US NAVY SeaDart F2Y (Flying boat) Build

#151

Thread Starter

[TABLE="width: 100%"]

[TR]

[TD="colspan: 2"][HR][/HR][/TD]

[/TR]

[/TABLE]

Epoxy mouldings were taken from the underside rear of the hull + the underside of the wingtips & the side of the fin/rudder to produce bases for the various fairings to be built onto. This would ensure a perfect fit of the final mouldings when fitted to the flying model. From front to back we have the tailwheel fairing, the two underwing tip floats, the rudder control linkage fairing & finally at the front, the small 3 part fairing on the top of the wingtips that covers over the tip elevon hinge.

The elevon tip hinge fairing is made from Chemiwood. This is only around 4-5" long and will be used to take a silicone mould before casting in fast cure PU resin.

Phil Clark, FighterAces

[TR]

[TD="colspan: 2"][HR][/HR][/TD]

[/TR]

[/TABLE]

Epoxy mouldings were taken from the underside rear of the hull + the underside of the wingtips & the side of the fin/rudder to produce bases for the various fairings to be built onto. This would ensure a perfect fit of the final mouldings when fitted to the flying model. From front to back we have the tailwheel fairing, the two underwing tip floats, the rudder control linkage fairing & finally at the front, the small 3 part fairing on the top of the wingtips that covers over the tip elevon hinge.

The elevon tip hinge fairing is made from Chemiwood. This is only around 4-5" long and will be used to take a silicone mould before casting in fast cure PU resin.

Phil Clark, FighterAces

#152

Thread Starter

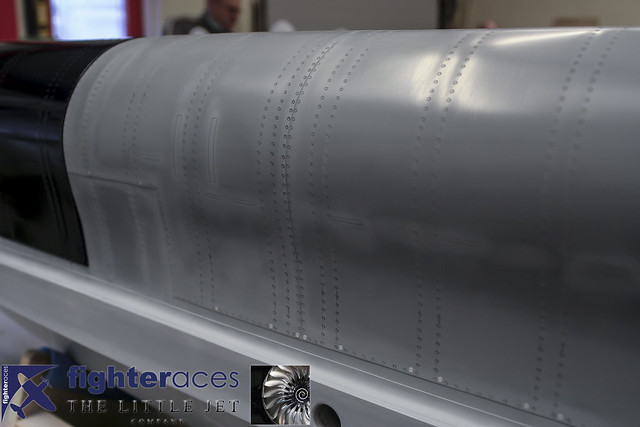

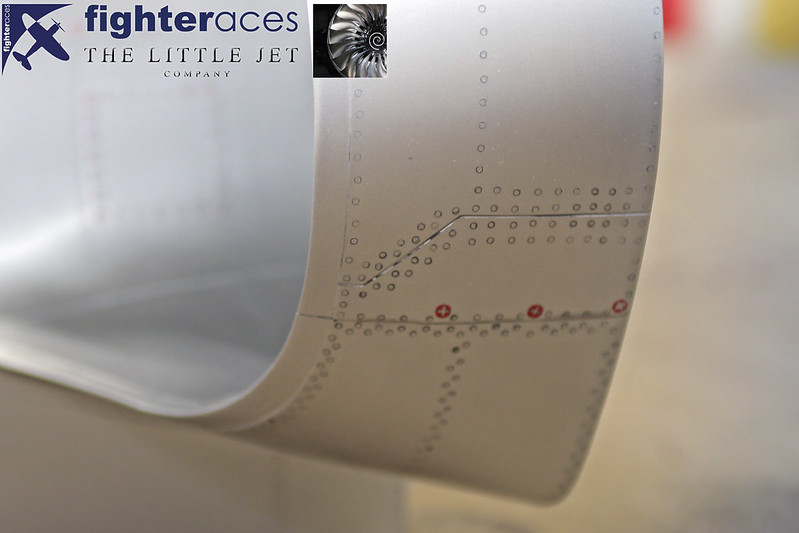

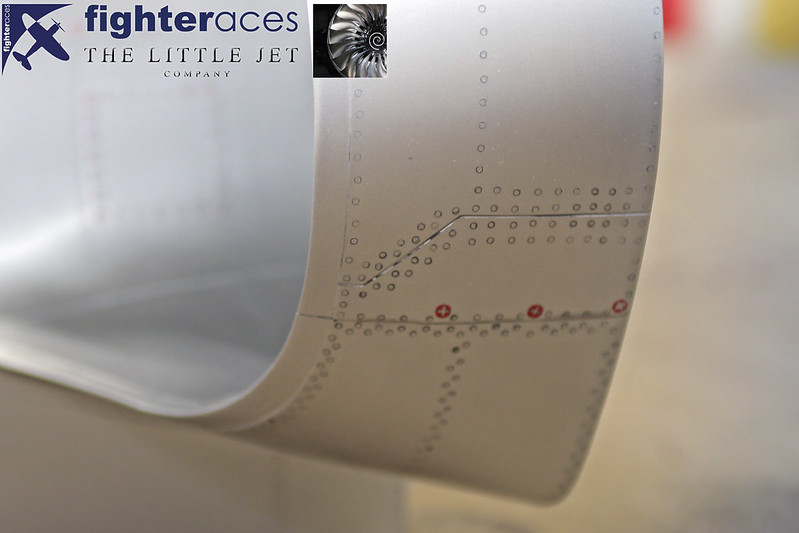

The forward fuselage having rivets applied.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

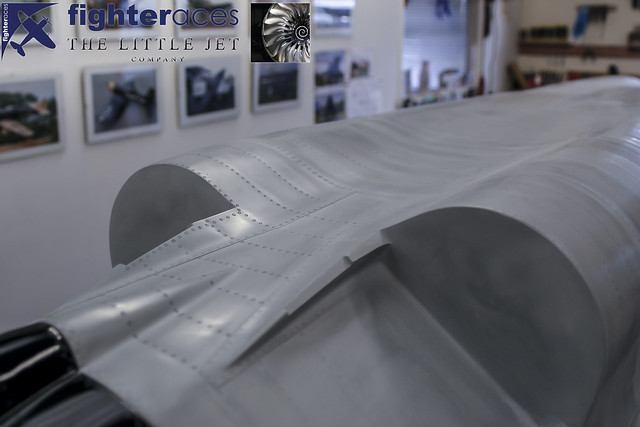

The finished result on the forward pattern section. FighterAces really have done an amazing job! Its worth noting this has been finished to a high gloss as this is the pattern not the flying model. The finished model will not be in a high gloss finish therefore the panel distortions will have a more subtle look as shown in the picture of this section in a satin primer.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

A picture of the full-size showing the distortions in the panels, this aircraft had a very unique structure more akin to a boat but one that had to survive doing 100kts plus on the waters surface and survive being dropped into the water with an equivalent force of 3G!

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>The finished result on the forward pattern section. FighterAces really have done an amazing job! Its worth noting this has been finished to a high gloss as this is the pattern not the flying model. The finished model will not be in a high gloss finish therefore the panel distortions will have a more subtle look as shown in the picture of this section in a satin primer.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>A picture of the full-size showing the distortions in the panels, this aircraft had a very unique structure more akin to a boat but one that had to survive doing 100kts plus on the waters surface and survive being dropped into the water with an equivalent force of 3G!

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

#157

Thread Starter

Thanks guys!

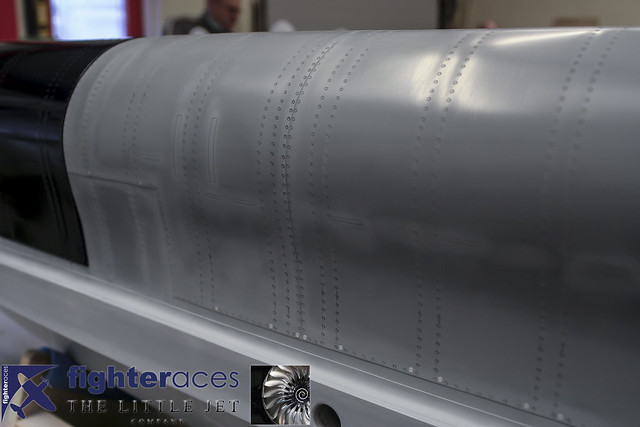

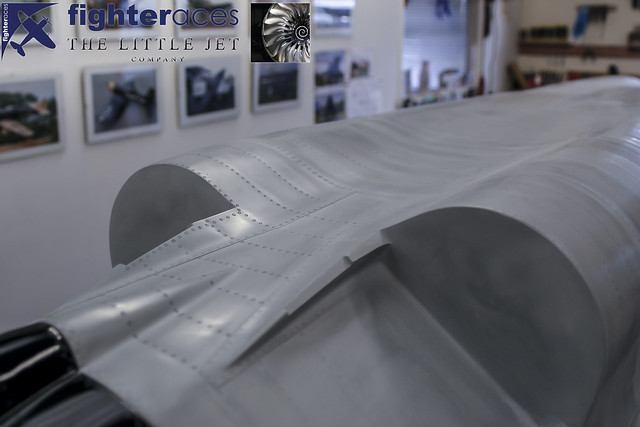

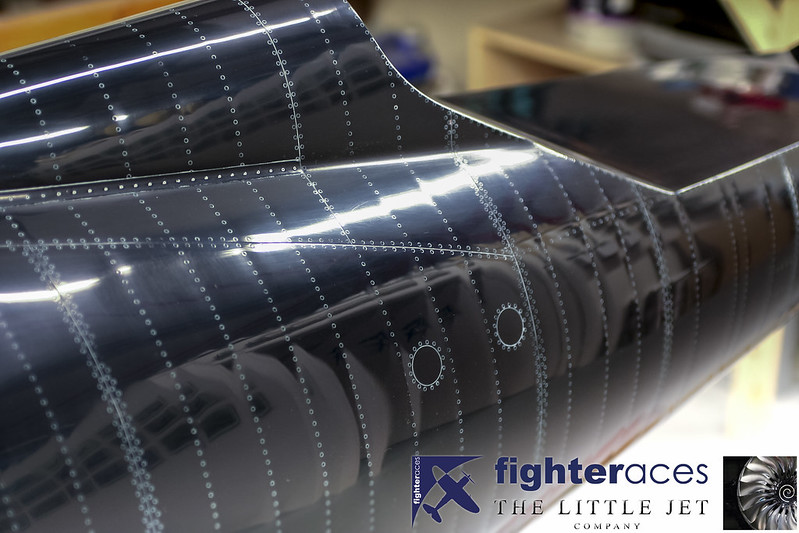

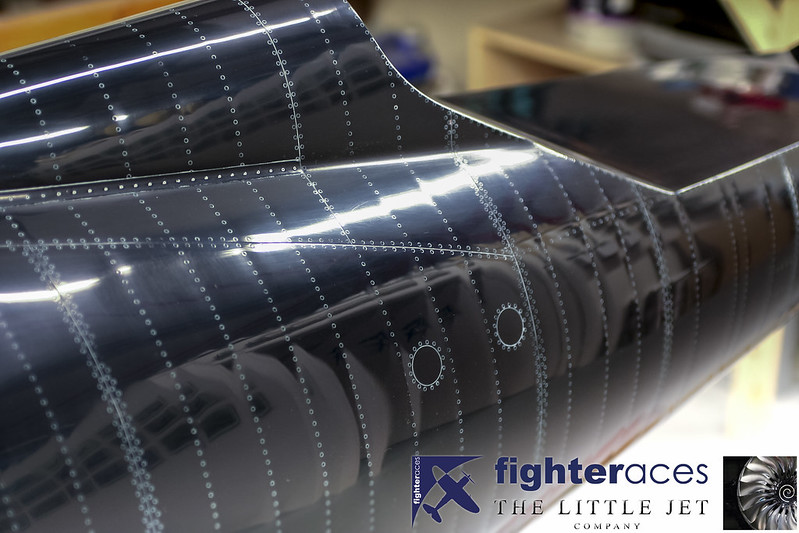

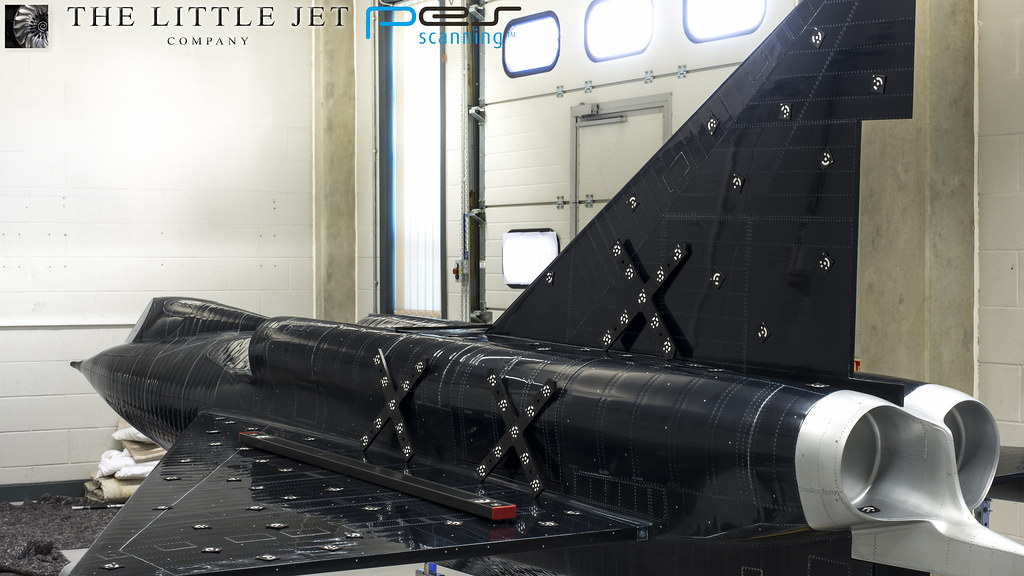

John from FighterAces working hard on detailing the rear section.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

A great image showing all the hard work that’s gone into reproducing each and every panel. Only 60,000 rivets to go!

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

John from FighterAces working hard on detailing the rear section.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>A great image showing all the hard work that’s gone into reproducing each and every panel. Only 60,000 rivets to go!

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

#158

Thread Starter

Phil from FighterAces has worked extremely hard applying over 100,000 individual rivets! I can't wait to show you what we've achieved with our other large composite projects. Our last post until we're back from the Christmas Holidays but I’ll leave this parting thought...

Next year is very exciting for everyone here at TLJC with a move to purpose built premises, a brand new website, different business opportunities and more importantly some huge never before seen custom built composite jets.

'Working at the cutting edge of composite design producing parts with firms who are involved at the forefront of Formula One and Aerospace in projects such as the Joint Strike Fighter guarantees this to be one of the most extraordinary model aircraft ever built.

Most composite parts will perform adequately with a generic composite lay-up but so often they are not optimised to exploit the performance that a composite can really provide. The key is to unlock that performance using modern materials and techniques applied correctly to achieve the lightest yet strongest structure possible…

Designing and producing sophisticated production-ready composite parts is highly complex and to our knowledge has never been achieved at this level of precision in an RC Jet.'

Merry Christmas & Happy New Year

TLJC Team

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

Next year is very exciting for everyone here at TLJC with a move to purpose built premises, a brand new website, different business opportunities and more importantly some huge never before seen custom built composite jets.

'Working at the cutting edge of composite design producing parts with firms who are involved at the forefront of Formula One and Aerospace in projects such as the Joint Strike Fighter guarantees this to be one of the most extraordinary model aircraft ever built.

Most composite parts will perform adequately with a generic composite lay-up but so often they are not optimised to exploit the performance that a composite can really provide. The key is to unlock that performance using modern materials and techniques applied correctly to achieve the lightest yet strongest structure possible…

Designing and producing sophisticated production-ready composite parts is highly complex and to our knowledge has never been achieved at this level of precision in an RC Jet.'

Merry Christmas & Happy New Year

TLJC Team

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

Last edited by Alex48; 12-21-2015 at 06:55 AM.

#160

Thread Starter

It's good to back from the holiday and we hope everyone had a great Christmas and New Year!

Our first day back was productive and very exciting. We have finally managed to get the gear geometry to work, this has been a major undertaking and a massive project in its own right with lots of ups and downs for all involved. It's a good feeling being able to move onto the surface modelling designs for the skis and oleos.

The pattern will be scanned using blue light technology at a resolution of around 29 microns so we can pick out every detail that the Fighteraces team have put so much effort into creating.

The end of January will see the tooling and layup designs finalised. We have some very talented composite specialists working on this project and its exciting to see technologies and techniques integrated into this model that have never before been used in a model aircraft.

The team at FighterAces have done an incredible job. I'm very much looking forward to visiting them this month and seeing the completed pattern!

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

Our first day back was productive and very exciting. We have finally managed to get the gear geometry to work, this has been a major undertaking and a massive project in its own right with lots of ups and downs for all involved. It's a good feeling being able to move onto the surface modelling designs for the skis and oleos.

The pattern will be scanned using blue light technology at a resolution of around 29 microns so we can pick out every detail that the Fighteraces team have put so much effort into creating.

The end of January will see the tooling and layup designs finalised. We have some very talented composite specialists working on this project and its exciting to see technologies and techniques integrated into this model that have never before been used in a model aircraft.

The team at FighterAces have done an incredible job. I'm very much looking forward to visiting them this month and seeing the completed pattern!

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>Last edited by Alex48; 01-05-2016 at 02:22 AM.

#161

Thread Starter

FighterAces have done an outstanding job, thanks Phil! I'm looking forward to collecting it next week and taking some photos of the finished pattern all together for the first time.

The pattern will now be scanned which will allow us to accurately design the internal structure. We aim to start tooling and manufacturing components ready for a basic prototype to be ground/water tested here in the UK in May. Lots of work to do!

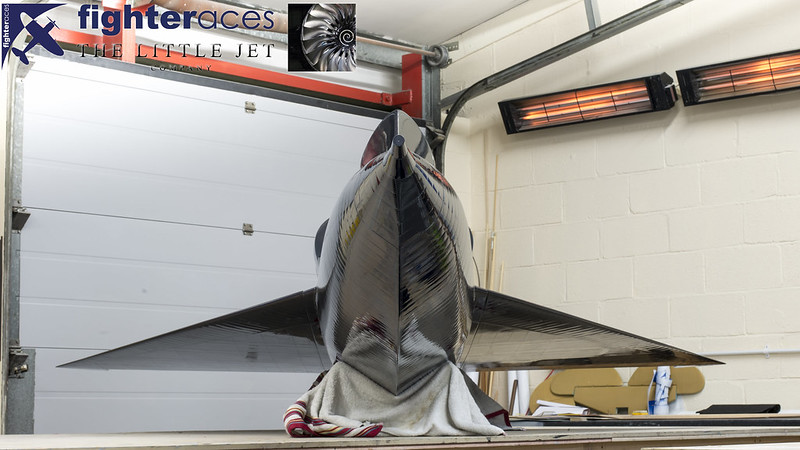

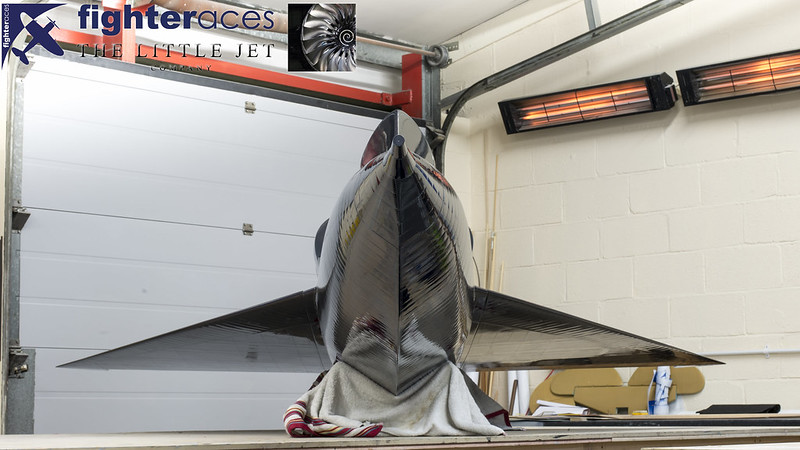

A few photos of the finished forward fuselage section. I love it but then I am heavily biased considering the last two years have been dedicated to getting it this far.

What could possibly go wrong.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

The pattern will now be scanned which will allow us to accurately design the internal structure. We aim to start tooling and manufacturing components ready for a basic prototype to be ground/water tested here in the UK in May. Lots of work to do!

A few photos of the finished forward fuselage section. I love it but then I am heavily biased considering the last two years have been dedicated to getting it this far.

What could possibly go wrong.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

Last edited by Alex48; 01-08-2016 at 10:23 AM.

#162

Join Date: Feb 2003

Location: Palmerston North, NEW ZEALAND

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

Happy New Year from down-under" and what a superb project and effort on this! Have sent you a PM on another matter (A4 related) as your email address bounced.

Cheers

Rene

NZ

Cheers

Rene

NZ

#163

Thread Starter

Hi Rene,

Thanks....

Was it [email protected]? I'll get back to shortly regarding the A4. Just incase you haven't looked the A4 build thread is here:

http://www.rcuniverse.com/forum/rc-j...awk-build.html

Cheers, Alex

Thanks....

Was it [email protected]? I'll get back to shortly regarding the A4. Just incase you haven't looked the A4 build thread is here:

http://www.rcuniverse.com/forum/rc-j...awk-build.html

Cheers, Alex

Last edited by Alex48; 01-10-2016 at 02:18 AM.

#164

Thread Starter

The pattern finally finished and what a pattern it is! Thank you to the team at Fighteraces who’ve dedicated 10 months of full time work and have really managed to capture the essence of the full-size which was no easy task. Great job guys and thank you! The pictures don't really show the scale or presence of this model... its huge!

Now onto scanning the pattern…

A few pictures at FighterAces of the finished pattern ready for delivery and thankfully I managed to get it to the scanners without damage! despite the blizzard and snow covered roads

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

Now onto scanning the pattern…

A few pictures at FighterAces of the finished pattern ready for delivery and thankfully I managed to get it to the scanners without damage! despite the blizzard and snow covered roads

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>Last edited by Alex48; 01-14-2016 at 03:45 PM.

#167

Thread Starter

Thanks guys

The project should move quite swiftly now as we hope to get a basic prototype complete for May. This can be evaluated here in the UK ready to send abroad for flight testing although we are still in talks with the appropriate aviation authorities as this model breaks almost every rule in the book in most countries. I consider myself lucky to have such a good large model scene here in the UK. This is run by the LMA on behalf of the CAA which allows us to do almost anything with the correct oversight, inspections and flight tests. So a quick thank you to everyone involved in the LMA.

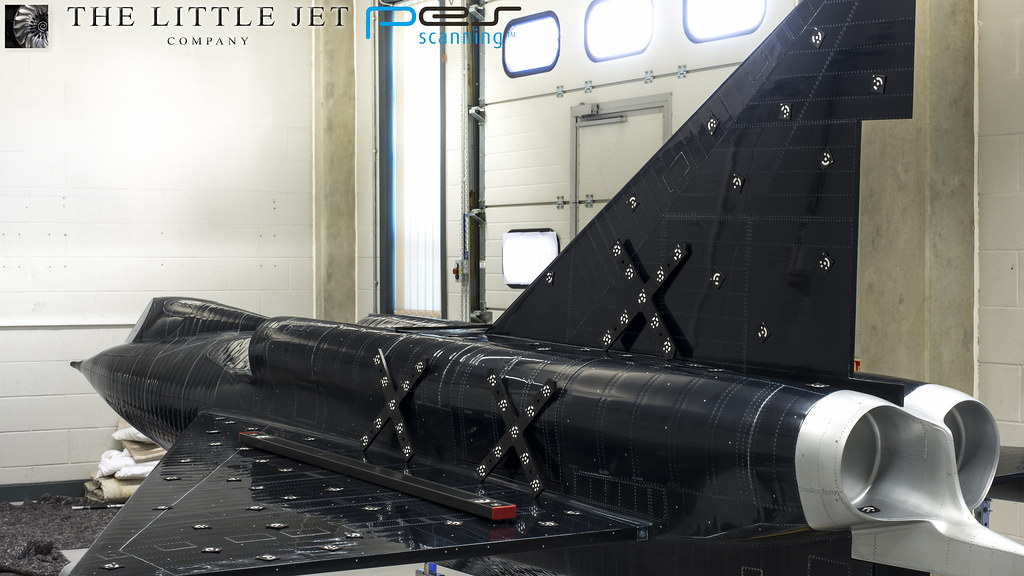

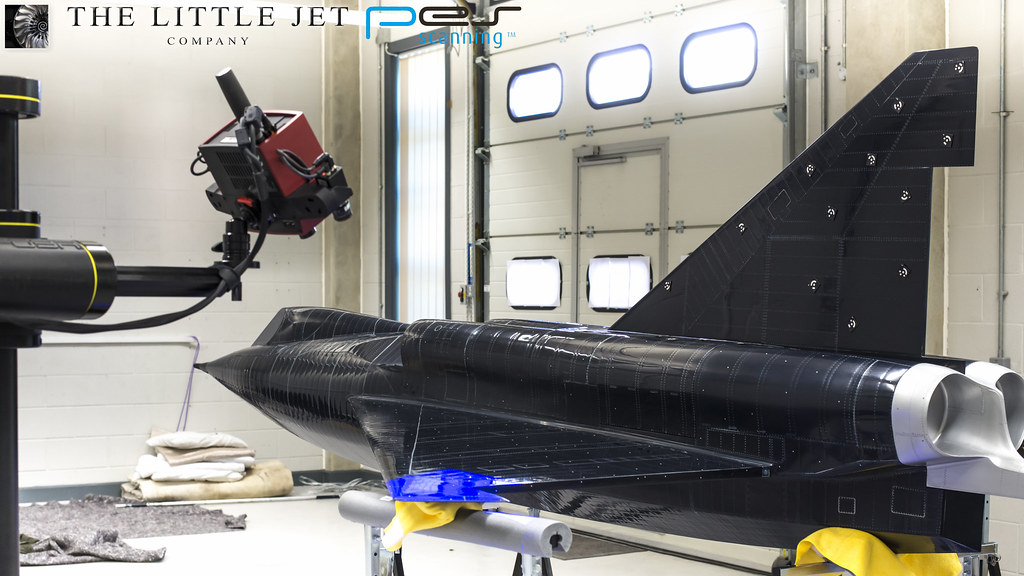

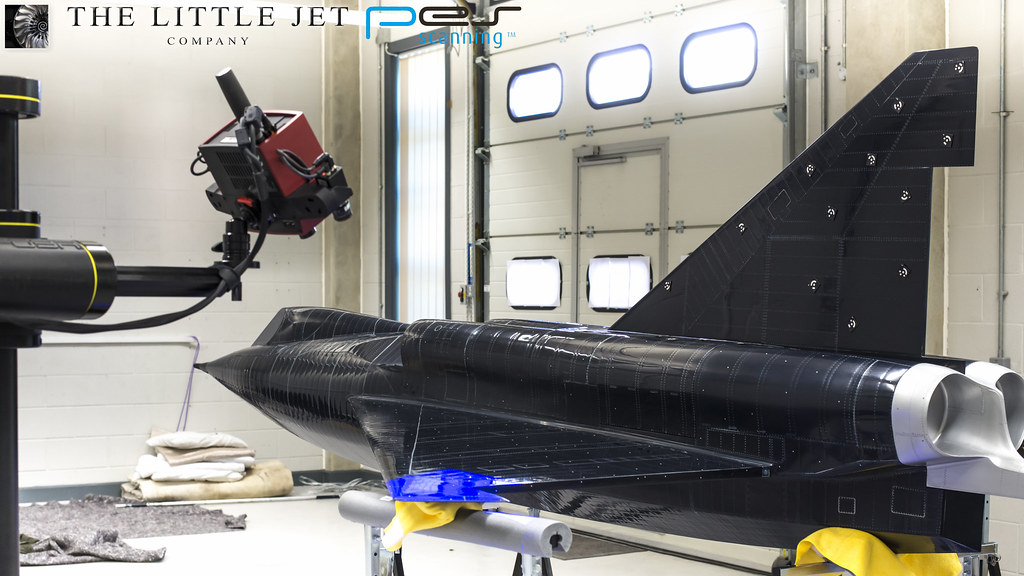

With phase 1 & 2 completed on schedule we can now move forward with the composite design. The next few months won’t actually see anything physical being built except the tooling. The time will be spent in CAD designing the internal structures, ski mechanisms and lay up designs etc… To facilitate this we are in the process of having the pattern scanned using blue light technology. There are many advantages to this that justify the significant expense of the process especially considering the resolution required to capture every rivet and panel deformation in the pattern.

Ordinarily on a project like this you would start with a CAD model, CNC the pattern and take the tooling from this. We don’t have the luxury of a CAD model which is where the scanning comes in. With the scan data we can accurately design all the internal structure but not only this we can now accurately determine the weight of the model before its built. This will significantly speed up the design process as weight it critical in determining how the model presents on the water. CG, ballast tanks, component position and many other areas of uncertainty can be designed in from the outset. Undoubtedly there will be changes in the design as there nearly always is but this allows us to get much closer to a finished model first time out.

The team at PES Scanning gave me a quick work flow run through of how they will scan the pattern along with a short demonstration starting with the photogrammetry. The scanning team have been very helpful through the whole process and I’m looking forward to seeing the results.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

The project should move quite swiftly now as we hope to get a basic prototype complete for May. This can be evaluated here in the UK ready to send abroad for flight testing although we are still in talks with the appropriate aviation authorities as this model breaks almost every rule in the book in most countries. I consider myself lucky to have such a good large model scene here in the UK. This is run by the LMA on behalf of the CAA which allows us to do almost anything with the correct oversight, inspections and flight tests. So a quick thank you to everyone involved in the LMA.

With phase 1 & 2 completed on schedule we can now move forward with the composite design. The next few months won’t actually see anything physical being built except the tooling. The time will be spent in CAD designing the internal structures, ski mechanisms and lay up designs etc… To facilitate this we are in the process of having the pattern scanned using blue light technology. There are many advantages to this that justify the significant expense of the process especially considering the resolution required to capture every rivet and panel deformation in the pattern.

Ordinarily on a project like this you would start with a CAD model, CNC the pattern and take the tooling from this. We don’t have the luxury of a CAD model which is where the scanning comes in. With the scan data we can accurately design all the internal structure but not only this we can now accurately determine the weight of the model before its built. This will significantly speed up the design process as weight it critical in determining how the model presents on the water. CG, ballast tanks, component position and many other areas of uncertainty can be designed in from the outset. Undoubtedly there will be changes in the design as there nearly always is but this allows us to get much closer to a finished model first time out.

The team at PES Scanning gave me a quick work flow run through of how they will scan the pattern along with a short demonstration starting with the photogrammetry. The scanning team have been very helpful through the whole process and I’m looking forward to seeing the results.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script> <script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>Last edited by Alex48; 02-01-2016 at 06:02 AM.

#168

Thread Starter

I forgot to mention that the above photos are a mock up and a quick demo only. It is a good representation of the process however the whole model will have to be sprayed with titanium dioxide before the scan. At the moment the pattern has the worst two properties for scanning, dark and glossy... The spray will allow the scanner to capture its data correctly with minimal noise. Its a very fine layer and on experimentation does not effect the detail built into the pattern.

Cheers, Alex

Cheers, Alex

#169

Thread Starter

A quick reminder as to the phase we are at with our SeaDart.

The next few weeks are going to be really interesting with several design meetings planned with the tooling firms and part manufactures along with a few specialist hydraulic companies. I'm very interested to see what we can come up with on the hydraulic side of things. The sequencing of the for and aft skis is critical in the retraction and extension sequences. Along with the need of full instantaneous proportional control of the water rudder/brake which we would also like to be hydraulic due to the forces involved in its deflection at speed in the water.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

The next few weeks are going to be really interesting with several design meetings planned with the tooling firms and part manufactures along with a few specialist hydraulic companies. I'm very interested to see what we can come up with on the hydraulic side of things. The sequencing of the for and aft skis is critical in the retraction and extension sequences. Along with the need of full instantaneous proportional control of the water rudder/brake which we would also like to be hydraulic due to the forces involved in its deflection at speed in the water.

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

Last edited by Alex48; 01-19-2016 at 04:23 AM.