Originally Posted by

Mr Cox

I felt I had to check the engine again to make sure I remembered correctly.

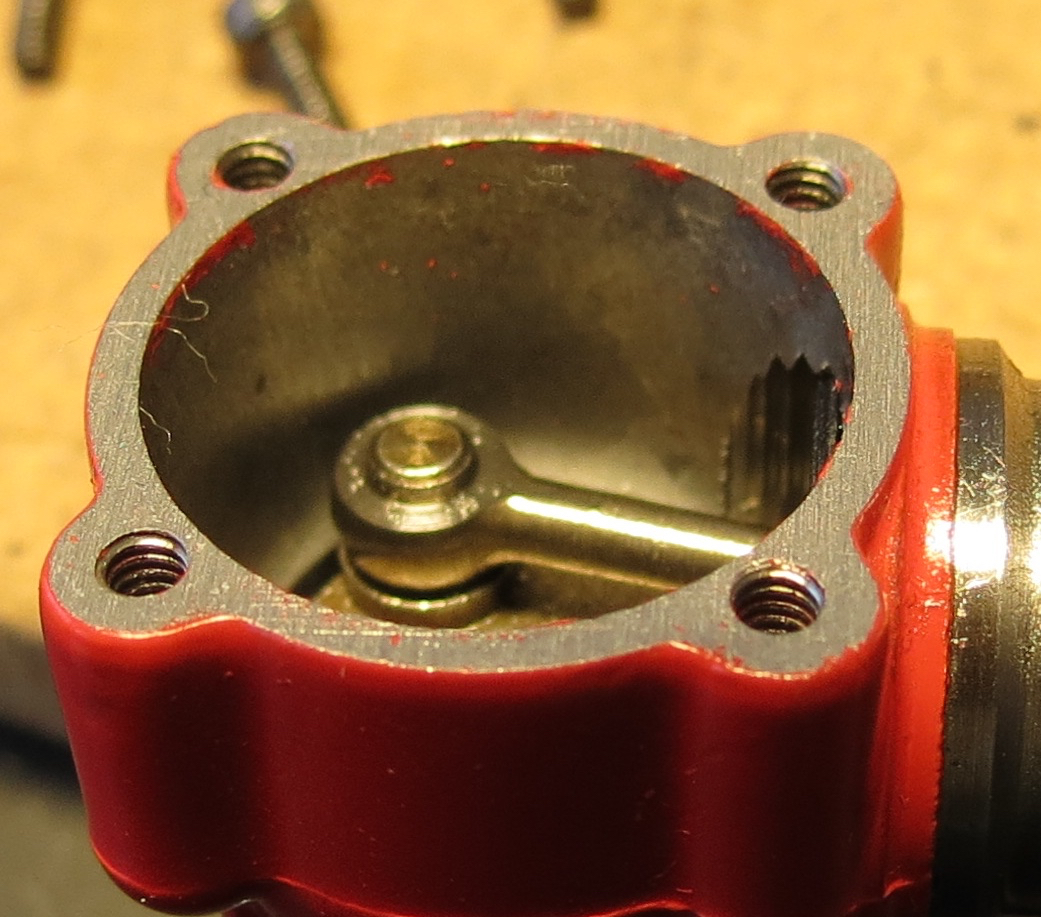

Below are two images in order to illustrate the issue with the short driving pin for the disc. As you can see (I hope) the crank pin is only protruding very little past the conrod, and the crank pin is also chamfered at its end. This gives very little material that can grab the disc, which in turn is made from a very soft material.

I think the design would have needed a new dedicated crank with a longer crank pin, together with a brass disc or a brass counter surface on the backplate, in order to work well.

Judging by the wear pattern in the disk's crank pin hole, one can see where that the collar like lip on the connecting rod is almost nearly fully seated in the hole. There is some wear at the bottom of the hole from the crank pin. Thus, it seems like it is working as it should.

IMO, there isn't the high mechanical forces on the disk, to warrant it being made of brass, like you would a prop drive plate running a pusher prop. There is some lateral movement from vacuum suction during upward piston movement drawing in the fuel charge from the venturi. On piston downward movement there is a slight positive pressure when fuel charge is transferred from the crankcase chamber to the piston head area.

One would not want the crank pin to be extended as in this design, the connecting rod lip has less movement against the aluminum disk's hole, more of a gentler back and forth motion, than the crank pin, which is rotary. Design seems to be best applied as a tractor, not pusher motor. As a pusher, wonder if that would cause the crank pin to rub alarmingly hard on the disk crank pin hole.

I cannot say though how well this design would wear over time. One would want to ensure that there was sufficient oil in the fuel (at least 20% IMO) to ensure proper lubrication of the disk.

Perhaps due to complications and manufacturing expense of the design is why Cox discontinued the rear rotary valve for the front rotary Tee Dee's and Bee's reed valves.