Jett Engine Trouble

#1

Junior Member

Thread Starter

Join Date: Sep 2020

Location: Denver, CO

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Hi All,

My Sun Fli 4 build is nearing completion, now in the finishing stage. So time to start dealing with the engine for this thing.

The engine is a Jett 56LX, designed to scream at high RPM. Will do something like 17.5K RPM running a 10x6 on 15% nitro. It has the Jett-supplied tuned muffler, and it is all stock.

I am having trouble getting it to run right. I live in Denver at 5400 feet and so altitude may be the problem, which is, when the engine spins up to high RPM (or tries to..) it QUITS and then is flooded. So flooded that it takes several minutes before it will even THINK about starting again. All testing is being done on a test stand at this point.

Plumbing: pressure line from pressure tap on Jett muffler to tank vent. Klunk pickup in tank, line going from this to the needle valve, fuel filter, then carb.

What I have found out is that when I DISCONNECT the muffler->tank vent line, and richen the mixture some, the engine WILL run all the way to top speed without the quit/flood. Otherwise, with the muffler->tank line connected, the engine QUITS when I try to transition to full speed, EVERY TIME, and is flooded EVERY TIME.

This suggests to me that my problem is that the engine/muffler is developing too much pressure, which goes to the tank and then causes the engine to flood. What do you think?

It seems like a tuning problem, but I don't have any knobs to turn. What do y'all think is the best way to limit the muffler pressure going to the tank vent?

My Sun Fli 4 build is nearing completion, now in the finishing stage. So time to start dealing with the engine for this thing.

The engine is a Jett 56LX, designed to scream at high RPM. Will do something like 17.5K RPM running a 10x6 on 15% nitro. It has the Jett-supplied tuned muffler, and it is all stock.

I am having trouble getting it to run right. I live in Denver at 5400 feet and so altitude may be the problem, which is, when the engine spins up to high RPM (or tries to..) it QUITS and then is flooded. So flooded that it takes several minutes before it will even THINK about starting again. All testing is being done on a test stand at this point.

Plumbing: pressure line from pressure tap on Jett muffler to tank vent. Klunk pickup in tank, line going from this to the needle valve, fuel filter, then carb.

What I have found out is that when I DISCONNECT the muffler->tank vent line, and richen the mixture some, the engine WILL run all the way to top speed without the quit/flood. Otherwise, with the muffler->tank line connected, the engine QUITS when I try to transition to full speed, EVERY TIME, and is flooded EVERY TIME.

This suggests to me that my problem is that the engine/muffler is developing too much pressure, which goes to the tank and then causes the engine to flood. What do you think?

It seems like a tuning problem, but I don't have any knobs to turn. What do y'all think is the best way to limit the muffler pressure going to the tank vent?

#2

Moderator

What prop are you running? I've heard this engine is finicky about being overpropped.

Is the head hotter or colder than normal? Cool would indicate rich, while hot would mean lean and would explain why it has to sit for a few minutes before it will start again.

I can't imagine muffler pressure being high enough to force so much fuel into the engine that it floods out and dies. Even engines that are running super rich to the point of missing a lot of ignition strokes will still keep running.

Is the head hotter or colder than normal? Cool would indicate rich, while hot would mean lean and would explain why it has to sit for a few minutes before it will start again.

I can't imagine muffler pressure being high enough to force so much fuel into the engine that it floods out and dies. Even engines that are running super rich to the point of missing a lot of ignition strokes will still keep running.

#3

Junior Member

Thread Starter

Join Date: Sep 2020

Location: Denver, CO

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Hi and thanks for the response.

I am using the recommended APC 10x6 on it.

It seems like it's hotter than normal, although I am very confused about the behavior and not sure about what I am seeing.

Thanks again!

I am using the recommended APC 10x6 on it.

It seems like it's hotter than normal, although I am very confused about the behavior and not sure about what I am seeing.

Thanks again!

#4

My Feedback: (54)

IMHO;

If you haven't flown tune pipes, the engine can't be tuned until the tank is pressurized. Just like YS engines. Jett's muffler is a tuned pipe. As the engine reaches top rpm and has pressurized the tank for a minute, then tune the engine. Just realize that the next start, the engine isn't too lean. You have to wait that minute to reach rpm.

Other issues that I have had with remote needle valves; is the fuel nipples on the carb and needle valve might be sucking air. But that usually doesn't flood the engine. The engine goes lean. Also check carb throat set screw for air leaks. Make sure that the pressure nipples aren't leaking from the pipe to the tank.

Another thing that is done with tuned pipes and YS engines, is to duct tape the fuel tank. This helps eliminate the fuel tank from bellowing a lot from pressure changes and will give a more precise tune adjustment. It also helps to keep the tank from splitting.

But, in my humble opinion, you just aren't being patient enough for the tank to pressurize, adjusting the needle valve too soon, then the tank pressurizes, and floods it out because you thought it was tuned.

Once high speed needle valve is tuned, with tank still pressurized, adjust low end with the engine running at about 3000rpm. It will peak just as the high end. Once peaked, richen 200-500 rpm.

If you haven't flown tune pipes, the engine can't be tuned until the tank is pressurized. Just like YS engines. Jett's muffler is a tuned pipe. As the engine reaches top rpm and has pressurized the tank for a minute, then tune the engine. Just realize that the next start, the engine isn't too lean. You have to wait that minute to reach rpm.

Other issues that I have had with remote needle valves; is the fuel nipples on the carb and needle valve might be sucking air. But that usually doesn't flood the engine. The engine goes lean. Also check carb throat set screw for air leaks. Make sure that the pressure nipples aren't leaking from the pipe to the tank.

Another thing that is done with tuned pipes and YS engines, is to duct tape the fuel tank. This helps eliminate the fuel tank from bellowing a lot from pressure changes and will give a more precise tune adjustment. It also helps to keep the tank from splitting.

But, in my humble opinion, you just aren't being patient enough for the tank to pressurize, adjusting the needle valve too soon, then the tank pressurizes, and floods it out because you thought it was tuned.

Once high speed needle valve is tuned, with tank still pressurized, adjust low end with the engine running at about 3000rpm. It will peak just as the high end. Once peaked, richen 200-500 rpm.

Last edited by RCFlyerDan; 02-02-2021 at 02:37 PM.

#8

My Feedback: (54)

[QUOTE

I am having trouble getting it to run right. I live in Denver at 5400 feet and so altitude may be the problem, which is, when the engine spins up to high RPM (or tries to..) it QUITS and then is flooded. So flooded that it takes several minutes before it will even THINK about starting again.?[/QUOTE]

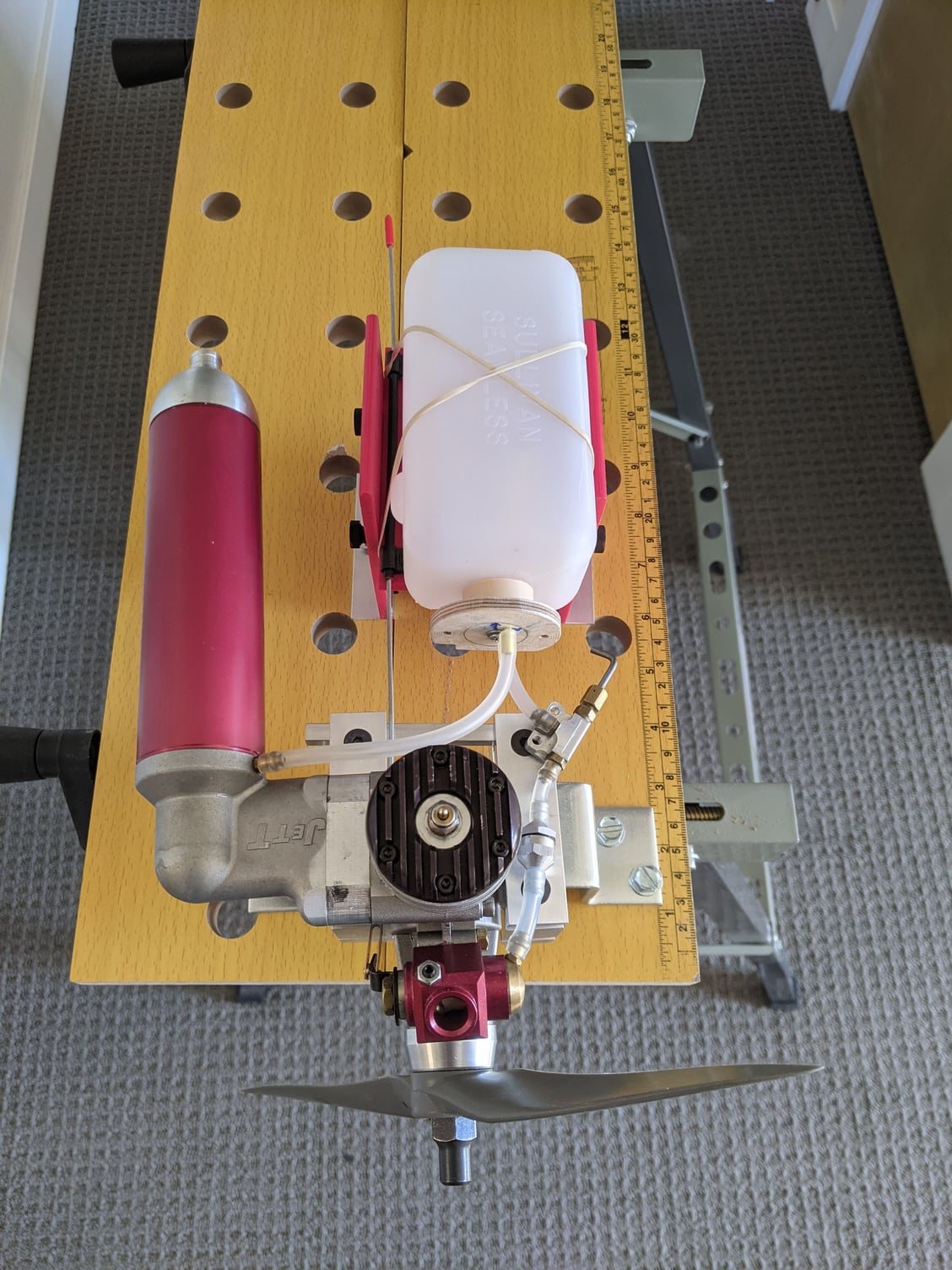

Thanks for the pictures. Are you using a HOT plug like an A3? A8 won't take the heat. Have you tried a new plug? With tuned pipes, they can break the filament, yet still work. A broken filament will start and run, yet not hit RPM. Because the filament is broken, the engine floods at the higher RPM. Then the glow plug isn't good enough to get the wet plug hot enough again to start. You said that it will reach full throttle without the pressure line. I bet that you aren't getting the same maximum RPMs that you will get under pressure. Change your plug, even if it lights. Also eliminate the in-line filter. I quoted things from the manual.

http://www.dubjett.com/documents/INSTSJ40-2017.pdf

Quote: YOU MUST HAVE A GOOD GLOW PLUG BEFORE ATTEMPTING TO SET YOUR NEEDLE VALVE. We

recommend Merlin 2003 HOT sport glow plugs – (Red). Others may perform equally as well.

Quote: TANK: Hayes type tanks work well for the Sport-Jett, but any good clunk is OK if you have no leaks and keep it clean. CLEAN YOUR TANK AND EQUIPMENT OFTEN AND USE A FILTER IN YOUR PUMP. If you mount your engine upright make sure that the needle valve assembly is at least as low as the centerline of the tank (this may be impossible). If not, turn your engine sideways so the engine won't have to draw up hill. ABOUT 80% OF THE TROUBLE CALLS WE GET ARE ULTIMATELY FOUND TO BE TANK PROBLEMS.

I am having trouble getting it to run right. I live in Denver at 5400 feet and so altitude may be the problem, which is, when the engine spins up to high RPM (or tries to..) it QUITS and then is flooded. So flooded that it takes several minutes before it will even THINK about starting again.?[/QUOTE]

Thanks for the pictures. Are you using a HOT plug like an A3? A8 won't take the heat. Have you tried a new plug? With tuned pipes, they can break the filament, yet still work. A broken filament will start and run, yet not hit RPM. Because the filament is broken, the engine floods at the higher RPM. Then the glow plug isn't good enough to get the wet plug hot enough again to start. You said that it will reach full throttle without the pressure line. I bet that you aren't getting the same maximum RPMs that you will get under pressure. Change your plug, even if it lights. Also eliminate the in-line filter. I quoted things from the manual.

http://www.dubjett.com/documents/INSTSJ40-2017.pdf

Quote: YOU MUST HAVE A GOOD GLOW PLUG BEFORE ATTEMPTING TO SET YOUR NEEDLE VALVE. We

recommend Merlin 2003 HOT sport glow plugs – (Red). Others may perform equally as well.

Quote: TANK: Hayes type tanks work well for the Sport-Jett, but any good clunk is OK if you have no leaks and keep it clean. CLEAN YOUR TANK AND EQUIPMENT OFTEN AND USE A FILTER IN YOUR PUMP. If you mount your engine upright make sure that the needle valve assembly is at least as low as the centerline of the tank (this may be impossible). If not, turn your engine sideways so the engine won't have to draw up hill. ABOUT 80% OF THE TROUBLE CALLS WE GET ARE ULTIMATELY FOUND TO BE TANK PROBLEMS.

#9

What you are describing makes little sense to me. I live at 5000' in Reno, and I have broken in literally hundreds of Jett engines for racers near and far, as well as sport engines. Never have I experienced a problem like you describe. Lets take it from the beginning. I will assume that this engine is new and has not been manhandled by anyone. Dub will test run all of his engines before he sends them out, so yours was fine when it left his shop. What glow plug is in it? I do not recognize the plug in the photo. It needs a hot plug, With the passing of Alton the only really available plug that is suitable is the Enya#3. What fuel are you using? Get a gallon of 15%, add 5 ounces of Castor oil to it, and shake it up. You now have suitable break in fuel. At your altitude it should pull a 10 x 6 at a healthy 17k, but that doesn't mean you can break the engine in on one. Put a 9.5 x 6 prop on it for bench runs. Pull the muffler off of it and look in both ends for any obstruction. If all is clean, check your fuel filter for blockage and leaks. Open the needle 6 turns or so, fire it up and immediately go to full throttle. It will spit and sputter, but if you keep glow heat on it, it will stay running. Lean the needle until it begins to clean up, pull glow heat, and lean it to a ragged 2 cycle. Pinch the muffler pressure line to lean it, and as it nears peak release the pressure line to richen it back up. Do this about once a minute for 4 tanks of fuel. At this point you can mount the engine in the plane. Burn the rest of the gallon of fuel you made, then add oil as necessary to your fuel to achieve 20% total oil. Never use less than 20%.

If the engine does not respond to this break in procedure, something is seriously wrong. Shoot me a PM and I will help you through it.

Scott

If the engine does not respond to this break in procedure, something is seriously wrong. Shoot me a PM and I will help you through it.

Scott

#10

Junior Member

Thread Starter

Join Date: Sep 2020

Location: Denver, CO

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Scott,

Thanks so much for your reply. I am going to pursue your suggestions, beginning with STARTING at full throttle to get the LSN out of the equation.

By that I mean I want to try to see if I can get it running a full throttle only, with the vent line connected.

A few more details: Dub Jett broke this engine in, and over the holidays I sent it back to him for examination because of its inability to run. He concluded that there is nothing wrong with it, and told me that it works perfectly at sea level, with the carb set up the way he set it up.

That's a nice data point, but it matters little. I still think the carb is set up wrong for my conditions, so I will get it to run at full throttle first, and then proceed to a "start over" on the LSN adjustment.

It is very hard (basically impossible) to get 20% where I live, so I have been living on the Jett-prescribed 15%, and will probably continue do have to do that. The fuel I am using is Cool Power 15%.

Right now it is going to be tough to make much progress since the weather in Colorado is pretty terrible. I'll post an update as soon as I can do some more running.

Thanks again for the help, I really appreciate it and will keep you posted on developments.

Thanks so much for your reply. I am going to pursue your suggestions, beginning with STARTING at full throttle to get the LSN out of the equation.

By that I mean I want to try to see if I can get it running a full throttle only, with the vent line connected.

A few more details: Dub Jett broke this engine in, and over the holidays I sent it back to him for examination because of its inability to run. He concluded that there is nothing wrong with it, and told me that it works perfectly at sea level, with the carb set up the way he set it up.

That's a nice data point, but it matters little. I still think the carb is set up wrong for my conditions, so I will get it to run at full throttle first, and then proceed to a "start over" on the LSN adjustment.

It is very hard (basically impossible) to get 20% where I live, so I have been living on the Jett-prescribed 15%, and will probably continue do have to do that. The fuel I am using is Cool Power 15%.

Right now it is going to be tough to make much progress since the weather in Colorado is pretty terrible. I'll post an update as soon as I can do some more running.

Thanks again for the help, I really appreciate it and will keep you posted on developments.

#11

Your 15% fuel is just fine, it just needs more oil. If need be, you should be able to buy a 4 ounce bottle of castor oil at the local pharmacy. Dump that bottle in a gallon of fuel and shake it up. With a proper glow plug and fuel, it should run just fine. Keep me posted. If you need any help I am here.

Scott

Scott