Turbine Engine Build

#1

Junior Member

Thread Starter

Join Date: Aug 2011

Location: , AUSTRALIA

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Hi all,

Geoff from Australia.

I've been interested in jets for a long time and only realised in the last two years that it was possible to make a small one.

I have zero experience in R/C planes until last week using a buddy system.... my god its hard.

My Trade as a Mechanical Designer/Engineer has helped somewhat.

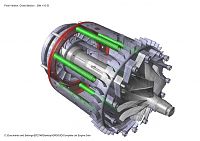

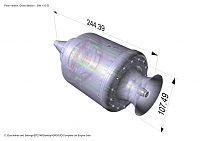

This is a 3d build based on the KJ66 with some modifications to make it easier to fabricate. Most of it will be CNC as I can just send them the 3d file (Don't want to do much my self as I'm clumsy and a bit **** with my hands).

At the present I'm looking at getting it made in China although I am struggling to find/contact one.

Ihave the bearings so far... haha as Iwork for SKF.

Geoff from Australia.

I've been interested in jets for a long time and only realised in the last two years that it was possible to make a small one.

I have zero experience in R/C planes until last week using a buddy system.... my god its hard.

My Trade as a Mechanical Designer/Engineer has helped somewhat.

This is a 3d build based on the KJ66 with some modifications to make it easier to fabricate. Most of it will be CNC as I can just send them the 3d file (Don't want to do much my self as I'm clumsy and a bit **** with my hands).

At the present I'm looking at getting it made in China although I am struggling to find/contact one.

Ihave the bearings so far... haha as Iwork for SKF.

#2

My Feedback: (22)

Join Date: Sep 2004

Location: Ft Collins,

CO

Posts: 127

Likes: 0

Received 0 Likes

on

0 Posts

Hi Geoff,

First of all, welcome to RCU. The world of RC is a lot of fun.

That's an impressive design you have so far. A few years ago I worked out most of the design for an axial flow turbine engine. Never got around to building it, I think I may have been too ambitious with my machining expectations. Turns out most of my parts weren't possible to build with the size and intricacies I needed.

What rpm is it expected to run? Auto-starting or manual?

P.S. since you work for SKF, maybe you can find out why no one ever responded to my inquiries about custom magnetic thrust bearings

First of all, welcome to RCU. The world of RC is a lot of fun.

That's an impressive design you have so far. A few years ago I worked out most of the design for an axial flow turbine engine. Never got around to building it, I think I may have been too ambitious with my machining expectations. Turns out most of my parts weren't possible to build with the size and intricacies I needed.

What rpm is it expected to run? Auto-starting or manual?

P.S. since you work for SKF, maybe you can find out why no one ever responded to my inquiries about custom magnetic thrust bearings

#3

Junior Member

Thread Starter

Join Date: Aug 2011

Location: , AUSTRALIA

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Thanks,

I'm only 20 so theres no way I could Machine it, I'm useless with my hands.

Basically if you can draw it it can be made no matter how small. Just need to find some one with the correct equipment.

Ie. 5 Axis CNC, just give them the 3d file and the machine spits it out.

I have found a chinese supplier now that can make the compresser fully machined in Inconical Alloy for $20 US so the ball

has started rolling.

As for RPM, its quite a large turbine dimensionally compared to other RC Jets it should max out 112k RPM.

I've looked at Auto turn on with the eletric motors and clutch. At the moment I just want to keep it simple, less things to go wrong.

Then Il start looking into FADEC systems.

If all works I'm hoping to get 30lbs of thrust.

I'm only 20 so theres no way I could Machine it, I'm useless with my hands.

Basically if you can draw it it can be made no matter how small. Just need to find some one with the correct equipment.

Ie. 5 Axis CNC, just give them the 3d file and the machine spits it out.

I have found a chinese supplier now that can make the compresser fully machined in Inconical Alloy for $20 US so the ball

has started rolling.

As for RPM, its quite a large turbine dimensionally compared to other RC Jets it should max out 112k RPM.

I've looked at Auto turn on with the eletric motors and clutch. At the moment I just want to keep it simple, less things to go wrong.

Then Il start looking into FADEC systems.

If all works I'm hoping to get 30lbs of thrust.

#4

Junior Member

Thread Starter

Join Date: Aug 2011

Location: , AUSTRALIA

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

http://www.skf.com/portal/skf_rev/ho...ntentId=079776 < Magnetic Thrust bearings with Sensors.

#5

My Feedback: (22)

Join Date: Sep 2004

Location: Ft Collins,

CO

Posts: 127

Likes: 0

Received 0 Likes

on

0 Posts

Well there you have it. I guess I just had to wait 7 years to have my questions answered.

Ok, excuse me while Igasp......If they can machine inconel (I assume that's what you meant instead of Inconical) for that price, how much is the raw material?? I'd say just order some bulk stock and import it to the states for pennies on the dollar and retire before you hit 30. By the way, why are you making the compressor out of such a material in the first place? The compressor won't experience enough heat to requireinconel and the rotational inertia will be much higher than an aluminum compressor....just a thought.

Have you done any CFD/thermal analyses on your model yet? I'm interested to see what the compressor and turbine efficiencies are. What sort of combustion pressure do you plan to achieve?

ORIGINAL: geoffrey.m.reynolds

I have found a chinese supplier now that can make the compresser fully machined in Inconical Alloy for $20 US so the ball

has started rolling.

I have found a chinese supplier now that can make the compresser fully machined in Inconical Alloy for $20 US so the ball

has started rolling.

Have you done any CFD/thermal analyses on your model yet? I'm interested to see what the compressor and turbine efficiencies are. What sort of combustion pressure do you plan to achieve?

#6

Junior Member

Thread Starter

Join Date: Aug 2011

Location: , AUSTRALIA

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

I only use Rhino 3d for my Modelling which dosn't have any CFD capabilities and Autocad Mechanical for 2d . Can you suggest any free ones out there?

Wait no Ive got confused Icon for the Shaft Iv'e used was tossing up between 7075 and that. Compresser wheel is

aluminium. As for compression ratio etc I haven't really touched that ground. Material Wise im thinking outer sheel SU304 S.S, most of the inside Aluminium. Only things im worried about is the shaft, NGV and exhaust fan for the exotic materials.

The actual compresser design I took froma Garrett turbo in a everday car and had a local company 3d scan it and I modelled over that with a few changes so it could be machined and changed around some sizing.

Wait no Ive got confused Icon for the Shaft Iv'e used was tossing up between 7075 and that. Compresser wheel is

aluminium. As for compression ratio etc I haven't really touched that ground. Material Wise im thinking outer sheel SU304 S.S, most of the inside Aluminium. Only things im worried about is the shaft, NGV and exhaust fan for the exotic materials.

The actual compresser design I took froma Garrett turbo in a everday car and had a local company 3d scan it and I modelled over that with a few changes so it could be machined and changed around some sizing.

#7

My Feedback: (22)

Join Date: Sep 2004

Location: Ft Collins,

CO

Posts: 127

Likes: 0

Received 0 Likes

on

0 Posts

I think Google has a free 3D program, but I haven't tried it. I get a free license through my school for Solidworks, which has built-in CFD and FEA capabilities. I also have ANSYS, but I haven't played around with it yet to learn how to use it.

I think a Garrett compressor is only good for about 25psi at ~100krpm (if I remember correctly, the rpm may be lower though). For the numbers you're talking about, you'll need at least 80-100psi. You can do a multi-stage compressor, just place multiple compressors in series until you get the desired pressure. However, I would recommend using a hybrid compressor instead of an automotive part. Automotive engines can't handle pressures higher than ~25psi, so the turbos don't need to produce more than that. Some diesels run mutliple turbos in series to achieve higher pressures, but those are specific cases.

I would also use stainless for the shaft and only use the exotic materials for the combustion screen, fuel lines/injectors, and turbine. That'll greatly lower cost and improve machineability.

Wow, I've gotten myself all excited to start my old engine project back up again.

I think a Garrett compressor is only good for about 25psi at ~100krpm (if I remember correctly, the rpm may be lower though). For the numbers you're talking about, you'll need at least 80-100psi. You can do a multi-stage compressor, just place multiple compressors in series until you get the desired pressure. However, I would recommend using a hybrid compressor instead of an automotive part. Automotive engines can't handle pressures higher than ~25psi, so the turbos don't need to produce more than that. Some diesels run mutliple turbos in series to achieve higher pressures, but those are specific cases.

I would also use stainless for the shaft and only use the exotic materials for the combustion screen, fuel lines/injectors, and turbine. That'll greatly lower cost and improve machineability.

Wow, I've gotten myself all excited to start my old engine project back up again.

#8

My Feedback: (94)

Geoff,

You design is a good start. Definitely recommend going here:

http://www.gtba.co.uk/

P.S. you posted in the "EDF" Electric dusted fan forum. Porbably get a better response in the regular "jets" forum.

Cheers,

Pedro

You design is a good start. Definitely recommend going here:

http://www.gtba.co.uk/

P.S. you posted in the "EDF" Electric dusted fan forum. Porbably get a better response in the regular "jets" forum.

Cheers,

Pedro