MOKI RADIAL Care and Maintenence

#4377

My Feedback: (2)

Yes, my next trick will be a hi temp thread lock and wrapping the collector ring nuts with heavy Teflon tape to keep them from backing off.

At this point, I'm not sure how much the nuts back off as opposed to the Teflon ring shrinking/melting into position.

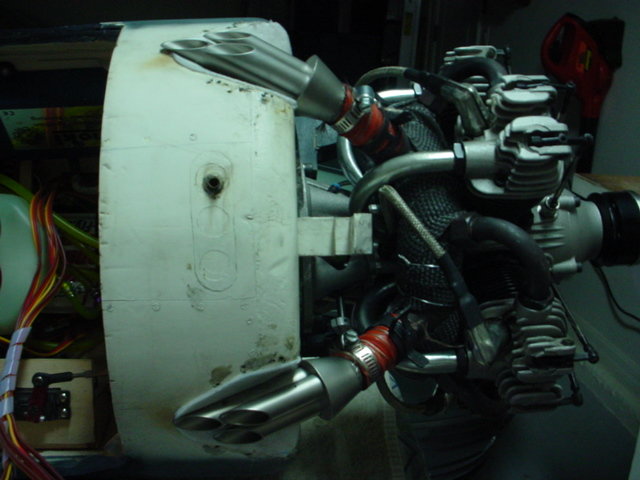

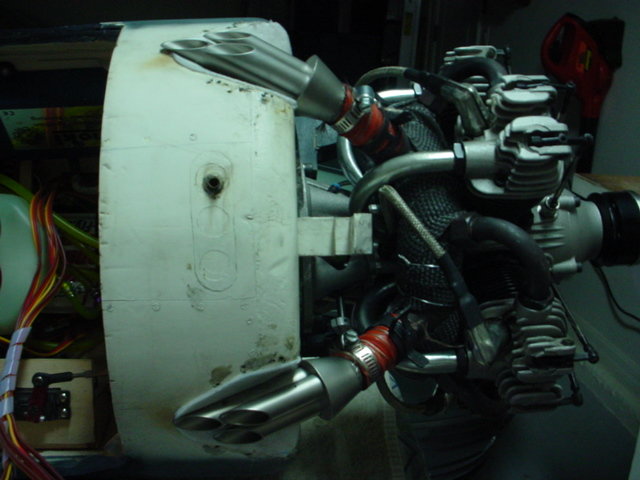

The pic is 2 of the tubes I replaced. The flange broke off on the cylinder end on all 5. On the collector ring nut end you can see a compression on the tube where the Teflon ring was seated.

Anyone who has this problem I would encourage them to let the dealer/manufacturer know of the problem - for what its worth.

Regards - J Tab

At this point, I'm not sure how much the nuts back off as opposed to the Teflon ring shrinking/melting into position.

The pic is 2 of the tubes I replaced. The flange broke off on the cylinder end on all 5. On the collector ring nut end you can see a compression on the tube where the Teflon ring was seated.

Anyone who has this problem I would encourage them to let the dealer/manufacturer know of the problem - for what its worth.

Regards - J Tab

#4378

My Feedback: (1)

I gave up reading through this thread at about page 392; through those pages, the recommendation was to employ red (#271) Loctite. I've yet to start on an Airworld SU-31 / 215cc, but this exhaust integrity issue keeps cropping up on here.

Its difficult to imagine this issue is widespread and end-users have not complained about it to either the engine Vendors or the OEM and demanded a solution.

Questions:

- Is this problem widespread; to get some perspective on this would be to invite a larger cross section of Readers to chime with their experience. Maybe its not an issue and more down to improper tightening

- One person's feel for tightening is going to be different than others; at what point is over-tightening is either deforming / over-compressing the washers and therefore causing them nuts to loosen, or, or simply under-tightening and increasing the propensity to loosen due to thermal expansion and / or vibration

- Is red (considered permanent / anaerobic) Loctite actually a confirmed fix / cure.

- What does Vogelsang / other Vendors / OEM recommend.

If I had to tighten these nuts as frequently others are having to do...that would be completely unacceptable! I would be finding a permanent solution; for example drilling the nuts / safety wiring.

We need feedback from more folks on this issue.

Its difficult to imagine this issue is widespread and end-users have not complained about it to either the engine Vendors or the OEM and demanded a solution.

Questions:

- Is this problem widespread; to get some perspective on this would be to invite a larger cross section of Readers to chime with their experience. Maybe its not an issue and more down to improper tightening

- One person's feel for tightening is going to be different than others; at what point is over-tightening is either deforming / over-compressing the washers and therefore causing them nuts to loosen, or, or simply under-tightening and increasing the propensity to loosen due to thermal expansion and / or vibration

- Is red (considered permanent / anaerobic) Loctite actually a confirmed fix / cure.

- What does Vogelsang / other Vendors / OEM recommend.

If I had to tighten these nuts as frequently others are having to do...that would be completely unacceptable! I would be finding a permanent solution; for example drilling the nuts / safety wiring.

We need feedback from more folks on this issue.

#4379

.... I think the need to retighten is pretty common but in my case I only needed about three flights with my Carf P47 and Moki 250 before things settled down.

Bob

Bob

#4380

My Feedback: (2)

Moebius44 I agree with your assessment completely. More feedback is needed.

I was lucky on my older Moki Teflon rings seated as the motor was run in.

Bottom line - very little or no guidance is given by the dealer or OEM regarding the issue or warning of crushing the rings.

It's a learning experience in progress.

Overtightening may have been the cause of the failure on the tubes on my AT-6 collector ring, but what is one to do when the collector ring rotates (in flight) out of position ?

The best advice I have been given so far is to never tighten when the motor is hot and only tighten the exhaust tube nuts with minimal torque until such time as the Teflon rings seat.

Thanks - J Tab

I was lucky on my older Moki Teflon rings seated as the motor was run in.

Bottom line - very little or no guidance is given by the dealer or OEM regarding the issue or warning of crushing the rings.

It's a learning experience in progress.

Overtightening may have been the cause of the failure on the tubes on my AT-6 collector ring, but what is one to do when the collector ring rotates (in flight) out of position ?

The best advice I have been given so far is to never tighten when the motor is hot and only tighten the exhaust tube nuts with minimal torque until such time as the Teflon rings seat.

Thanks - J Tab

#4381

My Feedback: (1)

1) Have you had to readjust / tighten since your exhaust system stabilized?

2) What do you think is different in your case?

This is tough as once again the following play a significant role:

- Starting nut torque across all nuts

- Tightness / initial washer crush across all nuts

- Amount of vibration present from one engine installation / displacement to the next from;

+ Prop mass --> greater mass --> more short duration physical engine movement

+ Prop balancing integrity

+ Larger displacement --> larger physical (and shorter duration) movement for a given engine / prop mass

+ Engine / firewall rigidity that exacerbates engine short-term movement / rotation

#4382

My Feedback: (1)

Moebius44 I agree with your assessment completely. More feedback is needed.

I was lucky on my older Moki Teflon rings seated as the motor was run in.

Bottom line - very little or no guidance is given by the dealer or OEM regarding the issue or warning of crushing the rings.

It's a learning experience in progress.

Overtightening may have been the cause of the failure on the tubes on my AT-6 collector ring, but what is one to do when the collector ring rotates (in flight) out of position ?

The best advice I have been given so far is to never tighten when the motor is hot and only tighten the exhaust tube nuts with minimal torque until such time as the Teflon rings seat.

Thanks - J Tab

I was lucky on my older Moki Teflon rings seated as the motor was run in.

Bottom line - very little or no guidance is given by the dealer or OEM regarding the issue or warning of crushing the rings.

It's a learning experience in progress.

Overtightening may have been the cause of the failure on the tubes on my AT-6 collector ring, but what is one to do when the collector ring rotates (in flight) out of position ?

The best advice I have been given so far is to never tighten when the motor is hot and only tighten the exhaust tube nuts with minimal torque until such time as the Teflon rings seat.

Thanks - J Tab

How many experience nuts coming loose on the other (copper crush washer) end?

#4383

I've always snugged mine using a wrench and just pinky finger torque, this is on a first generation 250 with around 240 flights on it. I have no issues with mine. My buddy has the second generation 250 with close to 300 flights on it and all he does is tighten them BY HAND and the end of each flying day, he has also never had a issue.

#4384

My Feedback: (2)

Did an experiment today on a relatively new Moki 250. The objective was to determine if the exhaust nuts on the collector ring were backing off or if the Teflon rings were shrinking after the engine was run up to operating temp and cycled 5 times. Before running the motor, I lightly hand wrench torqued up the nuts and marked each of the 5 nuts relative to its position on the collector ring. Total run time was about 30 minutes in 5 cycles. The cylinder temps did not exceed 225F when the engine was running. The heat sink after shut down did not exceed 250F. Since replacing the exhaust tubes, Teflon washers, and copper crush rings, the engine has about 60 to 90 minutes of run time. When the engine returned to room temperature, (65F) I noted the following:

1. The nuts securing the exhaust tubes to the collector ring did not move even a fraction. The marks on the 5 nuts and collector ring were aligned just as the start.

2. Checking the nuts for tightness and using the same approximate torque value, I moved all 5 nuts average of 3/16” to 1/4” which would be about the same as 1/16th rotation.

3. The nuts securing the tubes to the cylinder head were still at the same position and did not require tightening.

My take from this is that the Teflon rings/washers are compressing after the engine is brought up to operating temperature and returned to room temperature. Additionally, and from past experience, tightening the nuts when the engine is hot or warm will cause the Teflon rings to squeeze out the back side of the nut and could result in failure.

At some point soon I am hoping that the expansion and compression will become negligible just as others have noted and the frequent tightening of the nuts will become less and less frequent as the rings/washers become fully seated.

Thanks to all who offered input into the issue.

Regards - J Tab

1. The nuts securing the exhaust tubes to the collector ring did not move even a fraction. The marks on the 5 nuts and collector ring were aligned just as the start.

2. Checking the nuts for tightness and using the same approximate torque value, I moved all 5 nuts average of 3/16” to 1/4” which would be about the same as 1/16th rotation.

3. The nuts securing the tubes to the cylinder head were still at the same position and did not require tightening.

My take from this is that the Teflon rings/washers are compressing after the engine is brought up to operating temperature and returned to room temperature. Additionally, and from past experience, tightening the nuts when the engine is hot or warm will cause the Teflon rings to squeeze out the back side of the nut and could result in failure.

At some point soon I am hoping that the expansion and compression will become negligible just as others have noted and the frequent tightening of the nuts will become less and less frequent as the rings/washers become fully seated.

Thanks to all who offered input into the issue.

Regards - J Tab

#4385

My Feedback: (1)

Great test J Tab! What comes to mind immediately is the TEFLON receding / shrinking and not recovering due to loss of material (out-gassing) due to heat. When the Teflon cools, it does not recover. More questionS:

- Is the quality of the washers inconsistent (would explain low vs. high maintenance engine to engine)

- Is the material used consistent in it's constituent

- Are all washers supplied - actually Teflon or has there been a substitution we are not aware of.

Has anyone noticed replacement units looking of feeling different?

How about replacements that were inferior after install or worked perfectly - after install?

- Is the quality of the washers inconsistent (would explain low vs. high maintenance engine to engine)

- Is the material used consistent in it's constituent

- Are all washers supplied - actually Teflon or has there been a substitution we are not aware of.

Has anyone noticed replacement units looking of feeling different?

How about replacements that were inferior after install or worked perfectly - after install?

#4386

My Feedback: (2)

Just a final note to the topic of exhaust tube Teflon seals. Someone suggested to me that it's the pre-load on the nut that contributes. The Teflon seal squeezes out when heated due to expansion.

At this point I'm going to continue to run the engine with very minimal tightness.

Also, at this point I will not be using Hi Temp thread lock. Its difficult to remove once applied and I fear of damaging the threads on the collector ring if the tubes need be replaced.

Regards - J Tab

At this point I'm going to continue to run the engine with very minimal tightness.

Also, at this point I will not be using Hi Temp thread lock. Its difficult to remove once applied and I fear of damaging the threads on the collector ring if the tubes need be replaced.

Regards - J Tab

#4387

Hey guys, for those of you w the Moki 150, what size/type props have you found to be successful? I’m putting mine on a FW190 and would like to go w a scale looking prop (Biela 26-16 three blade) but cannot find anything on the net where it is being used.

any help would be appreciated, thanks!

any help would be appreciated, thanks!

#4388

My Feedback: (43)

I used to run a SEP 26 x 16 two blade prop, but that let my motor over rev and it kept throwing pushrods.I did like the handling of my Hellcat when I ran the SEP 26 x 16. Last year I ran a SEP 26 x 18 with no issues. The SEP props are soft wood, and flatten out at high rpm. This can be a benefit in case of a prop strike as the prop will easily break.

This summer I'll be trying a Biella 26 x 16 carbon fiber. hopefully this puts enough load on the motor, and gives me good aircraft handling.

This summer I'll be trying a Biella 26 x 16 carbon fiber. hopefully this puts enough load on the motor, and gives me good aircraft handling.

#4389

I used to run a SEP 26 x 16 two blade prop, but that let my motor over rev and it kept throwing pushrods.I did like the handling of my Hellcat when I ran the SEP 26 x 16. Last year I ran a SEP 26 x 18 with no issues. The SEP props are soft wood, and flatten out at high rpm. This can be a benefit in case of a prop strike as the prop will easily break.

This summer I'll be trying a Biella 26 x 16 carbon fiber. hopefully this puts enough load on the motor, and gives me good aircraft handling.

This summer I'll be trying a Biella 26 x 16 carbon fiber. hopefully this puts enough load on the motor, and gives me good aircraft handling.

#4390

the moki 150 i picked up has a ch ignition on it and it does have limiter on it to prevent it going over 6000 rpm's. The 26-16 SEP prop is what Gotz recommended as well as the 25-16 SEP three blade. Im sure people are flying the Moki's w other brand props (Fiala, Biela, Xoar, etc) - just curious what other options are out there that proved to work besides the SEP props.

Last edited by jraycut; 05-27-2020 at 06:34 PM.

#4392

I am thinking of installing the powerbox CORE radio on my carf P47 with the Moki 250. Can someone tell me on which part of the cylinder do we need to drill a hole for the temp probe?

thanks

thanks

#4394

Junior Member

I use a powerbox PBS-T250 for my S180. I did not want to drill any hole in my engine, so I simply used one cylinder head screw to fasten the sensors on each cylinder.

#4395

#4396

#4397

I have just installed temperature/rpm telemetry on my moki250. Whats the temp. spread one can expect across all 5 cyl? On the ground without a cowl and using a 4 bladed carf p47 stock carbon prop (32x18, I think) I am getting approx 65-75C on the top 3 cyl A, B and E. And approx 45-50C on the bottom cyl C and D. I use motel 40:1 fuel. The telemetry is by powerbox via the CORE radio. I have recorded a ground rpm of 3725 as well. How are these numbers?

thanks

thanks

#4399

My Feedback: (5)

You can have a set of scale exhaust for your Moki 180cc radial engines and Corsair for half the cost. These exhaust stacks were build by Custom Pipes RC for $240.00 I am selling them for $140.00. One of the exhaust has a couple of small dents due to a midair, but they still in great shape and operational. All the complete hardware comes with them.

Buyer pays shipping email to [email protected]

Buyer pays shipping email to [email protected]

#4400

Junior Member

I have just installed temperature/rpm telemetry on my moki250. Whats the temp. spread one can expect across all 5 cyl? On the ground without a cowl and using a 4 bladed carf p47 stock carbon prop (32x18, I think) I am getting approx 65-75C on the top 3 cyl A, B and E. And approx 45-50C on the bottom cyl C and D. I use motel 40:1 fuel. The telemetry is by powerbox via the CORE radio. I have recorded a ground rpm of 3725 as well. How are these numbers?

thanks

thanks

How long did you run the engine? Is it new?

On my S180, the C cylinder does not fire before mid throttle resulting in pretty low temperature (like yours) when idling. I still have to take time to solve this issue.

By the way, does anyone know the procedure to time a S180 (pinion position with respect to crankshaft position) ?