Taigen Track stretching

#1

Thread Starter

New Taigen Sherman chassis and worn in Taigen chassis. All I can say is DANG....

And no I cannot tighten them up by removing a link. They would compress the suspension just a tad. One reason why I liked the idea of the adjustable idler on the mato, its only good attribute. Ive discussed previously why I wont buy mato Sherman chassis any more.

Taigen, pay attention and add an adjustable idler or eventually the tracks will start to jam and or detrack.

And no I cannot tighten them up by removing a link. They would compress the suspension just a tad. One reason why I liked the idea of the adjustable idler on the mato, its only good attribute. Ive discussed previously why I wont buy mato Sherman chassis any more.

Taigen, pay attention and add an adjustable idler or eventually the tracks will start to jam and or detrack.

#4

Rich, Are you sure it is stretch? have you laid new tracks along side the old to see if it has gained length? or possibly just wear on the drive sprocket and links?

Just curious, my Taigen Sherman lies in between your old and new pics. My PIV's look the same as Dusty's, they have just the right amount of droop over the return rollers.

On my JS2, the idler adjuster was too coarse and I had to remove a link, so I had to slot the gearbox holes to slide the gearbox just slightly forward to prevent track jamming between the sprocket and metal overhang. I've done this technique several times before when the adjustment wouldn't quite meet my wants.....

I hope Erik has addressed your needs.

Jerry Rude

Roseburg, OR

Just curious, my Taigen Sherman lies in between your old and new pics. My PIV's look the same as Dusty's, they have just the right amount of droop over the return rollers.

On my JS2, the idler adjuster was too coarse and I had to remove a link, so I had to slot the gearbox holes to slide the gearbox just slightly forward to prevent track jamming between the sprocket and metal overhang. I've done this technique several times before when the adjustment wouldn't quite meet my wants.....

I hope Erik has addressed your needs.

Jerry Rude

Roseburg, OR

#6

Thread Starter

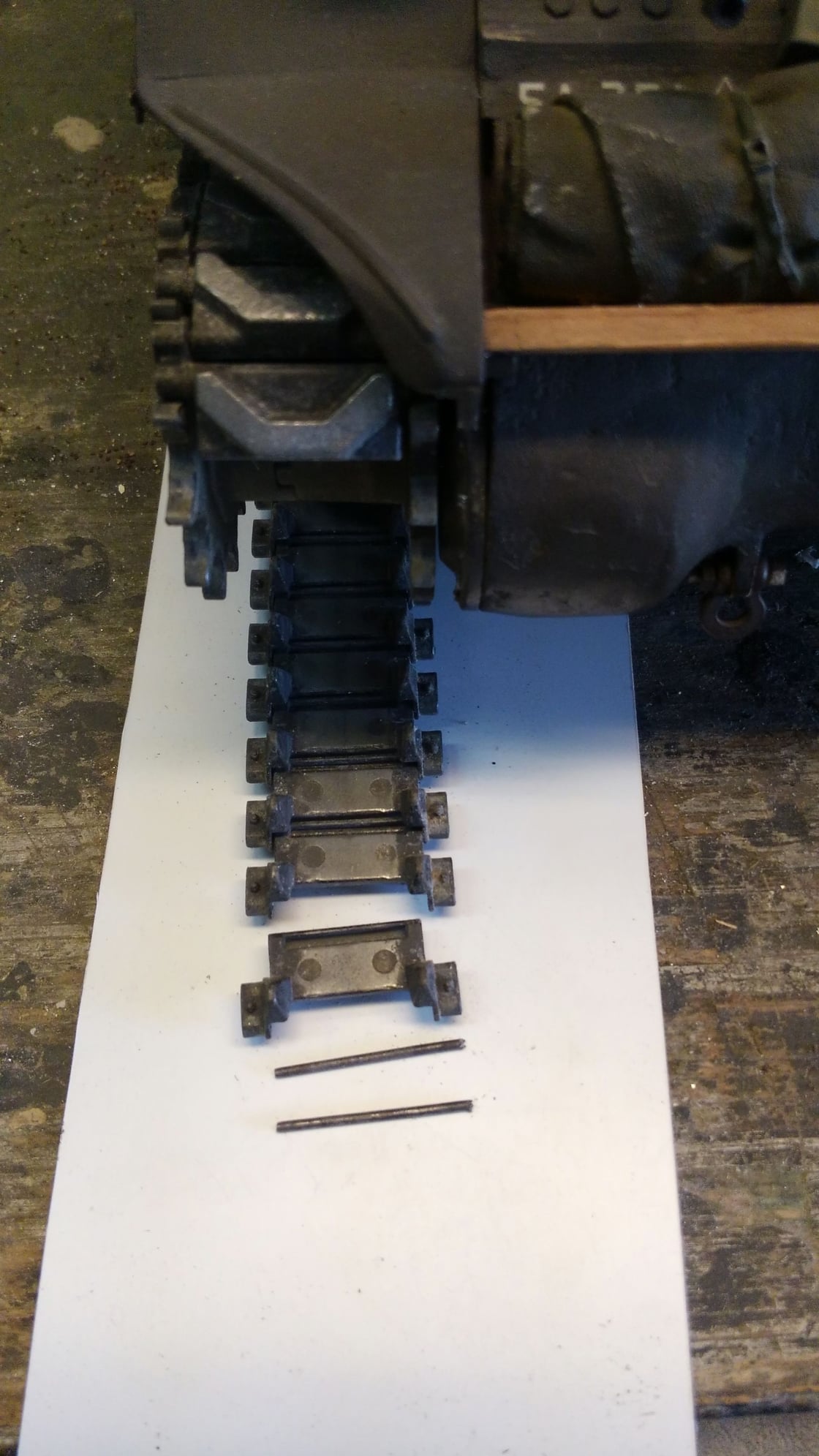

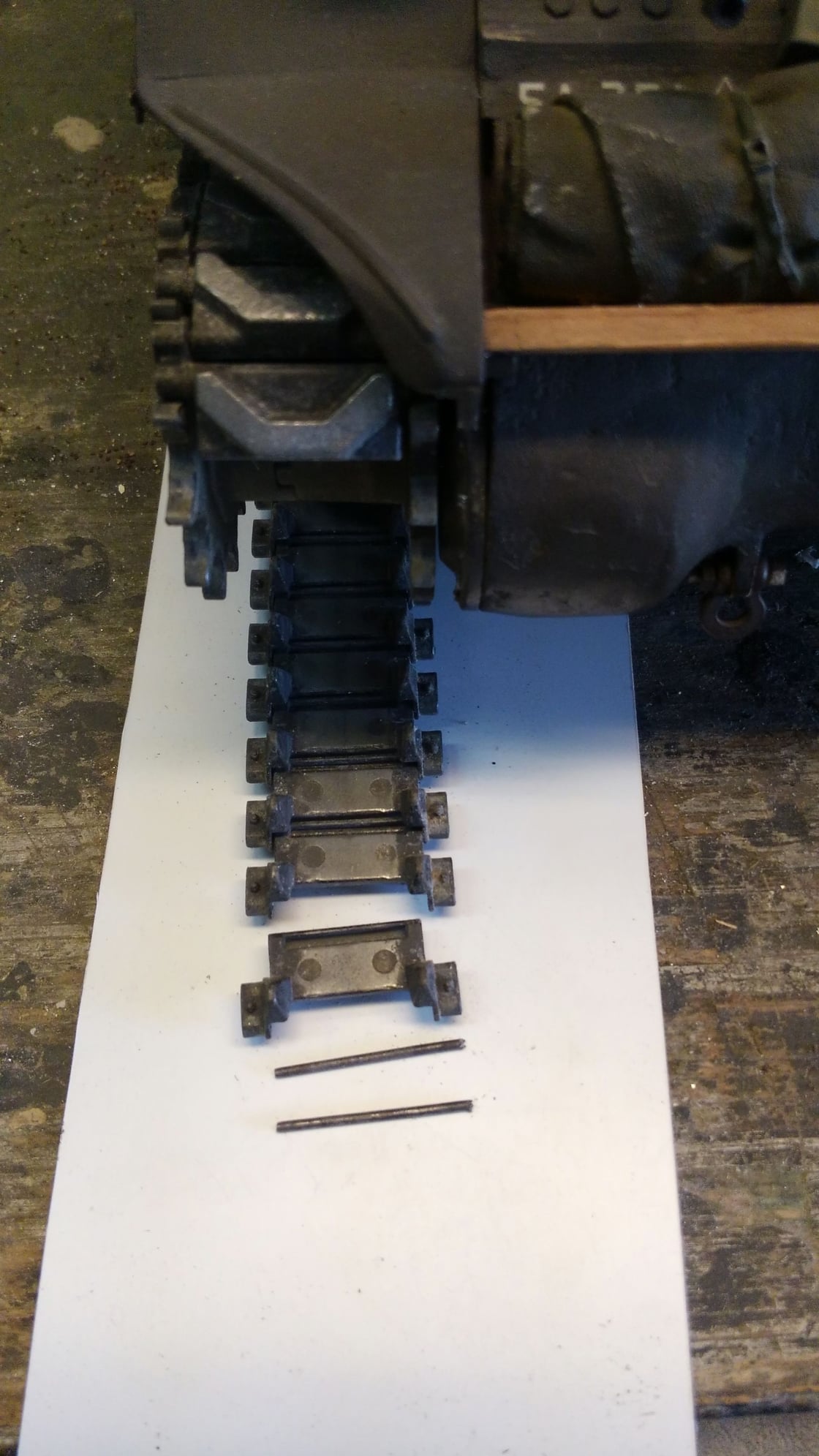

I was driving my M4 today that built on a taigen sherman chassis and noticed a track variance. Two pins in a row had the outside of the pin broken off in the end connector so the pin was only going through the end connector on the inside of the track. Two in a row. I must have gotten a rock in there a while ago and busted them because I cannot figure out how that would have happened other wise. I used some steel piano wire to make new pins. Its about .002 thousandth smaller in diameter but it should be ok since I super glued the end connectors. I dont have any more spare taigen pinson hand since just bought chassis and tracks almost every time I used one. Just a hint for repairs. Photo shows the broken short pins and the track links.

#7

Perhaps it was mentioned already but I missed it. Are the tracks that are stretching zinc alloy or polypropylene types.

I've actually seen both types stretch. That poly tracks stretch with respect to time doesn't surprise but zinc alloy is a bit more complicated.

I've read that Asian die casters a Zamak alloy which isn't as resistant to stretching as the US standard alloy. You can look it up

if you are curious. Perhaps Erik can research which alloys their suppliers are using; I'd be curious.

Jerry

I've actually seen both types stretch. That poly tracks stretch with respect to time doesn't surprise but zinc alloy is a bit more complicated.

I've read that Asian die casters a Zamak alloy which isn't as resistant to stretching as the US standard alloy. You can look it up

if you are curious. Perhaps Erik can research which alloys their suppliers are using; I'd be curious.

Jerry

#8

Thread Starter

The taigen tracks are some type of cast metal.

FYI I have found recently that the tamiya abrams tracks I put on my M60a3 have continued to stretch since I installed them a few months ago and I have had to re wrap my idler wheel with more tape to build it up a few times now. If they keep stretching any more I will have to take a link out and remove all my build up tape...

FYI I have found recently that the tamiya abrams tracks I put on my M60a3 have continued to stretch since I installed them a few months ago and I have had to re wrap my idler wheel with more tape to build it up a few times now. If they keep stretching any more I will have to take a link out and remove all my build up tape...

#9

I believe the tracks are Zamak 4, though it is possible to be 3. The last time I was there I didn't research this enough but I will focus more on material composition and molds on the next trip.

If you need pins just use the promo code RCULOVE on your order and put in the notes you need tracks/links and for what tank and I'll be happy to toss some in as long as I have them. Oh and for the wheels have you guys tried something like a TPU sleeve? They have some really hard TPU material that it is still soft enough to flex over a wheel. I believe NinjaFlex would be a good one. It would also allow you to get the perfect diameter on it too. I use TPU in a lot of stuff and if printed right it is super tough.

If you need pins just use the promo code RCULOVE on your order and put in the notes you need tracks/links and for what tank and I'll be happy to toss some in as long as I have them. Oh and for the wheels have you guys tried something like a TPU sleeve? They have some really hard TPU material that it is still soft enough to flex over a wheel. I believe NinjaFlex would be a good one. It would also allow you to get the perfect diameter on it too. I use TPU in a lot of stuff and if printed right it is super tough.

#10

I believe the tracks are Zamak 4, though it is possible to be 3. The last time I was there I didn't research this enough but I will focus more on material composition and molds on the next trip.

If you need pins just use the promo code RCULOVE on your order and put in the notes you need tracks/links and for what tank and I'll be happy to toss some in as long as I have them. Oh and for the wheels have you guys tried something like a TPU sleeve? They have some really hard TPU material that it is still soft enough to flex over a wheel. I believe NinjaFlex would be a good one. It would also allow you to get the perfect diameter on it too. I use TPU in a lot of stuff and if printed right it is super tough.

If you need pins just use the promo code RCULOVE on your order and put in the notes you need tracks/links and for what tank and I'll be happy to toss some in as long as I have them. Oh and for the wheels have you guys tried something like a TPU sleeve? They have some really hard TPU material that it is still soft enough to flex over a wheel. I believe NinjaFlex would be a good one. It would also allow you to get the perfect diameter on it too. I use TPU in a lot of stuff and if printed right it is super tough.

when I told him I was casting my first set of 1/10 Pz III tracks using zamak he said I would have a good service life from them. I wasn't even aware of the various alloys back in 1990 thinking there was just one I purchased. If he were here now I'd ask him which would be better for our application, not that anyone would listen. I have a feeling all tracks will stretch with time, probably even full sized ones. The trick is to find an alloy that gives the best of all worlds

strength, hardness, resistance to stretching and still be affordable.

I'm sure rc tank track makers made a price point decision and that isn't changing anytime soon...

jerry

#11

The material we use now is actually really good. Rarely ever do you see TG tracks stretching compared to the same use on other brands/platforms. It does happen though of course but out of all the time I've been here only a handful of people have had stretching like I see here. Luckily if it does happen you know who to contact  If you have serious stretching like this please hit me up on our site on the contact us/tech support sections and I'll do my best to make sure you have a good discount on a replacement set of tracks.

If you have serious stretching like this please hit me up on our site on the contact us/tech support sections and I'll do my best to make sure you have a good discount on a replacement set of tracks.

If you have serious stretching like this please hit me up on our site on the contact us/tech support sections and I'll do my best to make sure you have a good discount on a replacement set of tracks.

If you have serious stretching like this please hit me up on our site on the contact us/tech support sections and I'll do my best to make sure you have a good discount on a replacement set of tracks.

#12

My experience says the links does not strecht, but the pins get deformed. If you add all those pins deformation, you end with the tracks sagging quite a lot. It happened to me with Panzer IV taigen tracks

#13

Thread Starter

I agree. I dont believe the metal links are stretching.

On my shermans the track pins eventually work loose on all of them and start sliding out. As they do, if i dont catch them and glue them in, they get caught against the hull and bend or break off. Hence I have run out of track pins and resorted to piano wire.

what is actually happening is the pins are wearing in the end connectors and the pin hole is wearing out and enlarging.

i havent had this problem on the mato sherman track yet, which has as much or more use than the taigens in question. The mato sherman track pins are about twice the diameter as taigens, and much tigher pressed into the end connectors.

im not too worried overall, a mechanical device requires maintenance and PMCS before you use it. A quick check before use reveals issues. Over time, i will have to replace tracks i suppose, just like real tanks.

On my shermans the track pins eventually work loose on all of them and start sliding out. As they do, if i dont catch them and glue them in, they get caught against the hull and bend or break off. Hence I have run out of track pins and resorted to piano wire.

what is actually happening is the pins are wearing in the end connectors and the pin hole is wearing out and enlarging.

i havent had this problem on the mato sherman track yet, which has as much or more use than the taigens in question. The mato sherman track pins are about twice the diameter as taigens, and much tigher pressed into the end connectors.

im not too worried overall, a mechanical device requires maintenance and PMCS before you use it. A quick check before use reveals issues. Over time, i will have to replace tracks i suppose, just like real tanks.

#15

Thread Starter

Nope. Taigen is a solid cast metal chassis like a henglong, but metal. Mato all metal sherman has an adjustable idler, which i have installed on a henglng sherman that busted its idler off. However installing one on a taigen metal cassis, wile possible, would be a massive endeavour even I do not want to do.

#16

No, not at this time for the Sherman. Some tanks it was determined (not by me) to not be necessary for the model but I like you guys disagree here. Alas I wish I could get everything I want out of each model but sometimes they just don't listen, have other ideas, or just don't agree with me. The idler adjuster is in my opinion needed on this tank for heavy users, but the VAST majority (as in 98%+) do not use or need this feature. I still think it should be added and we will be speaking of this when bossman visits in the next few weeks. I am actually trying to collect a few of these tracks to show them the issues and possibly even to work on the tracks as well. I'm going to suggest a slightly bigger pin/hole and maybe even a track redesign if needed too just like we did with the KT tracks.

I really do rely on you guys to give us feedback. When things like this happen I can't make suggestions or help if I don't know about it. I'm actually trying to collect a set or two so bossman has some to take with him. My Shermans do not exhibit this issue but then again I have almost as many tanks as there are days in a month, it is hard to drive them all the amount you guys do. I really do appreciate the feedback, once again I am serious about this and please email me if you do have this issue so I can at least log these and/or offer some type of solution/discount for this.

I really do rely on you guys to give us feedback. When things like this happen I can't make suggestions or help if I don't know about it. I'm actually trying to collect a set or two so bossman has some to take with him. My Shermans do not exhibit this issue but then again I have almost as many tanks as there are days in a month, it is hard to drive them all the amount you guys do. I really do appreciate the feedback, once again I am serious about this and please email me if you do have this issue so I can at least log these and/or offer some type of solution/discount for this.

#17

I agree. I dont believe the metal links are stretching.

On my shermans the track pins eventually work loose on all of them and start sliding out. As they do, if i dont catch them and glue them in, they get caught against the hull and bend or break off. Hence I have run out of track pins and resorted to piano wire.

what is actually happening is the pins are wearing in the end connectors and the pin hole is wearing out and enlarging.

i havent had this problem on the mato sherman track yet, which has as much or more use than the taigens in question. The mato sherman track pins are about twice the diameter as taigens, and much tigher pressed into the end connectors.

im not too worried overall, a mechanical device requires maintenance and PMCS before you use it. A quick check before use reveals issues. Over time, i will have to replace tracks i suppose, just like real tanks.

On my shermans the track pins eventually work loose on all of them and start sliding out. As they do, if i dont catch them and glue them in, they get caught against the hull and bend or break off. Hence I have run out of track pins and resorted to piano wire.

what is actually happening is the pins are wearing in the end connectors and the pin hole is wearing out and enlarging.

i havent had this problem on the mato sherman track yet, which has as much or more use than the taigens in question. The mato sherman track pins are about twice the diameter as taigens, and much tigher pressed into the end connectors.

im not too worried overall, a mechanical device requires maintenance and PMCS before you use it. A quick check before use reveals issues. Over time, i will have to replace tracks i suppose, just like real tanks.

If it's the pins that are deforming in some way do you have a photo of an example of a deformed pin? Not sure I understand quite how a pin deforms if the track link

fully supports it and the link doesn't bend. Is it more common with Sherman type tracks with their multi part construction? If the pins bend at the point where the

track links actually join/ hinge that's going to be tough to overcome. I recognize there's a lot of power applied to the tracks so that components bend or deform

doesn't surprise. If the pins are bending then the harder piano wire pins should help. I used to run my models a lot once and while I've never thrashed them I wasn't shy at running through

less than ideal conditions and I've always concentrated on power over speed so if anyone would stress their tracks a lot it was me. The only time I ever had anything let go

was when I ran an Imai Elefant through what I can only describe as potting soil at an old club gathering at a military vehicle show: I actually broke a link when a track jammed.

The pins on that track are stubby relatively thick pins.

I have to say when this thread started I was surprised to read that tracks were stretching although I still maintain it's possible and know some older Bandai poly tracks stretched

on me. Stretched metal tracks, again possible just isn't talked about much. The enormously heavy zinc alloy tracks of my 1/10 scale Sankyo type 74 had very soft pins before I changed many of them and I know they appeared to stretch; and effectively they did stretch. When I pulled pins they had a slight arch to them.. In defense of the model it only threw a track once

and that was when an OEM ( crappy) sprocket broke due to gravel.

Jerry

Last edited by Tanque; 05-29-2019 at 05:29 PM.

#18

Thread Starter

I had two pins last week that had backed out of the second sherman in the photos with the broke pins. The two pins that backed out jammed the track as they backed to the inside. The pins ends had bent as they came out and eubbed the hull till one was out far enough to jam. That is how i found the two broken pins on either side of one track pad, fyi the taigwn sherman track is cheaped out single pin connected track that appears to look like double pin track.

#20

Interesting and I do agree and have experienced the pins are more likely to deform than the track itself, but I have also seen some roundout or cracking of the pin hole on weaker metals.

Never had an issue with Kenny Kong tracks BTW.

Never had an issue with Kenny Kong tracks BTW.

#21

Send me an email if you still have a few of these ok? I'm dead serious about fixing this. I only have a few weeks before bossman heads over, it is best to get all the samples I can of the issue.

#23

Hi, unfortunately I dont keep those tracks anymore... But if you are talking to the bossman, tell him several things from my side:

Stronger pings. Again, I trully believe the links were fine, there were the pins what were failing.

Retaining system for the pins (I have other brands tracks and the PIV pins never ever go away!)

Black tracks (because are way nicer than the silver)

Solid horns. The original PIII-PIV had solid and hollow horns... The taigen tracks I had, came with hollow horns. I broke some of the horns with small stones or things like that.. Yep, a real pain

A hole at the other side of the pin. You insert the pin from one side, but if for some reason you need to remove it, it might be very hard or almost impossible to remove them. Add just a hole at the other side of the track, so I can insert another pin or a tool there, and push the older pin away.

Just my feedback as a pasionate user, lol.

Stronger pings. Again, I trully believe the links were fine, there were the pins what were failing.

Retaining system for the pins (I have other brands tracks and the PIV pins never ever go away!)

Black tracks (because are way nicer than the silver)

Solid horns. The original PIII-PIV had solid and hollow horns... The taigen tracks I had, came with hollow horns. I broke some of the horns with small stones or things like that.. Yep, a real pain

A hole at the other side of the pin. You insert the pin from one side, but if for some reason you need to remove it, it might be very hard or almost impossible to remove them. Add just a hole at the other side of the track, so I can insert another pin or a tool there, and push the older pin away.

Just my feedback as a pasionate user, lol.

Last edited by Rad_Schuhart; 06-01-2019 at 02:03 PM.

#24

Ok so after checking some tracks I got last week I can definitely see two things I'm gonna suggest: thicker pins and a closed pin track. I think this should fix the issues. Oh and all tracks in the future from us should be black, that is already on the notes  I'm not a big fan of silver either. P3/P4 stuff I'll look into, I don't get many issues with those tracks but I'll see if that is feasible. For the holes in the tracks for the pins those are already there on all the tracks from Taigen, that is how I remove them myself. On the Sherman it is the same as well but one of the EEC pins is built into the link, only 1 is where the pin is inserted and can be pressed from the other side.

I'm not a big fan of silver either. P3/P4 stuff I'll look into, I don't get many issues with those tracks but I'll see if that is feasible. For the holes in the tracks for the pins those are already there on all the tracks from Taigen, that is how I remove them myself. On the Sherman it is the same as well but one of the EEC pins is built into the link, only 1 is where the pin is inserted and can be pressed from the other side.

I'm not a big fan of silver either. P3/P4 stuff I'll look into, I don't get many issues with those tracks but I'll see if that is feasible. For the holes in the tracks for the pins those are already there on all the tracks from Taigen, that is how I remove them myself. On the Sherman it is the same as well but one of the EEC pins is built into the link, only 1 is where the pin is inserted and can be pressed from the other side.

I'm not a big fan of silver either. P3/P4 stuff I'll look into, I don't get many issues with those tracks but I'll see if that is feasible. For the holes in the tracks for the pins those are already there on all the tracks from Taigen, that is how I remove them myself. On the Sherman it is the same as well but one of the EEC pins is built into the link, only 1 is where the pin is inserted and can be pressed from the other side.

#25

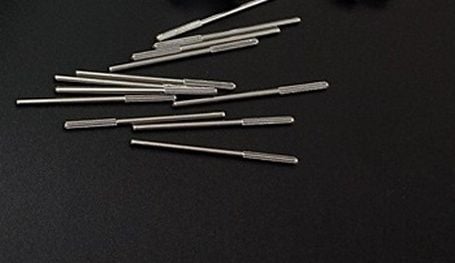

These are knurled steel track pins. They should have a 'head' but they don't, but this is the concept that prevents track pins from working their way out of the link. It's worked for years, starting with Impact and now DKLM, which is photoed. This system does not work well with 'closed end' track links, but with the dust, dirt and mud no one will notice whether the track link is 'open' or 'closed'. Pins should be inserted from the outside of the link whether they are knurled or have heads, reason being that if a pin starts to work it's way out it can be seen and fixed. Inserted from the inside, tank hull side, the driver usually does not notice the pin until it begins to catch on the hull.