Zeus

#152

Thread Starter

This block of 7075 high tensile aluminium is going to become 4 engine mount screws.

A new hacksaw blade and some elbow grease.

And we have 4 lumps of aluminium.

#153

Thread Starter

Roughed out the blocks first in the 4 jaw chuck then in the 3 jaw.

Finished off and a 5mm thread cut on the end.

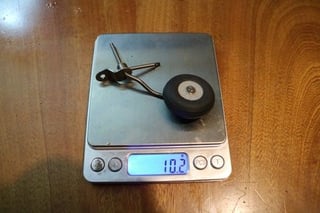

Steel screw.

Same length aluminium. 14gm saving for 4 of them. I was surprised at that.

#155

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

Just asking a quick question. You're not concerned about fatigue using a high tensile aluminium bolt in a mount like that?

We (Dad and I) had a Zenoah G62 (horrible, vibrating, petrol thing it was) mounted in a similar fashion and high tensile steel bolts (passing through rubber isolators on each side of the firewall) were breaking one after the other. Every dozen or so flights we'd find another broken bolt. General purpose steel bolts put up with the flexing much better. The DA is a much more refined engine and maybe it's not an issue?

Thanks for the build log...

We (Dad and I) had a Zenoah G62 (horrible, vibrating, petrol thing it was) mounted in a similar fashion and high tensile steel bolts (passing through rubber isolators on each side of the firewall) were breaking one after the other. Every dozen or so flights we'd find another broken bolt. General purpose steel bolts put up with the flexing much better. The DA is a much more refined engine and maybe it's not an issue?

Thanks for the build log...

#156

Thread Starter

Just asking a quick question. You're not concerned about fatigue using a high tensile aluminium bolt in a mount like that?

We (Dad and I) had a Zenoah G62 (horrible, vibrating, petrol thing it was) mounted in a similar fashion and high tensile steel bolts (passing through rubber isolators on each side of the firewall) were breaking one after the other. Every dozen or so flights we'd find another broken bolt. General purpose steel bolts put up with the flexing much better. The DA is a much more refined engine and maybe it's not an issue?

Thanks for the build log...

We (Dad and I) had a Zenoah G62 (horrible, vibrating, petrol thing it was) mounted in a similar fashion and high tensile steel bolts (passing through rubber isolators on each side of the firewall) were breaking one after the other. Every dozen or so flights we'd find another broken bolt. General purpose steel bolts put up with the flexing much better. The DA is a much more refined engine and maybe it's not an issue?

Thanks for the build log...

#157

Thread Starter

Just asking a quick question. You're not concerned about fatigue using a high tensile aluminium bolt in a mount like that?

We (Dad and I) had a Zenoah G62 (horrible, vibrating, petrol thing it was) mounted in a similar fashion and high tensile steel bolts (passing through rubber isolators on each side of the firewall) were breaking one after the other. Every dozen or so flights we'd find another broken bolt. General purpose steel bolts put up with the flexing much better. The DA is a much more refined engine and maybe it's not an issue?

Thanks for the build log...

We (Dad and I) had a Zenoah G62 (horrible, vibrating, petrol thing it was) mounted in a similar fashion and high tensile steel bolts (passing through rubber isolators on each side of the firewall) were breaking one after the other. Every dozen or so flights we'd find another broken bolt. General purpose steel bolts put up with the flexing much better. The DA is a much more refined engine and maybe it's not an issue?

Thanks for the build log...

#160

Thread Starter

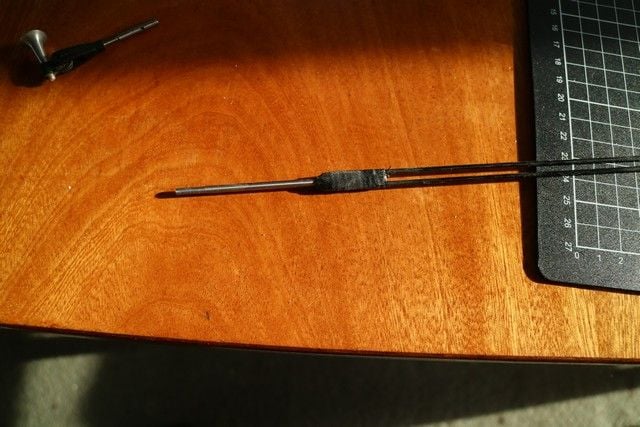

Made titanium push rod ends for the 2mm carbon elevator push rods.

3mm titanium bound with carbon tow epoxy and then heat shrink on the servo end. The carbon rods will run in teflon tubes bound to balsa sticks.

#161

Thread Starter

Push rod assembly ready to install.

Teflon tube bound to balsa with narrow ribbon and glued with thin CA.

I will 3D print some exit guides for these.

#165

I set up an old Goldberg Bucker Jungmann with dual carbon pushrods. Instead of binding the two pushrods into a single rod at the front, I used a ball joint on each rod and put a ball on each side of the servo horn. So far it is working well.

Ken

Ken

#166

Thread Starter

Hi Ken that would work and balance the forces. Here is my Bucker Jungmann ZDZ 120 on twin pipes. Actually that was the last aluminium brazing I did. But I am about to make a canister muffler for Zeus.

Sig dope finish.

Sig dope finish.

#167

Thread Starter

Something like this.

Fitting the exhaust header.

Silver soldered to the flange. I will fit the canister to this, It will be a series of cones and tubes nothing like a commercial item.

#173

Thread Starter

After quite a few versions I have arrived at this. You can probably see a tuned pipe influence as I have made a lot of them. I know what works for me in terms of assembling and brazing. This will have 4 chambers.

Last edited by RodneyFord; 06-10-2018 at 09:13 PM.

#175

Thread Starter

Yes Ken that has been my go to manual for years. However it is somewhat superseded now as they have worked out how to use a Helmholz resonator for significantly more boost. That is why you see such fat tuned pipes on the latest 2 strokes. I considered a helmholz resonator for active silencing on this setup but I need to know the frequency to design it at so that will need to wait. I wont need a tuned pipe on the Zeus as the DA 50 should have plenty of power without it.