BJ Craft Anthem

#26

Thread Starter

Just taken delivery of an Anthem. I opened the box hoping there would be no damage and I was delighted to find that everything was in perfect condition. Nice sturdy box and the fuselage is well retained using the wing tube hole to firmly fix the fuselage into the box. A wood cross member also helps to prevent the box being squeezed in. The other parts were all nicely packed in bubble wrap and securely taped into the box. Full marks to BJ Craft's box design.

Weights (in grams) for the bare components are:

Weights (in grams) for the bare components are:

Port Wing ............... 316

Stbd Wing ................ 315

Port TP and elevator 88

Stbd TP and elevator 88

Canalyser .............. 102

Fuselage ............... 1044

Rudder ................. 60

Canopy ................ 82

Wing joiner ................65

TP joiner rods ......... 10

I've not included the undercarriage, spats, wheels and other hardware as I might use other stuff. I was very impressed with the wings being within 1 g of each other and the TPs being the same. weight. Well done BJ.

Stbd Wing ................ 315

Port TP and elevator 88

Stbd TP and elevator 88

Canalyser .............. 102

Fuselage ............... 1044

Rudder ................. 60

Canopy ................ 82

Wing joiner ................65

TP joiner rods ......... 10

The following users liked this post:

wattsup (02-21-2023)

#30

Thread Starter

The following users liked this post:

barnowljenx (03-08-2023)

#33

My Feedback: (4)

Able to get 2 six minute flights on my Anthem today. CG somewhere between 280 and 320. Almost no trim changes needed. Slight pull to canopy both in left and right knife edge.

Adverrun contra with Kontronik XL20-55, both props are 22/22. TP 6000 10S. Battery not even warm. Motor very hot - have to think about this…

Adverrun contra with Kontronik XL20-55, both props are 22/22. TP 6000 10S. Battery not even warm. Motor very hot - have to think about this…

The following users liked this post:

wattsup (02-24-2023)

The following 3 users liked this post by BJM:

#35

Thread Starter

I took the precaution of checking bolt length

I used the silver bolt to check length and it wasn't quite long enough while the black bolt (supplied) contacted the fuselage as you said. So, I cut 5 mm off both supplied long bolts and all was fine. Thanks for the warning.

What delighted me was that the U/C legs came predrilled and the way they were shaped provided you aligned the front edge to the u/c box the wheels were aligned to run straight ahead. The other astonishing feature was that both predrilled holes in the u/c leg aligned with the slots in the u/c plate! The slots are across the fuselage but there is no real tolerance fore and aft. Well done BJ Craft on some accurate jigging.

#39

Thread Starter

BJM - at what stage are you measuring motor temperature? I had an onboard temp monitor on my motor. There was around a 7 deg C rise above ambient when in the air, but as soon as I touched down the temperature would start to rise and by the time I was back in the pits the temp rise above ambient was about 20-25 deg C. I did once take off with the motor temp at 20 deg C above ambient and as soon as I was airborne the temperature started to drop and stabilised at 7 Deg C above ambient.

So, what I learned was either take a temp reading as soon as you have landed or else fit an onboard temp sensor on the motor and monitor it in flight. Checking in the pits is a waste of time as heat soak and lack of cooling air push the temp up much higher than it would be when airborne.

So, what I learned was either take a temp reading as soon as you have landed or else fit an onboard temp sensor on the motor and monitor it in flight. Checking in the pits is a waste of time as heat soak and lack of cooling air push the temp up much higher than it would be when airborne.

#41

Thread Starter

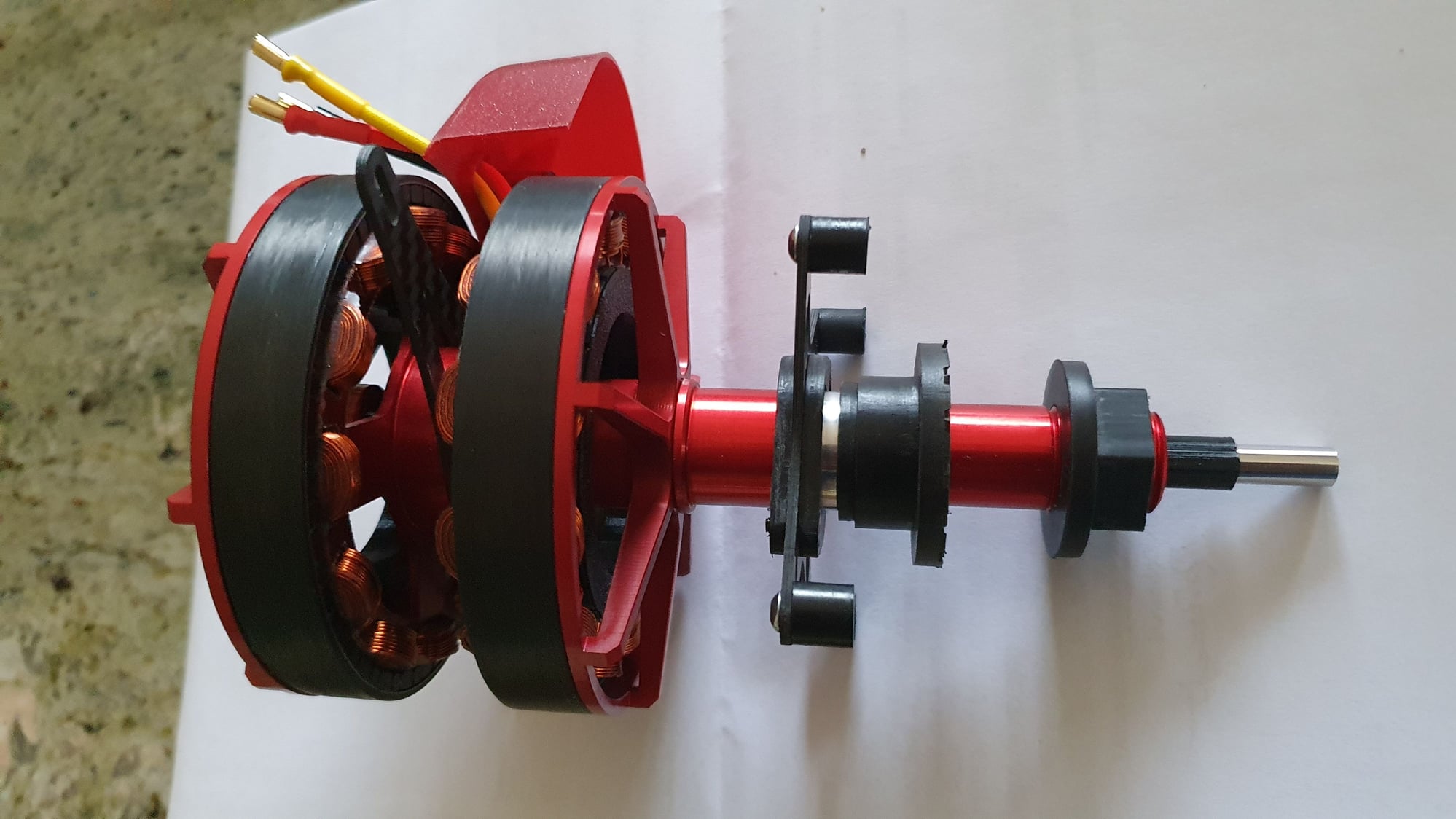

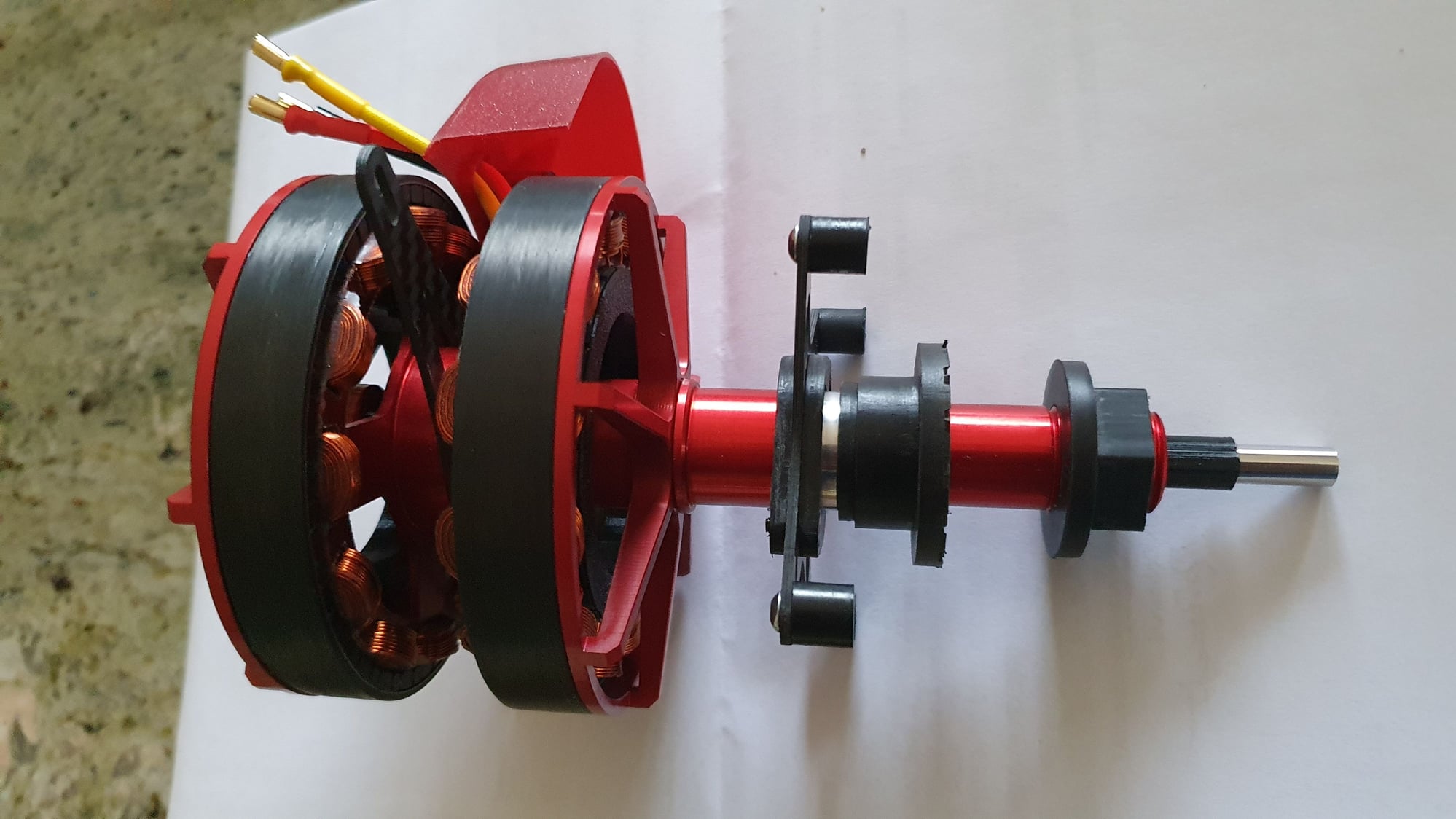

My Anthem is now complete. I have used the Debowski TMCR (twin motor contra rotating) motor and 2 D3 ESCs

TMCR

TMCR installed with 2 D3 ESCs

The empty aircraft weight came out at 3,805 g. The Rx battery and flight pack added 1,203 g so total flying weight was 5,008 g which is good enough to make weight. I do have some lighter flight packs that would drop the AUW to below 5,000 g. I'm using 2 x OnBo 5S 4800 packs. I see that for 2024 the latest FAI ruling is that both electric and IC must not exceed 5,500 g at take off so this extra 500 g (1.1 lb) will allow bigger capacity flight packs next year while still remaining within the weight limit.

I set the CG at the mid-point of 300 mm behind the wing root leading edge.

The TMCR drives 2 x Falcon 23x20 props. This gives a lot of power and I probably only use no more than 80% if that for the verticals. The speed control with the TMCR/D3 combination is exceptional. It is easy to keep a steady flight speed already. The only issue is that while the aircraft will drop into a spin, it almost immediately slows down the rate of rotation and sometimes goes the other way in a slow waffly way. It needs a good dose of in-spin aileron to continue the spin much more than I have been used to using and I put this down to the swept wing.

One thing to guard against when using the D3 ESC is not to close the throttle before you have completed the flare! On the maiden, I closed the throttle when beginning the flare and the braking from the props was sufficient to cause the aircraft to stall and drop onto the runway. Luckily, no damage ensued! So now, I don't close the throttle completely till I have finished the flare and the aircraft is virtually on the ground. You can still see the deceleration but with the aircraft safely on its wheels!

I am very pleased with the way this aircraft and motor combination is working.

TMCR

TMCR installed with 2 D3 ESCs

The empty aircraft weight came out at 3,805 g. The Rx battery and flight pack added 1,203 g so total flying weight was 5,008 g which is good enough to make weight. I do have some lighter flight packs that would drop the AUW to below 5,000 g. I'm using 2 x OnBo 5S 4800 packs. I see that for 2024 the latest FAI ruling is that both electric and IC must not exceed 5,500 g at take off so this extra 500 g (1.1 lb) will allow bigger capacity flight packs next year while still remaining within the weight limit.

I set the CG at the mid-point of 300 mm behind the wing root leading edge.

The TMCR drives 2 x Falcon 23x20 props. This gives a lot of power and I probably only use no more than 80% if that for the verticals. The speed control with the TMCR/D3 combination is exceptional. It is easy to keep a steady flight speed already. The only issue is that while the aircraft will drop into a spin, it almost immediately slows down the rate of rotation and sometimes goes the other way in a slow waffly way. It needs a good dose of in-spin aileron to continue the spin much more than I have been used to using and I put this down to the swept wing.

One thing to guard against when using the D3 ESC is not to close the throttle before you have completed the flare! On the maiden, I closed the throttle when beginning the flare and the braking from the props was sufficient to cause the aircraft to stall and drop onto the runway. Luckily, no damage ensued! So now, I don't close the throttle completely till I have finished the flare and the aircraft is virtually on the ground. You can still see the deceleration but with the aircraft safely on its wheels!

I am very pleased with the way this aircraft and motor combination is working.

#42

Thread Starter

I have found that the Anthem needs a lot of in-spin aileron to spin beyond the first 1/4 turn. Have others found this? This applies to upright and inverted spinning. I suspect it is a function of the swept wing which brings added yaw stability.

#43

Thread Starter

Shows my battery location that gives the CG at 300 mm aft of the wing leading edge. You can also see the twin D3 ESCs that control the 2 outrunner motors. The packs weigh 575 g each. The wiring has been tidied up since the photo was taken!

#45

Thread Starter

Usual split shaft and conical grip washer held down by the prop nut. Seems to work fine as I recorded 3,600 W max today with 92A current draw. That was deliberately using full power. On the couple of P23s I've flown the average has been 2,600 W at around 70 A. This is a very powerful motor/ESC combo. I'm running 23x20 front and rear as recommended by Adam Debowski.

#46

Thread Starter

I have now flown my Anthem in its first competition but I'm afraid to report that the pilot didn't live up to the Anthem's capabilities! More practice needed!

I finally took the decision to not just hang the flight pack off the back of the battery tray and made up four new tray supports and repositioned the tray some 70 mm aft of the original position. This allows the pack to sit centrally on the tray as in the photo below. Compare with the photo in post #43 above. This gives the CG at around 310 mm aft of the root leading edge. I did also try the pack back another 70 mm and that gave an inverted 45 deg climb with no need for down elevator. I prefer needing some down elevator so returned the pack to sitting right on the battery tray.

The combination of the aiframe and motor/ESC performance has been quite extraordinary. It is extremely easy to maintain a constant flight speed - except apparently when there's a competition on(!) - and there is no shortage of power. I'm using a pair of Falcon 23x12 front and rear as recommended by Adam Debowski.

My second Club has a field surrounded on three sides by large trees. Landing in anything other than a very light breeze involves negotiating considerable turbulence on the approach. Indeed, on one of the early flights when I was 6 ft off the ground the Anthem suddenly rolled 60 deg left but I managed to avoid the crop beneath the wing tip and landed safely. What the TMCR/D3 combination does is to provide very fast reaction to throttle movement and to control the speed of the aircraft very accurately. I can afford to approach faster than I would normally to give better control response to the turbulence while once the round out is complete closing the throttle provides excellent braking from both 23 in props and there was never a danger of running off the strip as was the case with my previous aircraft which had a Jeti Spin 99 ESC.

I finally took the decision to not just hang the flight pack off the back of the battery tray and made up four new tray supports and repositioned the tray some 70 mm aft of the original position. This allows the pack to sit centrally on the tray as in the photo below. Compare with the photo in post #43 above. This gives the CG at around 310 mm aft of the root leading edge. I did also try the pack back another 70 mm and that gave an inverted 45 deg climb with no need for down elevator. I prefer needing some down elevator so returned the pack to sitting right on the battery tray.

The combination of the aiframe and motor/ESC performance has been quite extraordinary. It is extremely easy to maintain a constant flight speed - except apparently when there's a competition on(!) - and there is no shortage of power. I'm using a pair of Falcon 23x12 front and rear as recommended by Adam Debowski.

My second Club has a field surrounded on three sides by large trees. Landing in anything other than a very light breeze involves negotiating considerable turbulence on the approach. Indeed, on one of the early flights when I was 6 ft off the ground the Anthem suddenly rolled 60 deg left but I managed to avoid the crop beneath the wing tip and landed safely. What the TMCR/D3 combination does is to provide very fast reaction to throttle movement and to control the speed of the aircraft very accurately. I can afford to approach faster than I would normally to give better control response to the turbulence while once the round out is complete closing the throttle provides excellent braking from both 23 in props and there was never a danger of running off the strip as was the case with my previous aircraft which had a Jeti Spin 99 ESC.

#48

Thread Starter

#49

Senior Member

#50

Thread Starter

Hi FBW

I took advice from Adam Debowki on mounting these ESCs. He sent me a photo that showed the configuration that I have adopted. I did check the ESC temps after the first flight and they were barely warm. I have had an ESC failure but following an exchange with Adam he sent me a replacement and said it was the very first D3 that has ever failed when properly cooled. Remember that the ESCs share the total power output so that the max I've seen in flight (99 A when testing out max power available, 3,600 W) means that each will be passing just under 60A in this worst case. The usual max current draw is between 80 and 85 A so that's 40 - 42.5 A on each ESC. The ESCs have never felt more than slightly warm except when the faulty ESC blew up! The view from the top of the fuselage looks as if the battery pack is behind the ESCs. The pack is mounted so that it's centre is aligned with the Motor shaft so the 1.2 Kg battery pack is on the motor centreline to avoid any out of balance during rolling. The ESCs are mounted below the motor so there is plenty of space for the air to flow in and past the ESC heat sinks.

I took advice from Adam Debowki on mounting these ESCs. He sent me a photo that showed the configuration that I have adopted. I did check the ESC temps after the first flight and they were barely warm. I have had an ESC failure but following an exchange with Adam he sent me a replacement and said it was the very first D3 that has ever failed when properly cooled. Remember that the ESCs share the total power output so that the max I've seen in flight (99 A when testing out max power available, 3,600 W) means that each will be passing just under 60A in this worst case. The usual max current draw is between 80 and 85 A so that's 40 - 42.5 A on each ESC. The ESCs have never felt more than slightly warm except when the faulty ESC blew up! The view from the top of the fuselage looks as if the battery pack is behind the ESCs. The pack is mounted so that it's centre is aligned with the Motor shaft so the 1.2 Kg battery pack is on the motor centreline to avoid any out of balance during rolling. The ESCs are mounted below the motor so there is plenty of space for the air to flow in and past the ESC heat sinks.