Servo pushrods for big jets

#1

What is the best (strongest) method you guys are using for your big jets? I had a 440 rod break on my F-16 and lost the

Jet. I need advise since I am curently working on a 1/3 Skymasters Hawk.

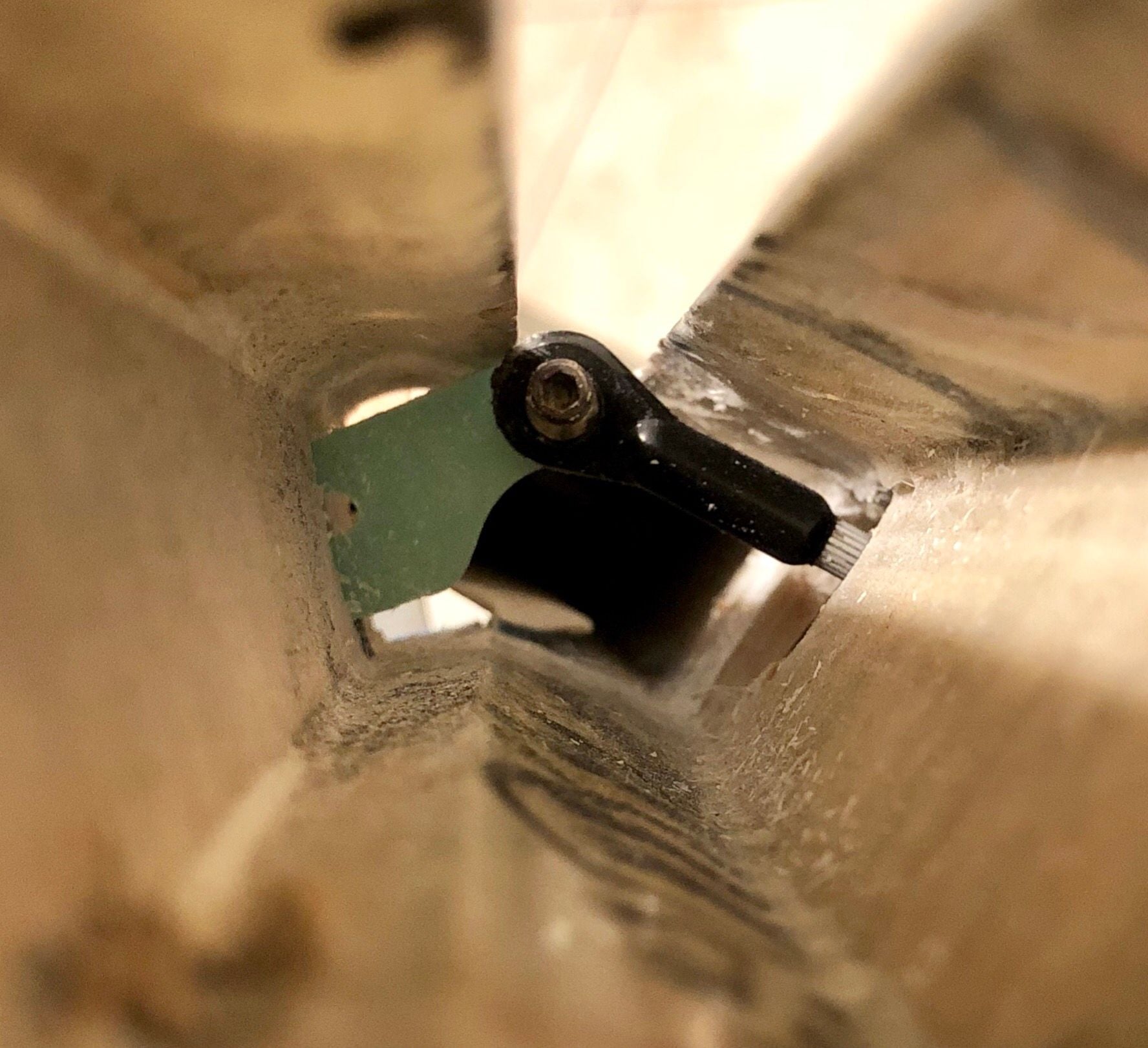

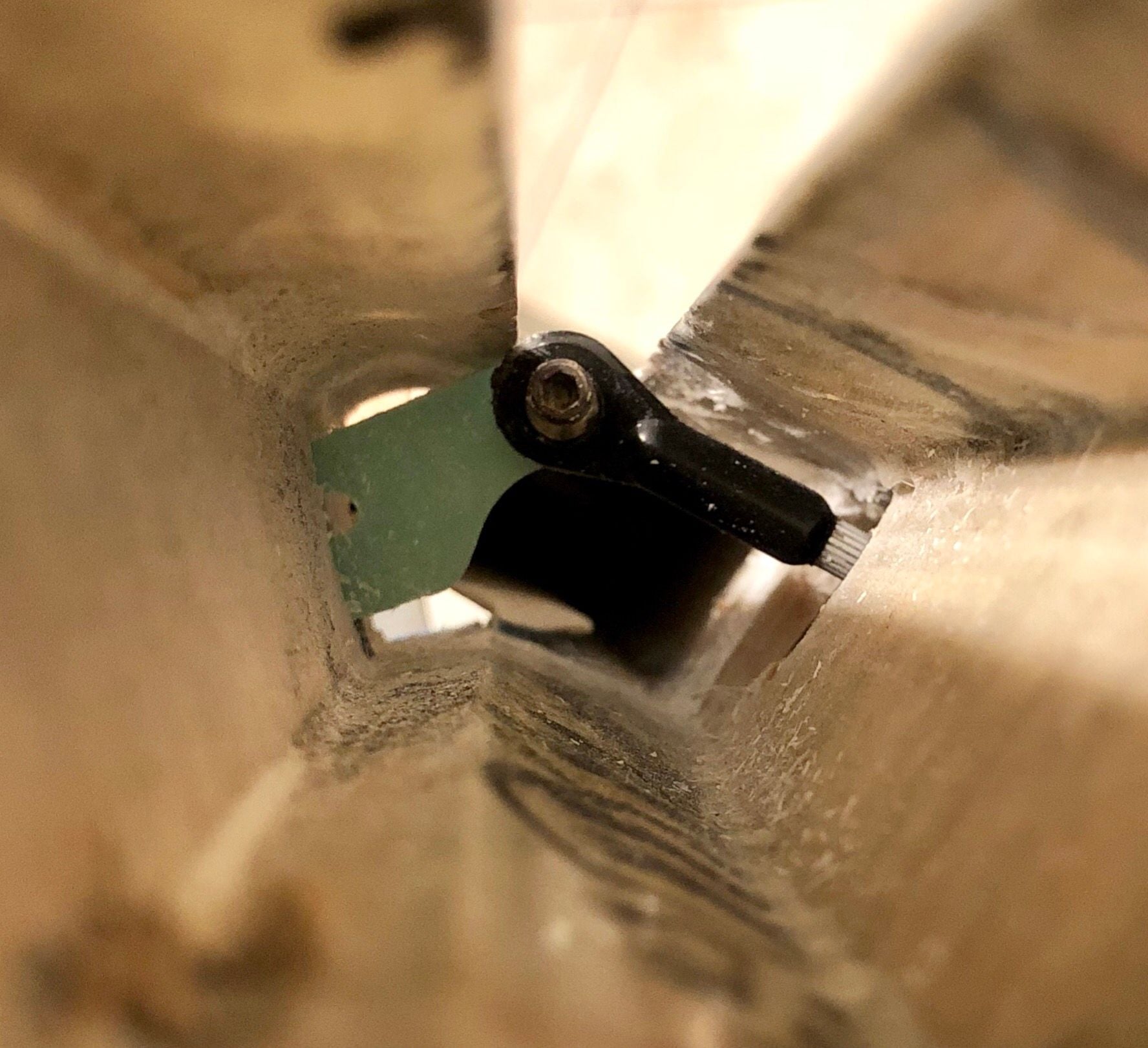

Is the method on the pic below sufficient? and where can i purchate the parts to make them?

Thank you in advence

Jet. I need advise since I am curently working on a 1/3 Skymasters Hawk.

Is the method on the pic below sufficient? and where can i purchate the parts to make them?

Thank you in advence

Last edited by jetsflyin; 10-12-2022 at 01:25 PM.

#2

The pic is blurry and hard to tell if you have carbon fiber tubes over the rod. I always do that to threaded rods. I always have the CF tube completely up against the end fittings. It looks like the CF in the pic is a bit short.

Threaded rods are weaker than solid rods. Also threaded rod is not hardened. There are prefabbed titanium rods available. They do not break.

Also, could it be that you are hitting the physical endpoints of the surface's travel? I use an ammeter in line on the servo if I think I am even getting close to that point.

Threaded rods are weaker than solid rods. Also threaded rod is not hardened. There are prefabbed titanium rods available. They do not break.

Also, could it be that you are hitting the physical endpoints of the surface's travel? I use an ammeter in line on the servo if I think I am even getting close to that point.

#3

My Feedback: (53)

I like the prefab titanium or stainless steel rod because of the left and right tread….make install easy with ball link….there’s a variety to seller for these, like Horizon, Secraft and others

#7

My Feedback: (54)

That looks like it is the flap? For flap extension, I do not like the flap being pulled by the servo. I’ve about lost a jet this way, due to 500oz servo failure. Fortunately, high enough to recover. I modify all flaps to be pushed from the top inside flap joint. It is an extremely easy mod that reduces servo, pushrod, link failure. The servo arm rotates on the inside of the top skin. This way the short servo arm is almost straight inline with the flap pushrod, and creates less fulcrum torque on the servo.

As others have said, using titanium pushrods, 6/32 threaded rod with a carbon fiber tube sleeve.

I simply cut a slot in the flap inside leading edge. I used G-10 with 9462. I beveled the control horn to fit as deep as possible into the flap.

This is the original setup as per SkyMaster.

You only see the control horn when flaps are extended.

As others have said, using titanium pushrods, 6/32 threaded rod with a carbon fiber tube sleeve.

I simply cut a slot in the flap inside leading edge. I used G-10 with 9462. I beveled the control horn to fit as deep as possible into the flap.

This is the original setup as per SkyMaster.

You only see the control horn when flaps are extended.

#12

I've been using Lunsford Racing titanium turnbuckles for years with zero issues. Made in USA and range from 2.5mm to 5mm and 4-40

For big jets like an EA Havoc, I use their 3.5mm and Dubro Monster ball links.

https://lunsfordracing.com/products/...-turnbuckles-2

For big jets like an EA Havoc, I use their 3.5mm and Dubro Monster ball links.

https://lunsfordracing.com/products/...-turnbuckles-2

The following 3 users liked this post by sc0tt:

#14

I'm using Lunsford 3.5mm turnbuckles with Dubro # 2320 3mm Monster Ball links.

I did need to drill the Dubro ball link up a bit for the 3.5mm to thread in easier but still tight.

I have not tried Dubro #2316 6-32 size, they may work with no drilling?

I did need to drill the Dubro ball link up a bit for the 3.5mm to thread in easier but still tight.

I have not tried Dubro #2316 6-32 size, they may work with no drilling?