Originally Posted by

rtn9105

I picked up a used Kadet Senior Sport ARF a couple weeks ago that I'm going to setup with a Rimfire 55 motor that I had. The plane had originally been setup with glow power so the firewall has been coated with fuel proof paint, unfortunately the centerline marks on the firewall are covered with the paint. I ordered one of the electric motor boxes for the plane from Sig, can anyone tell me if the box just gets centered on the firewall or if there's a thrust line location I need to find before mounting the motor box?

I Googled up the Senior sport ARF and got this from a builder who put a different engine in that did not fit the designated mounting holes:

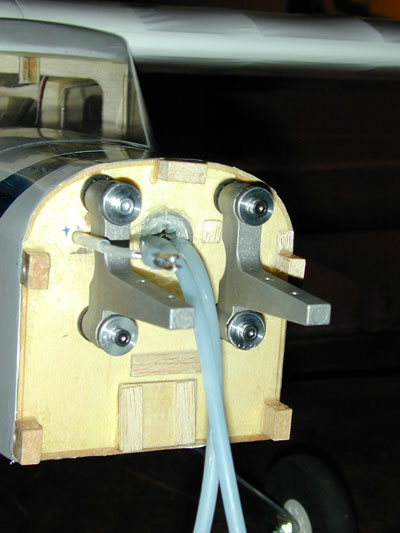

"I hate airframe vibration, so I’ve tried several vibration-reducing engine mounts over the years. This time, I’ve chosen DU-BRO’s .50-.75 2-cycle vibration reducing aluminum motor mount system. $25 is quite a bit to spend on mounts, but when I saw the quality of these, I felt it was worth it. I soaked the elastomeric (rubber) elements in fuel, according to the instructions, before inserting them into the mounts. I like to tap the mounts for the engine mounting bolts, and I did so here with a #36 drill bit and 6-32 tap. Before doing that however, I played around with balance, and ended up moving the engine a bit forward from the distance specified in the instructions. I knew this might affect the pre-drilled cowl, but I was determined to balance the aircraft without adding dead weight. I epoxied some balsa blocks to the firewall so the cowl could be mounted further forward, while still using the pre-drilled holes in the cowl.

Since these mounts are much bigger than those supplied with the Senior, I couldn’t use the pre-drilled holes in the ARF’s firewall, or the pre-installed blind nuts. I filled the holes with balsa and epoxied over them to fuel-proof. I also filled (or covered with pieces of balsa) and fuel –proofed all of the pre-drilled holes in the firewall, as they’re not needed for the nosegear and its pushrod. I had already rubbed CA all over the firewall for some fuelproofing.

Now the task was to determine where to drill holes for the new mounts. Here’s how I did it:

1) Tape or tack glue the engine temporarily onto the mounts

2) Test different possible positions and see how the mounts fit on the firewall, muffler clears fuselage, how the cowl would need to be cut out, etc.

3) After deciding on engine orientation (in this case upright) take it away and fit the cowl onto the fuse.

4) Take a long piece of piano wire, maybe 3 feet, and attach with tape to the top of the fuse. Bend in a curve so that the end of the wire points just in front, and exactly centered, in the round front opening of the cowl. Be sure this positioning is correct during the next step.

5) Hold the engine and mount in place so that the end of the prop shaft lines up perfectly with the wire, and mark the centers of the mount’s holes on the firewall.

Now that the position is marked, I just drilled the holes and installed the blind nuts. A little tape wrapped around the finger (to stick the blind nuts onto) made it possible to feed them in through the fuel tank opening and hold them in place for installation. This is a bit tricky, so rather than try to hold the mount in place before the blind nut was set, I threaded a nut onto one of the mounting bolts to set the nut into the back of the firewall permanently.

Now the mounts are drilled and tapped for the 6-32 mounting screws I chose. I used a nail and tapped lightly with a hammer to mark the drilling spots, which need to be drilled very precisely. Don’t forget to take it slow, back the tap out and use plenty of oil when tapping threads.

I attached the mounts and engine to the firewall and began the process of measuring, marking and creating the opening in the cowl. A Dremel tool and sanding drum work well. After creating the initial hole, I took a little at a time, constantly going back to re-fit, measure and mark where I needed to remove more. "

Since these mounts are much bigger than those supplied with the Senior, I couldn’t use the pre-drilled holes in the ARF’s firewall, or the pre-installed blind nuts. I filled the holes with balsa and epoxied over them to fuel-proof. I also filled (or covered with pieces of balsa) and fuel –proofed all of the pre-drilled holes in the firewall, as they’re not needed for the nosegear and its pushrod. I had already rubbed CA all over the firewall for some fuelproofing.

Now the task was to determine where to drill holes for the new mounts. Here’s how I did it:

1) Tape or tack glue the engine temporarily onto the mounts

2) Test different possible positions and see how the mounts fit on the firewall, muffler clears fuselage, how the cowl would need to be cut out, etc.

3) After deciding on engine orientation (in this case upright) take it away and fit the cowl onto the fuse.

4) Take a long piece of piano wire, maybe 3 feet, and attach with tape to the top of the fuse. Bend in a curve so that the end of the wire points just in front, and exactly centered, in the round front opening of the cowl. Be sure this positioning is correct during the next step.

5) Hold the engine and mount in place so that the end of the prop shaft lines up perfectly with the wire, and mark the centers of the mount’s holes on the firewall.

Now that the position is marked, I just drilled the holes and installed the blind nuts. A little tape wrapped around the finger (to stick the blind nuts onto) made it possible to feed them in through the fuel tank opening and hold them in place for installation. This is a bit tricky, so rather than try to hold the mount in place before the blind nut was set, I threaded a nut onto one of the mounting bolts to set the nut into the back of the firewall permanently.

Now the mounts are drilled and tapped for the 6-32 mounting screws I chose. I used a nail and tapped lightly with a hammer to mark the drilling spots, which need to be drilled very precisely. Don’t forget to take it slow, back the tap out and use plenty of oil when tapping threads.

I attached the mounts and engine to the firewall and began the process of measuring, marking and creating the opening in the cowl. A Dremel tool and sanding drum work well. After creating the initial hole, I took a little at a time, constantly going back to re-fit, measure and mark where I needed to remove more. "

Hope this helps.

Finally, I was happy with the cut-out in the top of the cowl, and found that the position of the prop shaft and thrust washer was a little skewed to the left. I added a couple of washers between the left mount and firewall as shims, which made the fit perfect. Now time for engine break-in and bench test.