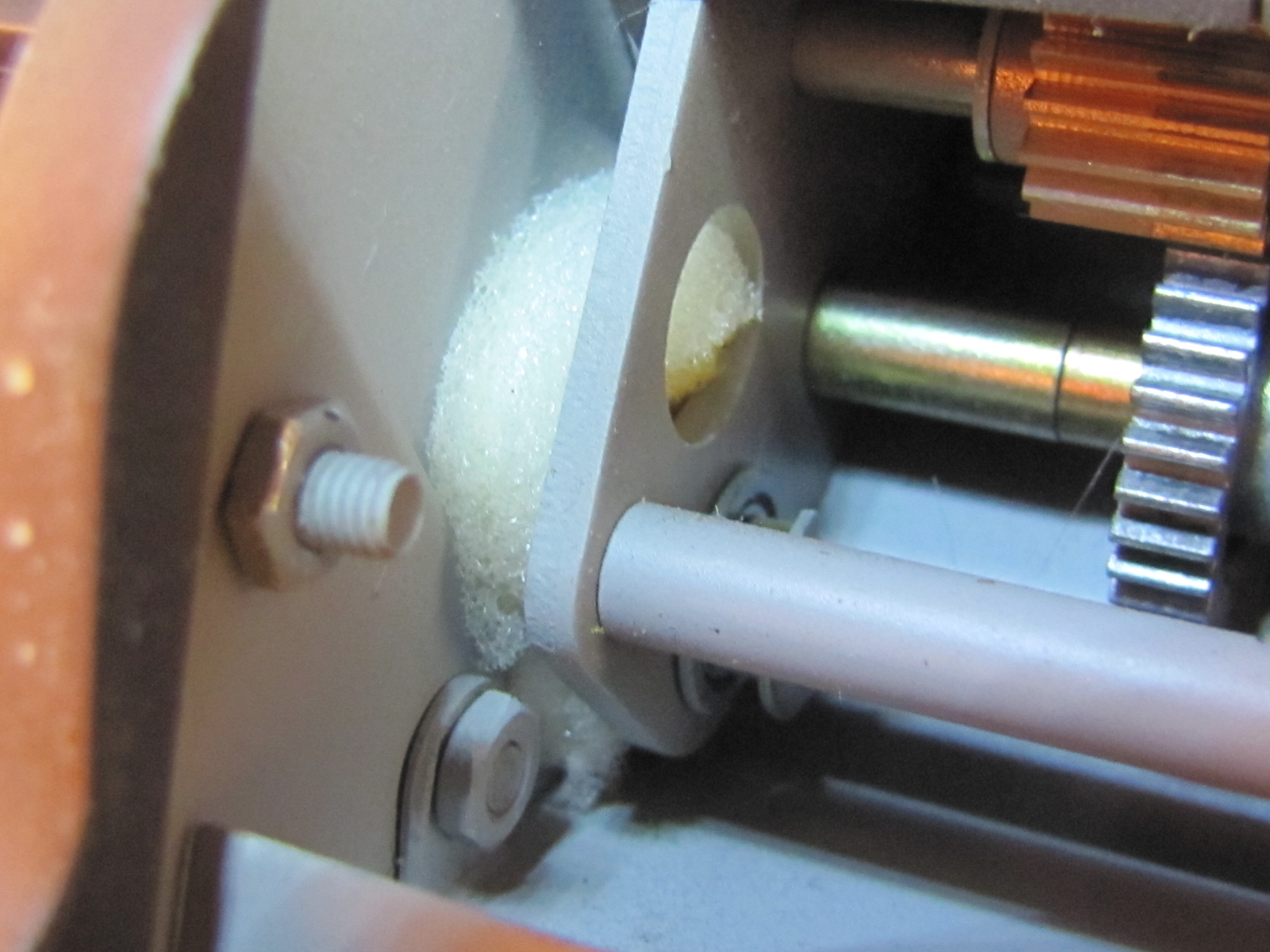

I have been battling my Panther for 7 or 8 years now and I have only wore out one right (at 4 1/2 years of use) and one left gearbox (at 7 years). The TUs were Tamiya and well maintained. I run it at every battle day I am now on my 4th set of tracks having worn the first three sets completely flat down to the nub. Your TUs should also be sealed off from the outside at the output shaft for the drive sprocket. I used dense foam to form a gasket type seal. Then seal off

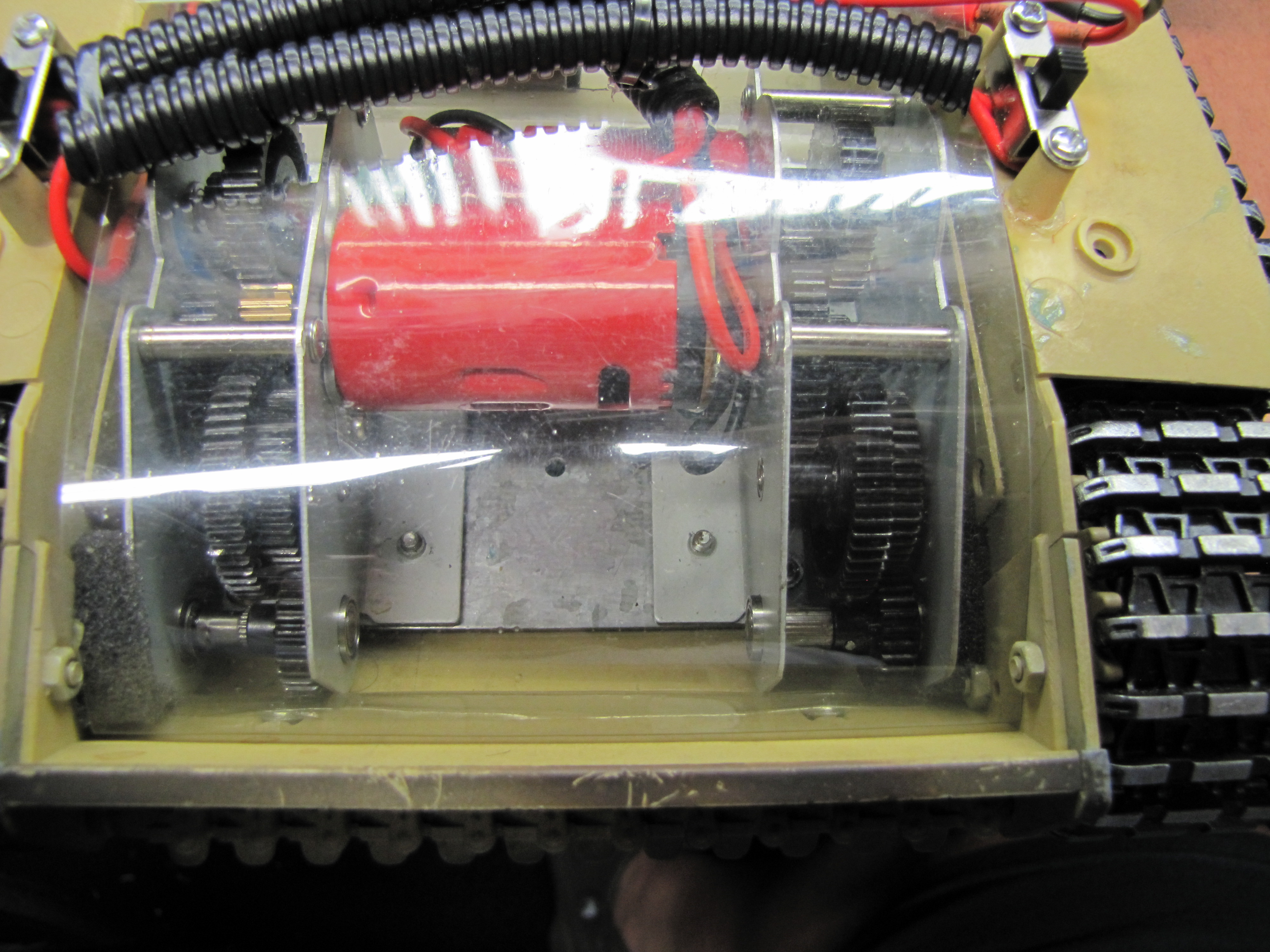

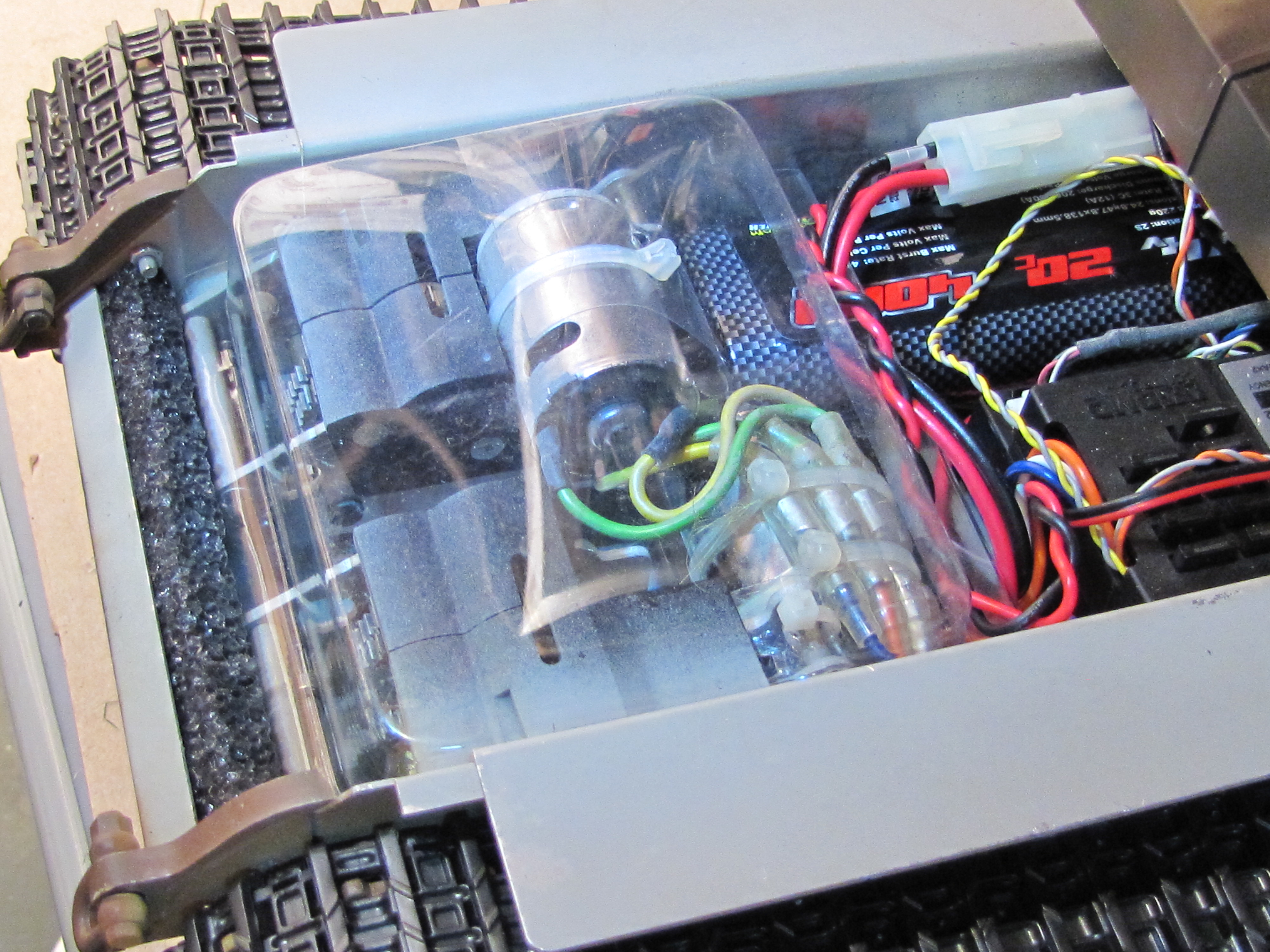

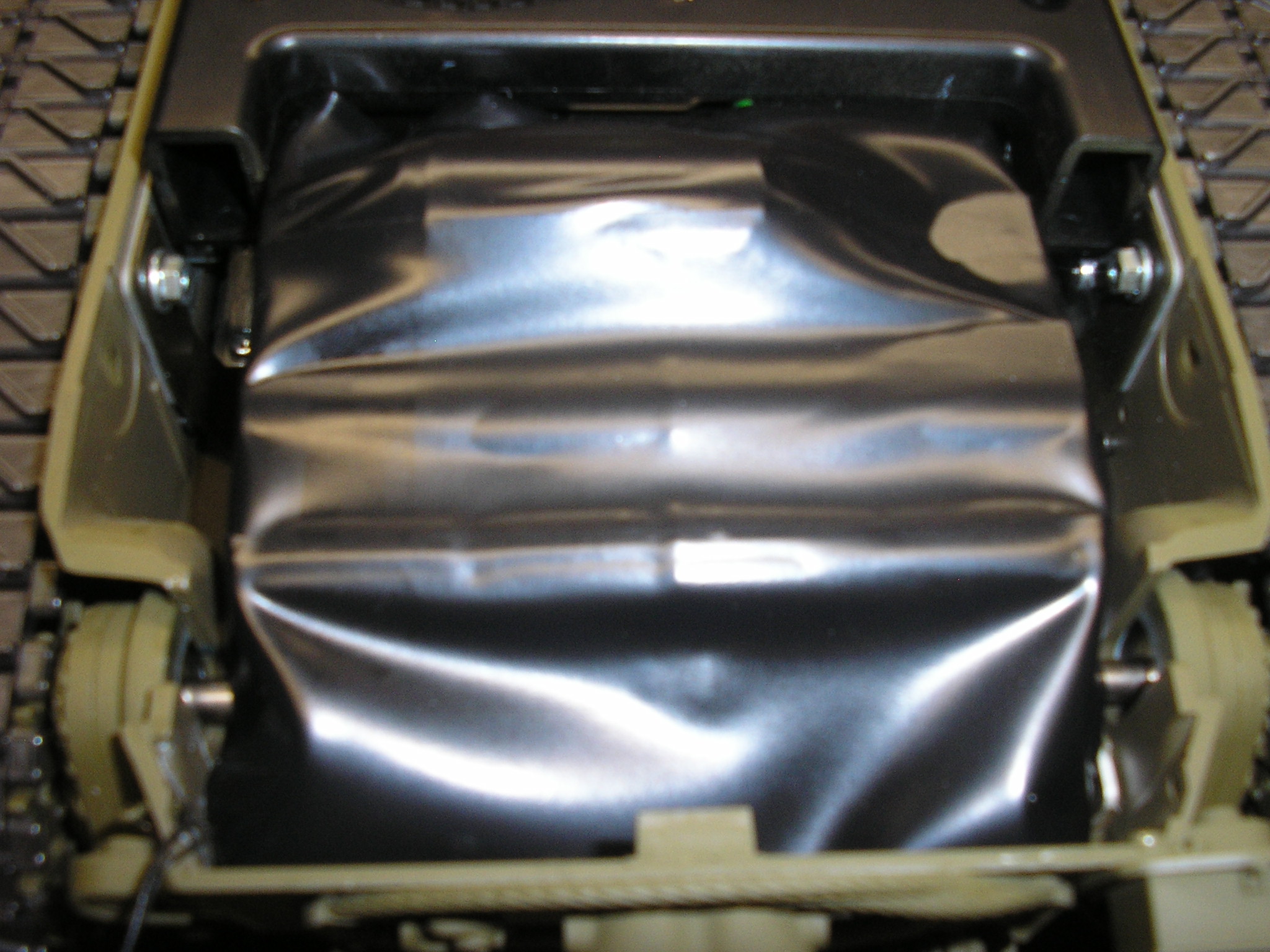

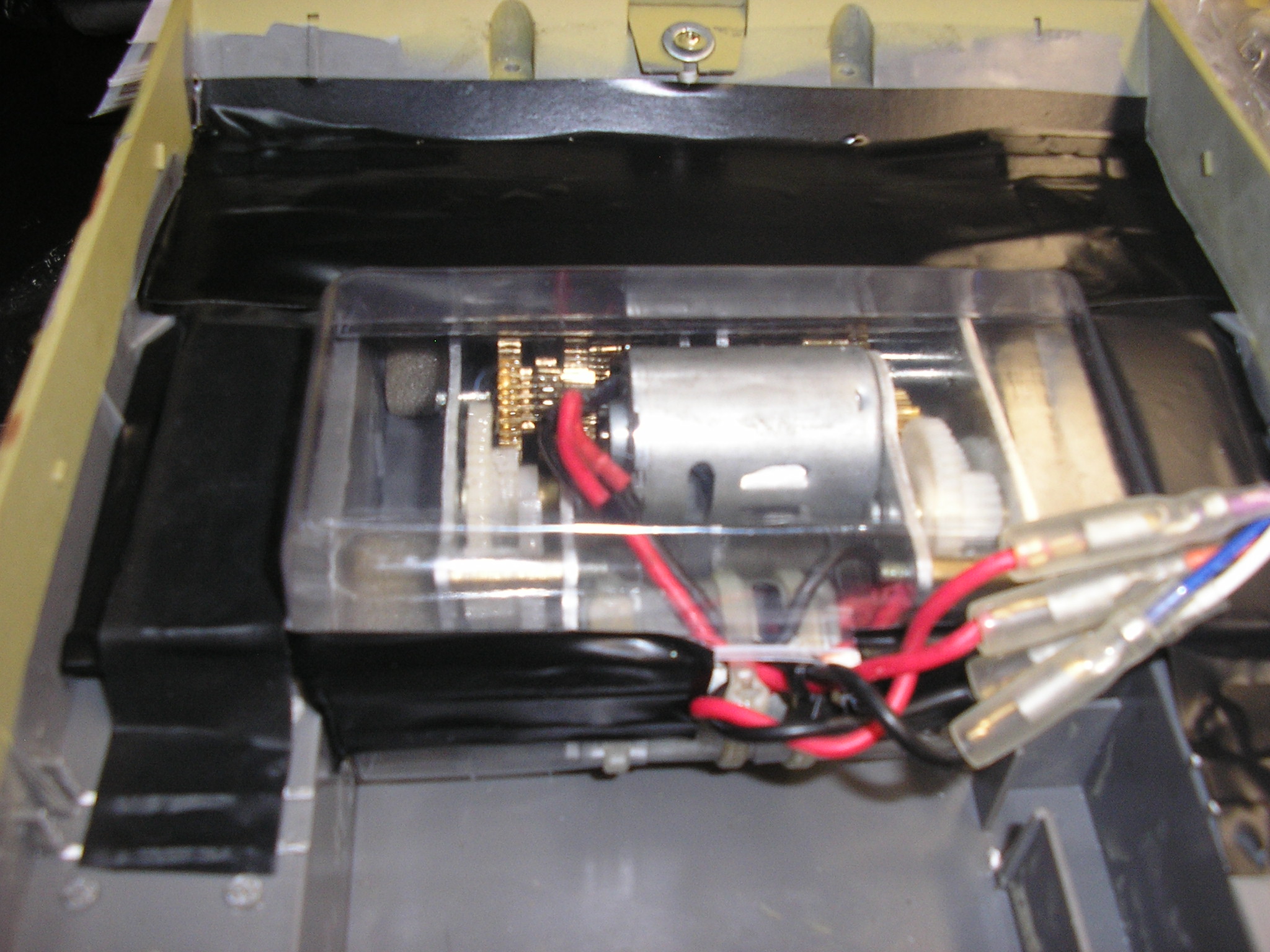

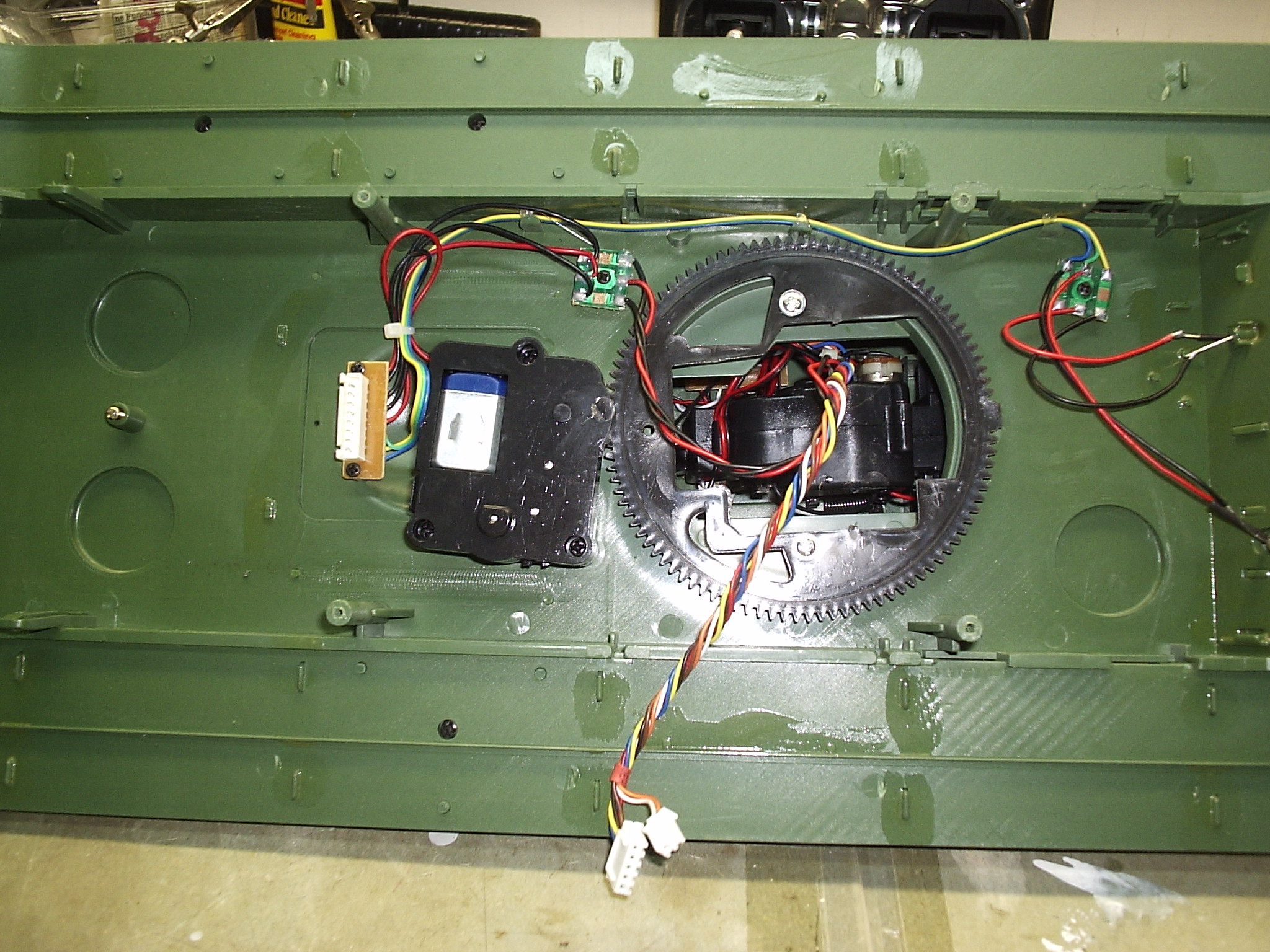

and cover the TUs from the rest of the tank. This keeps the grease and oil lube in the TU bay and the dirt out. It also keeps loose errant wires out of your gears and any screw or debris from getting into the gears and jamming them. Covers can be tape, sheet metal, clear plastic or a combination thereof. See pix.

Tracks: Remove rocks, grass, twigs, snow etc... after each run. Hold it up and drive the tracks to cast off debris. Avoid driving in tall/wet grass, pebbles & wood chips. Some tanks have zero track pin issues and some are always headaches. Most are plastic tracks. The worst are the Tamiya Tiger I & KT(check after every battle or replace with metal tracks if you use it alot) and the HL Pzr III & IV tracks (CA the ends). Stock HL Tiger tracks are very brittle.

Wire Hygiene: Keep them neat, clean and properly routed. Don't go crazy with wire ties.

Bind the wires too tight and they won't flex like the should. I use tape to keep many wires together, along with thin craft wire, and sparing use of wire tires.

Check this link:

http://www.rctankcommand.com/before-...er-photos.html It will give you some ideas too.

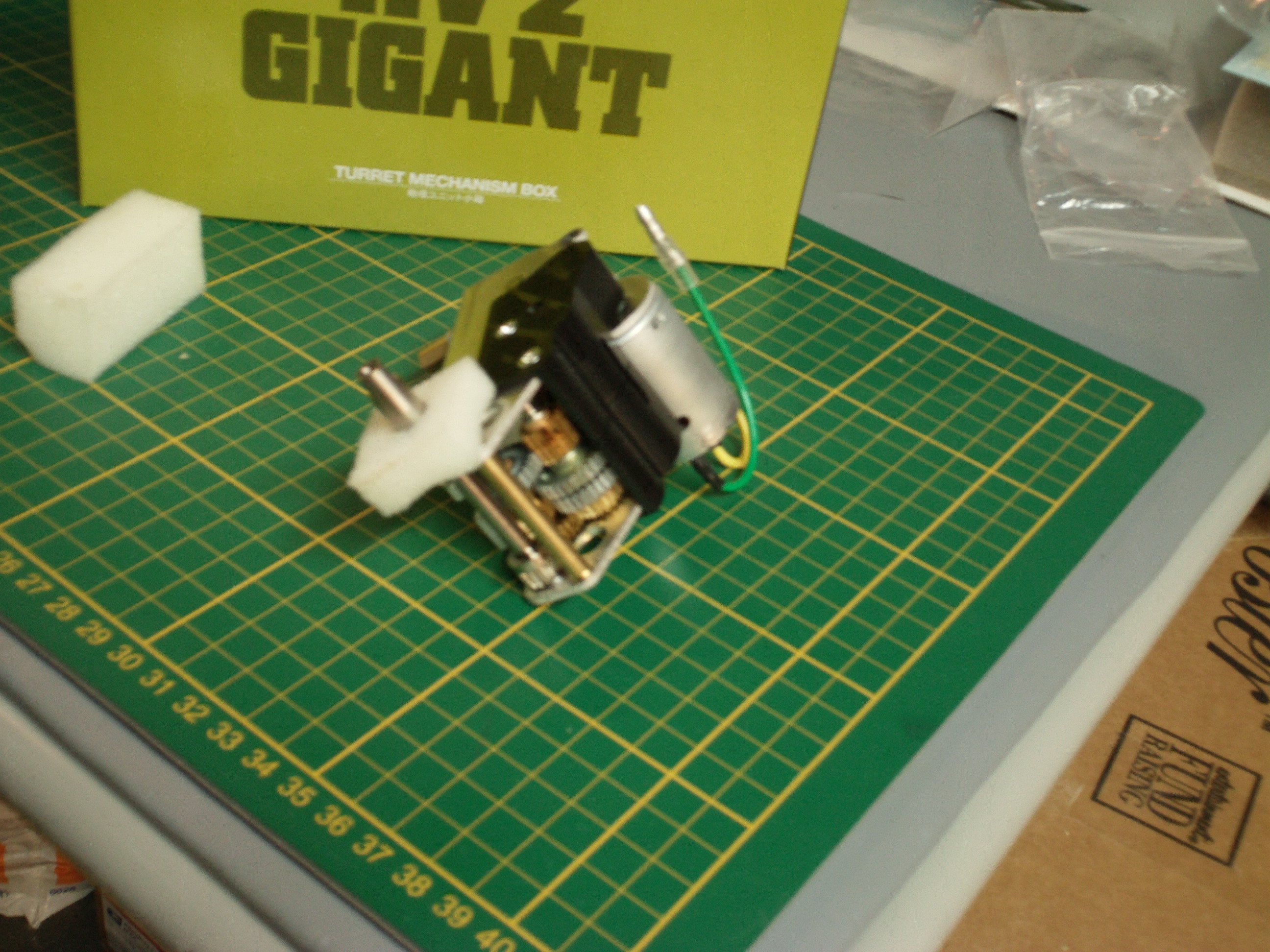

Rotation & Elevation units: DO NOT GREASE anything pertaining to turret rotation. These are not high wear items. For Tamiya tanks, I weld all the slipper gears solid with a soldering iron on my elevation & rotation units. You can Ca them too ...or is you like to spend money, buy the Tamiya blue gears. HL/Taigen units are both sealed inside a enclosed housing. Only lube in that housing.

Batteries: Keep them from knocking around inside and charge them outside the tank. Disconnect when not in use.

Always put your tank on a block when the battery is blipped in or working on it to prevent a runaway.

If you travel use a tool box for a carrier. Husky, Black & Decker etc... 22 inch boxes will hold most 1/16 tanks, The TX, Batteries & apple. Use padding to cover the tank and bag the radio in a large zip-lock. Remove the apple from the base (be sure tank is off) and secure it in a zip-lock or small box. My tanks travel 1100 miles round trip to Danville 5 times a year.

PL is critical to having a reliable, clean tank which will last long and retain resale value.

See my website for some before & after pix: I rehabilitate about 50 customer tanks a year to keep them fit for duty.