Best way to get more oomph in pneumatic retracts

#28

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

Correct, this is a very cheap component available on Ebay and needs tapping for the Festo fittings. It is normally on and switches off when it reaches 120 psi and on at 90 psi.

https://www.ebay.com/itm/90-PSI-120-...BKVv:rk:7:pf:0

There are varying pressures available but this one seems the best option to start with.

John

https://www.ebay.com/itm/90-PSI-120-...BKVv:rk:7:pf:0

There are varying pressures available but this one seems the best option to start with.

John

#29

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

John

#30

My Feedback: (20)

Correct, this is a very cheap component available on Ebay and needs tapping for the Festo fittings. It is normally on and switches off when it reaches 120 psi and on at 90 psi.

https://www.ebay.com/itm/90-PSI-120-...BKVv:rk:7:pf:0

There are varying pressures available but this one seems the best option to start with.

John

https://www.ebay.com/itm/90-PSI-120-...BKVv:rk:7:pf:0

There are varying pressures available but this one seems the best option to start with.

John

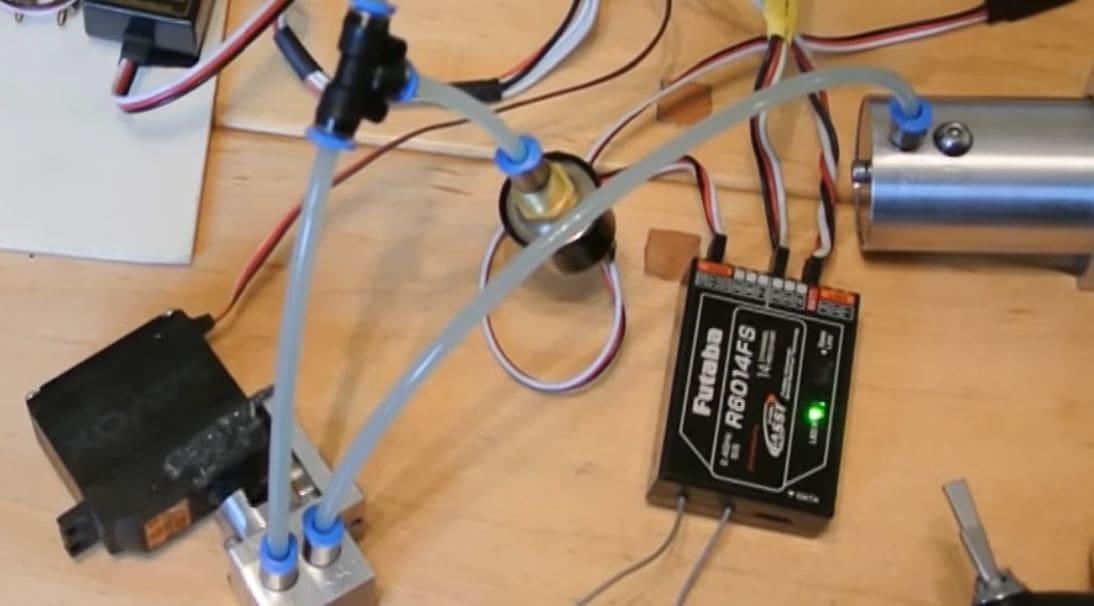

How did you wire the pressure switch into the ESC? Are you using just the black and red power wires through the switch or is the white signal wire used someway? From the photo it looks like the switch is powered from the receiver.

Also what fluid are you using. Is it a silicone oil like RC car shock oil and what weight is it?

Thanks, Gary

#31

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

Gary

All the pressure switch does is to break the signal to the ESC when it is up to pressure.

I wired the signal wire through the switch. Don't forget that the ESC needs to be armed.

The oil is LHM Citroen car suspension oil.

John

All the pressure switch does is to break the signal to the ESC when it is up to pressure.

I wired the signal wire through the switch. Don't forget that the ESC needs to be armed.

The oil is LHM Citroen car suspension oil.

John

#32

My Feedback: (20)

For a jet with main gear in the wings, what are the issues with taking off the wings for transport and disconnecting the hydraulic lines each time?

Thanks, Gary

#33

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

John, It looks like you are you using two channels, ch 1 for the ESC through the switch and ch 7 to the sequencer box. If so what millisecond signal are you sending thru the switch. I just trying to figure out how you have it set up and programed.

For a jet with main gear in the wings, what are the issues with taking off the wings for transport and disconnecting the hydraulic lines each time?

Thanks, Gary

For a jet with main gear in the wings, what are the issues with taking off the wings for transport and disconnecting the hydraulic lines each time?

Thanks, Gary

Gary

Yes 2 channels one for the ESC and one to switch the mechanical valve.

If you have mains in the wings and you are concerned about sealing the pipes, you can get ball valves that seal when disconnected. In the planes I had this was not a problem as my retracts were in the centre section. Festo have a huge range of fittings including one way valves incorporating ball seals. You need one of these in the system anyway to keep the system pressurised and you can see it sitting on the blue battery in the video.

John

John

#34

My Feedback: (20)

I completely missed the check valve looking so hard at the pressure switch. I've used those a long time ago with onboard start gas bottles.

Is the ESC running the pump motor at full speed from the 2S battery or is it slowed down some for pumping?

I'm not sure how you could keep air from entering the system even with ball valves if you had to disconnect the wings and brake the two hydraulic lines going to the main gears. Is there an easy way to purge the air from the system on both sides of the piston in the gear cylinders?

I'm looking at this as a possibility for my F-105 gear if the air system will not work.

Thanks,

Gary

Is the ESC running the pump motor at full speed from the 2S battery or is it slowed down some for pumping?

I'm not sure how you could keep air from entering the system even with ball valves if you had to disconnect the wings and brake the two hydraulic lines going to the main gears. Is there an easy way to purge the air from the system on both sides of the piston in the gear cylinders?

I'm looking at this as a possibility for my F-105 gear if the air system will not work.

Thanks,

Gary

#35

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

Gary

So long as the pipe is sealed at one end by the valve the liquid will not run out even without valves. Yes there may be a little air enter the system but cycling the retracts a few times will usually clear them. Yes I ran the ESC at full power on a low power battery pack. You can use a 3 position switch with full power for arming and mid for lower power and off to switch off. Alternatively you can make the channel variable. The choice is yours. I just kept things simple.

I purged the most of the air by disconnecting the Festos at the retracts one at a time so then air is expelled as the cylinder moves towards the fitting and expels the contents of the cylinder. Connecting the pipe that is full of fluid is then clear of air. You do not have to be obsessive about clearing then bubbles but it will work better with none as liquid is incompressible. The filler tank is very small and will need refilling during the bleed process. Bleeding the lines to the retracts is easy.

The system is not difficult or expensive to replicate, why not have a go making up a system on the bench to try it. Very few people seem willing to try anything different and soldier on with air systems when then combination of retract size speed of aircraft and doors attached make it very difficult to work. Do let us all know how you get on.

John

John

So long as the pipe is sealed at one end by the valve the liquid will not run out even without valves. Yes there may be a little air enter the system but cycling the retracts a few times will usually clear them. Yes I ran the ESC at full power on a low power battery pack. You can use a 3 position switch with full power for arming and mid for lower power and off to switch off. Alternatively you can make the channel variable. The choice is yours. I just kept things simple.

I purged the most of the air by disconnecting the Festos at the retracts one at a time so then air is expelled as the cylinder moves towards the fitting and expels the contents of the cylinder. Connecting the pipe that is full of fluid is then clear of air. You do not have to be obsessive about clearing then bubbles but it will work better with none as liquid is incompressible. The filler tank is very small and will need refilling during the bleed process. Bleeding the lines to the retracts is easy.

The system is not difficult or expensive to replicate, why not have a go making up a system on the bench to try it. Very few people seem willing to try anything different and soldier on with air systems when then combination of retract size speed of aircraft and doors attached make it very difficult to work. Do let us all know how you get on.

John

John

#36

My Feedback: (20)

Thanks John for all your info and help. I think I got the ideas now. I may give it a try.

I'm still a few months away from installing the gear system in the build process. So far only one person that I know of has flown the custom gear I have and he had to convert to electric to make it work. That was very very expensive. The hydraulic system may be the way to go and be lots cheaper too.

Thanks again,

Gary

I'm still a few months away from installing the gear system in the build process. So far only one person that I know of has flown the custom gear I have and he had to convert to electric to make it work. That was very very expensive. The hydraulic system may be the way to go and be lots cheaper too.

Thanks again,

Gary

#39

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

Bob

You may find this interesting

I made my own retracts to a larger size than I could get commercially and used commercial pneumatic air cylinders 1" bore 2" stroke. I used a tank made from an old gas canister (0.63 litres) with a fitting screwed into the end. Even in a large plane it is a struggle to fit really large tanks I had 2 with a capacity of 1.2 litres. I attach the video of the trials at various pressures and lifting various weights which looked fine in the workshop but it wouldn't work in the air. I abandoned air after that tried electric which was hopeless.

John

#40

My Feedback: (39)

My CARF Tucano has always been marginal retracting the mains. I originally plumbed it with a JetTronics valve and sequencer and found the JetTronics valve just had too much restriction. I modified the system to use two large tanks and 4mm plumbing to a Tom Cook high flow valve and also 4mm from there to the tee that splits the air flow to left/right wings.

This made a huge difference as before the gear would hesitate and kindof ”bounce” its way up. Now it goes up in one smooth motion. Used an SMC flow control with one way check to restrict the down speed a bit. The wheels/tires are very heavy on the Tucano gear and also the gear legs are long so I have to run 120 in the tank to have enough leverage but the real issue was mostly the air volume getting to the retracts.

The valve is the JMP-2 way part way down this page. You can order with 4mm nipples.

Large Fuel Tank Fittings

PaulD

p.s. - like the idea of stopping the wheel spin with brakes with a mix. Will add that to my programming

This made a huge difference as before the gear would hesitate and kindof ”bounce” its way up. Now it goes up in one smooth motion. Used an SMC flow control with one way check to restrict the down speed a bit. The wheels/tires are very heavy on the Tucano gear and also the gear legs are long so I have to run 120 in the tank to have enough leverage but the real issue was mostly the air volume getting to the retracts.

The valve is the JMP-2 way part way down this page. You can order with 4mm nipples.

Large Fuel Tank Fittings

PaulD

p.s. - like the idea of stopping the wheel spin with brakes with a mix. Will add that to my programming