OS 200 FS gas conversion problem

#1

Thread Starter

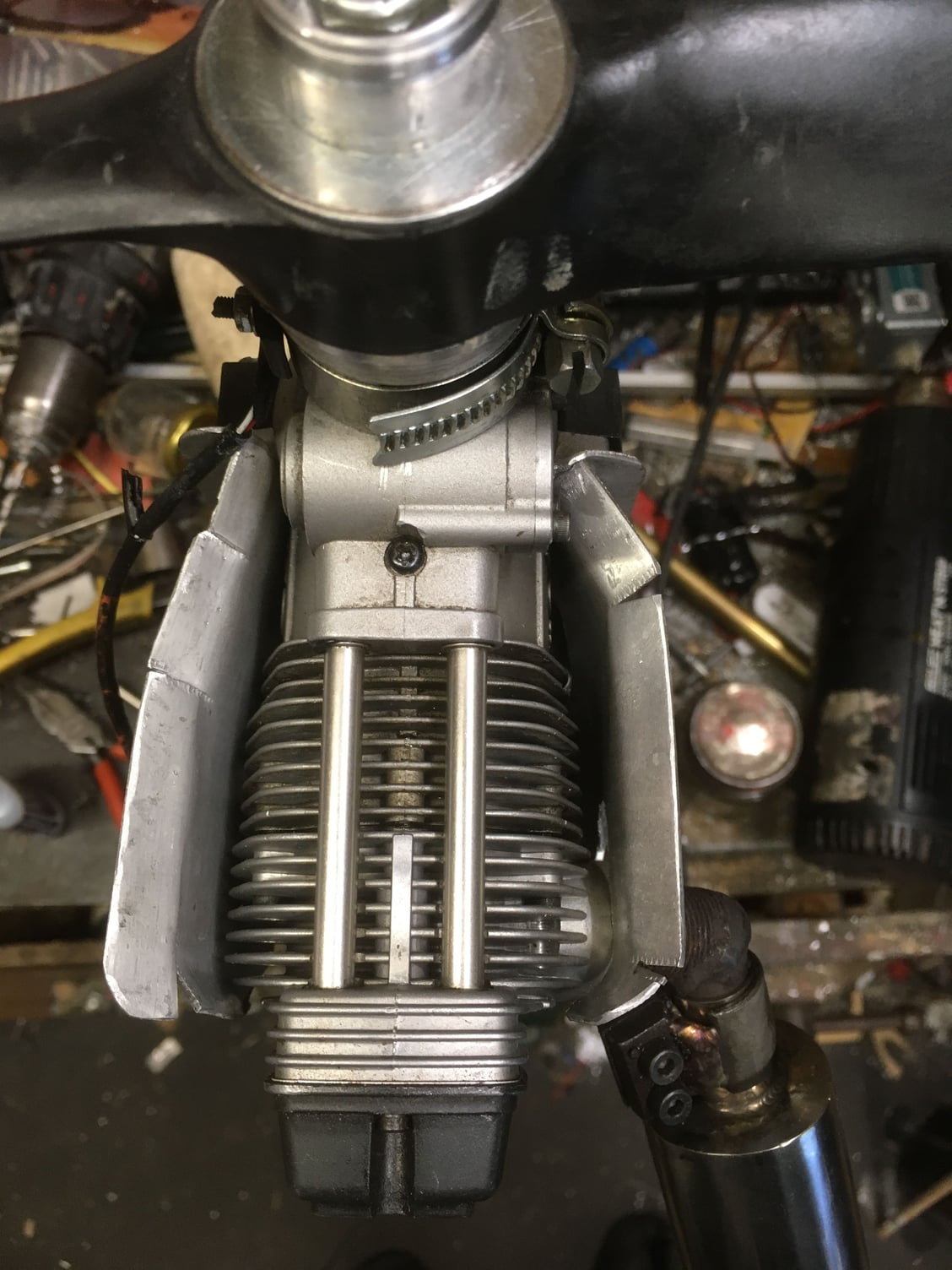

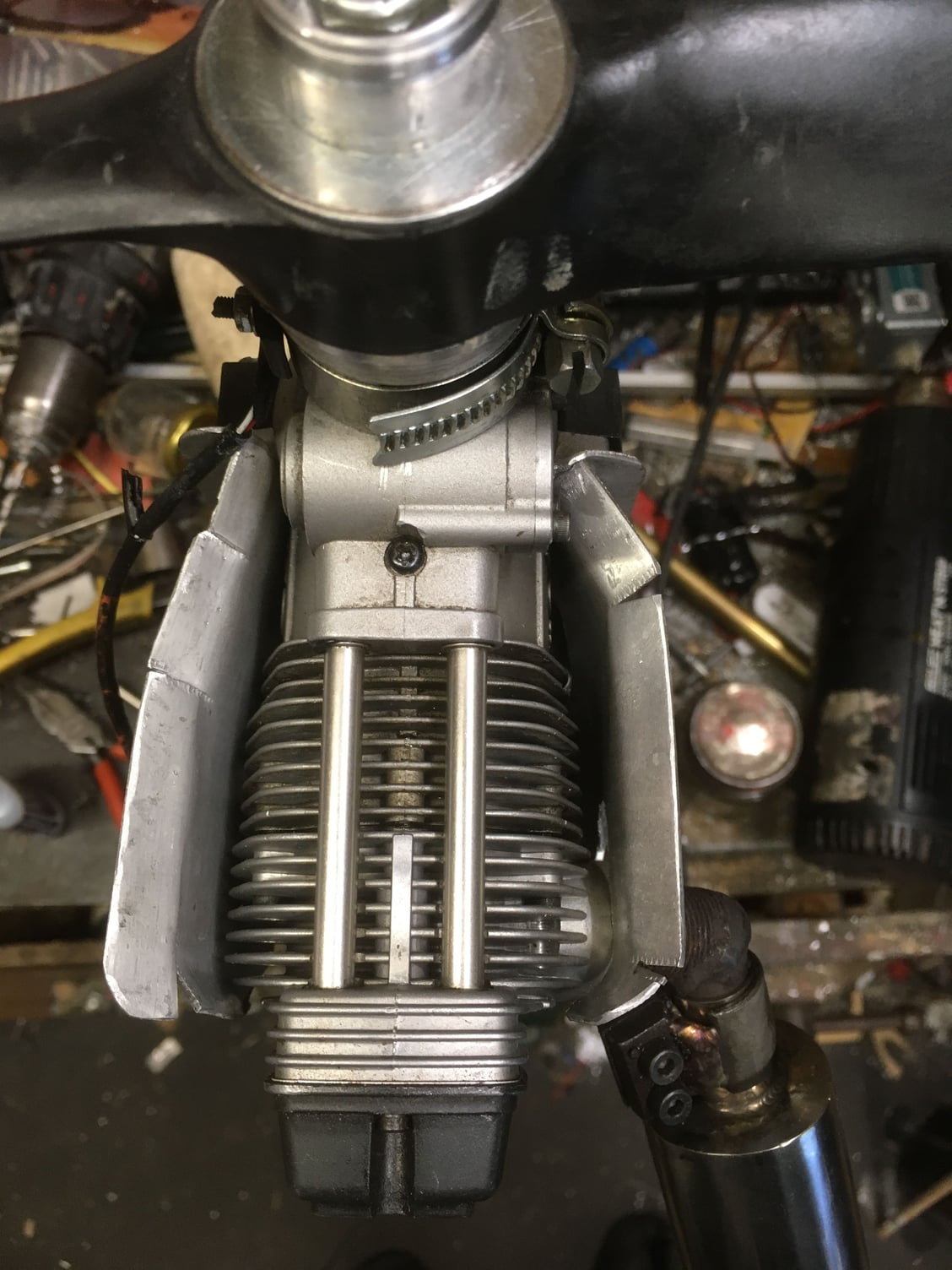

I converted an OS 200 FS to gas with Walbro and ignition and even put exhaust valve bronze seat in head.

Problem is it overheats and seizes at full throttle . Piston does not have any scuffing though and ring gap is 0.15 mm.

I have had conversions get hot but not to the extent that is seizes and stops.

Any help is appreciated

Problem is it overheats and seizes at full throttle . Piston does not have any scuffing though and ring gap is 0.15 mm.

I have had conversions get hot but not to the extent that is seizes and stops.

Any help is appreciated

#2

What you are seeing is not seizing. If there is no scuffing or other marks, it is not seizing. It is the engine reaching the temperature where the exhaustvalve is hot enough to start acting like a glowplug.

I take it, you have seen this on the ground? Static or bench run?

It will be a lot better in the air, but do try to keep an eye at the CHT if you have telemetry, and if possible, attempt to improve cooling by proper air ducting around the cylinder. Converting to gasoline will in cases be a compromis, albeit that in 99% of situations the endresult will be perfectly flyable. I flew my converted ASP twin under downright tropical conditions today and the engine functioned just like always

I take it, you have seen this on the ground? Static or bench run?

It will be a lot better in the air, but do try to keep an eye at the CHT if you have telemetry, and if possible, attempt to improve cooling by proper air ducting around the cylinder. Converting to gasoline will in cases be a compromis, albeit that in 99% of situations the endresult will be perfectly flyable. I flew my converted ASP twin under downright tropical conditions today and the engine functioned just like always

#3

Thread Starter

1967brutus Thanks for your comments

When it starts to slow down and I stop it there is certainly a lot of drag but quickly disappears.

I have put shrouds against the fins to force air past cooling fins but still starts to bind up. Yes you are right the tests are all static as yet.

I was wondering if it could be the bearings, not enough clearance check if (C3)

I have two ASP 180 fs running perfect on gas no problems, thermisters on the heads with telemetry to monitor temp, these convert really good and also have bronze guides and seats from factory..

I did convert an OS200FS in the past but it didn't behave like this but the exhaust valve ate its way through the alloy head and that was that.

When it starts to slow down and I stop it there is certainly a lot of drag but quickly disappears.

I have put shrouds against the fins to force air past cooling fins but still starts to bind up. Yes you are right the tests are all static as yet.

I was wondering if it could be the bearings, not enough clearance check if (C3)

I have two ASP 180 fs running perfect on gas no problems, thermisters on the heads with telemetry to monitor temp, these convert really good and also have bronze guides and seats from factory..

I did convert an OS200FS in the past but it didn't behave like this but the exhaust valve ate its way through the alloy head and that was that.

Last edited by cutarug; 06-17-2023 at 05:50 PM.

#4

That shroud MIGHT work, in flight...

On the ground it only makes things worse, because (and I too only found this out a couple of years ago) the propwash does not behave as most people, including me, would expect it to behave.

That shroud won't force air through the fins, it will cause the air to become more stagnant in front of the cylinder during benchtests.

Don't get me wrong, I am no expert on this but I tried what you tried and on the ground it does not work, in the air barely.

Not on my normal device right now so data is limited and typing awkward, will get back on this in one or two days.

On the ground it only makes things worse, because (and I too only found this out a couple of years ago) the propwash does not behave as most people, including me, would expect it to behave.

That shroud won't force air through the fins, it will cause the air to become more stagnant in front of the cylinder during benchtests.

Don't get me wrong, I am no expert on this but I tried what you tried and on the ground it does not work, in the air barely.

Not on my normal device right now so data is limited and typing awkward, will get back on this in one or two days.

#5

Thread Starter

Yes you are on the ball there, as I was recently told at a scale event that all model Tiger Moths overheat because the propeller rotates the wrong direction.

The cowl on a full size Tiger Moth was designed for a Gypsy Major engine which rotates CW, on a model the prop rotates the opposite direction more or less creating a vacuum at the front opening.

Hence I have modified the baffles and will see how that goes. I did think it got hotter with the baffles so this will open up the side of the fins.

#6

It is not so much in the direction of rotation of the prop. I tried that too and did not gain anything measurable.

It is more in the fact that air does not scale down, and as weird as this may sound, air is too "thick" to fall for this trick.

I tried similar in several different ways, and never got any measurable difference, UNLESS there was an extensive airscoop of sufficient dimension to force the air through the fins.

Flying, it will work better, but on the bench, no way Jose, that darned air won't go where you want it to be...

I found that in cowled engines, what made the most effect, was air deflectors in front of the air EXIT, creating a local low pressure zone. That seems to be way more effective, although I cannot explain why.

It's just an observation, just a thought.

It is more in the fact that air does not scale down, and as weird as this may sound, air is too "thick" to fall for this trick.

I tried similar in several different ways, and never got any measurable difference, UNLESS there was an extensive airscoop of sufficient dimension to force the air through the fins.

Flying, it will work better, but on the bench, no way Jose, that darned air won't go where you want it to be...

I found that in cowled engines, what made the most effect, was air deflectors in front of the air EXIT, creating a local low pressure zone. That seems to be way more effective, although I cannot explain why.

It's just an observation, just a thought.

Last edited by 1967brutus; 06-18-2023 at 02:59 PM.