AMR Trainer 26 - (my) official build thread

#151

Senior Member

Thread Starter

#152

Senior Member

Thread Starter

#153

Senior Member

Thread Starter

#154

Senior Member

Thread Starter

#157

Banned

#158

Senior Member

Thread Starter

Thanks, fellas. I used to take my DSLR into the shop for project photos - now I do all that with the camera on my Samsung Galaxy S4.

#159

Senior Member

Thread Starter

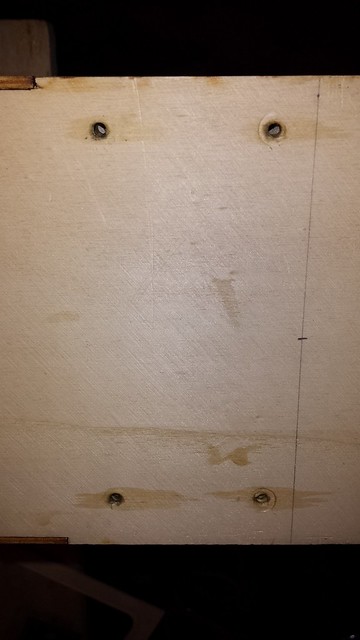

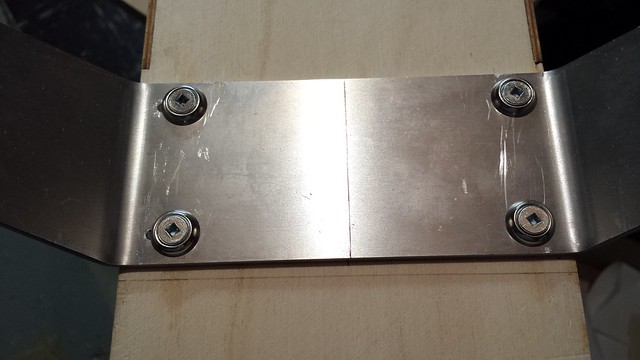

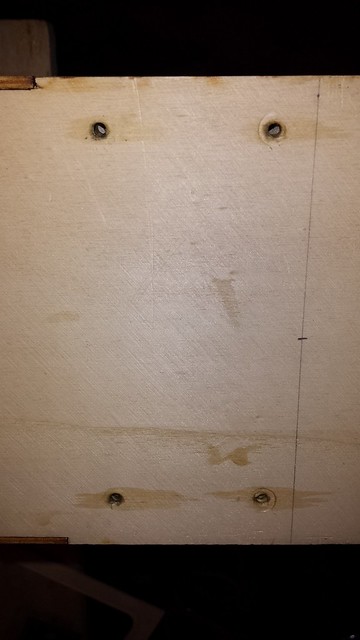

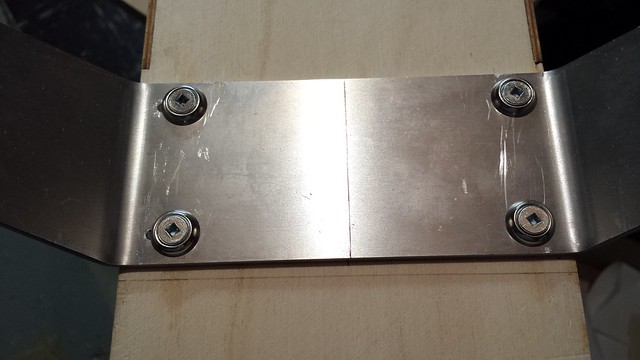

Step 77 specifies installation of the gear with 6-32 bolts and blind nuts. This would work if installation of tank try F10 back in step 10 hadn't covered up inside access to the front holes. No sweat; I have another tried and true method at hand: #10 wood screws.

Drilling the holes.

Drilled, threaded and drizzled with CA.

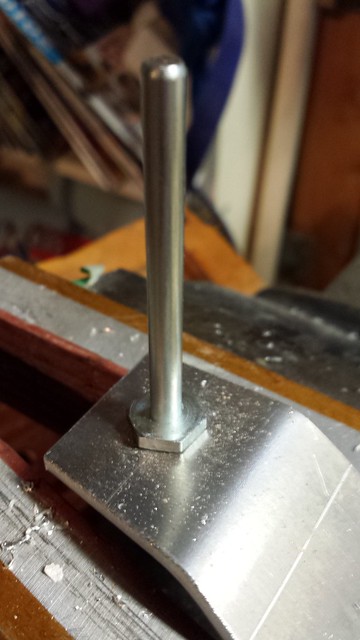

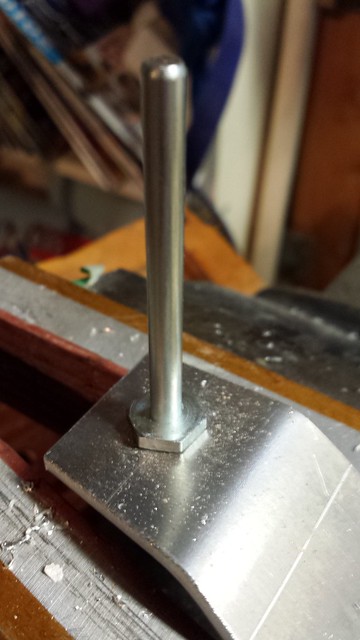

Step 78 directs the builder to use socket head cap screws as axles. I prefer the spring steel Du-Bro models so I drilled out the axles holes to 5/16" to accommodate them.

Landing gear mounted.

Drilling the holes.

Drilled, threaded and drizzled with CA.

Step 78 directs the builder to use socket head cap screws as axles. I prefer the spring steel Du-Bro models so I drilled out the axles holes to 5/16" to accommodate them.

Landing gear mounted.

#160

Senior Member

Thread Starter

I had some 4" wheels in the shop so I'm using those instead of the supplied 3-1/2" wheels.

I also don't like the supplied tail wheel bracket so I'm going with a Great Planes model that I've used before.

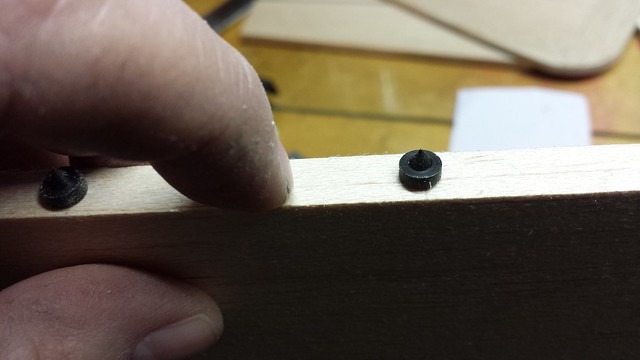

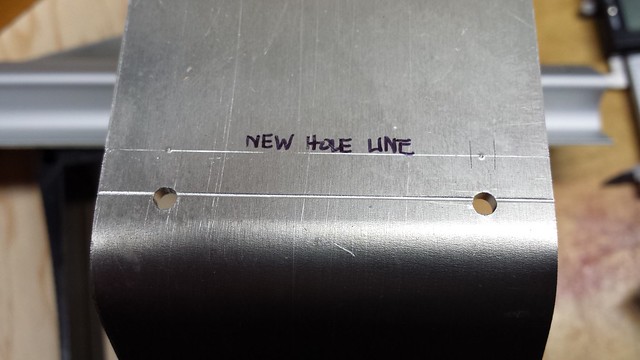

I figured that the tail wheel arm would benefit from a third hole - here the location is marked.

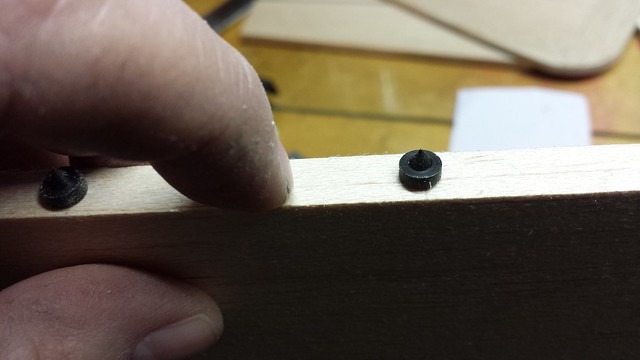

Hole drilled.

I also don't like the supplied tail wheel bracket so I'm going with a Great Planes model that I've used before.

I figured that the tail wheel arm would benefit from a third hole - here the location is marked.

Hole drilled.

#161

Senior Member

Thread Starter

#163

Senior Member

Thread Starter

On to the empennage. Back in the first pages I cut all the pieces out from 3/8" balsa and glued the relevant parts together. When I got them out again the first thing I did was to go over the joined with a razor plane to knock off any glue and high spots.

The manual makes no reference to the stabilizer leading edges but I've not see square ones yet. I clamped the horizontal stabilizer in the vise - GENTLY - to work on it.

The very first pass with the razor plane.

Nicely rounded.

The manual makes no reference to the stabilizer leading edges but I've not see square ones yet. I clamped the horizontal stabilizer in the vise - GENTLY - to work on it.

The very first pass with the razor plane.

Nicely rounded.

#165

#166

Senior Member

Thread Starter

#168

Senior Member

Thread Starter

The rudder one of the rudder hinges is supposed to go in the rear of the fuselage. Not going to happen until I fill this gap.

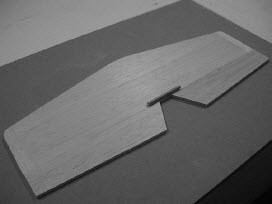

This was a piece of 3/8" balsa but I've planed it to thickness. The notch is for the part of the tail wheel bracket screw that sticks out. Why didn't I just remove the screw and re-install it afterwards? Damn good question!

Just the right depth for a hinge point.

Glued in place.

This was a piece of 3/8" balsa but I've planed it to thickness. The notch is for the part of the tail wheel bracket screw that sticks out. Why didn't I just remove the screw and re-install it afterwards? Damn good question!

Just the right depth for a hinge point.

Glued in place.

#169

Senior Member

Thread Starter

#170

Senior Member

Thread Starter

Time to make the hinge holes in the vertical stabilizer and rudder. I marked across the trailing edge of the stab where I wanted the hinges to go and made sure the line was visible through the Robart centring jig.

Drilling the hinge point holes.

When all of the holes were drilled I put these 1/8" blind hole spotters in place.

Drilling the hinge point holes.

When all of the holes were drilled I put these 1/8" blind hole spotters in place.

#171

Senior Member

Thread Starter

#172

Senior Member

Thread Starter

#174

Banned

I would add a U shaped 1/8 inch metal piano wire epoxied along the edges that goes a good inch toward the trailing edge of the elevator.

Zor

#175

Senior Member

Thread Starter

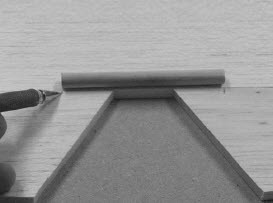

There are servo bays at the back of the fuse and I plan to use two elevator servos there.

The dowel is a backup in case the plane is too tail heavy and requires a single centrally located elevator servo. If that's the case then I'll consider your suggestion, Zor. If all goes to plan I will separate the dowel halves.

Thanks, fellas.

Last edited by grosbeak; 12-01-2014 at 07:41 AM.

[/url

[/url