Pump Voltages/ Fuel System Restrictions

#1

Thread Starter

Got a question regarding pump voltages and fuel system restrictions. I know it's a good idea to monitor pump voltages so that if you see an increase it may be the sign of an issue. I'm wondering how much of an increase would cause concern? For example I know my Merlin 140 has a normal pump voltage of ~.5v at idle, and ~4.0v at full. With these numbers in mind would a 0.1v increase be an indication, or would it be more dramatic like 1.0v? TIA!

#2

My Feedback: (2)

I run two Merlin 140XBLs, and have had some pump voltage issues in one of my models (Ultra Flash), so I now run an alarm if my pump voltage goes over 5.5V. My nominal is somewhere in the 4V range (going from memory).

A few months ago I started to get a Pump Voltage alarm at full throttle in flight, which then progressed to a couple of flame-outs. Flushed the Air Trap (MAP) to no effect, so I replaced the MAP Air Trap which has an integrated paper filter, which lowered the pump voltage and cured the flame-outs.

Having the Tx alarm at 5.5V saves checking the data every flight and gives adequate warning that something is deteriorating in the fuel system.

Paul

A few months ago I started to get a Pump Voltage alarm at full throttle in flight, which then progressed to a couple of flame-outs. Flushed the Air Trap (MAP) to no effect, so I replaced the MAP Air Trap which has an integrated paper filter, which lowered the pump voltage and cured the flame-outs.

Having the Tx alarm at 5.5V saves checking the data every flight and gives adequate warning that something is deteriorating in the fuel system.

Paul

#3

Thread Starter

Thanks Paul...I had a flameout on my Merlin (also in an UF), but everything pointed to an air bubble (“low speed” error msg, normal pump voltage). I like the idea of setting a pump voltage alarm which is why I asked how much above the norm would cause concern. I’ve got a JC Cheetah SE and a Kingtech K85G2 in the fleet...would like to set those planes up with alarms as well. Maybe I’ll start with 1.0v over max and keep an eye on the data logs.

#4

1v is a huge over voltage, 0.2-0.3v would bother me with a JetCat.

Composite tanks that don.t have all the dust/debris flushed with alcohol before assembly would do exactly what you are describing.

Composite tanks that don.t have all the dust/debris flushed with alcohol before assembly would do exactly what you are describing.

#5

Thread Starter

Thanks Dave...Looking at my logs the max pump voltage is pretty consistent (within .2V). Sounds like setting an alarm in the neighborhood of a .5V increase might be more appropriate.

#6

My Feedback: (2)

Just got back from Bomber Field, TX with my Merlin 140XBL powered DerJet Hawker Hunter, where I experienced a Pump Voltage warning for the first time with this model.

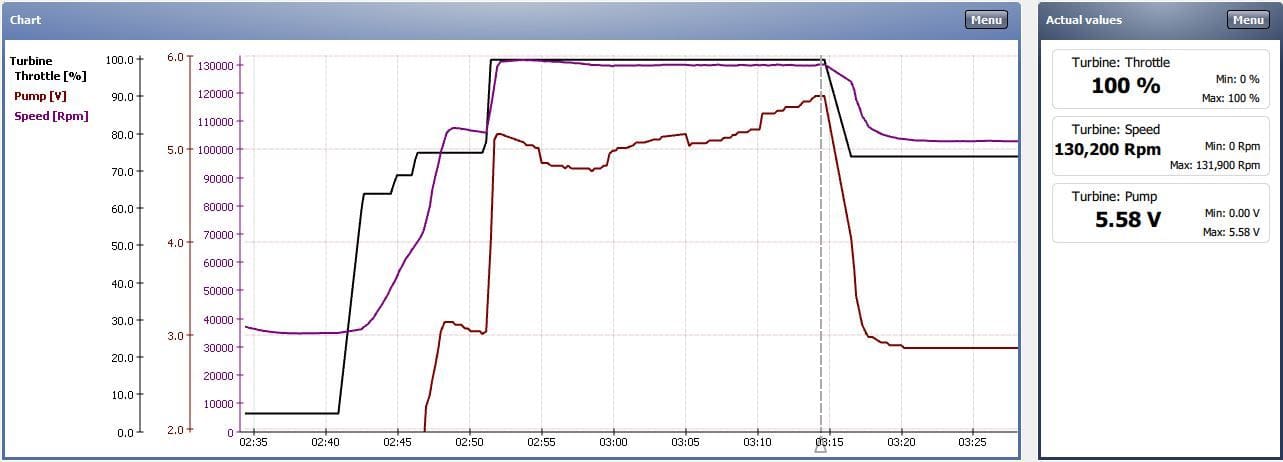

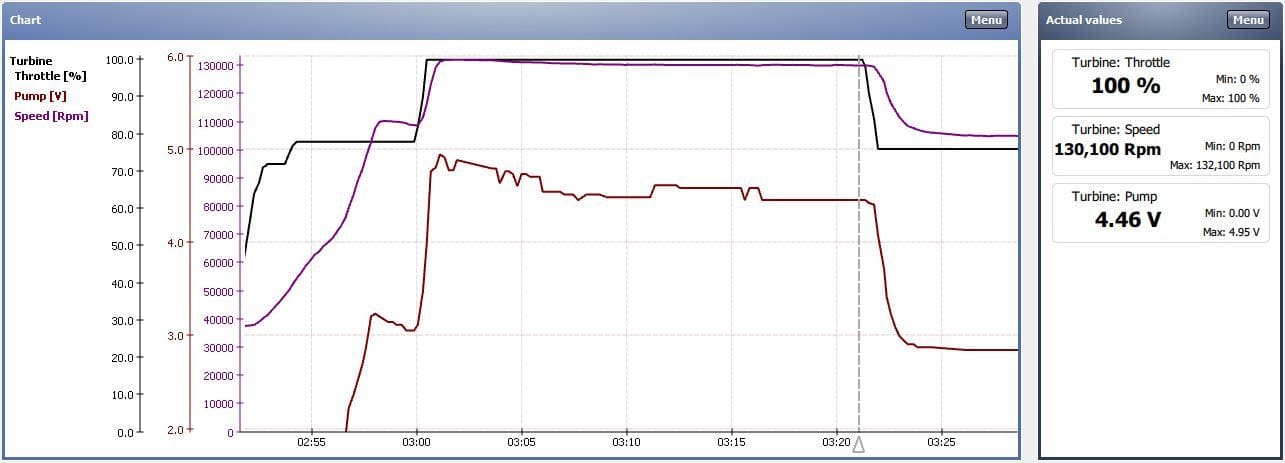

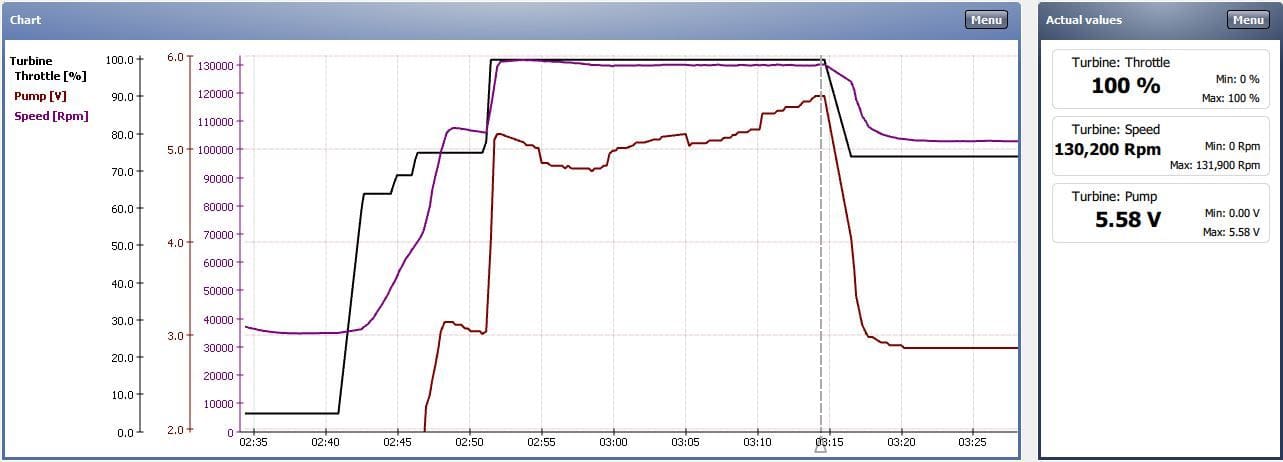

Part way through the first flight I went to full throttle and moments later got the pump voltage warning so immediately throttled back to part power. The rest of the flight was normal. Looking at the telemetry logs post flight, I could see that whilst the take-off was normal (Image 1), something happened mid-flight to cause the pump voltage to start increasing when I went to full power (Image 2). Accepting the risk I flew again, but got the warning after take-off whilst accelerating downwind at full power (Image 3) - the rest of the flight at part power was normal.

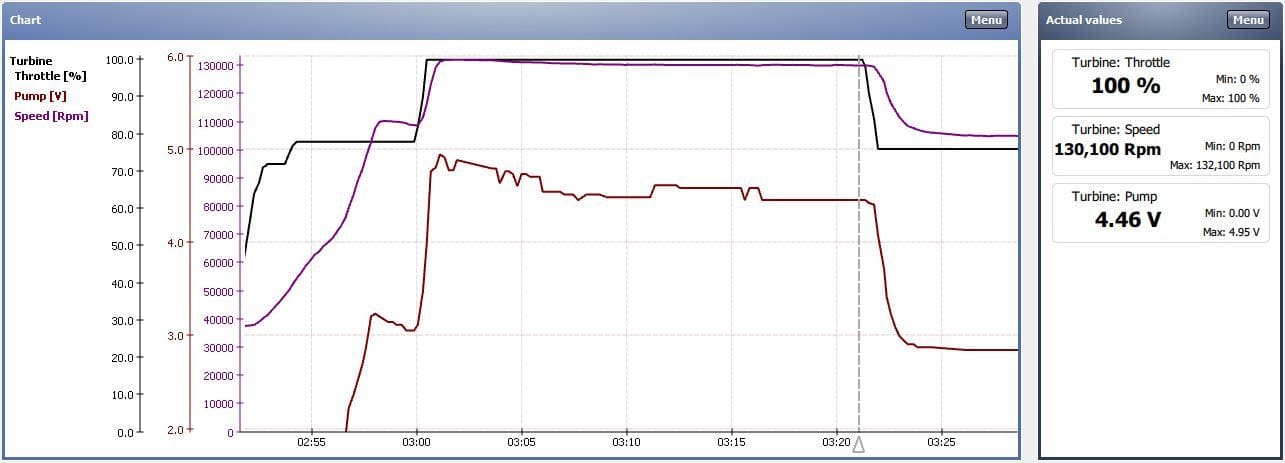

Whilst pondering my options while at an event with limited resources, and with the data showing the max pump voltages staying just over my 5.5 alarm threshold, I flew again with a similar warning after take-off (Image 4), again with the rest of the flight at part power. With the pump voltage now exceeding 5.8V, it was time to do something if I wanted to keep flying.

I ended up back-flushing my MAP hopper tank with integrated paper filter. I pumped about 1/2gal of fuel back through the Air Trap output line back into the tanks. I then de-fueled the plane normally and then fully re-fueled, again back-flushing the hopper tank & filter. In all, I must have pumped about 1.5 gal back though the filter.

The subsequent flights showed that the pump voltage had returned to normal levels (~4.5V), (Image 5) and no further alarms were triggered.

Paul

Flight 1 Take Off

Flight 1 Mid-Flight

Flight 2 Take Off

Flight 3 Take Off

Flight 4 Take Off

Part way through the first flight I went to full throttle and moments later got the pump voltage warning so immediately throttled back to part power. The rest of the flight was normal. Looking at the telemetry logs post flight, I could see that whilst the take-off was normal (Image 1), something happened mid-flight to cause the pump voltage to start increasing when I went to full power (Image 2). Accepting the risk I flew again, but got the warning after take-off whilst accelerating downwind at full power (Image 3) - the rest of the flight at part power was normal.

Whilst pondering my options while at an event with limited resources, and with the data showing the max pump voltages staying just over my 5.5 alarm threshold, I flew again with a similar warning after take-off (Image 4), again with the rest of the flight at part power. With the pump voltage now exceeding 5.8V, it was time to do something if I wanted to keep flying.

I ended up back-flushing my MAP hopper tank with integrated paper filter. I pumped about 1/2gal of fuel back through the Air Trap output line back into the tanks. I then de-fueled the plane normally and then fully re-fueled, again back-flushing the hopper tank & filter. In all, I must have pumped about 1.5 gal back though the filter.

The subsequent flights showed that the pump voltage had returned to normal levels (~4.5V), (Image 5) and no further alarms were triggered.

Paul

Flight 1 Take Off

Flight 1 Mid-Flight

Flight 2 Take Off

Flight 3 Take Off

Flight 4 Take Off

Last edited by JSF-TC; 04-07-2018 at 03:32 PM. Reason: Fixing Photos

#7

Paul

What clunks do you use in the main tanks?

This is classic composit tanks with fine debris inside, coating the Bubble Trap filter. I have even had them where I can feel the ‘grit’ on the outside of the filter.

Did you use the DJ bungs, or change the tank hardware? Did you fit any parts to the tanks, also what did you flush the tanks with just before final assembly?

Dave

What clunks do you use in the main tanks?

This is classic composit tanks with fine debris inside, coating the Bubble Trap filter. I have even had them where I can feel the ‘grit’ on the outside of the filter.

Did you use the DJ bungs, or change the tank hardware? Did you fit any parts to the tanks, also what did you flush the tanks with just before final assembly?

Dave

#8

My Feedback: (2)

Dave,

These were flights 72-77 on the Hunter. The tanks have not been opened since initial build 3 years ago.

I use BVM Hi-Flow clunks and Skymaster style screw-in fuel tank fittings, going to a MAP 4oz Air Trap.

I have experienced the same effect on my Ultra Flash (Jet-Tech main + saddle tanks with the same installation fittings) and ended up replacing the Air Trap.

I run pump kerosene that I add algicide to every time, and it is filtered twice coming out of my Jersey Modeller tank. I even replaced my fuel caddy fuel filter last year after the problems with my Ultra Flash.

The only thing that I don't do is filter the fuel as I pump it at the gas station, or when I decant it into my main fuel caddy.

Any other thoughts on maintaining a clean fuel system are welcome.

Paul

These were flights 72-77 on the Hunter. The tanks have not been opened since initial build 3 years ago.

I use BVM Hi-Flow clunks and Skymaster style screw-in fuel tank fittings, going to a MAP 4oz Air Trap.

I have experienced the same effect on my Ultra Flash (Jet-Tech main + saddle tanks with the same installation fittings) and ended up replacing the Air Trap.

I run pump kerosene that I add algicide to every time, and it is filtered twice coming out of my Jersey Modeller tank. I even replaced my fuel caddy fuel filter last year after the problems with my Ultra Flash.

The only thing that I don't do is filter the fuel as I pump it at the gas station, or when I decant it into my main fuel caddy.

Any other thoughts on maintaining a clean fuel system are welcome.

Paul

#12

My Feedback: (2)

I had not noticed anything - I changed the paper filter on the Jersey Modeller can for good measure as it was a few years old, and I only run the MAP Air Trap filter on the model. I've been running pump kerosene from the same pump for about 5 years now.

When I checked my Ultra Flash MAP filter when it had the same issue, I did not see anything obvious on the paper filter.

I might add a second filter to my Jersey Modeller can.

Paul

#14

Dave,

I had not noticed anything - I changed the paper filter on the Jersey Modeller can for good measure as it was a few years old, and I only run the MAP Air Trap filter on the model. I've been running pump kerosene from the same pump for about 5 years now.

When I checked my Ultra Flash MAP filter when it had the same issue, I did not see anything obvious on the paper filter.

I might add a second filter to my Jersey Modeller can.

Paul

I had not noticed anything - I changed the paper filter on the Jersey Modeller can for good measure as it was a few years old, and I only run the MAP Air Trap filter on the model. I've been running pump kerosene from the same pump for about 5 years now.

When I checked my Ultra Flash MAP filter when it had the same issue, I did not see anything obvious on the paper filter.

I might add a second filter to my Jersey Modeller can.

Paul

I would always run a JetCat type filter between the Pump and turbine, itís Ultra Fine. I also use a Mr Funnel for the fuel into fuel station.

Dave

#15

Thread Starter

I reached out to Gaspar, and may reach out to the other manufacturers as well. This is his response (which he approved for me to share here)....

Regarding what parameter above normal max to set an alarm;

"I would say 0.5V, to avoid false alarms, at winter the engine consume more fuel and the cold fuel is thicker, so you should leave margin to avoid false alarms."

Regarding ECU shutdown;

"There isnít a fixed power for the engine, the important is to see if the power deviated from origin. Type of fuel, altitude, particular pump and turbine combinations, filters, etc will cause changes on the pump power, but once stable, it should keep always about the same. The ecu will not command a shutdown, just will fail to reach to rpm when the pump runs out of steam."

Great discussion, I'm OCD with my fuel (Mr. Funnel, multiple filters before it makes it's way on board, Biobor, etc.) which is why I'm looking to understand the pump voltages better. I appreciate everyone's input!

Regarding what parameter above normal max to set an alarm;

"I would say 0.5V, to avoid false alarms, at winter the engine consume more fuel and the cold fuel is thicker, so you should leave margin to avoid false alarms."

Regarding ECU shutdown;

"There isnít a fixed power for the engine, the important is to see if the power deviated from origin. Type of fuel, altitude, particular pump and turbine combinations, filters, etc will cause changes on the pump power, but once stable, it should keep always about the same. The ecu will not command a shutdown, just will fail to reach to rpm when the pump runs out of steam."

Great discussion, I'm OCD with my fuel (Mr. Funnel, multiple filters before it makes it's way on board, Biobor, etc.) which is why I'm looking to understand the pump voltages better. I appreciate everyone's input!