Don Smith A-26 Build

#27

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Starting to hinge the rudder to the V-Stab and install the rudder control horn. I'm using Robart pin hinges. Looking the plans there's an issue with using the pin hinge as described. The rudder control horn/rod pass through the hinge. See first photo. The blue line is the hinge and the red line is the rudder control horn/rod.

I could move the hinge above the control rod (switch locations effectively). But I like having the control rod reach up into the control surface. So, I'll incorporate it into a custom hinge. The image below shows the new design. I'll make the blue part (in the upper left of the diagram) and slide it onto the control rod before gluing the rod to the rudder. When ready to mount the rudder, this new piece will get glued into a slot in the V-stab.

I could move the hinge above the control rod (switch locations effectively). But I like having the control rod reach up into the control surface. So, I'll incorporate it into a custom hinge. The image below shows the new design. I'll make the blue part (in the upper left of the diagram) and slide it onto the control rod before gluing the rod to the rudder. When ready to mount the rudder, this new piece will get glued into a slot in the V-stab.

Last edited by Eldher; 11-27-2014 at 09:50 AM.

#29

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Yah, the nose gear is fairly unique. It rotates and travels through about 120 degrees of movement. Fortunately, Century Jet makes a custom set, designed specifically for the Don Smith 105". $755. This is the easy choice, they drop right in, no mods needed.

Sierra Giant Scale does make them too, BUT not on a regular basis. So if he has them in stock, then you can get them. Otherwise he queue's up orders till he has enough for a production run. I need to call him and see what he has.

Here's a pict of the CJ gear.

Sierra Giant Scale does make them too, BUT not on a regular basis. So if he has them in stock, then you can get them. Otherwise he queue's up orders till he has enough for a production run. I need to call him and see what he has.

Here's a pict of the CJ gear.

#30

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

The tail assembly is complete. Most recently hinged the rudder / fin hinged, shaped it, installed triangle stock to hide the hinge line. One big thing that has to be planned at this point is how the final assembly will go. The rudder control rod passes through the H-stab and all the hinges have to align. I cut a slot in the H-stab to allow the control rod to pass through. This means that the rudder can be assembled after all the painting is done. Same with the elevators. A balsa block will be fit under the rudder. This will have to be install after the rudder is in place.

#31

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Well after a month of biz travel and family activities, I am back to work on the Invader. Finally!

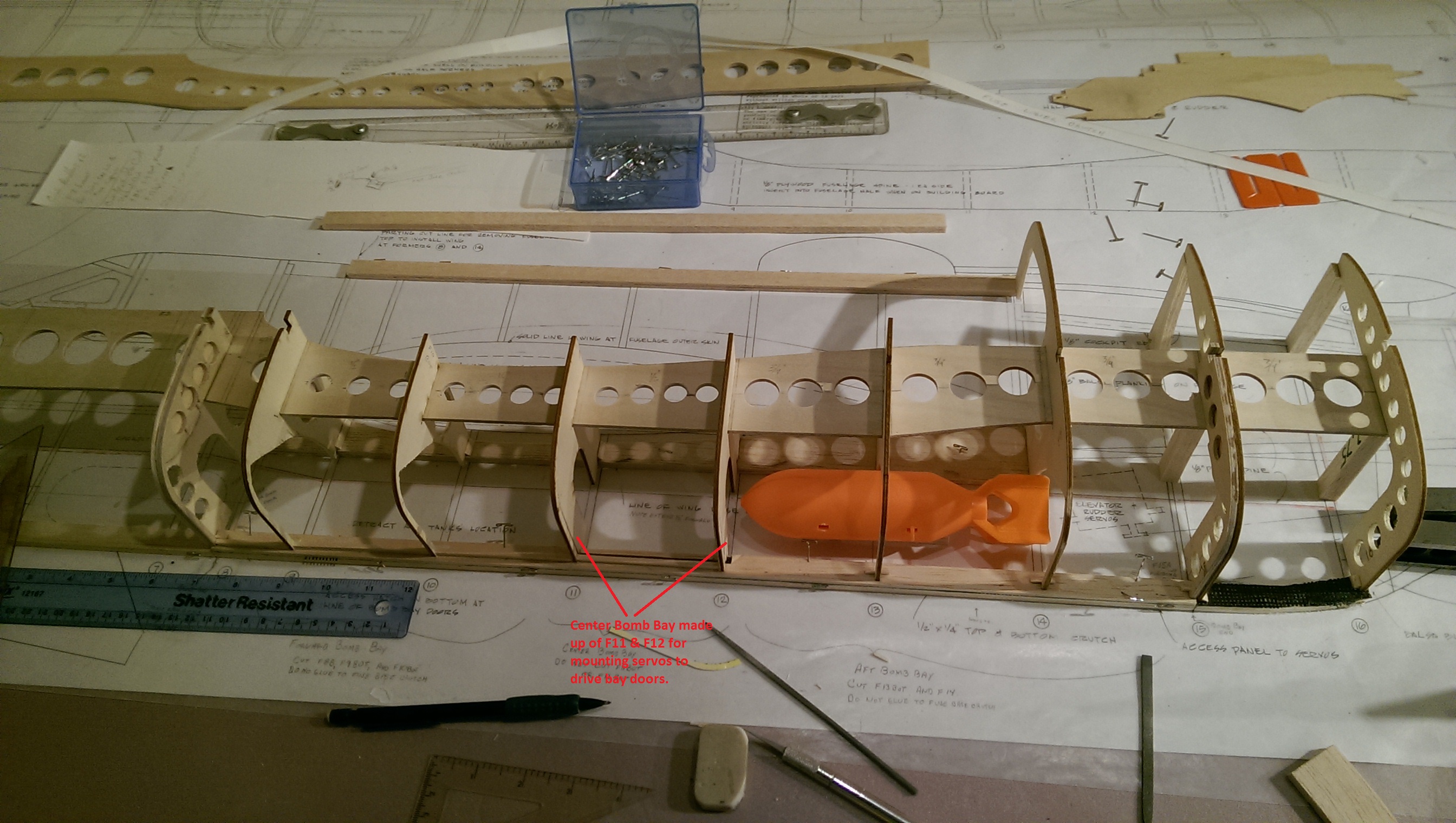

OK, starting the fuse. I want a working bomb bay, gotta have it. The fuse design is for the top of the fuse to be removable to mount the wing. This, obviously, means that ALL loads through the fuse are carried under the wing. There is a ply based spine that runs right under the wing. Clearly this handles most of the load. However, there is also a 1/2" x 1/4" balsa member that runs the length of the fuse. It is tied into 8 formers and the fuse sheeting. It is entirely possible (likely?) that this member is load bearing, especially in pitching maneuvers and landings. Likewise, the ply spine could take all the load and this member could be cut out for easy access to a bomb bay. I chose NOT to cut out this member. Whats more, being conservative, going with the assumption that it is load bearing AND the fact that I will HAVE TO remove several formers and associated sheeting, I have laminated it with 2oz carbon fiber cloth.

Here's some pictures of the very start of the bomb bay and how I'll build it. Basically, I want to be able to sheet/plank the fuse normally and then cut out the bomb bay doors. This sounds easy, but there is a LOT of wood under the wing. Additional complexity from the fact that I'm building a scale Invader, let me say that the bomb bay is HUGE. So it has taken significant planning to get this all to work out. More pictures as I glue more part in place.

OK, starting the fuse. I want a working bomb bay, gotta have it. The fuse design is for the top of the fuse to be removable to mount the wing. This, obviously, means that ALL loads through the fuse are carried under the wing. There is a ply based spine that runs right under the wing. Clearly this handles most of the load. However, there is also a 1/2" x 1/4" balsa member that runs the length of the fuse. It is tied into 8 formers and the fuse sheeting. It is entirely possible (likely?) that this member is load bearing, especially in pitching maneuvers and landings. Likewise, the ply spine could take all the load and this member could be cut out for easy access to a bomb bay. I chose NOT to cut out this member. Whats more, being conservative, going with the assumption that it is load bearing AND the fact that I will HAVE TO remove several formers and associated sheeting, I have laminated it with 2oz carbon fiber cloth.

Here's some pictures of the very start of the bomb bay and how I'll build it. Basically, I want to be able to sheet/plank the fuse normally and then cut out the bomb bay doors. This sounds easy, but there is a LOT of wood under the wing. Additional complexity from the fact that I'm building a scale Invader, let me say that the bomb bay is HUGE. So it has taken significant planning to get this all to work out. More pictures as I glue more part in place.

#32

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

The forward section of the bomb bay begins to take shape.

NOTE that on most of these bomb bay picts (including ones in prev post) have notes on them. You'll have to click on them 2x times to get to the blowup where you can read the notes.

NOTE that on most of these bomb bay picts (including ones in prev post) have notes on them. You'll have to click on them 2x times to get to the blowup where you can read the notes.

#33

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Here's the aft left bomb bay and a shot of the entire bomb bay. There are basically 3 sections to it, forward, center, aft. The center section will retain formers F11 & F12 that join with the fuse bottom crutch. This provides an area to install servos to operate the bomb bay doors.

#34

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

The left bay and bay door are now complete, ready for sheeting/planking. I've added 1/8" stringers and 1/4"x1/2" blocks for strength/rigidity. the centerline of the 1/4 x 1/2 blocks is the hinge line.

#35

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

ONE IMPORTANT THING that I have not mentioned for anyone actually building this plane is the ply "spine". You can see it clearly in the middle photo above (fuse 08.jpg). It's the long and wide ply member with all the holes in it. This is NOT glued in yet. The plans say to set all the formers first, then slide this member into position. I have found it more effective to build around it as it has a key role in setting the wing incidence. As I add the formers I keep checking that this member is in the correct location and edit any formers as needed along the way. I'll glue it AFTER all formers and the spine are in the correct locations.

#39

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Digging into the H-stab position issue, the source of the problem is the angle of the fuse at the aft end of the gunner's compartment. The H-Stab only needs to move down 1/2" so the resulting change in the aft section of fuse is not major.

At this point the entire forward section of the fuse structure is complete and ready for sheeting. The "spine" and landing gear mount rail have both been glued in. You'll see some carbon fiber has been used to reinforce key former joints with the spine. Here's some picts of the progress.

At this point the entire forward section of the fuse structure is complete and ready for sheeting. The "spine" and landing gear mount rail have both been glued in. You'll see some carbon fiber has been used to reinforce key former joints with the spine. Here's some picts of the progress.

#40

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

I didn't care for the way the last former in the tail was done. It's a 1/8" piece of ply and no string to support it. Also, the former is too small (height wise) for the scale outline. So I made one out of 1/4" balsa and added a stringer. The 1/4" balsa will provide more glue surface for the final edge of the sheeting. Here's the resulting change.

The aft section is now also ready for sheeting & planking. Lot's of final shaping of the formers to get a good line. Also, in a locations the sheeting runs into the former, instead of riding on it. (1) rear of F16 (just ahead of the lower turret) and front of F21 (at the LE of the H-stab). Here I've added some balsa supports for the sheeting to attach.

The aft section is now also ready for sheeting & planking. Lot's of final shaping of the formers to get a good line. Also, in a locations the sheeting runs into the former, instead of riding on it. (1) rear of F16 (just ahead of the lower turret) and front of F21 (at the LE of the H-stab). Here I've added some balsa supports for the sheeting to attach.

#42

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Weekend's work ... you guessed it, more planking. This is my first time doing it. The fuse center section is almost complete. As you can see from the aft section I alternate top, bottom, side as I put the planking and sheeting on to not introduce a warp.

#44

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Well, another couple of weeks slid by ... been planking away. Finally, the left side is done. Once the glue sets up I'll lift it from the plan and do some trimming.

#46

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

And ... back on the board. This time flipped over to work on the opposite side. Note the crutches placed strategically around the fuse to support it while assembling the right side. This will be especially needed when planking.

#47

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Adding all the structure to the top. Interesting problem to get the "spine" (long ply piece floating in the formers) aligned with the other side. ended up using 2 ways to ensure alignment. 1) aligned the spine at the same relative position in the formers. That is, matching it with the relative position of the first half. 2) I used a plumb bob to align the top with the bottom. Of course, had to ensure that the fuse is level first for this to work. Regardless, using both of these approaches gave me confidence that it's in the correct location. So I glued it in!

#48

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

Oh, one other thing, I came up with a rough calculation of the weight savings cutting all the holes in the fuse formers and spine. Total savings is 7oz. That's not bad, but not huge either. Once the fuse planking is complete I'll weigh it to see what percentage of the total the 7oz is. Of course, the hole cutting is just part of the weight saving approach. Recall I am also using "Aero Light" balsa to remove weight as well. Only time will tell how much of an impact all this is having on my goal of saving weight. My target weight is 30 - 32 lbs.

#50

Thread Starter

Join Date: Nov 2005

Location: fort collins,

CO

Posts: 448

Likes: 0

Received 0 Likes

on

0 Posts

All the fuse formers are now in place and stringers too. Almost ready to start planking.

In the nose a much care must be taken when installing F2 - F6 that support the retract rail. The rail must be spaced properly both in the distance between the rails and keeping the mounting faces in the same plane so the retract will sit flush.

Linkages for the elevators and rudder are, of course, in the tail. The plans don't call for any access to these. But I would like to get at them if needed. So on the right side here I've rerouted the stringer, added a 2nd one and then built framing for a hatch in the open space.

In the nose a much care must be taken when installing F2 - F6 that support the retract rail. The rail must be spaced properly both in the distance between the rails and keeping the mounting faces in the same plane so the retract will sit flush.

Linkages for the elevators and rudder are, of course, in the tail. The plans don't call for any access to these. But I would like to get at them if needed. So on the right side here I've rerouted the stringer, added a 2nd one and then built framing for a hatch in the open space.