I solved the problem of mounting the L.G. blocks to the wing L.E. I cut some tri stock down so it would fit to the wing leading edge. Took a few tries to get it right. Sure loving that little 4" Dremel table saw. I glued the tri stock to the upper and lower surfaces of the l.e. to make a flat to glue the l.g. blocks to. I think this is going to work.

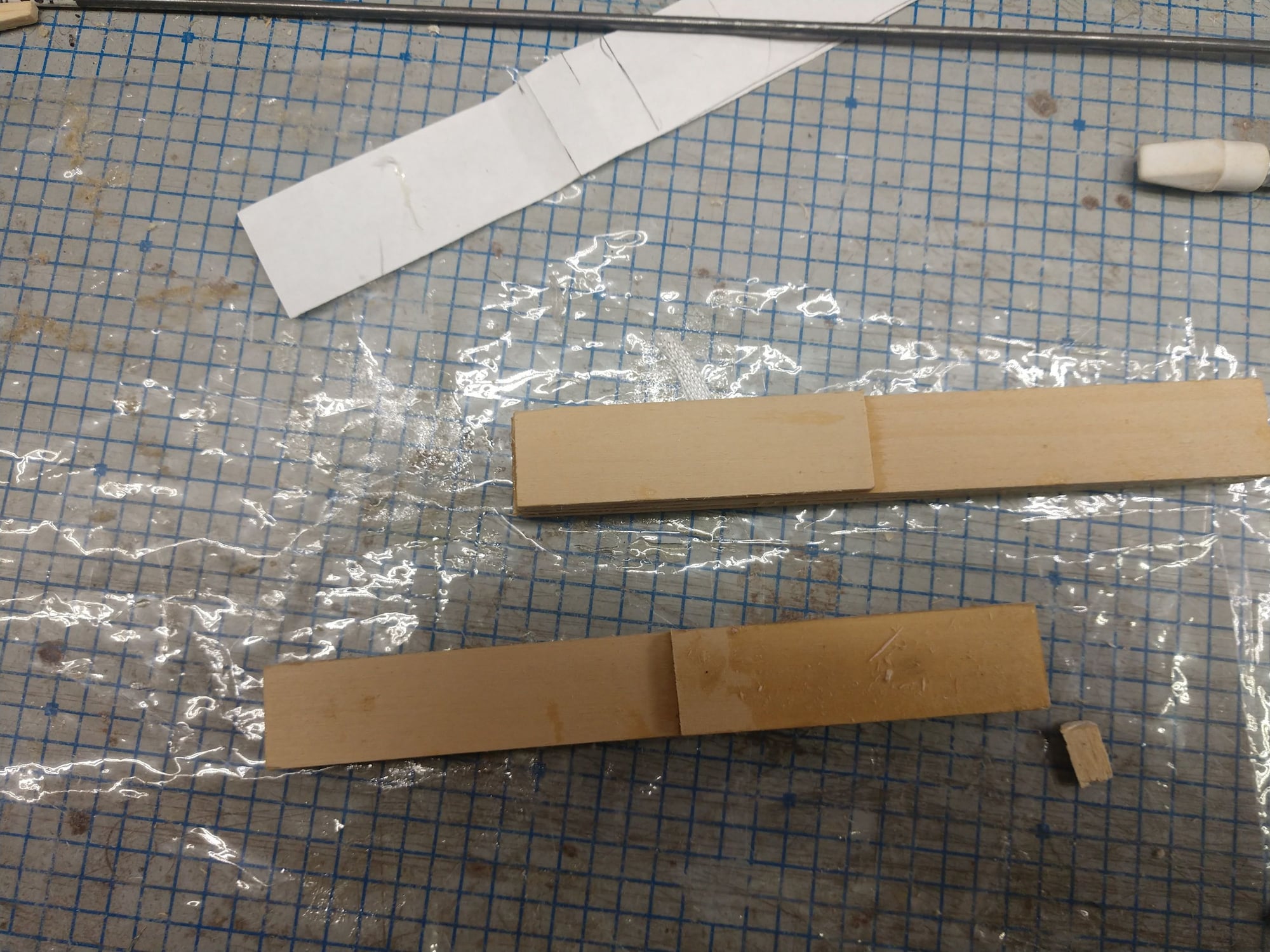

I had one l.g. block in a junk bin. Can't go out and get material now. This entire state is on lock down due to the Corona virus. I doubt that the hobby shop is even open for the same reason. Did not go flying either, that is not essential business, but dang it, it sure feels essential to me. So I laminated up some 1/8' bass that I ripped to the same width as the l.g. block I have. I makes a great template. So I lamented 2 strips of 1/8" bass together with epoxy. I also laminated a shorter piece of bass to the back opposite side of the block. The wing dowels need to go thru the blocks at least a little ways. Maybe the wing dowels will be strong enough to just penetrate into the blocks a short distance I ripped the 3rd strip and epoxied it to the other 2 with a piece of 1/8" music wire between the 2 strips to act as a spacer. That gives me a ready made slot for the l.g. wire to lay in. I have not yet drilled the hole for a leg of the l.g. wire to go thru. I should make the l.g. wires first I think. To do that I need to rebuild my wire bender. I ruined the pivot hole testing to see if I could bend 3/16" wire. A piece of 1/4" steel is in order for the pivot pin's hole. The hard ware stores are still open.

I am going to use 2 servos for the ailerons, so they are mounting out board. I tried to drill with a fostner bit servo wire holes in the ribs. That was a big no go. No way to get the bit in between ribs. I just ended up cutting square-ish holes for the wire wires. The rib in between the center ribs and the rib at the end of the center section sheating was a real bugger. I finally said nuts on it and cut a slot in the center section sheating big enough to work my knife thru to cut the hole I needed. I really hate cutting extra holes, but I just could not do the job till then. Well it isn't like there weren't already plenty of holes to fix.

I really did not spend a lot of time working in the garage on planes today. This lock down has me feeling a bit antsy. Thinking of buy a flight sim, since I can't go out and fly. But the down side there is that is funds I would otherwise use for building. So we'll see.

Ken