Thanks, Mike. That sounds like a simple solution to me. I'll make sure to do that.

Tonight I was able to install the aileron linkage, rudder and landing gear. I don’t have any pics of the aileron linkage, but that’s very straightforward and for once I even used the supplied hardware.

I almost always convince myself to upgrade, but there was no need whatsoever in this case.

The landing gear, however, is a different story. As designed, the tail wheel wire is attached directly to the rudder for steering purposes. I moved away from this a long time ago because it transfers shock directly to the servo and the rudder, which can cause damage to both of them if the impact is hard enough. And in my case, I need all the protection I can get.

I like to use Dubro steerable tail wheel units because they are light and simple to install. First, here is the bottom of the rudder post as delivered with holes drilled to accept the Dubro unit.

The only problem is that this part of the fuse is not designed to accept such an assembly. My solution was to carefully cut out the bottom sheeting of the fuse in this area and replace it with a couple layers of ply. Here is the cut section, along with the replacement ply section.

And here is the new section glued into place.

And finally, here is the area after being recovered.

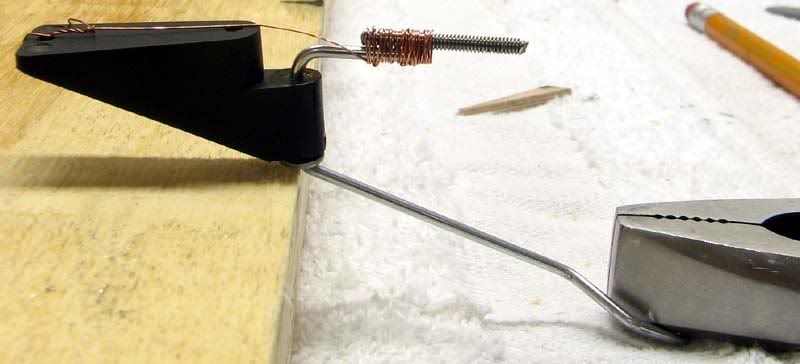

It’s not perfect, but it’s on the bottom of the plane and in a place where no one will probably ever look, so I’m satisfied with how it turned out. The Dubro unit is designed to be fastened to the rudder in the same way as the supplied one, but I’ve used it so many times, that I can almost modify it with my eyes closed. After making the necessary bends in the wire, I take a 1 inch length of 2-56 all-thread and bind it to the end of the wire as shown here.

After a little heat and solder, the joint is solid and durable. I’ve never had one of these come apart, but maybe I shouldn’t say that too loud.

I then take a scrap of nyrod or whatever I have laying around and screw it onto the stud so that it extends out to under the rudder. Finally, a small eye hook is screwed into the bottom of the rudder. The hook is removed, thread-hardened with CA and then reinstalled. The nyrod scrap is fed through the eye and the result is a flexible link between the rudder and the tailwheel. On a hard landing, the nyrod bends and pops out of the eye, preventing the transfer of force to the rudder or servo.

You can fine tune the amount of force required to pop the nyrod out by leaving more material to the rear of the eye. The more you leave, the more force it takes to break it loose. This is lightweight and simple. It doesn’t require any additional springs or connections to the rudder linkage. I added about 14 grams to the tail doing this mod, and 10 of that was the incremental weight of the Dubro unit over the stock one, so the plywood plate did not amount to much.

As far as the main gear, here too I changed a little something. The stock wheels are about 2” in diameter and although they are high quality and very light, they are just too small for the condition of our field. I routinely go up to at least 2.5 inch wheels, and I was happy to discover that they fit into the wheel pants with no problem. Here are both wheels for comparison.

Finally, here is the fuse with gear fully installed.

Next up is the installation of the horizontal stab and elevators. With a little luck, that will be completed tomorrow night.